Professional Documents

Culture Documents

Curs

Uploaded by

Bobaru MariusOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Curs

Uploaded by

Bobaru MariusCopyright:

Available Formats

1

In order to increase the productivity of work in the construction field, one way

of improving the performances of the construction works is to produce the

objects from precast elements.

It is necessary to closely and discerningly study as many variants as possible,

taking into account the fact that producing construction objects from precast

elements has an important disadvantage that is the necessity of an adequate

solution for the joining elements in order to establish the monolithism of the

structure.

It is therefore necessary to adopt the right structures, starting from the

conception stage, structures which would fulfil the conditions of a rational

mounting with a reduced resources cost.

2

There can be lined out the difficulties in mounting a ground floor hall with

the main beams disposed transversely and bays of six meters wideness.

It is also necessary to adopt joining details which are possible to be done and

will not require high precision classes, (impovarator) burden-some costs or

difficult make ups, which sometimes may be impossible to solve.

There are not to be ignored the special characteristics of the concrete; each

type of material has its own properties, its own way of behaving, so that

choosing to use methods from the metallic joining may turn up to be an

aberration.

3

The realization of ground floor halls with tall, precast columns begins to

expand due to the facilities offered by the relization of the elements in a

horizontal position.

The methods of realizing the joining elements have to be known, especially the

deviations (abatere) allowed in the processes of precasting and mounting, the

shape of the joints, the possibilities of monolithization, etc.

The complex process of transport, storage, handling and

mounting of the precast units

The real location of the construction site regarding the resources, will

condition the possibility of realising different flows which, at the present, can

be summarised as follows:

in case that the main resources, respectively the precast elements, are

situated at a great distance from the site, usually more than 30 km, it is only

rational to transport them using the railway.

4

This variant implies the existence of a storing place on the construction site,

situated near the railway, where the precast elements can be stocked until they

will be assembled.

This storing place has to be well conceived from the beginning, to be organised

and equipped with all the necessary installations; the precast elements have to

be organised in a certain order so as not to be difficult to find them when

necessary or to need further interior transportations.

in case that the precast elements are realised at relatively short distances

from the construction site, usually in production plants situated near the

urban areas, it is reasonable to use the motorway for transport.

5

This flow can have several variants, one of them being the existence of a

storage place on site situated in the operating range of the lifting device,

usually the tower crane when building the multi storey block of flats.

It is therefore reasonable to have storage place large enough to stock the

precast elements necessary to keep the mounting process running.

Although from a pessimistic point of view this variant seems kind of rigid and

difficult to realise, we still have to remember it and adopt it.

It is true that this will take more effort to organise and correlate all the

resources; not lastly it will also take an intellectual effort.

This is the variant that will lead to an increase of productivity and a reduction

of the costs.

in case of heavy or very large elements, or small series, it is reasonable to

perform the precasting process on the construction site. We need to specify

that by precasting we mean arranging some places where the elements are

produced in the neighbourhood of the assembling devices.

6

These locations where the elements are produced need to be disposed such as

to allow a direct mounting, with no supplementary handling; it is also

necessary to create spaces to allow the means of transportation to pass.

Whenever the conditions described above can not be fulfilled it is preferable to

perform the precasting process on special construction polygons.

7

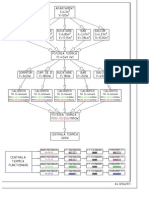

START

1

MANIPULARE

INCAC. MIJL.

TRANSPORT

Asezare in

mijloace de

transport

Manipulare

pentru

descarcare

Storehouse

placing

Manipulare

pentru

incarcare

A

Asezare in

mijl. transp.

auto

Railway

transportat

ion

Internal

transportation

auto

transp.

Manipulare

pentru

descarcare

Storehouse

placing

Preturnare

Set out

Joining

make-up

Manip.pt.mont

Fix.prov.

Elib.dinmacar

Position

rectification

reinforc

ing

formwo

rking

Concre

te

placing

Formwor

k

removal

Start

2n

B

C

A

1

2

Auxiliary fluxes - other resources

SUPPLIER

SITE

TRANSPORTA

TION

SITE

STOREHOU

SE

TRANSPORT

WORKING PLACE ACTIVITIES

HANDLING MOUNTING

REALIZARE

IMBINARI

8

The features of the precast elements

From the mounting process point of view we are interested in certain

characteristics of the precast elements, such as the geometrical sizes and their

framing into acceptable limits, the stress they suffer when being handled

adopting the adequate holding and handling systems, the weight of the

elements, the characteristics of the joining details, the support surfaces, the

incorporated metallic plates, the exterior reinforcements, etc.

