Professional Documents

Culture Documents

Pipe Rack

Uploaded by

Saurabh DixitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Rack

Uploaded by

Saurabh DixitCopyright:

Available Formats

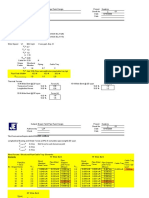

PIPE RACK

Pipe rack is the main artery of any plant. Pipe racks or pipe bridges are structures designed and built specifically to support multiple pipes where adequate structure is not available.

Pipe racks are necessary for arranging the process and service pipelines throughout the plant. A large number of process pipelines, flare lines and manifold lines running through this racks from one equipment to another, or from one unit to another.

A typical view of pipe rack

There are three types of pipe rack:1) Conventional pipe rack 2) Non Conventional pipe rack 3) Modular pipe rack

This is essentially a system where multiple 2-dimensional (2D) frame assemblies, comprised of two or more columns with transverse beams, are tied together in the longitudinal direction utilizing beam struts and vertical bracing to form a 3D space frame arrangement. Pipe racks supporting equipment such as air-cooled heat exchangers must utilize the continuous system approach.

A Conventional pipe rack

This is a system comprised of independent cantilevered, freestanding 2D frames not dependent on longitudinal beam struts for system stability. This system, where feasible, should result in lower total installed cost.

A Non Conventional pipe rack

Structural Frames completely fitted with pipes, Cable trays and miscellaneous equipment is a modular pipe rack. Now a module is a series of standard units that function together.

A modular pipe rack

You might also like

- Pipe RackDocument25 pagesPipe RackVernie SorianoNo ratings yet

- Pipe Rack Design PhilosophyDocument18 pagesPipe Rack Design PhilosophyselvakumarNo ratings yet

- Pipe Rack PresentationDocument19 pagesPipe Rack Presentationkaushalacharya67% (3)

- Pipe RackDocument20 pagesPipe RackKehinde AdebayoNo ratings yet

- Pipe Rack Design PhilosophyDocument13 pagesPipe Rack Design Philosophyप्रभु नाथ सिंहNo ratings yet

- Pipe Rack Sizing and Loading DataDocument5 pagesPipe Rack Sizing and Loading DataAnand.5No ratings yet

- Pipe Racks ArrangementDocument42 pagesPipe Racks ArrangementShailin ShahNo ratings yet

- Aspects of Piperack DesignDocument70 pagesAspects of Piperack Designdhdahanuwala100% (3)

- Pipe RacksDocument14 pagesPipe RacksWilson100% (1)

- Presentation On PiperackDocument27 pagesPresentation On Piperackabdussalam_zahrani100% (1)

- Design Practice For Piping Arangement (Pipe Rack)Document53 pagesDesign Practice For Piping Arangement (Pipe Rack)Chairul Anwar100% (2)

- General Pipe Rack Configuration 0 DivDocument2 pagesGeneral Pipe Rack Configuration 0 DivhumshkhNo ratings yet

- Pipe Rack LAYOUTDocument25 pagesPipe Rack LAYOUTSAMI UR RAHMANNo ratings yet

- Pipe Rack Design Philosophy (Continuous Pipe Racks)Document17 pagesPipe Rack Design Philosophy (Continuous Pipe Racks)Umer AleemNo ratings yet

- Pipe Rack Design PhilosophyDocument6 pagesPipe Rack Design PhilosophyLogesh PerumalNo ratings yet

- Optimum Design of Steel Pipe RacksDocument17 pagesOptimum Design of Steel Pipe RacksRamesh PrabhakarNo ratings yet

- Design Consideration of PiperackDocument3 pagesDesign Consideration of PiperackPrantik Adhar SamantaNo ratings yet

- Expansion Joints & LoopsDocument8 pagesExpansion Joints & Loopsandbrit10No ratings yet

- Piperack Design ExampleDocument42 pagesPiperack Design ExampleSushant Bijam67% (6)

- Analysis and Design On Pipe RacksDocument46 pagesAnalysis and Design On Pipe Racksduy thanh75% (4)

- A Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack StructuresDocument8 pagesA Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack Structuresvirat_daveNo ratings yet

- Pipe Rack DesignDocument3 pagesPipe Rack DesignBalamuruganNo ratings yet

- 11 Pipe RacksDocument24 pages11 Pipe RacksKusailaNo ratings yet

- Pipe RackDocument1 pagePipe RackJinu JacobNo ratings yet

- Pipe Rack Loading Calculation Forflare UnitDocument35 pagesPipe Rack Loading Calculation Forflare UnitYethish Maroli100% (1)

