Professional Documents

Culture Documents

Me Machine Design Notes 09

Uploaded by

Ravi YadavOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me Machine Design Notes 09

Uploaded by

Ravi YadavCopyright:

Available Formats

ME311 Machine Design

W Dornfeld

05Nov2009 Fairfield University

School of Engineering

Lecture 9: Screws

(Chapter 16)

Thread Geometry

Hamrock

Page 707

Diameters

Major

Crest

Pitch

Root

Minor

Thread Height

Thread Pitch

Thread

Angle

p

inch Threads n

1

) / (

The Pitch Diameter

is midway between

the Major and Minor

Diameters.

Thread Types

Hamrock

Page 708

Single-, double-, and triple-threaded screws.

Also called single-, double-, and triple-start.

Lead =

3 x Pitch

Acme

Thread

Square

Thread

Lead =

1 x Pitch

Acme threads are used in C-Clamps, vices, and cartoons.

Details of Thread Profiles

Hamrock

Page 708

Relationships for M (metric) and UN (unified = US) screw threads.

Example:

UN: -20, means 0.25in. Major diameter & 20 threads/inch.

M: M8x1.25, means 8mm Major diameter & pitch of 1.25mm

Thread Height

p

p

h

t

8660 . 0

) 30 tan(

5 . 0

Power Screws

Looking at a square

thread screw, we unwind

one turn:

Lead

2 r

m

This shows an inclined

ramp with angle

m

r

Lead

2

tan

1

W

r

m

r

c

Lead

Thread

friction

Collar

friction

Mean

thread

radius

Mean

collar radius

Load

on nut

c

The Mean Radius is midway

between the Crest and Root Radii.

Square Thread Screw Torque

The torque required to

raise the load W is

and to lower the load, we

flip two signs:

1

]

1

c c m raise

r r W T

tan 1

tan

1

]

1

+

+

c c m lower

r r W T

tan 1

tan

W

r

m

r

c

Lead

c

Hamrock

Page 715

If the thread form is not square but has an angle ,

replace the thread friction with the effective friction

Power Screw Thread Angle

) 2 / cos(

e

The effect:

Square: = 0, /2 = 0, 1/cos(0) = 1.0

Acme: = 29, /2 = 14.5, 1/cos(14.5) = 1.033

Unified: = 60, /2 = 30, 1/cos(30) = 1.15

The thread angle effectively increases surface friction between 3 and 15%

Note: Instead of /2, Hamrock uses

The difference is negligible.

) 1 tan (cos tan

1

n

Power Screws - Overhauling

If the collar friction is small (e.g., it may have a

ball thrust bearing), too small a thread friction

may let the weight screw down on its own.

This can happen when

(the numerator goes negative).

This is the same case for a weight sliding down a ramp

when the incline angle exceeds tan

-1

.

m

r

Lead

2

tan <

Lead

2 r

m

1

]

1

+

+

c c m lower

r r W T

tan 1

tan

0

tan

Ball Screws Have Low Friction

Recirculating balls roll between ball screw

and ball nut to minimize friction.

These almost always overhaul.

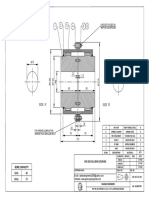

Our Scissors Jack

End with nut Handle End with ball

thrust bearing

1522 Lb Tension

1015 Lb

Scissors Jack Analysis

Thread ID = 0.398 in.

Thread OD = 0.468 in.

Estimate d

p

= (0.398+0.468)/2

= 0.433 in.

Handle length = 135/25.4 = 5.31 in.

What torque is required to raise the jack?

What force is required on the handle?

Lead = 0.10 in.

Thread angle = 29

Guess = 0.20

c

= 0 due to bearing

W = 1522 Lb.

C-Clamp Analysis

Thread ID = 0.391 in.

Thread OD = 0.480 in.

Handle length = 3 in.

N = 8 Threads/Inch

Thread angle = 60

Guess = 0.15

c

= 0 to simplify things

W = 500 Lb.

What torque is required to cause

the 500 Lb. squeeze?

Note: If Acme, could use Eqn. 16.4

. 1111 . 1 00 . 1 ) 000 . 1 )( 1 . 1 ( 00 . 1 11 . 1 1 . 1 in p d d

c p

But with a 60 thread angle, this is NOT an Acme.

Estimate d

p

= (ID+OD)/2 = (0.390+0.480)/2 = 0.436 in.

Using Dornfeld Lecture Equations

d

p

= 0.436 in.

N = 8 Threads/Inch

Lead = 1/N = 0.125 in.