The concordance quality

The construction elements, their mounting and assembling into parts of

construction and then into a whole construction, are almost impossible to be

performed respecting their original design from the project. The making up

process tries to respect the original conception, but inaccuracies are inherent,

certain deviations from the original concept will appear during the execution

stage.

These deviations usually regard the designed geometrical characteristics of the

elements, such as dimensional deviations, geometrical ones, the reciprocal

orientation of the profiles and surfaces.

9

The accuracy class of the metallic formwork

An important element for the characteristics of the precast elements is

represented by the exact shape of the pouring form. In the precast plants there

are generally used some metallic forms made in different sizes.

The technical specifications mention the accuracy classes, according to the

method of realising the form, table 1. These accuracy classes are imposed by

the processes taking place in the metallic confections and mechanical

processing fields.

Due to the processes that take place during the fluxes, the dimensional

variations of the metallic components, the temperature, the contraction of the

concrete, etc, the precast elements result to be classified into an inferior

accuracy class than that stipulated by the metallic form.

The designer is the one to establish the accuracy classes, according to the

special conditions of fitting, support, joining, the complexity of the mounting

method, taking into account the main dimensions of the precast element,

parameters which condition the mounting possibilities.

Table 1 Accuracy classes

No. Formwork feature

Dimensional Tolerances (T)

Basic Dimension (mm)

900

901

3000

3000

9000

>

9000

1

Fix forms, metal cutting &

pouring

PC5 PC5 PC5 PC6

2

Forms with mobile elements,

metal cutting & pouring

PC5 PC5 PC6 PC6

3

Fix forms, welded metallic

profiles, plates & strips, metal cutting

PC6 PC6 PC6 PC7

4

Forms with mobile elements,

welded metallic profiles, plates &

strips, metal cutting

PC6 PC6 PC7 PC7

5

Fix forms, welded metallic

profiles, plates & strips, without metal

cutting

PC6 PC6 PC7 PC7

6

Forms with mobile elements,

welded metallic profiles, plates &

strips, without metal cutting

PC7 PC7 PC7 PC7

7

Metallic profiles, plates & strips

assembled by clinch

PC7 PC8 PC8 PC8

11

Precast elements attaching systems for handling and mounting

devices

These devices are hung or settled to the precast units or they are attached

using other procedures in accordance with the precast elements features and

the specific of transportation, storage and mounting.

In order to realize the transportation and the mounting there are needed some

handling devices with specific parameters corresponding to the precast

elements features.

The mounting systems have to be conceived so as to function perfectly, to be

safe during all phases, to require a minimum material consumption which

could be retrieved.

After use there should be no complicated dismantle procedures.

One of the simplest mounting systems is made of steel, it is loop shaped and it

has the extremities incorporated in the element during the forming phase; it is

currently in use although it doesnt have the best performances.

12

Mounting system with hanging shackle

This system called hanging shackle (ureche de agare) has several

disadvantages as shown in the figure.

Thus, in the case there is used a handling device with inclined cables and the

shackles are located in the longitudinal plane of the element, figure 5.1 a,

during the moments of hanging and loading the arms of the system place

themselves following the direction of the cable; the interior arm tends to get

curved without being loaded.

In this situation the entire load is on the arm from exterior which can collapse.

13

It is therefore necessary that, when using devices with inclined cables the

shackles should be disposed in a perpendicular plane on the device plane; in

this case the arms will bent equally.

It is also necessary to use the same type of device during all the phases -

transportation, storage, and mounting in order to maintain the same angle

between the cables, which will lead to repeated bending of the shackles arms

and their possible breaking.

Other disadvantages of this system are: a quite large consumption of steel; the

usage of high supports at storage in order to create spaces between the

elements bigger than the height of the shackles; the need to cut or bend the

shackles after the mounting process is completed.

Next we are going to present the devices fulfilling the same functions, but

having clear advantages. Thus the mounting system is made of two elements.

14

One of the elements formed of a pipe screwed at the interior or of a wire

made coil, has welded around it steel curls and it is incorporated in the

concrete. The other element is made of a bolt having a screwed hole on its

superior part. After it is stored or placed at the mounting place the bolt is

retrieved.

Mounting system with bolt screwed in the element

The following figure presents how the mounting

system made of a cable is introduced into a hole in

the precast element through a plastic tube.

Mounting system made of a cable introduced into the

holes of the element

The mounting system presented in figure implies

realising some holes into the element when it is

produced, holes which will allow, during the

handling stage, to introduce pipes screwed at their

ends in order to hang the handling devices.

