Professional Documents

Culture Documents

Adsorption Vivek Neeri

Uploaded by

Vivek KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adsorption Vivek Neeri

Uploaded by

Vivek KumarCopyright:

Available Formats

ADSORPTION EQUILIBRIA

AND REGENERATION

VIVEK KUMAR

Adsorption is the process in which matter is extracted from one phase and concentrated at the surface of

a second phase. (Interface accumulation). This is a surface phenomenon as opposed to absorption where

matter changes solution phase, e.g. gas transfer. This is demonstrated in the following schematic.

ADSORPTION

d

Adsorption Mechanism

ADSORPTION MECHANISM

Exchange adsorption (ion exchange) electrostatic due to charged sites on the surface.

Adsorption goes up as ionic charge goes up and as hydrated radius goes down.

Physical adsorption: Van der Waals attraction between adsorbate and adsorbent. The attraction

is not fixed to a specific site and the adsorbate is relatively free to move on the surface. This is

relatively weak, reversible, adsorption capable of multilayer adsorption.

Chemical adsorption: Some degree of chemical bonding between adsorbate and adsorbent

characterized by strong attractiveness. Adsorbed molecules are not free to move on the surface.

There is a high degree of specificity and typically a monolayer is formed. The process is seldom

reversible.

TYPES OF ADSORPTION

SOME GENERAL ISOTHERMS

IRREVERSIBLE

FAVORABLE

STRONGLY

FAVORABLE

UNFAVORABLE

FLUID PHASE CONCENTRATION, MASS/VOL

Adsorption process

Adsorbent and adsorbate

Adsorbent (also called substrate) - The solid that provides surface for adsorption

high surface area with proper pore structure and size distribution is essential

good mechanical strength and thermal stability are necessary

Adsorbate - The gas or liquid substances which are to be adsorbed on solid

Surface coverage,

The solid surface may be completely or partially covered by adsorbed molecules

ADSORPTION ON SOLID SURFACES

define u = u = 0~1

number of adsorption sites occupied

number of adsorption sites available

Rate of adsorption

Rate of desorption

) 1 ( f p k r

a a

=

f k r

d d

=

At equilibrium

d a

a

k p k

p k

f

+

=

Mono-layer coverage

f k m

a

' =

( m: mass of adsorbate adsorbed

per unit mass of adsorbent)

Adsorption Isotherm: the mass of adsorbate per unit mass of adsorbent at equilibrium & at a

given temperature

(f: fraction of surface

area covered)

f

1-f

LANGMUIR ISOTHERM

For the Langmuir model linearization gives:

0

a

e

0

a e

e

Q

C

Q K

1

q

C

+

=

A plot of C

e

/q

e

versus C

e

should give a straight line with intercept :

and slope:

0

a

Q K

1

0

a

Q

1

e

0

a

0

a e

C

1

Q K

1

Q

1

q

1

+ =

Or:

For the special case of heterogeneous surface energies (particularly good for mixed wastes) in

which the energy term, K

F

, varies as a function of surface coverage we use the Freundlich

model.

n and K

F

are system specific constants.

n

1

e F e

C K q =

FREUNDLICH ISOTHERM

Here a plot of 1/q

e

versus 1/C

e

should give a straight line with intercept 1/Q

a

o

and slope 0

a

Q K

1

For the Freundlich isotherm use the log-log version :

C log

n

1

K log q log

F e

+ =

A log-log plot should yield an intercept of log K

F

and a slope of 1/n.

The BET isotherm

( )

( )

0 0 a

0 m m 0 a

p

p

s I

p p v

p

or

p

p

C v

1 C

C v

1

p p v

p

+ =

Theoretical development based on several

assumptions:

multimolecular adsorption

1st layer with fixed heat of adsorption H

1

following layers with heat of adsorption

constant (= latent heat of condensation)

constant surface (i.e. no capillary

condensation) gives

OT fig1.3

BET method useful, but has limitations

microporous materials: mono - multilayer

adsorption cannot occur, (although BET surface

areas are reported routinely)

assumption about constant packing of N

2

molecules not always correct?

theoretical development dubious (recent

molecular simulation studies, statistical

mechanics) - value of C is indication o f the

shape of the isotherm, but not necessarily

related to heat of adsorption

0

a B

S

e

0

a B

B

e e S

e

Q K

1

C

C

Q K

1 K

q ) C C (

C

=

0

a B

Q K

1

B

0

B a s

K 1

K Q C

For the BET isotherm we can arrange the isotherm equation to get:

Intercept =

Slope =

Simplified method

1-point method

simplefied BET assuming value of C ~ 100 (usually the case), gives

usually choose p/p

0

~ 0,15

method underestimates the surface area by approx. 5%.

