Professional Documents

Culture Documents

New Microsoft Power Point Presentation

Uploaded by

SamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Microsoft Power Point Presentation

Uploaded by

SamCopyright:

Available Formats

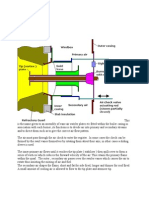

COOLING ARRANGEMENT FOR TURBINE

ROTOR AND

STATOR

BY AMIT TYAGI

DISCUSSION

GENERAL LAYOUT TURBINE ROTOR AND ITS COOLING ARRANGEMENT. TURBINE STATOR AND ITS COOLING ARRANGEMENT. GLAND SEALING AND ITS COOLING ARRANGEMENT.

ROTOR

SINGLE ROTOR BUILT UP FROM A NUMBER OF DISCS A FRONT ,CENTRAL AND REAR HOLLOW SHAFT ALL CLAMPED BY A CENTRAL TIE ROD EACH DISC CARRY ONE ROW OF BLADE

ROTOR

INDIVIDUAL PARTS ARE CENTERED BY HIRTH COUPLING IT PROVIDE FOR CENTRING IT ALLOWS FREE THERMAL EXPANSION AND CONTRACTION. TRANSMIT THE TORQUE. ROTOR IS INTERNALLY AND EXTERNALLY COOLED. ALL ROTOR BLADES CAN BE REPLACED WITUOUT DISASSEMBLING THE ROTOR.

TURBINE ROTOR BLADES.

BALDE CONSIST OF AN AIRFOIL, BLADE PLATFORM, AND BLADE ROOT AIRFOIL IS TAPERED TOWARDS BLADE TIP. BLADE PLATFORM PROTECTS THE BLADE FIXING ROOT AGAINST HIGH TEMPERATURES

BALDE ROOT CONSIST OF A FIR TREE DOVETAIL WITH TWO OR THREE SERRATIONS. BLADES ARE LOCKED BY MEANS OF KEYS FIRST TWO SATGES BLADES ARE INTERNALLY COOLED WITH AIR. BLADES ARE COATED TO REDUCE HIGH TEMP. CORROSION.

FIRST STAGE BLADES DESIGN FOR COOLING

ARE CAST HOLLOW BLADES WITH DUCTS FOR GUIDING THE COOLING AIR. COOLING AIR ENTERS THE AIRFOIL IN THE RADIAL DIRECTION VIA THE BLADE ROOT, COOLING AIR EXITS THROUGH HOLES BEHIND THE TRAILING EDGE.

SECOND STAGE BLADES DESIGN FOR COOLING

ARE PROVIDED WITH SEVERAL DUCTS EXTENDED RADIALLY THROUGH THE AIRFOIL COOLING AIR ENTERS THE BLADE VIA HOLES AT THE BLADE ROOT, COOLING AIR EXITS FROM THE BLADE TIP IN THE RADIAL DIRECTION.

TURBINE STATOR

TURBINE STATOR BLADES

COOLING ARRANGEMENT IN STATOR AND ROTOR BLADES

COOLING AND SEAL AIR SYSTEM FOR ROTOR

WHY COOLING IS REQUIRED?

HOT GAS TEMP. ARE FAR ABOVE THE SERVICE TEMP RANGES OF SPECIAL BLADE MATERIAL. INCREASE SERVICE RELIABILITY BY INCREASING THEIR RESISTANCE TO HOT CORROSION. PROTECT TURBINE ROTOR DRUM AGAINST OVERHEATING.

COOLING AIR FOR TURBINE MOVING BLADES ROW 1

IS EXTRACTED AT THE HUB DOWNSTREAM OF THE LAST COMPRESSOR MOVING BLADE ROW. SMALL PROPORTION FLOWS THROUGH THE LABYRINTH AS SEAL AIR. MAJORITY OF AIR PASSES THROUGH HOLLOW CENTER SHAFT.

COOLING AIR FOR TURBINE MOVING BLADES ROW 2,3 AND 4.

IS EXTRACTED AT THE HUB DOWNSTREAM OF THE COMPRESSOR STATIONARY BLADE ROW 12. PASS THROUGH BORES IN COMPRESSOR ROTOR DISC. FLOW THROUGH THE COOLING AIT PARTION PIPE AND ON TO THE BLADES THROUGH THE HUB BORES IN TURBINE DISC.