Mounting system made of a bolt introduced into the

element through a hole

15

16

Holding systems by laying are presented in figure. Thus, the system presented

includes a yoke with its sizes corresponding to the section of the element; this

yoke has on its inferior part several holes.

The usage of the device requires placing it on the superior

part of the precast element and introducing several pipes

into the holes from the inferior part.

In order to safeguard the operation it is necessary to put

some keys between the yoke and the element.

Mounting systems by laying

The system on the left side of the figure is fork shaped

and is frequently used when handling the precast strips.

17

Handling and mounting devices

The handling devices have to be conceived so as to satisfy certain requirements

such as: a good functionality, a reduced consumption of labour, a certain

degree of universality in order to use them on a wide range of elements.

The precast elements have to be held by lifting devices in order to allow

handling procedures during the last manufacture stages, to allow loading and

unloading in the intermediate storages and also to allow mounting.

They also should not determine higher loads on the elements handled than

those appearing during exploitation, while other types of loads should be as

small as possible.

The handling devices should not be very high, nor heavy in order to use the

working parameters of the lifting devices as rational as possible, to be perfectly

safe during exploitation.

Furthermore they should be properly conceived and dimensioned so as to

avoid their breaking or some of their elements falling apart provoking work

accidents.

18

The figure presents the angles that could be produced by the cables with the

horizontal, the loads they suffer and also the element which is handled.

The most simple and frequently used devices with two holding points are made

of inclined cables.

The loads that appear due to cables

tilting

Devices for linear elements with two holding points

Thus, decomposing the action of the gravitational loadG/2, in the holding

point, following the direction of the cable (N) and the axes of the element (H)

the result will be:

19

For different inclinations of the cables, respectively values of the angle a, it

results the dimension of the loads N and H.

Therefore, for = 10

it results the value of load from the cable three times

higher than the weight of the element, also similar values for the compression

strength H.

For = 30

the load from the cable drops down to the value of the elements

weight, for = 45

it is 0.7 G; it reaches 0.5 G in the case of the value = 90

.

It is important to remember that for small angles ( = 10

) the load N in the

cables is six time higher than in the case of their vertical placement.

The load H which compresses the element offers concordant values as well.

The angle is limited to a maximum 45

in order not to introduce unfavourable

loads into the element and there wouldnt be needed thick cables.

tan

2

G

H ; sin

2

G

N = =

20

It is not allowed the free passage of a cable over the hook of the lifting device

since this can slide and lead to shocks, respectively to cable breakings and

accidents during exploitation.

At their inferior part the cables are provided with hooks. The hook is a piece

made by forging, having a specific form.

During forging the fibres are disposed following the direction of the hooks

shape so as there would be no deformation before cracking while under loads.

Each hook is marked with nominal load from manufacture.

The devices from this group have cables held

at their superior part with a closed or opened

ring.

In order to reduce the inclination of the cables, respectively the loads existing

within these and the element, there can be conceived systems with short

sleepers, which have the advantage of reduced weights and relatively short

heights .

The systems with cables positioned vertically, case in which there are

minimum loads, need to be provided with long sleepers, accordingly

dimensioned.

The result will be relatively heavy devices having reduced heights.

21

Device with long sleeper

The following figure presents a more functional device with a higher degree of

universality.

22

The holding points are realised so as to be functional in any position on

horizontal through some carriages moving on the sleeper.

Device which automatically places the cables

vertically

The movement of

proximity or that of

remoteness is

synchronized through a

continuous cable passed

over two pulleys placed in

a horizontal plane at the

ends of the sleeper. One

carriage is held by a cable

on one of the sleepers

side, the other one on the

other side.

When the element is held in any position, the cables are coming automatically

on vertical under the action of the horizontal components moving the

carriages. The movement is realised during the beginning of the lifting phase,

while the device starts to load itself and there are only reduced forces to induce

important horizontal loads in the element.

23

In case of the particular system of forces, respectively the action produced by

the gravitational load, a linear element needs two simple connections only.

In order to produce devices with more than two connections it is necessary

that each supplementary connection should be compensated with a proper

system such as a cantilever with equal arms or a fixed pulley.

Devices for linear elements with more than two attaching points

The following figure presents a device with three holding points used when

handling large panels.

24

The panel with the same configuration as that in

the figure can not be handled by catching in two

points because there would be some loads that can

damage it; therefore there are needed three

catching points properly placed.

The device realises the compensation for the extra connection, respectively it

creates equal loads in the catching points through an equal armed lever.

