Professional Documents

Culture Documents

AMR Project: Engagement of Suppliers in Product Development Process

Uploaded by

ssnegi_dce0 ratings0% found this document useful (0 votes)

22 views13 pagesThis document discusses supplier involvement in product development processes. It covers different degrees of supplier involvement from traditional subcontracting to black box strategies. Benefits include accessing complementary skills and knowledge, while risks include increased costs and loss of control. Critical success factors are identified as technological competence, open expectations, long-term strategy, and project management. The automotive industry's selection of a supplier strategy depends on technical complexity, available knowledge, legal factors, and supply chain parameters. A questionnaire is designed to assess supplier effectiveness based on knowledge, trust, teamwork, and customer value.

Original Description:

Original Title

AMR Project

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses supplier involvement in product development processes. It covers different degrees of supplier involvement from traditional subcontracting to black box strategies. Benefits include accessing complementary skills and knowledge, while risks include increased costs and loss of control. Critical success factors are identified as technological competence, open expectations, long-term strategy, and project management. The automotive industry's selection of a supplier strategy depends on technical complexity, available knowledge, legal factors, and supply chain parameters. A questionnaire is designed to assess supplier effectiveness based on knowledge, trust, teamwork, and customer value.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views13 pagesAMR Project: Engagement of Suppliers in Product Development Process

Uploaded by

ssnegi_dceThis document discusses supplier involvement in product development processes. It covers different degrees of supplier involvement from traditional subcontracting to black box strategies. Benefits include accessing complementary skills and knowledge, while risks include increased costs and loss of control. Critical success factors are identified as technological competence, open expectations, long-term strategy, and project management. The automotive industry's selection of a supplier strategy depends on technical complexity, available knowledge, legal factors, and supply chain parameters. A questionnaire is designed to assess supplier effectiveness based on knowledge, trust, teamwork, and customer value.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 13

AMR Project

Engagement of Suppliers in Product

Development process

Shailender Singh Negi

09Bm8046

Topics covered so far

Degree of Supplier involvement in product

development

Issues in the engagement with suppliers

Risk involved in the Engagement

Whether at all the companies have been benefitted

Design of Questionnaire for

Manufactures(Automobile manufacturer)

Degree of Supplier involvement

Traditional Subcontracting

Grey box strategy(Advanced Subcontracting)

Black box Parts strategy

Traditional Subcontracting

All design work and related problem solving was done

internally.

The supplier received detailed drawings and technical

specifications to be met for a component.

Only those parts which was not considered to

critically affect other parts of the overall project.

The supplier’s action domain is therefore limited to

meet these technical specifications.

Suppliers worked on components with low interdependency

with the rest of the project.

Grey box strategy (Advanced Subcontracting)

The manufacturer, here, limited its own activities by selecting

an area of the project and delegating it entirely to the

supplier.

The supplier’s domain of action is therefore widened,

although limited to areas of potentially low influence on the

overall project.

In this type of relationship, the manufacturer tried to access a

specific knowledge domain of the supplier, without limiting

its potential outcome by a predetermined set of solutions.

Suppliers are responsible for the whole problem

solving activity for highly critical components.

Black box Parts strategy

Despite the potentially high influence on the overall

project, suppliers are given freedom to define the

solution starting from the concept design domain and

then moving to the functional parameter domain.

Components developed according to these

arrangements have been identified as “black box”

parts.

Supplier involvement—potential benefits and critical factors

Partnership relation can afford the involved parties

access to complementary skills

Economies of scale in joint research

Access to new technologies or markets

Risk sharing and access to knowledge located outside

the boundaries of the firm

Engineering capabilities in the supplier network allow

the firm to benefit from the suppliers’ know-how,

thereby, reducing the development time

Simply adopting the techniques suggested in the literature

Supplier involvement—Drawbacks and potential risks

will not necessarily reduce development time or lead to

technical success in the project.

Supplier involvement could affect product development

time negatively, especially when markets and technologies

are rapidly and unpredictably evolving.

General view that collaboration makes product development

more costly, more complicated

Joint development projects are less efficient, more time

consuming and more difficult to control and manage.

Legal issues involved in joint development.

Technological competence.

Suppliers’ co-operation with other manufacturers and

own suppliers.

Factors were identified as critical for a successful outcome

Openness and matching of expectations.

Long-term strategy for involvement.

Coupling between production and product

development

Project management.

Pro-active supplier.