- Pipe Rack Design WESTDocument8 pagesPipe Rack Design WESTdrmjj1100% (4)

- Pipe Rack & Rack PipingDocument23 pagesPipe Rack & Rack Pipingtrung652092100% (2)

- P/R Design Tips For Steel Design (IFC)Document17 pagesP/R Design Tips For Steel Design (IFC)apara_jitNo ratings yet

- Pipe Rack Design PhilosophyDocument5 pagesPipe Rack Design PhilosophyMUTHUKKUMARAMNo ratings yet

- Piperack Design ConceptDocument46 pagesPiperack Design ConceptNagesh Kumar100% (1)

- Pipe Supports Design CriteriaDocument11 pagesPipe Supports Design CriteriaJaykumar75% (4)

- Modular Pipe Rack ConceptDocument29 pagesModular Pipe Rack ConceptPhilippe LAVOISIERNo ratings yet

- Pipe Rack DesignDocument3 pagesPipe Rack DesignDarshan NakawalaNo ratings yet

- ConX Modular Pipe Rack BrochureDocument25 pagesConX Modular Pipe Rack BrochureYulian JesúsNo ratings yet

- Piping Engineering Design Criteria Rev02Document15 pagesPiping Engineering Design Criteria Rev02swatkoolNo ratings yet

- Pipe Rack Design PhilosophyDocument8 pagesPipe Rack Design Philosophygk80823100% (1)

- Onshore Modular ConstructionDocument8 pagesOnshore Modular ConstructionGustavo Gonzalez ServaNo ratings yet

- 6.1 Purpose of Pipe SupportDocument10 pages6.1 Purpose of Pipe SupportRaju NaiduNo ratings yet

- 1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsDocument6 pages1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsHenry HoyosNo ratings yet

- Bend Freq Beams Rods PipesDocument47 pagesBend Freq Beams Rods PipesAsur Cortes GNo ratings yet

- Pipe Rack DesignDocument119 pagesPipe Rack DesignSumanth86% (7)

- Modular Calculation PiperackDocument5 pagesModular Calculation Piperacksaebanny100% (1)

- Pipe Supports DesignDocument29 pagesPipe Supports Designpbao_12No ratings yet

- Design of Structural Steel Pipe Racks Part 1Document1 pageDesign of Structural Steel Pipe Racks Part 1Charlie ChuNo ratings yet

- Vertical Brace ConnectionsDocument13 pagesVertical Brace ConnectionsAnkit GuptaNo ratings yet

- Pipeline Inspection: Pipe RackDocument4 pagesPipeline Inspection: Pipe RackAnushi DahariaNo ratings yet

- Pipe Rack Sizing and Loading DataDocument7 pagesPipe Rack Sizing and Loading DataRambabuNo ratings yet

- Chapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deDocument21 pagesChapter 12 - Pipe Ra - 2018 - The Engineer S Guide To Plant Layout and Piping deezeabrilNo ratings yet

- Pipe Rack Sizing and Loading DataDocument6 pagesPipe Rack Sizing and Loading DataapirakqNo ratings yet

- Supporting of Piping SystemsDocument3 pagesSupporting of Piping Systemsaap150% (2)

- Pipe RackDocument33 pagesPipe RackSaid Ahmed Salem100% (1)

- Metallic Cable Tray PDFDocument227 pagesMetallic Cable Tray PDFlhikbaniNo ratings yet

- Pipe Routing InstructionsDocument37 pagesPipe Routing InstructionsDANLIN ENGINEERS100% (1)

- Piping FundamentalsDocument12 pagesPiping FundamentalsKurian JoseNo ratings yet

- Busway SiemensDocument72 pagesBusway SiemenssnakelostNo ratings yet

- 18.pipe SupportsDocument16 pages18.pipe SupportsEnrique BlancoNo ratings yet

- 1.explain The Following Types of Distribution Systems : (A) Dead EndDocument15 pages1.explain The Following Types of Distribution Systems : (A) Dead EndMichael LangatNo ratings yet

- Piperack Design PhiloshipyDocument10 pagesPiperack Design PhiloshipyJatinTankNo ratings yet

- Principles For Layout Plans and Sectioning Diagrams For 25 KV Ac TractionDocument4 pagesPrinciples For Layout Plans and Sectioning Diagrams For 25 KV Ac TractionPragati SrivastavaNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)