Device with three attaching points used when

handling large panels

When handling the truss there are conceived proper devices with two pulleys

in order to realise loads similar to those from the exploitation phase,

respectively compression at the superior end and stretching at the inferior one.

25

The truss can be held in four points while the compensation of the two

connections is realised by a continuous passing of two cables over the pulleys.

Device used for handling the trusses

Long linear elements with reduced transversal section need a large number of

holding points.

26

The compensation of the extra connections, meaning realising equal loads in

the holding points, is realised with the device presented in figure.

Device used for handling linear

elements with n attaching points

This device is made up of a sleeper

on the extremities of which it is held

a continuous cable passed over a

system of fixed and mobile pulleys.

Since in the continuous cable the

stress is the same, the load in the

holding points is represented by the

relation: N = G/n.

27

In order to conceive rational devices both from the point of view of the static

equilibrium as well as from that of the compatibility with the features of the

elements being handled it is necessary to analyse these aspects and to realise a

correlation between them. It is presented a floor element held in a three

connections device.

Device incompatible with the features of the

elements

Handling devices for the surface elements

Although the device is correctly conceived from

the point of view of static equilibrium under the

action of the gravitational load it is not compatible

with the features of the element.

During exploitation the element is being supported

on four sides and it is therefore accordingly

dimensioned. In the situation presented in the

figure on one of the sides there has been introduced

a support in the middle realising some cantilevers

which are not reinforced properly; these will lead

to cracks and will destroy the element.

It is thus compulsory the compatibility between the device and the features of

the element. Presently, on sites, there is frequently used a device with four

holding points, with no compensation.

28

Device with four holding points and no

compensation

As it can be seen in the figure, the lack of

compensation of the extra connections

leads to the deformation and cracking of

the element until the longest cable start

working.

Although the crack closes after the element

is placed on the supports it still allows the

access of noxious, corrosive agents,

especially during the mounting of the floor

panels in the area of the toilets at the

apartment buildings.

Dispozitivul de manipulare prezentat n figura urmtoare este corect conceput

deoarece asigur echilibrul sub aciunea sarcinii gravitaionale, legtura n

plus fiind compensat printr-un scripete fix, ct i din punct de vedere al

compatibilitii cu caracteristicile elementului care reazem pe patru laturi.

29

Device with four cables provided with pulley

to compensate the extra connections

In the case of some surface elements having one of the sides longer it is

necessary to place six holding points in order to realise the compatibility with

the exploitation situation.

30

Device with six cables and three

compensation pulleys

The starting point is the ring hanged in the

cranes hook with three connections, while

the six cable strands are compensated by

three fixed pulleys.

31

In order to manipulate

relatively tall colums but with

reduced transversal sections it is

presented a device that has six

attaching.

Device for handling columns

The column has three holes

where there are introduced rods

so as to realise six holding

points. Although the column is a

linear element it behaves as a

surface one because of the

particular way of attachment to

the device.

To perform the handling process on horizontal, the shipping and unshipping

processes, as well as that of the superimposed precasting, the column is held in

all the six connections.

Two of the connections are compensated by two pulleys attached on one lever,

while the third one, at the base of the pillar is compensated by an equal

armed cantilever.

In order to place the column vertically the connections from the bottom are

untied, the column turns around it while the pulleys from the sleeper realise

the compensation of the lengths. In this phase the column supports itself on

five points two of which are compensated by the pulleys of the sleeper.

32

After reaching the vertical position the pillar is lifted from the ground while it

is supported on four points compensated by the pulleys of the sleeper.

The following figures present a handling device used for shipping, unshipping

and mounting. It is also used for transporting the floors vertically.

33

Device for handling the floors during

transportation in horizontal position

Device for handling the floors during

transportation in vertical position

The conditions imposed by the norms are:

it is strictly forbidden to improvise handling devices on the construction site;

in case of devices with extra non-compensated connections some of the cables

do not work, the other cables overheat so that the safety during exploitation is

compromised;

the devices have to be certified by ISCIR and manufactured in specialised

laboratories only;

when the working period has started the devices are checked on a daily basis,

and they are periodically loaded with loads higher than the nominal one,

according to the indications from the norms.

When performing the handling manoeuvres during the mounting phase one of

the pulleys from the superior part is blocked by a bolt. Pulling out the bolt will

turn the system into a mechanism and will allow tipping.

34

35

Transportation and storage of the precast elements

In accordance with the features of the precast elements their transportation

and storage need specific procedures methods and means.