( )

( )

0

0 a

'

m

0

'

m 0 m m 0 a

p

p p v

v

p v

p

p

p

C v

1 C

C v

1

p p v

p

=

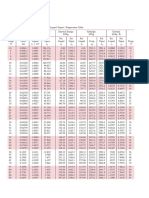

Summary of adsorption isotherms

Name Isotherm equation Application

Langmuir

Temkin u =c

1

ln(c

2

P)

Freundlich

BET

ADSORPTION ON SOLID SURFACE

) (

1 1

1

0

0

0

P / P

cV

c

cV ) P / P ( V

P / P

m m

+ =

u= =

+

C

C

BP

BP

s 0

0

1

2

1

1

C /

p c = u

Chemisorption and

physisorption

Chemisorption

Chemisorption and

physisorption

Multilayer physisorption

Useful in analysis of

reaction mechanism

Chemisorption

Easy to fit adsorption

data

Useful in surface area

determination

Five types of physisorption isotherms are found over all solids

Type I is found for porous materials with small pores e.g. charcoal.

It is clearly Langmuir monolayer type, but the other 4 are not

Type II for non-porous materials

Type III porous materials with cohesive force between adsorbate

molecules greater than the adhesive force between adsorbate molecules

and adsorbent

Type IV staged adsorption (first monolayer then build up of additional

layers)

Type V porous materials with cohesive force between adsorbate

molecules and adsorbent being greater than that between adsorbate

molecules

ADSORPTION ON SOLID SURFACE

I

II

III

IV

V

relative pres. P/P

0

1.0

a

m

o

u

n

t

a

d

s

o

r

b

e

d

To determine which model to use to describe the

adsorption for a particular adsorbent/adsorbate

isotherms experiments are usually run. Data from

these isotherm experiments are then analyzed

using the following methods that are based on

linearization of the models.

DETERMINATION OF APPROPRIATE MODEL

ADSORPTION-DESORPTION HYSTERESIS

Hysteresis is classified by IUPAC (see

fig.)

Traditionally desorption branch used

for calculation

H1: narrow distribution of mesopores

H2: complex pore structure, network

effects, analysis of desorption loop

misleading

H2: typical for activated carbons

H3 & 4: no plateau, hence no well-

defined mesopore structure, analysis

difficult

H3: typical for clays

Handbook

fig 2 s 431

Pore sizes

micro pores d

p

<20-50 nm

meso-pores 20nm <d

p

<200nm

macro pores d

p

>200 nm

Pores can be uniform (e.g. polymers) or non-uniform (most metal oxides)

Pore size distribution

Typical curves to characterise pore size:

Cumulative curve

Frequency curve

Uniform size distribution (a) &

non-uniform size distribution (b)

PORES AND POROUS SOLIDS

b

d

a

dw

dd

Ad

wt

b

a

Awt

d

Cumulative curve Frequency curve

POROSITY AND PORE SIZE

The pore structure (porosity, pore diameter, pore shape) is important for the

catalytic properties

pore diffusion may influence rates

pores may be too small for large molecules to diffuse into

Measurement techniques:

Hg penetration

interpretation of the adsorption - desorption isotherms

electron microscopy techniques

Hg PENETRATION

Based on measuring the volume of a non-wetting liquid forced into the pores by

pressure (typically mercury)

Surface tension will hinder the filling of the pores, at a given pressure an

equilibrium between the force due to pressure and the surface tension is

established:

where P = pressure of Hg, is surface tension and o is the angle of wetting

Common values used: = 480 dyn/cm and o= 140 give average pore

radius

valid in the range 50 - 50000

o t = t cos r 2 r P

2

| |

] cm / kp [ P

75000

r

2

=

PORE SIZE DISTRIBUTION

If the Hg-volume is recorded as a function of pressure and this curve is

differentiated we can find the pore size distribution function V(r)=dV/dr

OT fig 2.3.