COOLING AIR THEN ENTERS THE HOT GAS FLOW COOLING AIR ENSURES THAT THE STRUCTURAL ROTOR DRUM IS ENVELOPED IN COOL AIR IN THE HOT GASV REGION OF TURBINE. IT PREVENTS PEAK THERMAL STRESSES AND ROTOR DEFORMATION ON LOAD CHANGE AND FAST STARTUP.

COOLING AND SEAL AIR SYSTEM FOR TURBINE STATOR

COOLING AIR FOR TURBINE STATOR BLADES ROW 1,2

AIR IS EXTRACTED FROM COMPRESSOR OUTLET. PASSES THROUGH BORES IN STATIONARY BLADE CARRIER TO THE COOLING CHAMBER COOLOS THE BLAE SHROUD FOR BLADE ROW 1- ENTERS BLADE AND THEN RE ENTERS THE HOT GAS PATH THROUGH THE TRAILING EDGES OF THE BLADE.

COOLING AIR FOR TURBINE STATOR BLADES ROW 2, 3,4

AIR IS EXTRACTED DOWNSTREAM OF COMPRESSOR BLADE ROW 10. FOR BLADE ROW 2,3,4 PART IS USED FOR COOLING THE BLADE AND MAJORITY OF AIR PASSE TO HUB PREVENT ENTRY OF HOT GAS INTO SHAFT GLAND UNDER THESE ROWS.

COMBINED JOUNRAL AND THRUST BEARING

COMBUSTION CHAMBER

CONSTRUCTION AND FUNCTIONAL DETAILS

ROTOR COMPRESSOR TURBINE

ROTOR BLADES

ROTOR BLADES

CONSTRUCTION AND FUNCTIONAL DETAILS(continue)

COMPRESSOR

STAIONARY BLADE

ASSEMBLY

COMPRESSOR TURBINE

STATOR BLADES

STATOR BLADES

CONSTRUCTION AND FUNCTIONAL DETAILS(continue)

CENTER

CASING CASING DIFFUSER

EXHAUST EXHAUST INNER

CASING

You might also like

- Everything You Need to Know About Air PreheatersDocument77 pagesEverything You Need to Know About Air PreheatersBala VigneshNo ratings yet

- Am ItDocument30 pagesAm ItSamNo ratings yet

- Air ConditionDocument15 pagesAir Conditionarch powerNo ratings yet

- O & M PreviewDocument22 pagesO & M PreviewtrieharyantoNo ratings yet

- Air Distribution SystemDocument21 pagesAir Distribution SystemRohit JainNo ratings yet

- Bharat Heavy Electricals Limited Edc - Air Preheaters: WelcomeDocument66 pagesBharat Heavy Electricals Limited Edc - Air Preheaters: Welcomeharpreetresearch100% (3)

- Soot Blowers & Burners GuideDocument13 pagesSoot Blowers & Burners GuideGanesh MuruganNo ratings yet

- Air Cooled CondensersDocument13 pagesAir Cooled CondensersSyed ShoebNo ratings yet

- Turbine Engine Cooling System: Assignment No. 2 (Prelim)Document4 pagesTurbine Engine Cooling System: Assignment No. 2 (Prelim)Chim FiguerasNo ratings yet

- Condensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaDocument36 pagesCondensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaJorgee RossaNo ratings yet

- PT6T ENGINES SERIES BASIC COURSE HOT SECTION OVERVIEWDocument65 pagesPT6T ENGINES SERIES BASIC COURSE HOT SECTION OVERVIEWmotores4297No ratings yet

- Boost Boiler Efficiency With an Air PreheaterDocument44 pagesBoost Boiler Efficiency With an Air PreheaterAtef BouabdallahNo ratings yet

- Cooling Tower and Gearbox OverhaulDocument17 pagesCooling Tower and Gearbox OverhaulIrfan UllahNo ratings yet

- Seal PlateDocument14 pagesSeal PlateRubén Leal RuizNo ratings yet

- Construction Features of Gas Turbine: N.V.S.Murthy Dy. Manager/ BHELDocument67 pagesConstruction Features of Gas Turbine: N.V.S.Murthy Dy. Manager/ BHELSai KrishnaNo ratings yet