No matter the variant of transportation and storage chosen, there need to be

observed some specific rules in order to prevent the damage of the elements

and to avoid work accidents. These rules are:

the position of the holding points in the handling device and that of the

support areas during storage should be chosen so as not to change the support

diagram from exploitation or, if there are any other schemes adopted, there

should be no need for further reinforcements. To check the bearing capacity as

a consequence of the handling, transportation and mounting shocks, the

gravitational load is amplified with a dynamic coefficient of 1.5, according to

the norms;

during all the transportation, handling and mounting stages the holding

devices and the supports should be conceived so as the precast elements will

not loose stability;

it is necessary for the support systems of the transport means to guarantee

stability for the elements when starting, sudden braking or sharp turnings;

according to the features of the precast elements the supports will be

manufactured so as not to damage the edges or the finished surfaces;

36

when the precast elements are stacked, it is necessary that the supports of

each precast element should be placed on the same vertical so as not to damage

the elements located at the base.

The supports between the precast elements should have a proper height so as

not to damage the holding system. When handling the elements with fork

devices the heights of the supports should be correlated with the features of the

device.

In order to cope with the supplementary loads appearing during handling and

transportation, the slender elements should be strengthen with pre

compressed coupling bars disposed following a rational course.

There are conceived fixed racks to place the elements in warehouses which

have some degree of permanency.

37

Fixed racks

Inclined elements

The elements are inclined and

support each other; there will be

needed supplementary manoeuvres

to choose a panel from the central

area

38

Organizing the working place for the precast elements mounting

In order to realise rational mountings, with a maximum use of the resources,

respecting high quality and security conditions, requires the analysis of the

functional parameters of the equipments used and the real characteristics of

the field situations.

It is mainly necessary the correlation of the functional parameters of the lifting

and transport equipments with the characteristics of the mounting places.

To study the work places it is necessary to observe the following stages:

establishing the position in plane of the mounting and transport devices, the

shifting direction; the devices can make transversal and longitudinal circuits

within the object;

establishing the position in plane of the precast element for different

mounting stages;

correlating the gauges, in transversal and longitudinal sections, of the

transport and mounting devices, with the sizes of the mounting places in order

to make the process possible and secure.

39

The study of the work places is necessary for every element part of the

construction object.

A careful performed study of every possible variant will allow choosing the

best solution in realising a quality mounting with minimum costs.

Organizing the working places for the columns mounting

40

It is presented a transversal section of the working place to help determine the

position of tracks axis for the mounting and transport devices.

Transversal section through the

working place

Marking down the positions of the tracks axis towards the objects axis with

d

1

and d

2

, these have to fulfil the following conditions:

1

2 2

F B

d b > + +

where b represents a safety space of 0.5 1 m.

The distances between the tracks axes respectively the distance d

2

, have to

fulfil several conditions, observing the notations in the figure:

to allow the circulation of the two vehicles, respectively:

41

to allow the circulation of the transport means in the phase when the

mounting device is in the station, respectively:

the back of the lifting device, its balance weight, should not hit, during

mounting, the transport device standing for unshipping, respectively:

2

2 2

B E

d a > + + where a is a safety space of 0.5 1 m.

2

E

a

2

C

d

2

+ + >

2

E

a A d

2

+ + >

42

The position in plane of the mounting device is determined by the number of

columns which are mounted at the same station.

This is dictated by the columns features, the gauges, the weight and the

dimensions between the transversal and longitudinal axes of the object.

For the large sized columns, longer than 12

m, and for the bays of 12 m or longer, it is

rational to mount one pillar from one station.

The position of the station, respectively the

radius of the crane, is established in

accordance with the dimensions d

1

and d

2

.

The value of d

2

is generally higher, so it is

necessary for the radius to fulfil the following

condition:

2

d R >

The position of the station

43

From the geometrical elements of the figure, with the radius being established,

we can determine the position of the station.

The position in plane of the transport mean is established so that the centroid

of the element will be on the vertical part of the hook from the mounting

device.

When lifting the element from the mounting device and placing it on the

ground, it is necessary that the centroid find itself on the circle described by

the projection of the hook, in order to realise the tipping operation; the bottom

of the pillar should be on the circle as well, so that it can rotate without

creeping.

It is recommended for the bottom of the pillar to be placed nearby the

foundation in order to reduce the manoeuvre time needed during the

mounting process.