FACTORS WHICH AFFECT ADSORPTION EXTENT (AND

THEREFORE AFFECT ISOTHERM) ARE:

Adsorbate:

Solubility

In general, as solubility of solute increases the extent of adsorption decreases. This is known

as the Lundelius Rule. Solute-solid surface binding competes with solute-solvent attraction

as discussed earlier. Factors which affect solubility include molecular size (high MW- low

solubility), ionization (solubility is minimum when compounds are uncharged), polarity (as

polarity increases get higher solubility because water is a polar solvent).

pH

pH often affects the surface charge on the adsorbent as well as the charge on the solute.

Generally, for organic material as pH goes down adsorption goes up.

Temperature

Adsorption reactions are typically exothermic i.e., H

rxn

is generally negative. Here heat is

given off by the reaction therefore as T increases extent of adsorption decreases.

Presence of other solutes

In general, get competition for a limited number of sites therefore get reduced extent of

adsorption or a specific material.

If the adsorbent and adsorbate are contacted long enough an equilibrium will be established between the

amount of adsorbate adsorbed and the amount of adsorbate in solution. The equilibrium relationship is

described by isotherms.

Define the following:

q

e

= mass of material adsorbed (at equilibrium) per mass of adsorbent

C

e

= equilibrium concentration in solution when amount adsorbed equals q

e.

q

e

/C

e

relationships depend on the type of adsorption that occurs, multi-layer, chemical, physical adsorption,

etc.

Adsorption heat:

The increase in enthalpy when 1 mole of a substance is adsorbed upon another at constant

pressure.

Adsorption is usually exothermic (in special cases dissociated adsorption can be endothermic)

The heat of chemisorption is in the same order of magnitude of reaction heat; the heat of

physisorption is in the same order of magnitude of condensation heat.

DEFINITION

ADSORPTION EQUILIBRIA

If the adsorbent and adsorbate are contacted long enough an equilibrium will be

established between the amount of adsorbate adsorbed and the amount of adsorbate

in solution. The equilibrium relationship is described by isotherms.

Heats of Adsorption

Gas adsorption to a solid is exothermic.

The magnitude and variation as a function of coverage may reveal information

concerning the bonding to the surface.

Calorimetric methods determine heat, Q evolved.

V

i

n

Q

q

|

.

|

\

|

=

q

i

= integral heat of adsorption

T V

D

n

Q

q

,

|

.

|

\

|

=

o

o

q

D

= differential heat of adsorption

3/22/2012

HEAT OF ADSORPTION .. CONTINUED

Since AG=AH-TAS, it is clear that for AG to be negative,

AH of adsorption process must be negative. That is, the

adsorption is an exothermic process.

the amount of gas adsorbed will decrease as the

temperature is increased.

The molar enthalpy, A

ads

H

m

, of adsorption in reversible

system will adhere to the Clausius-Clapeyron equation

The subscript n represents an isosteric adsorption.

A

ads

H

m

is called the molar isosteric enthalpy of

adsorption.

ads m

2

ln

n

H p

T RT

A c

| |

=

|

c

\ .

ENTHALPY OF ADSORPTION

Heats of adsorption change as a function of surface coverage

2

0

0

0 0

0

0 0 0 0

K ln

K ln

K ln

RT

H

T

R

S

RT

H

S T H RT G

S M S M

AD

AD AD

AD AD AD

surface surface g

u

differentiate

Vant Hoff equation

DESORPTION AND REGENERATION OF ADSORBENTS

Adsorbent particles have finite capacity for fluid phase molecules. An extended

contact with the feed fluid will ultimately lead to the creation of a

thermodynamic equilibrium between the solid adsorbent and the fluid phases. At

this equilibrium condition the rates of adsorption and desorption are equal and

the net loading on the solid cannot increase further, It is now becomes necessary

either to regenerate the adsorbent or to dispose of it.

In certain applications it may be more economical to discard the adsorbent after

use. Disposal would be favoured when the adsorbent is of low cost, is very

difficult to regenerate, and the non-adsorbed component is the desired product of

very high value. In the majority of applications, the disposal of adsorbents as

waste is not an economic option and therefore regeneration is carried out either

in situ or external to the adsorption vessel to an extent that the adsorbents can be

reused.