- Piston Cooling SystemDocument31 pagesPiston Cooling SystemAfiq ZikriNo ratings yet

- Rac Lab ManualDocument36 pagesRac Lab ManualAftab Alam100% (2)

- Specification - Screw Chiller - DraftDocument8 pagesSpecification - Screw Chiller - DraftSupriya RoyNo ratings yet

- Fired Furnace - KtiDocument88 pagesFired Furnace - Ktir.arun100% (3)

- Gasturbine-Maintenance and OperationDocument117 pagesGasturbine-Maintenance and OperationervikranthNo ratings yet

- Air Pre-Heater (Aph) : Presented By:-Sujeet Kumar Operation, Talcher KanihaDocument38 pagesAir Pre-Heater (Aph) : Presented By:-Sujeet Kumar Operation, Talcher KanihaPrinshu GuptaNo ratings yet

- Rac ExpDocument44 pagesRac ExpAkash Kumar DevNo ratings yet

- Condensers: Report By-Ashna Anamika Mugdha PratishthaDocument17 pagesCondensers: Report By-Ashna Anamika Mugdha PratishtharashmiNo ratings yet

- Chapter 4 Heat Exchangers With High-Finned Trufin TubesDocument0 pagesChapter 4 Heat Exchangers With High-Finned Trufin TubesManuel ArroyoNo ratings yet

- Air Cooled Heat Exchnger FormatedDocument43 pagesAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- Current Trends in Cooling of BladesDocument8 pagesCurrent Trends in Cooling of BladesPRAVEENNo ratings yet

- Air Pre HeaterDocument0 pagesAir Pre HeaterkablikhogeNo ratings yet

- Blue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualDocument123 pagesBlue Star Chiller Air & Water Cooled Screw Chiller R22 DX ManualAwdhesh Singh Bhadoriya71% (35)

- Air Heaters: Requirement, Types ConstructionDocument20 pagesAir Heaters: Requirement, Types ConstructionArvind ShuklaNo ratings yet

- Technical Training - Air DistributionDocument163 pagesTechnical Training - Air Distributionrasheedillikkal100% (1)

- E10Document16 pagesE10minuriNo ratings yet

- Industrial Gas TurbineDocument20 pagesIndustrial Gas TurbineSekar.S100% (1)

- Mesh Belt Type Conveyor Furnace Koyo LindbergDocument15 pagesMesh Belt Type Conveyor Furnace Koyo LindbergArmando HenríquezNo ratings yet

- Ge MS 5000 5341Document45 pagesGe MS 5000 5341helmybh100% (3)

- Air Conditioning Systems ExplainedDocument26 pagesAir Conditioning Systems Explainedvivek kumarNo ratings yet

- Write Up On GeneratorDocument62 pagesWrite Up On GeneratorAbhishek RanjanNo ratings yet

- Hot Gas Defrost Systems For Large Evaporators PDFDocument18 pagesHot Gas Defrost Systems For Large Evaporators PDFBehnam AshouriNo ratings yet

- Twin Screw ExtruderDocument33 pagesTwin Screw ExtruderHEMANTKHERANo ratings yet

- Turbo ChargersDocument11 pagesTurbo Chargersali bastomiNo ratings yet

- Charge Air System by P.KDocument28 pagesCharge Air System by P.Kkr_abhijeet72356587100% (1)

- GE Frame 9E Turbine Stator and Rotor ConstructionDocument14 pagesGE Frame 9E Turbine Stator and Rotor ConstructionMohammad Ibnul Hossain100% (1)

- Sr. Description No. NoDocument17 pagesSr. Description No. Nosushilalway4uNo ratings yet

- Aph 15Document0 pagesAph 15Parameswararao BillaNo ratings yet

- Chilled Beam Design GuideDocument68 pagesChilled Beam Design GuidearifkhadeerNo ratings yet

- United States Patent (19) : 11 Patent Number: 5,807,171 Felsen (45) Date of Patent: Sep. 15, 1998Document13 pagesUnited States Patent (19) : 11 Patent Number: 5,807,171 Felsen (45) Date of Patent: Sep. 15, 1998Kyle HorwarthNo ratings yet