In the case of the small sized bays, of 6 m, it is recommended to mount two

columns in the same station. The sizes of the working place are given by the

values d

1

and d

2

, while the radius is established from the geographical

elements of the figure:

44

2

t

1

2

L

d R

|

.

|

\

|

+ >

respecting also the condition:

2

d R >

The mounting process of two

columns from one station,

longitudinal circuits

45

The following figure presents the organization of the working place for the

mounting of one column from one station, in the variant of the transversal

circulation of the mounting and transport devices.

The mounting process of one column from one station,

transversal circuits

46

In case of the 6 m bays, organizing the working place following transversal

circuits it is not recommended since the circulation of the transport device is

performed in the next bay and the result will be a radius of the mounting

device larger than 6 m and its parameters will be used improperly.

In case of bays smaller than 6 m, the transversal circulation is generally not

possible.

The mounting process of two columns from one station,

transversal circuits

47

The following figure presents a transversal section through the work place to

help determine the necessary parameters for the mounting device.

The height at the hook is

determined by the relation, with the

notations from the figure:

h

h

= h

c

+ h

d

+h

s

Where: h

d

represents the height of

the handling and manoeuvre device

and h

s

represents the safety space

with the value 0.5m.

The necessary parameters for the

mounting device

Organizing the working place for the mounting process of the

beams

The organization of working place for beams mounting process mainly

respects the same conditions imposed for the mounting of the columns,

respectively the determination of the distances d

1

and d

2

.

Mounting the crane beam and the main

longitudinal beam from the same station

The following figure presents, in plane and

transversal section, the working place for

mounting the main beams and the crane

beams from the same station, devices that

circulate longitudinally.

48

Mounting the main beams

It is presented, in plane and

transversal section, the organization

of the working place for the

mounting process of the main beams

for the halls where these are

disposed transversally.

The circulation of the mounting and

transport devices is performed

following longitudinal circuits.

49

Organizing the work places for mounting the roof elements

When mounting the roof elements the organisation of the work place is done

by determining the distances d

1

and d

2

.

A special attention has to be given to the study of the work places in

transversal and longitudinal sections.

The work places, when contracting during the mounting process of the inferior

elements, have to adopt stations for the mounting device so as to create

manoeuvre gauges for the arm, and also to adopt equipments which allow

mounting the roof elements, mainly developed on the surface, in safety

conditions.

The following figure presents the organization of the work place for mounting

the roof elements in the case of a hall having the bay equal or longer than 12

m, with transversal circulation of the devices.

50

Mounting the roof elements, transversal circuits

51

The technological flux for mounting a totally prefabricated ground floor

industrial hall

From the technological mounting point of view we distinguish two types of

halls:

Ground floor industrial halls having the main girders longitudinally disposed:

For mounting the columns it was adopted a successive disposal, the crane

covers a circuit on the presented working sector.

The main girders

longitudinally disposed

52

By studding the working fronts resulted an advantageous mounting of two

columns from a single stationary cranes position.

There were adopted longitudinal circuits that lead to minimum mounting

ranges.

The columns mounting, 6 meters bay

From the second longitudinal circuit the crane and main girders are mounted

by using the same stationary position of the crane.

53

The crane and main girders

mounting, 6 meters bay

The roof elements are mounted by using a third longitudinal circuit.

By taking into consideration the span dimensions, the lifting device covers the

second circuit or changes the position with the transportation device.

The mounting and the transportation devices covers the same circuits for all

the mounted elements.

The mounting devices use the minimum ranges by taking into consideration

the working fronts characteristics.

54

In the case when for each circuit is adopted a mounting device, this will work

to optimum functional parameters.

The roof elements mounting, 6 meters bay

55

If the ground floor industrial hall has a twelve meters bay, by studding the

working fronts characteristics it becomes advantageous to mount a single

column from a stationary position of the crane. The next mounting phases

remain the same.

The columns mounting, 12 meters bay

56

The crane and main girders mounting,

12 meters bay

The roof elements mounting, 12 meters

bay

57

Ground floor industrial halls having the main girders transversally disposed:

In the following pictures there are presented different organization options for

mounting columns to industrial halls having 6 meters bays.

The main girders transversally disposed

58

By studying the working fronts it results favourable the mounting of two

columns from a single stationary cranes position. If it is emphasised the routes

it is observed that due to lack of space, the transportation vehicle in a

transversal circuit has to run in the next bay.

For this the crane in order to do the job has to have a greater working range.

By taking into consideration this aspect is better to work with longitudinal

circuits, because the working radius will be smaller, hence the lifting device

will lighter.

The columns mounting,

transversal circuits, 6

meters bay

59

In order to mount the main girders, when realising the circuits, is necessary to

adopt the working front by taking into consideration the real dimensions of

the mounted elements.