Practical methods of desorption and regeneration include one, or more usually a

combination, of the following:

Increase in temperature

Reduction in partial pressure

Reduction in concentration

Purging with an inert fluid

Displacement with a more strongly adsorbing species

Change of chemical conditions, e.g. pH

The final choice of regeneration method(s) depends on technical and economic

considerations.

PRACTICAL REGENERATION METHODS

FIXED-BED ADSORPTION PROCESS AND THEIR

REGENERATION METHODS

A. Pressure Swing Adsorption (PSA)

Regeneration in a PSA process is achieved by reducing the partial pressure

of the adsorbate. There are 2 ways in which this can be achieved: (1) a

reduction in the system total pressure, and (2) introduction of an inert gas

while maintaining the total system pressure. In the majority of pressure

swing separations a combination of the 2 methods is employed. Use of a

purge fluid alone is unusual.

The Figure below shows the effect of partial pressure on equilibrium loading for

a Type I isotherm at a temperature of T1. Reducing the partial pressure from p1

to p2 causes the equilibrium loading to be reduced from q1 to q2.

PICTORIAL EXPLAINATION

Changes in pressure can be effected very

much more quickly than changes in

temperature, thus cycle time of pressure

swing adsorption (PSA) processes are

typically in the order of minutes or even

seconds.

PSA processes are often operated at low

adsorbent loadings because selectivity

between gaseous components is often

greatest in the Henry's Law region. It is

desirable to operate PSA processes close

to ambient temperature to take advantage

of the fact that for a given partial pressure

the loading is increased as the temperature

is decreased.

Typical PSA processes consist of 2-Bed

system, although other systems (e.g. 1-

Bed system or complex, multiple-beds

system) had also been developed.

PSA processes is a popular process for performing bulk separations of gases.

Separations by PSA and VSA are controlled by adsorption equilibrium or

adsorption kinetics. Both types of control are important commercially. For the

separation of air with zeolites, adsorption equilibrium is the controlling

factor. Nitrogen is more strongly adsorbed than oxygen. For air with about

21% oxygen and 79% nitrogen, a product of nearly 96% oxygen purity can be

obtained. When carbon molecular sieves are used, oxygen and nitrogen have

almost the same adsorption isotherms, but the effective diffusivity of oxygen

is much larger than nitrogen. Hence more oxygen is adsorbed than nitrogen,

and a product of very high purity nitrogen ( 99%) can be obtained.

USES OF PSA PROCESSES

B. TEMPERATURE SWING ADSORPTION (TSA)

Regeneration of adsorbent in a TSA process is ahieved by an increase in temperature.

The Figure below showed schematically the effect of temperature on the adsorption

equilibrium (Type I isotherm) of a single adsorbate.

For any given partial pressure of the

adsorbate in the gas phase (or

concentration in the liquid phase), an

increase in temperature leads to a decrease

in the quantity adsorbed. If the partial

pressure remains constant at p1,

increasing the temperature from T1 to T2

will decrease the equilibrium loading from

q1 to q2.

A relatively modest increase in

temperature can effect a relatively large

decrease in loading. It is therefore

generally possible to desorb any

components provided that the temperature

is high enough. However, it is important

to ensure that the regeneration

temperature does not cause degradation of

the adsorbents.

A change in temperature alone is not used in commercial processes

because there is no mechanism for removing the adsorbate from the

adsorption unit once desorption from the adsorbents has occurred.

Passage of a hot purge gas or steam, through the bed to sweep out the

desorbed components is almost always used in conjunction with the

increase in temperature.

A very important characteristic of TSA processes is that they are used

virtually exclusively for treating feeds with low concentrations of

adsorbates.

TSA.. CONTD........

C. DISPLACEMENT PURGE ADSORPTION (DPA)

Adsorbates can be removed from the adsorbent surface by replacing them with a

more preferentially adsorbed species. This displacement fluid, which can be a

gas, a vapour or a liquid, should adsorb about as strongly as the components

which are to be desorbed. If the displacement fluid is adsorbed too strongly then

there may be subsequent difficulties in removing it from the adsorbent.

The mechanism for desorption of the original adsorbate involves 2 aspects:

(1) partial pressure (or concentration) of original adsorbate in the gas phase

surrounding the adsorbent is reduced

(2) there is competitive adsorption for the displacement fluid. The

displacement fluid is present on the adsorbent and thus will contaminate the

product.