11 . 1 ) 11111 . 1 ( tan

) 1 / 111 . 1 ( 1

111 . 1

tan

1

tan

1 1 1

m

r

Lead

. . 11 . 11

0000 . 1

00000 . 1

) 000 . 1 )( 111 (

) 11111 . 1 )( 0000 . 1 ( 1

11111 . 1 1111 . 1

1

111 . 1

111

tan 1

tan

In Lb

r r W T

c c m raise

1

]

1

1

]

1

+

Thread angle b = 60

= 0.15

W = 500 Lb.

Because this is not a square thread, must use effective coefficient of

friction = /cos(/2) = 0.15/cos(30) = 0.15/0.866 = 0.1732

0

Using Hamrock Equations

d

p

= 0.436 in.

N = 8 Threads/Inch

Lead = 1/N = 0.125 in.

111 . 11 ) 11111 . 1 ( tan

) 00000 . 1 1111 . 1 ( tan ) 11 tan 00 . 1 (cos tan )

1

tan (cos tan

11111 . 1 ) tan( ; 11 . 1

1

tan

1

1 1 1

1

n

n

m

r

Lead

. . 11 . 11

11111 . 1

11111 . 1

) 111 (

) 00000 . 1 )( 11 . 1 ( 111 . 1

11 . 1 ) 11111 . 1 )( 111 . 1 (

) 111 . 1 )( 111 (

11 . 1 tan 11 . 1 1 . 11 cos

) 11 . 1 11 . 1 tan 1 . 11 )(cos 1 / 111 . 1 (

111

tan cos

) tan )(cos 1 / (

In Lb

r

d

W T

c c

n

n p

raise

1

]

1

1

]

1

+

Thread angle b = 60

= 0.15

W = 500 Lb.

[Eqn.

16.10]

The equations are equivalent. Pick whichever one suits you best.

How close is this to /2 = 30?

0

Overhauling Revisited

1

]

1

+

+

c c

n

n p

lower

r

d

W T

tan cos

) tan cos )( 2 / (

Power screws can lower all by themselves if the friction

becomes less than the tangent of the lead angle, .

This corresponds to the numerator in the T

lower

equation going

negative, with the transition being where the numerator is Zero.

You can use either Dornfeld or Hamrock equation, but

remember that the Dornfeld equation is Effective friction, and you

must multiply by cos(/2) to get the actual friction.

The equations are equivalent. Pick whichever one suits you best.

1

]

1

+

+

c c m lower

r r W T

tan 1

tan

tan cos

n

tan ) 2 / cos( ) 2 / cos(

tan

e

e

Transition when:

Hamrock:

Dornfeld:

Failure Modes: Tensile Overload

When the tensile stress on a bolt exceeds the

materials Proof Strength, the bolt will

permanently stretch.

t

A

P

Where A

t

is the Tensile Stress Area for

the bolt the equivalent area of a

section cut through the bolt.

Hamrock

Page 731

2

9743 . 0

) 7854 . 0 (

,

_

n

d A

c t

For UN threads,

2

) 9382 . 0 )( 7854 . 0 ( p d A

c t

For M threads,

d

c

= Crest Dia (in.)

n = threads/in.

d

c

= Crest Dia (mm)

p = pitch (mm)

Failure Modes: Thread Shear

Shear of Nut Threads

Shear of Bolt Threads

l d A

crest shear

l d A

root shear

l

The shear strength

of the bolt and nut

material may not

be the same.

Failure Modes: Shank Shear

4

2

shank

shear

d

A

Bolts are not really intended to be used this way unless they are

Shoulder Bolts:

Typically the preload from tightening the bolt clamps the joint,

and the friction between the members holds the joint.

1 1

1

1 1

shank shank

shear

d d

A

Bolt Preload

So the bolt is really a spring that stretches

and creates preload on the joint.

JH Bickford explains :

'When we tighten a bolt,

( a) we apply torque to the nut,

( b) the nut turns,

( c) the bolt stretches,

( d) creating preload.'

P KD T

crest

We use the Power Screw equations to determine how torque results

in preload. This can be approximated simply by:

Where T is torque, D

crest

is the bolt crest diameter, P is the preload,

and K is a dimensionless constant. K = 0.20 for clean, dry threads

and K = 0.15 for lubricated threads.

Bolt Stiffness

A bolt looks like two

springs in series: one

rod with the Crest

diameter and one with

the Root diameter.

Their lengths are

increased to reflect the

head and nut.

