Professional Documents

Culture Documents

Protective Coating For Steel Structures

Uploaded by

crazyrimzyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protective Coating For Steel Structures

Uploaded by

crazyrimzyCopyright:

Available Formats

Defined

as a material which is applied to a surface as a fluid and which forms, by chemical and/or physical processes, a solid continuous film bonded to the surface.

Pigments Non-Volatile Vehicles (Binders) Volatile Vehicles (Solvents) Additives

Pigments are included in coatings to perform any of the following functions: ! Add colour ! Adjust the flow properties of wet coatings ! Resist light, heat, moisture, chemicals ! Inhibit corrosion ! Reflect light for opacity or hiding ! Contribute mechanical strength

The binder or resin portion (polyurethane, epoxy, etc.) of the coating is the "glue" that holds the coating together and onto the substrate.

The physical properties of the coating are mainly derived from the physical properties of the solid resin, but pigments and additives can affect the final properties.

A solvent is used to dissolve the resins and additives in order to reduce the viscosity of the mixture to provide application consistency . And allow the paint to flow out properly. In every case, it is designed to evaporate from the film during or after application.

Additives make up only a small proportion of any paint. Yet without these chemicals the paint could not deliver all of its potential performance.

Zinc-Rich Primers Epoxy Acrylics Polyurethane Alkyds

Intumescent Paint Hot-Dip Galvanizing

Inorganic zinc coatings

Powdered metallic zinc mixed into a reactive silicate solution Organic zinc-rich primers The binders of which are based on organic or carbon-based compounds.(phonoxies, catalyzed epoxies, urethanes, chlorinated rubbers, vinyls).

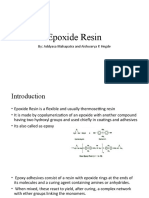

Epoxy binders are available in three types: epoxy ester; epoxy lacquer resin; and two-

component epoxy.

The two-component epoxies are most commonly used for painting structural steel The epoxy is generally combined with either of two types of hardeners (polyamine or polyamide) to form epoxy-polyamine and

epoxy-polyamide.

Acrylics can be supplied as solvent- or waterbased coatings with varying performance characteristics. Exhibit good color and gloss retention, are single package, relatively low in cost and easy to apply. Solvent and chemical resistance, however, is lacking. They are best for interior, noncorrosive environments.

Moisture-cure polyurethane Two-component polyurethane

Reacts with air moisture to cure. They produce the hardest, toughest coatings available in one package, and are increasingly popular due to the wide range of application

! Can be applied to cold damp surfaces ! Can be applied at temperatures below freezing ! No dew point restriction ! Year round application season ! Excellent recoatability ! Single component

Polyurethanes can also be reacted with products such as polyols, polyethers, polyesters or acrylics to produce extremely hard, resistant durable coatings.

These are commonly used as topcoats

Alkyds are available in both water dispersion and solvent-based formulations. Alkyd-oil vehicles can be formulated in flat and semi-gloss finishes over a wide compositional range. Generally, alkyds have poor color and retention properties and tend to chalk when exposed to sunlight. Their primary advantage is low cost.

Intumescent paints are examples of special purpose coating systems. They can provide fire ratings for exposed steel for up to three hours

Hot-dip galvanizing is a process in which a steel article is cleaned in acid (pickled) and then immersed in molten zinc that is heated to approximately 850 Fahrenheit. This results in formation of a zinc and a zinciron alloy coating that is metallurgically bonded to the steel. The galvanized member is then cooled in air or quenched in water. .

The zinc coating acts as a barrier that separates the steel from the environmental conditions that can cause corrosion

Thank u!!

You might also like

- Epoxy Resin Arts and Crafts for BeginnersFrom EverandEpoxy Resin Arts and Crafts for BeginnersRating: 3 out of 5 stars3/5 (5)

- Protect Concrete With CoatingsDocument6 pagesProtect Concrete With CoatingsPinaki RahaNo ratings yet

- Introduction To Generic Coating TypesDocument8 pagesIntroduction To Generic Coating TypesChimuelin100% (1)

- Types of PaintsDocument5 pagesTypes of PaintsSatyamTiwariNo ratings yet

- Paints Final Assignment 6th NovDocument8 pagesPaints Final Assignment 6th NovGlobal PMCNo ratings yet

- Classification of PaintsDocument2 pagesClassification of Paints9440864459No ratings yet

- Water-based Acrylic Dispersions: Applications in Architectural CoatingsFrom EverandWater-based Acrylic Dispersions: Applications in Architectural CoatingsNo ratings yet

- Classification of PaintsDocument2 pagesClassification of Paints9440864459No ratings yet

- CH 7 Corrosion Control CoatingsDocument42 pagesCH 7 Corrosion Control Coatingslatifa99100yNo ratings yet

- Vehicles and BindersDocument7 pagesVehicles and Bindersberchard100% (1)

- CorrosionDocument13 pagesCorrosionbourneremembersNo ratings yet

- Paint: Prof - DR/ Mostafa KhafagyDocument16 pagesPaint: Prof - DR/ Mostafa Khafagysic 20162085No ratings yet