One advantage of the displacement fluid method of regeneration is that the net

heat generated or consumed in the adsorbent will be close to zero because the

heat of adsorption of the displacement fluid is likely to be close to that of the

original adsorbate. Thus the temperature of the adsorbent should remain more or

less constant throughout the cycle.

With neither pressure nor temperature changes from adsorption to desorption,

regeneration by displacement purge depend solely on the ability of the displacement

fluid to cleanse the bed in readiness for the next adsorption step. A typical

Displacement Purge Adsorption (DPA) process is shown in the Figure below.

PICTORIAL EXPLAINATION

A is the more strongly adsorbed

component in the binary feed mixture

of (A and B) while D is the

displacement purge gas. The feed

mixture of (A and B) is passed

through Bed 1 acting as the adsorber,

which is preloaded with D from the

previous cycle (when Bed 1 was the

regenerator).

A is adsorbed and the product of a

mixture of (B and D) emerges from

the top of the column. (B and D) are

easily separated by distillation so that

B is collected in a relatively pure

state.

The displacement gas D then enters

Bed 2 acting as regenerator and from

which emerges a mixture of (A and

D). (A and D) can be separated

without difficulty in another

distillation column.

In effect the original mixture of (A and B), which would have been difficult to separate by PSA or TSA, is separated

by the "intervention" of another strongly adsorbed component D. The ease of separation of A from D, and B from D,

in the additional distillation stages, is crucial in determining the economies of displacement purge cycle operation.

Examples of commercial processes include the separation of linear paraffins from mixtures containing branched

chain and cyclic isomers in the range of C10 - C18 hydrocarbons.

DPA.. CONTD........

Other Adsorption Cycles

Virtually all adsorption processes use changes in temperature, pressure, concentration of a competitvely

adsorbing component to effect adsorption and desorption. But presumably any other variables which could

effect changes in the shape of an adsorption isotherm could also be used.

One such variable is the pH. The bonding between some adsorbents and adsorbates such as amino acids in

water can be changed remarkably as the pH is changed from above the isoelectric point of the amino acid to

below its isoelectric point. The isoelectric point is the pH at which the amino acid molecule has zero charge.

The economic problem of using pH swing as a means to drive a cyclic process is the cost of the acid and base

required to change the pH, as well as the cost of disposal of the salt by-product.

Another means for changing the shape of the adsorption isotherm is the use of electric charge.

Electrosorption involves adsorption when the adsorbent is subjected to one voltage and the desorption when

the voltage is changed. Typically the voltage can be small, such as 1V or less. This process can only be

accomplished in cases in which both the adsorbent and the feed stream are highly conductive. An example is

EDA (ethylenediamine), which demonstrates different loading at different voltages.

THANK

YOU

You might also like

- ENERGY EMANATIONS FROM GEOMETRIC SHAPESDocument3 pagesENERGY EMANATIONS FROM GEOMETRIC SHAPESPanther PantherNo ratings yet

- ADSORPTION: THE ACCUMULATION OF MOLECULES ON SURFACESDocument20 pagesADSORPTION: THE ACCUMULATION OF MOLECULES ON SURFACESkrisha chauhanNo ratings yet

- Grade 10 Lesson Plan Electricity and MagnetisDocument6 pagesGrade 10 Lesson Plan Electricity and MagnetisNicko Rodolfo100% (1)

- Identify The Choice That Best Completes The Statement or Answers The QuestionDocument5 pagesIdentify The Choice That Best Completes The Statement or Answers The Questiontwinckel mae bienesNo ratings yet

- CH 6701 Cre IiDocument230 pagesCH 6701 Cre IiVaibhav Gupta100% (1)

- 8 AdsorptionDocument85 pages8 AdsorptionRush WahabNo ratings yet

- Unit-3 Mass Transfer Operation1Document41 pagesUnit-3 Mass Transfer Operation1chinna erannaNo ratings yet

- Chapter 5 AdsorptionDocument46 pagesChapter 5 AdsorptionSyahmiNo ratings yet

- Simona Onori, Lorenzo Serrao, Giorgio Rizzoni (Auth.) - Hybrid Electric Vehicles - Energy Management Strategies-Springer-Verlag London (2016)Document121 pagesSimona Onori, Lorenzo Serrao, Giorgio Rizzoni (Auth.) - Hybrid Electric Vehicles - Energy Management Strategies-Springer-Verlag London (2016)mpurperNo ratings yet