,

_

+

+

+

2 2

4 . 0 4 . 0 4 1

r

r t

c

c s

b

d

d L

d

d L

E k

shank

L

thread

L

Hamrock

Page 725

Bolt Stiffness Exercise

Calculate the stiffness of a 3/8-16 screw that is

4 in. long and clamps 3.5 of material. Use

Eqn. 16.23 to determine shank length.

shank

L

thread

L

Hamrock

Page 726

bolt

L

clamp

L

thread

L

Note: Hamrock uses L

t

in Eqns. 16.21 and

16.22/23, BUT THEY ARE DIFFERENT THINGS!

In 16.21 it is the Clamped thread length;

in 16.22/23 it is Total thread length.

L

t

in

16.22/23

L

t

in

16.21

Joint Stiffness

The material clamped by

the bolt also acts like a

spring in compression.

Effectively, only the material

in the red double conical

area matters.

There are many methods to

calculate this stiffness.

Compare these calculator

stiffness results from

tribology-abc.com with

Hamrocks Example 16.6

Hamrock

Page 727

How Bolt Preload Works

From Norton, Chap. 14

Preload isolates the bolt from most of any external loads.

The joint stiffness factor, C

j

, determines what fraction of

external loads the bolt actually sees.

j b

b

j

k k

k

C

+

Hamrock

Eqn. 16.17

Bolt Strength

For Metric grades, the first number x 100 = Sut in MPa. The

fraction x Sut = Sy. Ex: grade 12.9 has Sut 1200 MPa and

Sy 0.9x1200 = 1080 MPa.

Hamrock

Page 731

Bolt Loading

Generally, bolts are preloaded to:

75% of Proof Load for reused

connections

90% of Proof Load for permanent

connections

where Proof Load = Proof Strength x A

t

.

The Proof Strength is approximately at

the elastic limit for the material.

Hamrock

Page 733

Proof

0.2%Yield

Ultimate

Recommended Site:

BoltScience.com

You might also like

- ME311 Screws LectureDocument26 pagesME311 Screws LectureantoniodellisantiNo ratings yet

- Lead Screw Design CalculationDocument10 pagesLead Screw Design CalculationsamirNo ratings yet

- Calculation of Screw Action ForceDocument3 pagesCalculation of Screw Action ForceShivam Gukhoul100% (1)

- Formulae HandbookDocument60 pagesFormulae Handbookmgvpalma100% (1)

- Screw Jack CalculationsDocument6 pagesScrew Jack CalculationsDaniel SherwinNo ratings yet

- Ball Screw CalculatorDocument60 pagesBall Screw Calculatorمنير بوزيدNo ratings yet

- CFturbo enDocument184 pagesCFturbo enDefinal ChaniagoNo ratings yet

- Practical Data For MetallurgistsDocument37 pagesPractical Data For MetallurgistsmetallurgistNo ratings yet

- D815 Technical SectionDocument233 pagesD815 Technical SectionRZW RNo ratings yet

- Computer Simulation of Pipe-Bending Processes With Small Bending Radius Using Local Induction HeatingDocument5 pagesComputer Simulation of Pipe-Bending Processes With Small Bending Radius Using Local Induction Heatingsatheeshsep24No ratings yet

- Oring Us enDocument160 pagesOring Us enroger1231175No ratings yet

- Gear Technical FundamentalsDocument176 pagesGear Technical Fundamentalsjoe9000No ratings yet

- SW FEA Tutorial ShaftDocument10 pagesSW FEA Tutorial ShaftJoséMiguelSánchezGNo ratings yet

- SKF Rolling Bearings InformationDocument117 pagesSKF Rolling Bearings InformationchoongzjNo ratings yet

- Aluminium Bluebook-L Earle JorgensenDocument26 pagesAluminium Bluebook-L Earle Jorgensenjohnjohn52No ratings yet

- 4c-Design of Fasteners PDFDocument41 pages4c-Design of Fasteners PDFVedanth NarayanNo ratings yet

- A Meanline Model For Impeller Flow RecirculationDocument8 pagesA Meanline Model For Impeller Flow RecirculationJun GWan Park100% (1)

- Calculation HDLDocument14 pagesCalculation HDLAlberto NocheNo ratings yet

- Press Brake Metric Tonnage Chart For Air BendingDocument1 pagePress Brake Metric Tonnage Chart For Air BendingkokyawzawNo ratings yet

- Modified 2 1-4CrDocument45 pagesModified 2 1-4CrandreahankNo ratings yet

- Bore and Keyway TolerancesDocument8 pagesBore and Keyway TolerancesIgor San Martín PeñalozaNo ratings yet

- Name: Aarsh Trivedi Roll No: 16BME176D Sub: MD 2 Case Study Topic: Worm GearDocument40 pagesName: Aarsh Trivedi Roll No: 16BME176D Sub: MD 2 Case Study Topic: Worm GearVirajNo ratings yet