- Types of Paints With GlossaryDocument22 pagesTypes of Paints With Glossarylaniejane bedesNo ratings yet

- Properties and Types of Paint CoatingsDocument64 pagesProperties and Types of Paint CoatingsMuhammad IrfanNo ratings yet

- What Is Epoxy?Document2 pagesWhat Is Epoxy?Ali ImranNo ratings yet

- BINDERSDocument16 pagesBINDERSHamidNo ratings yet

- 4 - Coating FundamentalsDocument32 pages4 - Coating FundamentalsLeon PanjaitanNo ratings yet

- Francesco Patti Professor Cuevas CHM-1020 04 November 2020: History of Epoxy ResinsDocument2 pagesFrancesco Patti Professor Cuevas CHM-1020 04 November 2020: History of Epoxy Resinsfrancesco pattiNo ratings yet

- Chapter 2-RRL BindersDocument4 pagesChapter 2-RRL BindersAlfred Louie RimorinNo ratings yet

- Formulating High Perf WB Paper Hexion PDFDocument16 pagesFormulating High Perf WB Paper Hexion PDFMaxime Delbury100% (1)

- Epoxy ResinDocument17 pagesEpoxy ResinIrfan AliNo ratings yet

- Corrosion Removal: Before Starting Any Corrosion Removal, You Must Conduct An Inspection andDocument8 pagesCorrosion Removal: Before Starting Any Corrosion Removal, You Must Conduct An Inspection andHorhe TheGreatNo ratings yet

- Cleaning and Painting of Structural SteelDocument25 pagesCleaning and Painting of Structural SteelthirumalNo ratings yet

- PaintsDocument24 pagesPaintsanique_senior100% (1)

- Technical Paper: Waterborne Resins For The Paint Industry - Theory and PracticeDocument28 pagesTechnical Paper: Waterborne Resins For The Paint Industry - Theory and PracticeDantvNo ratings yet

- Types of EpoxyDocument5 pagesTypes of EpoxybalsamNo ratings yet

- Paint components and classificationDocument26 pagesPaint components and classificationM Busairi MusimNo ratings yet

- Surface Coatings Types and ApplicationsDocument17 pagesSurface Coatings Types and ApplicationsAshish ParmarNo ratings yet

- Coatings PDFDocument17 pagesCoatings PDFAshish ParmarNo ratings yet

- Paints and CoatingsDocument29 pagesPaints and CoatingsRai JeanNo ratings yet

- Bonded Mild Steel PlatesDocument2 pagesBonded Mild Steel PlatesJaswant SharmaNo ratings yet

- PAINTDocument2 pagesPAINTKIM PAULO DE GUZMANNo ratings yet

- Epoxy ChalkingDocument2 pagesEpoxy Chalkingiran1362100% (1)

- Types of PaintsDocument22 pagesTypes of Paintsssm_majeed82% (11)

- Paints, Varnishes and Inks GuideDocument26 pagesPaints, Varnishes and Inks GuideAbdulRahim059No ratings yet

- Paints DataDocument17 pagesPaints DatadagnachewNo ratings yet

- Epoxy - Wikipedia, The Free EncyclopediaDocument6 pagesEpoxy - Wikipedia, The Free EncyclopediaSoumyabrata DasNo ratings yet

- Performance Coatings - Greenheck FansDocument12 pagesPerformance Coatings - Greenheck Fansprsum_572100% (1)

- Acrylic Binders For Low Voc PaintsDocument31 pagesAcrylic Binders For Low Voc PaintsMaina1206550% (2)

- What is Paint? Introduction to Jotun's Technical Data ManualDocument112 pagesWhat is Paint? Introduction to Jotun's Technical Data Manualwdavid81No ratings yet

- How To Decide Between Anodizing Painting & PVDF CoatingDocument5 pagesHow To Decide Between Anodizing Painting & PVDF CoatingNaveen Karki100% (1)

- Anti-corrosion Product GuideDocument6 pagesAnti-corrosion Product Guidedosetiadi100% (1)

- Paints and CoatingsDocument2 pagesPaints and CoatingsMartin Lizarbe WilliamsNo ratings yet

- Waterborne Paints DescriptionDocument3 pagesWaterborne Paints DescriptionChrysler Kane DepnagNo ratings yet

- Fillerliqureprotective CoatingsDocument3 pagesFillerliqureprotective CoatingsengineeringchemistryNo ratings yet

- Paints and VarnishesDocument24 pagesPaints and VarnishesEmina HuseinovicNo ratings yet

- Epoxy Resin Uses, Advantages and DisadvantagesDocument11 pagesEpoxy Resin Uses, Advantages and DisadvantagesDevyani RamamoorthyNo ratings yet

- Finishing Processes: 1. CoatingDocument2 pagesFinishing Processes: 1. CoatingJackson Okang'aNo ratings yet

- Corrosion Full ReportDocument12 pagesCorrosion Full ReportVagishan ArumugamNo ratings yet

- 4580881PA Paper - High Performance Epoxy Systems For Applications in Coatings and Construction1Document13 pages4580881PA Paper - High Performance Epoxy Systems For Applications in Coatings and Construction1Javed AnsariNo ratings yet