- Mass Transfer Mass Transfer Coefficients Notes 10-11-2015Document28 pagesMass Transfer Mass Transfer Coefficients Notes 10-11-2015John OliverNo ratings yet

- PolypyrroleDocument106 pagesPolypyrrolesurya rajNo ratings yet

- Introduction To Mass Transfer - Part 1Document39 pagesIntroduction To Mass Transfer - Part 1Biniyam haile100% (1)

- ECH3118 (Adsorption)Document68 pagesECH3118 (Adsorption)Wen Feng YeowNo ratings yet

- Vector CalculusDocument37 pagesVector CalculuserNo ratings yet

- 05 Characterization of Heterogeneous Catalyst (256512)Document86 pages05 Characterization of Heterogeneous Catalyst (256512)kitchaya UHVNo ratings yet

- Note 5 - Fractional Distillation Using Enthalpy-Concentration MethodDocument30 pagesNote 5 - Fractional Distillation Using Enthalpy-Concentration MethodKaleesh100% (1)

- 1-Introduction and Basic Concepts PDFDocument18 pages1-Introduction and Basic Concepts PDFsara sofeaNo ratings yet

- Interplanetary Climate Change - Prof. Dr. Alexey DmitrievDocument25 pagesInterplanetary Climate Change - Prof. Dr. Alexey DmitrievExopolitika Magyarország100% (1)

- CME 3303 HW 6 Solution PDFDocument4 pagesCME 3303 HW 6 Solution PDFrum kaunNo ratings yet

- Adsorbents and Carbon Technology For Air Sampling & Thermal DesorptionDocument38 pagesAdsorbents and Carbon Technology For Air Sampling & Thermal DesorptionskNo ratings yet

- Adsorption SlidesDocument24 pagesAdsorption Slidesdivyachauhan050No ratings yet

- Adsorption Surface PhenomenonDocument13 pagesAdsorption Surface PhenomenonjakkiNo ratings yet

- Anna Univ 3rd Sem, 5th Sem, 7th Sem Syllabus For Agriculture Irrigation Engg WWW - Annaunivedu.infoDocument72 pagesAnna Univ 3rd Sem, 5th Sem, 7th Sem Syllabus For Agriculture Irrigation Engg WWW - Annaunivedu.infosudentsideaNo ratings yet

- Low-Cost Adsorbents Remove PhosphateDocument13 pagesLow-Cost Adsorbents Remove PhosphateManasa Reddy BillaNo ratings yet

- Mass Transfer QuizzesDocument10 pagesMass Transfer QuizzesNate JamesNo ratings yet

- Surface Phenomena PDFDocument5 pagesSurface Phenomena PDFDurga Prasad KalamNo ratings yet

- Syllabus For B.SC Physics Semester Pattern2013Document23 pagesSyllabus For B.SC Physics Semester Pattern2013GnetTechnologies GondiaNo ratings yet

- Solution Tutorial 3 Q1-Q10Document7 pagesSolution Tutorial 3 Q1-Q10hoboslayer97No ratings yet

- CP302 Mass Transfer Principles: Diffusion in SolidsDocument38 pagesCP302 Mass Transfer Principles: Diffusion in SolidsDeneshVijayNo ratings yet

- Environmental Chemistry PPT 1314022018 TUGASDocument56 pagesEnvironmental Chemistry PPT 1314022018 TUGASRahmat Al-khaliq Herman0% (1)

- O O (S) - Glycidyl Benzyl Ether: 4.6 PPM 3.7 PPM 3.4 PPMDocument3 pagesO O (S) - Glycidyl Benzyl Ether: 4.6 PPM 3.7 PPM 3.4 PPMShailendra AgarwalNo ratings yet

- Least Squares Approximations in Data FittingDocument10 pagesLeast Squares Approximations in Data Fittingnima1977No ratings yet

- Radioactive Waste Management: Presented By: Kamran Ullah Khan NE-023Document24 pagesRadioactive Waste Management: Presented By: Kamran Ullah Khan NE-023Kamran Ullah KhanNo ratings yet