- Gear1 - 02Document74 pagesGear1 - 02adnantopalovicNo ratings yet

- Investigations of Butterfly Control Valve Flow CharacteristicsDocument16 pagesInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Filete ASMEDocument28 pagesFilete ASMEMarcel MaresNo ratings yet

- 17-1cs-Normal Tightening and Loosening of Flange BoltsDocument3 pages17-1cs-Normal Tightening and Loosening of Flange Boltsyulianus_sr100% (1)

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- How To Calculate TorqueDocument6 pagesHow To Calculate TorqueAiza Caboles100% (1)

- Shafts and BearingsDocument43 pagesShafts and BearingsMario AndrewNo ratings yet

- Bearing Steel 52100Document10 pagesBearing Steel 52100Dan PascuNo ratings yet

- Shaft KeywayDocument8 pagesShaft KeywayturboconchNo ratings yet

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24No ratings yet

- Butter Valve Thickness PDFDocument10 pagesButter Valve Thickness PDFAnand KumarNo ratings yet

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesDocument14 pagesCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasNo ratings yet

- ISO Standardisation of Bevel Gears: Overview and Ideas On Method A"Document28 pagesISO Standardisation of Bevel Gears: Overview and Ideas On Method A"vincemugnaioNo ratings yet

- Conveyor CatalogDocument60 pagesConveyor Catalogtushar7000No ratings yet

- Motor Torque CalculationDocument5 pagesMotor Torque CalculationSanjula Darshana WickramasingheNo ratings yet

- SINOPEC Research Institute of Petroleum Engineering, China University of PetroleumDocument9 pagesSINOPEC Research Institute of Petroleum Engineering, China University of Petroleum2591995No ratings yet

- Manufacturing Process - Module2.0Document33 pagesManufacturing Process - Module2.0Fiza KamaNo ratings yet

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocument4 pagesSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutNo ratings yet

- Milling Speeds and Feeds PDFDocument1 pageMilling Speeds and Feeds PDFrobNo ratings yet

- An Engineers CasebookDocument87 pagesAn Engineers CasebookParesh AdhwaryuNo ratings yet

- Megyesy Pressure Vessel Handbook 2008Document2 pagesMegyesy Pressure Vessel Handbook 2008Ale Farfan0% (1)

- Design Against Fluctuating Loads of Helical SpringsDocument29 pagesDesign Against Fluctuating Loads of Helical SpringsVikranth Deepak100% (1)

- BFC 20903 (Mechanics of Materials) Chapter 6: TorsionDocument26 pagesBFC 20903 (Mechanics of Materials) Chapter 6: TorsionHamierul MohamadNo ratings yet

- Power Screws: Looking at A Square Thread Screw, We Unwind One Turn: WDocument4 pagesPower Screws: Looking at A Square Thread Screw, We Unwind One Turn: WMohammed AlnasharNo ratings yet

- Machine Design MD by S K Mondal T&QDocument263 pagesMachine Design MD by S K Mondal T&QSatish Kumar100% (2)

- 5 - Threaded Fasteners PDFDocument41 pages5 - Threaded Fasteners PDFViven Sharma100% (1)

- DMS Cource ProjectDocument18 pagesDMS Cource ProjectBabu100% (1)

- Machine Design MD by S K Mondal T&Q PDFDocument263 pagesMachine Design MD by S K Mondal T&Q PDFAbhijeet SahuNo ratings yet

- Design of Clutch: Nilesh PancholiDocument28 pagesDesign of Clutch: Nilesh Pancholijaved samaaNo ratings yet

- Wire Springs, - Flat Springs, or - Special ShapedDocument25 pagesWire Springs, - Flat Springs, or - Special Shapedbiruk tolossaNo ratings yet

- Machine Design 2013Document44 pagesMachine Design 2013cooLkiD1412No ratings yet

- BFC 20903 (Mechanics of Materials) Chapter 8: Torsion: Shahrul Niza Mokhatar Shahruln@uthm - Edu.myDocument24 pagesBFC 20903 (Mechanics of Materials) Chapter 8: Torsion: Shahrul Niza Mokhatar Shahruln@uthm - Edu.myanies naziraNo ratings yet

- Week 11 - TorsionDocument44 pagesWeek 11 - TorsionRichie BobbyNo ratings yet

- Bearings ShaftsDocument74 pagesBearings ShaftsCik MinnNo ratings yet

- Chapter 3Document35 pagesChapter 3Andrew SebastianNo ratings yet

- Power Screw Sir GDocument34 pagesPower Screw Sir GGodwill EscabelNo ratings yet