- Types of PaintDocument25 pagesTypes of PaintRichard Williamson100% (4)

- A Complete Guide of Epoxy Coatings For Industrial and Marine ApplicationsDocument8 pagesA Complete Guide of Epoxy Coatings For Industrial and Marine ApplicationsCông NguyễnNo ratings yet

- Understanding Paint SystemDocument37 pagesUnderstanding Paint SystemMayank KumarNo ratings yet

- Paint SystemsDocument4 pagesPaint SystemsHung Mai VanNo ratings yet

- Department of Chemistry: Name - Soumya Ray Course - M.SC Semester - 3Document15 pagesDepartment of Chemistry: Name - Soumya Ray Course - M.SC Semester - 3Soumya RayNo ratings yet

- PaintDocument10 pagesPaintTú NgọcNo ratings yet

- Survey Analyzes India's Toll Collection SystemsDocument15 pagesSurvey Analyzes India's Toll Collection SystemsmohitvermakspNo ratings yet

- Machine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILUREDocument5 pagesMachine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILURE9965399367No ratings yet

- Tps65070X Power Management Ic (Pmic) With Battery Charger, 3 Step-Down Converters, and 2 LdosDocument98 pagesTps65070X Power Management Ic (Pmic) With Battery Charger, 3 Step-Down Converters, and 2 Ldosmok waneNo ratings yet

- Structures Module 3 Notes FullDocument273 pagesStructures Module 3 Notes Fulljohnmunjuga50No ratings yet

- Stellar Competent CellsDocument1 pageStellar Competent CellsSergio LaynesNo ratings yet

- Characteristics: Wheels Alloy Aluminium Magnesium Heat ConductionDocument4 pagesCharacteristics: Wheels Alloy Aluminium Magnesium Heat ConductionJv CruzeNo ratings yet

- Verifyning GC MethodDocument3 pagesVerifyning GC MethodHristova HristovaNo ratings yet

- Forms of Business Organization: Sole Proprietorship, Partnership, Corporation, CooperativesDocument17 pagesForms of Business Organization: Sole Proprietorship, Partnership, Corporation, CooperativesSanti BuliachNo ratings yet

- Embedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDocument27 pagesEmbedded Systems: Martin Schoeberl Mschoebe@mail - Tuwien.ac - atDhirenKumarGoleyNo ratings yet

- Czar Alexander IIDocument11 pagesCzar Alexander IIMalachy ChinweokwuNo ratings yet

- JIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test MethodsDocument43 pagesJIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test Methodsbignose93gmail.com0% (1)

- United States Court of Appeals, Third CircuitDocument3 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- Continuous torque monitoring improves predictive maintenanceDocument13 pagesContinuous torque monitoring improves predictive maintenancemlouredocasadoNo ratings yet

- 1 N 2Document327 pages1 N 2Muhammad MunifNo ratings yet

- 3000W InverterDocument2 pages3000W InverterSeda Armand AllaNo ratings yet

- Statement of PurposeDocument2 pagesStatement of Purposearmaan kaurNo ratings yet

- Jenga Cash Flow Solution: InstructionsDocument1 pageJenga Cash Flow Solution: InstructionsPirvuNo ratings yet

- 702190-Free PowerPoint Template AmazonDocument1 page702190-Free PowerPoint Template AmazonnazNo ratings yet

- Capran+980 CM en PDFDocument1 pageCapran+980 CM en PDFtino taufiqul hafizhNo ratings yet

- Ridge Regression: A Concise GuideDocument132 pagesRidge Regression: A Concise GuideprinceNo ratings yet

- 272 Concept Class Mansoura University DR Rev 2Document8 pages272 Concept Class Mansoura University DR Rev 2Gazzara WorldNo ratings yet

- Green Solvents For Chemistry - William M NelsonDocument401 pagesGreen Solvents For Chemistry - William M NelsonPhuong Tran100% (4)

- Programming in Java Assignment 8: NPTEL Online Certification Courses Indian Institute of Technology KharagpurDocument4 pagesProgramming in Java Assignment 8: NPTEL Online Certification Courses Indian Institute of Technology KharagpurPawan NaniNo ratings yet

- MSDS Metafuron 20 WPDocument10 pagesMSDS Metafuron 20 WPAndi DarmawanNo ratings yet

- cp2021 Inf03p02Document242 pagescp2021 Inf03p02bahbaguruNo ratings yet

- Sierra Wireless AirPrimeDocument2 pagesSierra Wireless AirPrimeAminullah -No ratings yet

- Wheat as an alternative to reduce corn feed costsDocument4 pagesWheat as an alternative to reduce corn feed costsYuariza Winanda IstyanNo ratings yet

- Ultrasonic Examination of Heavy Steel Forgings: Standard Practice ForDocument7 pagesUltrasonic Examination of Heavy Steel Forgings: Standard Practice ForbatataNo ratings yet

- ThesisDocument18 pagesThesisapi-29776055293% (15)

- Organization Structure GuideDocument6 pagesOrganization Structure GuideJobeth BedayoNo ratings yet