- Adsorption Kinetics and Modelling of Copper (II) Ion Sorption Using Mercaptoacetic Acid Modifed Cassava WasteDocument14 pagesAdsorption Kinetics and Modelling of Copper (II) Ion Sorption Using Mercaptoacetic Acid Modifed Cassava WasteEdidiong AsuquoNo ratings yet

- Report Rafael Damar ArjanggiDocument28 pagesReport Rafael Damar ArjanggiRafael DamarNo ratings yet

- 08 Chapter3Document25 pages08 Chapter3Longdien AnngaiNo ratings yet

- Boundary LayerDocument8 pagesBoundary LayerVenkatarao ChukkaNo ratings yet

- ch30 PDFDocument19 pagesch30 PDFRodrigo S QuirinoNo ratings yet

- Tute ProblemsDocument5 pagesTute Problemsralston204No ratings yet

- Dissolution of Benzoic AcidDocument2 pagesDissolution of Benzoic AcidAngela Calatayud100% (1)

- 28 2 Diff Vec CalcDocument21 pages28 2 Diff Vec CalcSachin AroraNo ratings yet

- Transport Phenomena - 2-3 - Vector and Tensor 2 and CoordinatesDocument22 pagesTransport Phenomena - 2-3 - Vector and Tensor 2 and CoordinatesHareritamNo ratings yet

- Chapter 10Document24 pagesChapter 10Lucy BrownNo ratings yet

- PR 1-5Document18 pagesPR 1-5Febryan CaesarNo ratings yet

- Chapter 14 - Quantitative Risk AssessmentDocument2 pagesChapter 14 - Quantitative Risk Assessmenthuyarchitect89No ratings yet

- Tutorial 1 WastewaterDocument2 pagesTutorial 1 WastewaterAnonymous Vx9KTkM8nNo ratings yet

- Chem Xi Chap 2, Worksheet 3Document4 pagesChem Xi Chap 2, Worksheet 3nazish kiranNo ratings yet

- Paschen-Back EffectDocument3 pagesPaschen-Back EffectSreedevi KrishnakumarNo ratings yet

- Newton's Law Viscosity & Rheology LectureDocument51 pagesNewton's Law Viscosity & Rheology LecturefamiliarityNo ratings yet

- 2 - Modelling and Control of Forward-Feed Evaporator For The Production of Glucose SyrupDocument7 pages2 - Modelling and Control of Forward-Feed Evaporator For The Production of Glucose SyrupKate MayerNo ratings yet

- Gaussian PlumesDocument7 pagesGaussian PlumesVeky PamintuNo ratings yet

- Kalkulator ICPHDocument1 pageKalkulator ICPHaulia utamiNo ratings yet

- Transport Phenomena (Newtonian Fluid Flow in A Falling Film)Document6 pagesTransport Phenomena (Newtonian Fluid Flow in A Falling Film)rachma tia100% (1)

- Probset 3 (Mass)Document2 pagesProbset 3 (Mass)Ralph EvidenteNo ratings yet

- SEDIMENTATION PresentationDocument45 pagesSEDIMENTATION PresentationShai Sta CatalinaNo ratings yet

- Kartika Fajarwati H., S.T., M.TDocument54 pagesKartika Fajarwati H., S.T., M.Tpoiuy14595No ratings yet

- Kremser EquationDocument3 pagesKremser EquationAjay ShekhawatNo ratings yet

- Solids Drying Basics and ApplicationsDocument7 pagesSolids Drying Basics and ApplicationsEarl De La China100% (1)

- Enhancing Heat Exchanger Performance Using NanofluidsDocument44 pagesEnhancing Heat Exchanger Performance Using NanofluidsSrinivasa bnNo ratings yet

- Fluidized bed reactor design and fabricationDocument11 pagesFluidized bed reactor design and fabricationHarshaNo ratings yet

- CL 333 Chemical Engineering Lab-2 (2019) : Experiment Number FM 302 TitleDocument31 pagesCL 333 Chemical Engineering Lab-2 (2019) : Experiment Number FM 302 TitleAkshat PunekarNo ratings yet

- Unsteady 3D Flow Past A Cylinder: Created in COMSOL Multiphysics 5.5Document20 pagesUnsteady 3D Flow Past A Cylinder: Created in COMSOL Multiphysics 5.5Luis RiosNo ratings yet