- Torsion of Circular Shaft SeminarDocument38 pagesTorsion of Circular Shaft SeminarPradip PatelNo ratings yet

- Brakes: Presented By: Cerda, JoshuaDocument22 pagesBrakes: Presented By: Cerda, JoshuaJoshua100% (2)

- Scan me! Hardware & Accessories CatalogDocument9 pagesScan me! Hardware & Accessories Catalogshe02No ratings yet

- M16X2.0 CARRIAGE BOLT SPECIFICATIONSDocument1 pageM16X2.0 CARRIAGE BOLT SPECIFICATIONSqualityNo ratings yet

- BSP (British Standard Pipe)Document5 pagesBSP (British Standard Pipe)bintolalNo ratings yet

- Liebherr 9250 Bucket Cylinder Protection System Parts ListDocument3 pagesLiebherr 9250 Bucket Cylinder Protection System Parts ListISRAEL GONZALESNo ratings yet

- HPV105-02 - 2640002621 - ControlDocument4 pagesHPV105-02 - 2640002621 - ControlSarah DelloNo ratings yet

- Workstation Assembly Instructions PDFDocument1 pageWorkstation Assembly Instructions PDFChris EfstathiouNo ratings yet

- General Specification For Acme ThreadsDocument1 pageGeneral Specification For Acme ThreadsAgus MulyadiNo ratings yet

- TC AcmeThreadformsDocument3 pagesTC AcmeThreadformsdbaldricaNo ratings yet

- Bolt Tightening Torques PDFDocument3 pagesBolt Tightening Torques PDFSH1961100% (2)

- Types of Screws and Bolts: Fasteners With A Tapered Shank (Self-Threading Screws)Document8 pagesTypes of Screws and Bolts: Fasteners With A Tapered Shank (Self-Threading Screws)Saiful AmreeNo ratings yet

- Dexterity Basic Skills Training EvaluationDocument1 pageDexterity Basic Skills Training EvaluationBalachandar SathananthanNo ratings yet

- Measure Effective Diameter Using Two-Wire Three-Wire MethodsDocument8 pagesMeasure Effective Diameter Using Two-Wire Three-Wire MethodsSimranjeet SinghNo ratings yet

- Hex Head Bolts - UNC - BS 1768Document7 pagesHex Head Bolts - UNC - BS 1768ssureshkar7699No ratings yet

- Is 1364 Part 2 or ISO 4017Document19 pagesIs 1364 Part 2 or ISO 4017santhosh kumarNo ratings yet

- 6 Nos Ø17 Holes On 185 PCD Equispaced.: Bore CapacityDocument1 page6 Nos Ø17 Holes On 185 PCD Equispaced.: Bore CapacityShyam J VyasNo ratings yet

- RATV - Socket Head Fasteners - MetricDocument1 pageRATV - Socket Head Fasteners - MetricGustavo CarvalhoNo ratings yet

- Backstay connection design and analysisDocument4 pagesBackstay connection design and analysisRené Mella CidNo ratings yet

- Ms33537 Rev EDocument11 pagesMs33537 Rev Eskiboarder213No ratings yet

- 36-6020 20series 20table 20saw 20parts 20list 20 20rev 204Document5 pages36-6020 20series 20table 20saw 20parts 20list 20 20rev 204Jose Daniel RosarioNo ratings yet

- Dial Indicators: SERIES 3 - Large Dial Face and Long StrokeDocument2 pagesDial Indicators: SERIES 3 - Large Dial Face and Long StrokeAkmalNo ratings yet

- Self Locking Ring ElementsDocument44 pagesSelf Locking Ring ElementsRolffoTelloNo ratings yet

- Ring NutDocument2 pagesRing NutnvkjayanthNo ratings yet

- UK Bolt SizesDocument26 pagesUK Bolt SizesVincent ChuNo ratings yet

- YG100R - YG88R - MPL - Komplet Maitenance Manual-1Document66 pagesYG100R - YG88R - MPL - Komplet Maitenance Manual-1loyasiy249No ratings yet

- Asme B18.2.3.4M 1999Document14 pagesAsme B18.2.3.4M 1999Jesse ChenNo ratings yet

- Chapter 4 Screw ThreadsDocument38 pagesChapter 4 Screw ThreadsDishank UpadhyayNo ratings yet

- Hydrogen-Oxygen Fuel CellDocument5 pagesHydrogen-Oxygen Fuel CellmannarNo ratings yet

- Catalogue VisserieDocument145 pagesCatalogue VisserieMallouli YassineNo ratings yet

- Din 929 Decembre 2013Document10 pagesDin 929 Decembre 2013Franck SavignardNo ratings yet