It is observed that transversal circuits are possible only if the spans have

eighteen meters or more. For industrial halls with span smaller than eighteen

meters is necessary that the circuits to be longitudinal, otherwise the crane will

hit the columns.

The main girders mounting, transversal circuits, 6

meters bay

60

When mounting the roof elements, for halls with six meters bay, because the

working front is shortened by mounting the previous elements, is necessary to

study the working in vertical section. It results the fact that is impossible to

mount the roof elements by using transversal circuits situated in the bays axle,

by lifting the element from the next bay. It is necessary that the transversal

circuits to be placed at a certain distance with regard to the bays axle. This

distance is correlated between the dimension of the working front in

transversal section and the cranes parameters.

The roof elements mounting, transversal circuits, 6

meters bay

61

It follows the mounting of precast elements for twelve meters bay.

The columns mounting, transversal circuits, 12 meters bay

62

The main girders mounting,

transversal circuits, 12 meters

bay

The roof elements mounting,

transversal circuits, 12

meters bay

63

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- NCCI VibrationsDocument17 pagesNCCI VibrationsJoseph Booker100% (1)

- Room Integrity Testing, Room Integrity Test, Enclosure Integrity Testing, Blower Door Test PDFDocument6 pagesRoom Integrity Testing, Room Integrity Test, Enclosure Integrity Testing, Blower Door Test PDFJomyJose100% (1)

- Staad Pro ManualDocument51 pagesStaad Pro Manualsumit kamble100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Steel ConnectionsDocument69 pagesSteel Connectionsmaomontes75% (4)

- Design of Spill Through Abutment FoundationDocument42 pagesDesign of Spill Through Abutment Foundationinfra120No ratings yet

- PDFDocument244 pagesPDFRené Mella CidNo ratings yet

- Rubber Manufacturing Process ReportDocument17 pagesRubber Manufacturing Process ReportAriel GamboaNo ratings yet

- BCISM - Costbook 2020Document52 pagesBCISM - Costbook 2020Abdul Qadir100% (3)

- Absorption Refrigeration SystemsDocument33 pagesAbsorption Refrigeration SystemsAdedire FisayoNo ratings yet

- Metals and AlloysDocument49 pagesMetals and Alloysmasterdol1983No ratings yet

- Quotation Anshul Sangal For Mushroom FarmingDocument8 pagesQuotation Anshul Sangal For Mushroom Farminganshul sangalNo ratings yet

- Worked Examples Ec2 Def080723Document120 pagesWorked Examples Ec2 Def080723dan_ospir67% (3)

- Tutorial ETABSDocument60 pagesTutorial ETABSValentin VrabieNo ratings yet

- PT Concrete Storage StructuresDocument51 pagesPT Concrete Storage StructurescavnqnNo ratings yet

- Sizing and Performance of Safety Valve Relief Systems For Two-Phase FlowDocument56 pagesSizing and Performance of Safety Valve Relief Systems For Two-Phase FlowAGP100% (1)

- Economiser & DrumDocument75 pagesEconomiser & DrumGaurav ChauhanNo ratings yet

- Calcul TermicDocument23 pagesCalcul TermicVanzatorul de IluziiNo ratings yet

- Arch ElevationDocument1 pageArch ElevationBobaru MariusNo ratings yet

- Calcul CT+ CalorifereDocument1 pageCalcul CT+ CalorifereBobaru MariusNo ratings yet

- Sbe MS1Document75 pagesSbe MS1Bobaru Marius100% (1)

- Cyclic Behaviour of A Full Scale RC Structural WallDocument11 pagesCyclic Behaviour of A Full Scale RC Structural WallAzhar PLNo ratings yet

- SBE M2 SecureDocument83 pagesSBE M2 SecureemmanuelNo ratings yet

- Geotehnica SubiecteDocument9 pagesGeotehnica SubiecteBobaru MariusNo ratings yet

- Radia3 - KDFDocument56 pagesRadia3 - KDFBobaru MariusNo ratings yet

- NCCI: Tying Resistance of A Simple End Plate ConnectionDocument7 pagesNCCI: Tying Resistance of A Simple End Plate ConnectionBobaru MariusNo ratings yet

- NCCI: Tying Resistance of A Simple End Plate ConnectionDocument7 pagesNCCI: Tying Resistance of A Simple End Plate ConnectionBobaru MariusNo ratings yet

- SEO Cantilever Beam CalculationDocument13 pagesSEO Cantilever Beam CalculationBobaru MariusNo ratings yet