SELECTION OF STRATEGY IN AUTOMOBILE

INDUSTRY

Technical complexity of the product

• R&D required

• Number of components to be sourced

• Tight specifications

Availability of the technical know how

• Technical expertise of R&D department

• Manufacturing capabilities

• Experience in design field

SELECTION OF STRATEGY IN AUTOMOBILE

INDUSTRY

Legal complexity

• Legal binding on contract

• Custom regulation in case of import of tech and

equipments

• Government policy, rules and regulations

Supply chain parameters

• Quality and quantity of component

• Lead time

• Delivery requirements

• Flexibility and adoptability

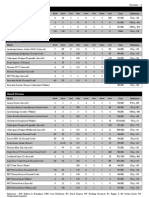

Questionnaire for

Manufactures(Automobile manufacturer)

A Questionnaire has be designed to assess the

effectiveness of supplier in product development. Each

item is based on five point Likert scale. The questions

are based on following factors.

Supplier Knowledge

Supplier Trust

Team work

Value to the customer

Questionnaire

Questionnaire.xlsx

You might also like

- Challenges in Project ManagementDocument3 pagesChallenges in Project Managementarshadtk100% (1)

- LO3 Conduct Walk Through and Compare or Contrast Expected PerformanceDocument6 pagesLO3 Conduct Walk Through and Compare or Contrast Expected Performanceasnake bogaleNo ratings yet

- Project ManagementDocument28 pagesProject ManagementSAVINo ratings yet

- IPPDDocument19 pagesIPPDPankaj NarvekarNo ratings yet

- Chapter Five (Managing For Product Quality)Document5 pagesChapter Five (Managing For Product Quality)Marica ShaneNo ratings yet

- DSP Re Formatted PaperDocument8 pagesDSP Re Formatted Papersyedqutub16No ratings yet

- Chapter 4 - Product and Service DesignDocument4 pagesChapter 4 - Product and Service Designhello_khay100% (1)

- موجز تصميمDocument7 pagesموجز تصميمhuseNo ratings yet

- 1.1 Definition and Types of SpecificationsDocument21 pages1.1 Definition and Types of SpecificationsSeth Emmanuel RamosNo ratings yet

- Assignment 1 CompleteDocument16 pagesAssignment 1 CompleteEvonYongNo ratings yet

- Presentation New Product Design 3Document39 pagesPresentation New Product Design 3priyaa03No ratings yet

- QSE Lecture 3Document21 pagesQSE Lecture 3Fortiter FysproNo ratings yet

- The Feasibility of Developing New Automotive Parts From The Supplier Perspective: Proposal of A Managerial Tool For A Plastics CompanyDocument9 pagesThe Feasibility of Developing New Automotive Parts From The Supplier Perspective: Proposal of A Managerial Tool For A Plastics Companytran huytrungNo ratings yet

- Should-Cost Challenges Demystified: Kumar VaradarajanDocument9 pagesShould-Cost Challenges Demystified: Kumar VaradarajanPramod HegdeNo ratings yet

- The Value of Early Analysis (Part 1) : by Gregory RothDocument4 pagesThe Value of Early Analysis (Part 1) : by Gregory RothanandakoeNo ratings yet

- Manufacturability of Large Sheet Metal Part.: April 2008Document6 pagesManufacturability of Large Sheet Metal Part.: April 2008AuraNo ratings yet

- Procurement MethodologyDocument4 pagesProcurement MethodologyThanhNo ratings yet

- Group WorkDocument4 pagesGroup WorkfatrupNo ratings yet

- Supplier Agreement ManagementDocument11 pagesSupplier Agreement ManagementalexbbastosNo ratings yet

- Product and Service DesignDocument48 pagesProduct and Service Designbugzmio0% (1)

- Competitive Strategies: Technology Leadership Cost Leadership Customer Focus ImitativeDocument10 pagesCompetitive Strategies: Technology Leadership Cost Leadership Customer Focus ImitativesumikannuNo ratings yet

- 5 Tips For Feed SuccessDocument3 pages5 Tips For Feed SuccessStephen EmmanuelNo ratings yet

- Procurment OptionsDocument20 pagesProcurment OptionsShipra JainNo ratings yet

- Managing Fast Track Projects: A Guide and ChecklistsDocument76 pagesManaging Fast Track Projects: A Guide and ChecklistsawaisjinnahNo ratings yet

- Pros Cons Handout Delivery SystemsDocument35 pagesPros Cons Handout Delivery SystemsRufus ChengNo ratings yet

- Best Practices in Delivery of EPC ProjectsDocument13 pagesBest Practices in Delivery of EPC ProjectsDaniel WismanNo ratings yet