- Mass Transfer Lab ManualDocument29 pagesMass Transfer Lab ManualPrajwal ChavanNo ratings yet

- Removal of Methylene Blue Using Moss Grass and AlgaeDocument37 pagesRemoval of Methylene Blue Using Moss Grass and Algaesamar_biotech100% (2)

- Physical Chemistry LaboratoryDocument8 pagesPhysical Chemistry Laboratorydaimon_pNo ratings yet

- Physical Chemistry II-class 20Document28 pagesPhysical Chemistry II-class 20PARVATHY ANILNo ratings yet

- MICMAT4070Document7 pagesMICMAT4070Vivek KumarNo ratings yet

- E& F Accepted PaperDocument29 pagesE& F Accepted PaperVivek KumarNo ratings yet

- Energy and Fuels - CADocument10 pagesEnergy and Fuels - CAVivek KumarNo ratings yet

- E& F Accepted PaperDocument29 pagesE& F Accepted PaperVivek KumarNo ratings yet

- MICMAT4070Document7 pagesMICMAT4070Vivek KumarNo ratings yet

- Tutorials PTT 205Document2 pagesTutorials PTT 205Celine NathaliaNo ratings yet

- Chapter 7Document130 pagesChapter 7vipulNo ratings yet

- Ahmed HassanDocument4 pagesAhmed Hassanah_hassanNo ratings yet

- Physical Science SHS 6.2 Properties of Molecules Based On IMFADocument18 pagesPhysical Science SHS 6.2 Properties of Molecules Based On IMFAjouselleduayNo ratings yet

- Handheld Handheld Handheld Handheld Digital Digital Digital Digital Multimeter Multimeter Multimeter MultimeterDocument16 pagesHandheld Handheld Handheld Handheld Digital Digital Digital Digital Multimeter Multimeter Multimeter MultimeterAntonio MarcosNo ratings yet

- 04-Cet12-Cr2 C+M+P - 10-07-2021 - M1Document36 pages04-Cet12-Cr2 C+M+P - 10-07-2021 - M1Fcd CjllNo ratings yet

- WORKSHEETS GRADE 4 SciDocument8 pagesWORKSHEETS GRADE 4 SciQurrat-Ul-Ain - 47255/TCHR/BMBNo ratings yet

- Science Grade 9: Quarter 4 - Module 2Document16 pagesScience Grade 9: Quarter 4 - Module 2Normina DagendelNo ratings yet

- Tabletop Simulator Script ObjectDocument10 pagesTabletop Simulator Script ObjectMichael MelloNo ratings yet

- Data Sheet: Capacitor For Power ElectronicsDocument6 pagesData Sheet: Capacitor For Power Electronicsraza239No ratings yet

- History of The Atom Ass. ATCDocument4 pagesHistory of The Atom Ass. ATCArnold E. DiazNo ratings yet

- SudaisDocument3 pagesSudaisamirbadshahNo ratings yet

- Friction and Its EffectsDocument18 pagesFriction and Its EffectszahoorNo ratings yet

- Atomic Structure WorksheetDocument2 pagesAtomic Structure WorksheetAryan Agrawal50% (2)

- NSEJS/NSEC Physics, Chemistry, Biology QuizDocument31 pagesNSEJS/NSEC Physics, Chemistry, Biology Quizamit starboyNo ratings yet

- Landauer Buttiker FormalismDocument15 pagesLandauer Buttiker FormalismGokaran ShuklaNo ratings yet

- PP Elmasonic S15H GBDocument1 pagePP Elmasonic S15H GBliska ramdanawatiNo ratings yet

- The IsochroneDocument6 pagesThe IsochronePriscilla RochaNo ratings yet

- FBD StaticDocument5 pagesFBD StaticBrianChanNo ratings yet

- Moran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Document5 pagesMoran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Marco GassaniNo ratings yet

- 4 Lab Sheet BDA27401 Sem 1 20182019 Edition1 2018Document73 pages4 Lab Sheet BDA27401 Sem 1 20182019 Edition1 2018Zarul IkramNo ratings yet

- Kinetics of Particles Study of The Relations Existing Between TheDocument90 pagesKinetics of Particles Study of The Relations Existing Between Theskmishra3914100% (3)