- Beton Subiecte ExamenDocument9 pagesBeton Subiecte ExamenBobaru MariusNo ratings yet

- NCCI: Initial Sizing of Non-Bearing Column Splices SN024a-EN-EUDocument7 pagesNCCI: Initial Sizing of Non-Bearing Column Splices SN024a-EN-EUBobaru MariusNo ratings yet

- Link LookupDocument9 pagesLink LookupBobaru MariusNo ratings yet

- Tying Resistance of A Fin Plate ConnectionDocument9 pagesTying Resistance of A Fin Plate ConnectionSam Samoura0% (1)

- Link LookupDocument23 pagesLink LookupBobaru MariusNo ratings yet

- Elastic Critical Moment For Lateral Torsional BucklingDocument14 pagesElastic Critical Moment For Lateral Torsional BucklingAndrey SemjonovNo ratings yet

- NCCI: Modelling of Portal Frames - Elastic AnalysisDocument5 pagesNCCI: Modelling of Portal Frames - Elastic AnalysisBobaru MariusNo ratings yet

- NCCI: Initial Design of Non Composite BeamsDocument17 pagesNCCI: Initial Design of Non Composite BeamsBobaru MariusNo ratings yet

- Link LookupDocument8 pagesLink LookupBobaru MariusNo ratings yet

- NCCI: Initial Design of Composite BeamsDocument9 pagesNCCI: Initial Design of Composite BeamsBobaru MariusNo ratings yet

- NCCI SN003 Elastic Critical Moment For LTB PDFDocument14 pagesNCCI SN003 Elastic Critical Moment For LTB PDFscegtsNo ratings yet

- Link LookupDocument7 pagesLink LookupBobaru MariusNo ratings yet

- Link LookupDocument7 pagesLink LookupBobaru MariusNo ratings yet

- OHRU EcoAir CompactDocument4 pagesOHRU EcoAir Compactlabelel100% (1)

- Glass Performance DataDocument4 pagesGlass Performance DataJOSEPH APPIAHNo ratings yet

- 201211A AQTTB Underground Thermal ExpansionDocument2 pages201211A AQTTB Underground Thermal ExpansionAndreas KalamarasNo ratings yet

- Manual Aire TDS-11 PDFDocument40 pagesManual Aire TDS-11 PDFpabloNo ratings yet

- Piping System DesignDocument139 pagesPiping System DesignNatty SarathunNo ratings yet

- Aq 211103 001Document1 pageAq 211103 001Qudsi NayazNo ratings yet

- RTHDDocument32 pagesRTHDizmaya72660No ratings yet

- Ladish CatalogDocument9 pagesLadish CatalogCamilo VarelaNo ratings yet

- Specifications: Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2018-09Document1 pageSpecifications: Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2018-09omerNo ratings yet

- Chilean Steel Design ManualDocument295 pagesChilean Steel Design ManualshakibbrNo ratings yet

- Course Code: MTPC13 Course Title: Metallurgical Thermodynamics Number of Credits 4 Prerequisites (Course Code) : Nil Course Type: PCDocument1 pageCourse Code: MTPC13 Course Title: Metallurgical Thermodynamics Number of Credits 4 Prerequisites (Course Code) : Nil Course Type: PCNags DevaNo ratings yet

- FERROELECTROMAGNETSDocument109 pagesFERROELECTROMAGNETSAamerNo ratings yet

- Thermal Conductivity of Refractory Brick PDFDocument7 pagesThermal Conductivity of Refractory Brick PDFFerNo ratings yet

- Chapala Brochure 2013Document16 pagesChapala Brochure 2013Marcus KriegNo ratings yet

- Concrete Tech 1 Sample Questions AnsDocument18 pagesConcrete Tech 1 Sample Questions AnsJohn luckyNo ratings yet

- Material Characteristics PDFDocument4 pagesMaterial Characteristics PDFELTIPAZONo ratings yet

- Jonas 2009Document15 pagesJonas 2009Deepika RajamNo ratings yet

- Experimental Studies of Thin-Ply Laminated Composites: Composites Science and TechnologyDocument13 pagesExperimental Studies of Thin-Ply Laminated Composites: Composites Science and TechnologyCarlo PignagnoliNo ratings yet

- Gundu Rao Sanc Plan - A2 SizeDocument1 pageGundu Rao Sanc Plan - A2 SizeBHARATH KUMARNo ratings yet

- Pump Cutaways and Drawings: Material CodesDocument11 pagesPump Cutaways and Drawings: Material CodesSAMANTHANo ratings yet