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiNo ratings yet

- Sketch ThriDocument35 pagesSketch ThrisahilNo ratings yet

- Air and Flue Gas SystemsDocument48 pagesAir and Flue Gas Systemst manoj100% (1)

- Rotary KilnDocument7 pagesRotary KilnDarshan PatelNo ratings yet

- Registers: Air RegisterDocument2 pagesRegisters: Air RegisterTin Aung KyiNo ratings yet

- Registers and purging for safe boiler operationDocument2 pagesRegisters and purging for safe boiler operationMeghanath AdkonkarNo ratings yet

- 120-275 KW Generator SpecificationDocument47 pages120-275 KW Generator SpecificationDUVASU UPNo ratings yet

- Basic RefrigerationDocument9 pagesBasic RefrigerationDarren Jeff Manuel MicumaoNo ratings yet

- Airconditioning Systems Introduction01Document52 pagesAirconditioning Systems Introduction01ajNo ratings yet

- APHDocument59 pagesAPHBrijraj Pandey100% (5)

- Oral and Practical Review: Reflections on the Part 147 CourseFrom EverandOral and Practical Review: Reflections on the Part 147 CourseNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Water Circulation SystemDocument37 pagesWater Circulation SystemSam50% (2)

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- An Ode To SilenceDocument1 pageAn Ode To SilenceSamNo ratings yet

- Ppe DisDocument12 pagesPpe DisSam100% (1)

- Design & Construction Features of TurbogeneratorsDocument92 pagesDesign & Construction Features of TurbogeneratorsArpit Kumar100% (1)

- User PPT Acmotors1Document88 pagesUser PPT Acmotors1SamNo ratings yet

- Water Circulation SystemDocument37 pagesWater Circulation SystemSam50% (2)

- StepsDocument62 pagesStepsSam100% (1)

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- L-03 Spring Loaded Foundation-PresentationDocument34 pagesL-03 Spring Loaded Foundation-PresentationSam100% (1)

- Overview of Hydro Power ProjectDocument21 pagesOverview of Hydro Power ProjectSamNo ratings yet

- L-2 Presentation Gen Mech AuxDocument36 pagesL-2 Presentation Gen Mech AuxSam100% (1)

- NeedsDocument66 pagesNeedsSamNo ratings yet

- Recording, Reporting of OutputDocument30 pagesRecording, Reporting of OutputSam100% (3)

- Introduction To Turbovisory InstrumentsDocument40 pagesIntroduction To Turbovisory InstrumentsSam0% (1)

- Infrastructure in Power Project 1Document51 pagesInfrastructure in Power Project 1SamNo ratings yet

- Automatic Turbine TestorDocument26 pagesAutomatic Turbine TestorSam100% (2)

- Causes, Factors, CostDocument37 pagesCauses, Factors, CostSamNo ratings yet

- Generator CommissioningDocument90 pagesGenerator CommissioningSam94% (18)

- KWU Turbine SystemDocument90 pagesKWU Turbine Systemvenukumare100% (6)

- Feedwater SystemDocument70 pagesFeedwater SystemishanpahwaNo ratings yet

- Equipment at HPSDocument60 pagesEquipment at HPSSam100% (1)

- Automatic Turbine Tester EeDocument17 pagesAutomatic Turbine Tester EeSam100% (1)

- Generator ClassDocument93 pagesGenerator ClassSam100% (5)

- Boiler Erection PDFDocument44 pagesBoiler Erection PDFShankar Jha100% (1)

- 1 Elect ActuatlorDocument29 pages1 Elect ActuatlorSamNo ratings yet

- KWU Text GoverningDocument43 pagesKWU Text GoverningSam100% (2)

- DuctDocument100 pagesDuctSam100% (2)

- Accident - Causes & FactorsDocument38 pagesAccident - Causes & FactorsSam100% (1)

- 2013 Book ProceedingsOfTheFISITA2012Worl PDFDocument805 pages2013 Book ProceedingsOfTheFISITA2012Worl PDFdaniel leon marinNo ratings yet

- EasyMethodforTestingTransformerDifferentialRel PDFDocument15 pagesEasyMethodforTestingTransformerDifferentialRel PDFAgam Rodhi AditiawarmanNo ratings yet

- Soalan ObjektifDocument9 pagesSoalan ObjektifHairul Nizam OmarNo ratings yet

- Research PaperDocument5 pagesResearch PaperHoney AbdullahNo ratings yet

- Sample Thesis Defense Powerpoint PresentationDocument8 pagesSample Thesis Defense Powerpoint Presentationafjrtopab100% (2)

- Lithium-Ion BetteriesDocument9 pagesLithium-Ion BetteriesTasya OsipovaNo ratings yet

- Catalogo PDFGeneratorDocument3 pagesCatalogo PDFGeneratoredwraulNo ratings yet

- D7 - SOW Fire Fighting Upgrading Project - Rev1-16Sep22Document18 pagesD7 - SOW Fire Fighting Upgrading Project - Rev1-16Sep22Giang Phạm LêNo ratings yet

- R C T (RCT) : Iser Leaning OolDocument2 pagesR C T (RCT) : Iser Leaning OolAhmed MagedNo ratings yet

- Chapter Fluid MachineryDocument50 pagesChapter Fluid MachineryWan AimanNo ratings yet

- Three-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionDocument7 pagesThree-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionuakragunathanNo ratings yet

- Material Spec 1.4571Document2 pagesMaterial Spec 1.4571Vishal GoelNo ratings yet

- Tutorial 19 - Thermal Stress - SwitchDocument11 pagesTutorial 19 - Thermal Stress - SwitchKelvin HewNo ratings yet

- HIGH FREQUENCY FATIGUE FAILURE IN SILENCER/PULSATION DAMPERSDocument6 pagesHIGH FREQUENCY FATIGUE FAILURE IN SILENCER/PULSATION DAMPERS4jawwy markme026100% (1)

- NIT for EPC Bidding of Coal Fired Power ProjectDocument9 pagesNIT for EPC Bidding of Coal Fired Power ProjectLavu Anil ChowdaryNo ratings yet

- Ficha Técnica - Titan 1000 AE (Inglés)Document2 pagesFicha Técnica - Titan 1000 AE (Inglés)Pedro Ramos PAchecoNo ratings yet

- Availability Based Tariff PDFDocument8 pagesAvailability Based Tariff PDFakshay jawaleNo ratings yet

- Astor: Test TransformerDocument1 pageAstor: Test TransformermominzadahNo ratings yet

- Field Bus CommunicationDocument30 pagesField Bus CommunicationArun KumarNo ratings yet

- Welding HandbookDocument729 pagesWelding HandbookIvan Dario BenitezNo ratings yet

- Service Manual: Chassis & Mast MC/FCDocument9 pagesService Manual: Chassis & Mast MC/FCyojar apazaNo ratings yet

- Sedimentation PDFDocument16 pagesSedimentation PDFjamaiiicaNo ratings yet

- Summary Sheets Complete Version F2013Document58 pagesSummary Sheets Complete Version F2013Minjae LeeNo ratings yet

- GV Actuator Adv. Rev.4 (Webinar)Document37 pagesGV Actuator Adv. Rev.4 (Webinar)Boriche DivitisNo ratings yet

- FM400 8X4 Tipper With Rock Body Specs & DetailsDocument4 pagesFM400 8X4 Tipper With Rock Body Specs & DetailsHaneefa ChNo ratings yet

- Aaqib Iqbal: Work Experience SkillsDocument1 pageAaqib Iqbal: Work Experience SkillsSyedAsadAliNo ratings yet

- Lecture 7 8 Synchronous MotorDocument19 pagesLecture 7 8 Synchronous MotorCHATHURA MADURANGANo ratings yet

- Robin Engine EH650 EH650DA JapanDocument29 pagesRobin Engine EH650 EH650DA JapanyewlimNo ratings yet

- Motorcycle Powertrain Diagnosis GuideDocument7 pagesMotorcycle Powertrain Diagnosis GuideNurul Huda Ali0% (1)

- Chapter 1.3 Women EnvironmentDocument27 pagesChapter 1.3 Women Environmentdonna mendozaNo ratings yet