- Preparing For Successful Design TransferDocument7 pagesPreparing For Successful Design TransferRahul Dhingra100% (1)

- How To Write SpecificationsDocument9 pagesHow To Write SpecificationsaudrinanorbertNo ratings yet

- "TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationDocument11 pages"TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationPovenesan Krishnan100% (1)

- The Role: Design Engineer (Pipes)Document3 pagesThe Role: Design Engineer (Pipes)ninju1No ratings yet

- Precision Design For ManufacturabilityDocument8 pagesPrecision Design For ManufacturabilityFuadNo ratings yet

- 18MEO113T - DOE - Unit 2 - AY2023 - 24 ODDDocument177 pages18MEO113T - DOE - Unit 2 - AY2023 - 24 ODDRuggedrouge RascalNo ratings yet

- Design and BuildDocument16 pagesDesign and BuildBernard DavidNo ratings yet

- Institute of Management Studies: Outsourcing and ProcurementDocument20 pagesInstitute of Management Studies: Outsourcing and ProcurementMahath MohanNo ratings yet

- Material ManagementDocument5 pagesMaterial ManagementDevendra DhakarNo ratings yet

- Concurrent Engineering: Automated Production SystemsDocument14 pagesConcurrent Engineering: Automated Production SystemsPao SalazarNo ratings yet

- New Product DevelopmentDocument40 pagesNew Product DevelopmentSaurabh ShindeNo ratings yet

- Design For Manufacturability PDFDocument4 pagesDesign For Manufacturability PDFCarlos Andrés Pérez EstradaNo ratings yet

- Chapter 9 Procurement and Outsourcing StrategiesDocument46 pagesChapter 9 Procurement and Outsourcing Strategiesfatwacahyokusumo100% (1)

- Network Outsourcing July 2011Document18 pagesNetwork Outsourcing July 2011Shankar VenugopalNo ratings yet

- Assess and Justify The Relative Importance Procurement Versus Other Project Management Areas/dimensions That Affect Project OutcomesDocument10 pagesAssess and Justify The Relative Importance Procurement Versus Other Project Management Areas/dimensions That Affect Project OutcomesSajawal BhattiNo ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Project Management Approaches For IT ProjectsDocument33 pagesProject Management Approaches For IT ProjectsNat TikusNo ratings yet

- L - 9 Make or Buy DecisionDocument25 pagesL - 9 Make or Buy DecisionNikhil KhobragadeNo ratings yet

- Procurement JMDocument27 pagesProcurement JMTakhleeq AkhterNo ratings yet

- Unit 4 Role of PLM in IndustriesDocument35 pagesUnit 4 Role of PLM in IndustriesSenthilkumaar JSNo ratings yet

- Product, Process, and Service DesignDocument63 pagesProduct, Process, and Service DesignRupaam DebNo ratings yet

- Design ManagerDocument4 pagesDesign ManagerRamona PaulaNo ratings yet

- Development Engineer Generic JDDocument4 pagesDevelopment Engineer Generic JDDivya SharmaNo ratings yet

- Strong Points and Weak Points For Paper ReviewDocument4 pagesStrong Points and Weak Points For Paper ReviewKanagala Raj ChowdaryNo ratings yet

- Roland Berger Supplier Procurement Study 2008 20080101Document34 pagesRoland Berger Supplier Procurement Study 2008 20080101Vaibhav KukrejaNo ratings yet

- The Future Is Now: Proposal TemplateDocument8 pagesThe Future Is Now: Proposal TemplateIrene LyeNo ratings yet

- Best Practices For Implement 346916Document13 pagesBest Practices For Implement 346916AndersonVieiraNo ratings yet

- Case 3 - HP DeskjetDocument4 pagesCase 3 - HP DeskjetElbert Leo AstilleroNo ratings yet

- PRINCE2 2017 Project BriefDocument5 pagesPRINCE2 2017 Project BriefAnonymous 1cby6nNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-41Document1 pagePages From SIMABUS Tubular Busbar Accesories-41asi midobarNo ratings yet

- Analysis of A Case StudyDocument4 pagesAnalysis of A Case StudyPovenesan KrishnanNo ratings yet

- Project AppraisalDocument27 pagesProject Appraisallechu_16100% (3)

- Aluminium Cladding Method StatementDocument4 pagesAluminium Cladding Method StatementGirithar M Sundaram100% (2)

- Sequence Based SpecificationsDocument11 pagesSequence Based SpecificationsrexthrottleNo ratings yet

- CIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumDocument8 pagesCIA and Pentagon Deploy RFID Death Chips - Coming Soon To A Product Near You - DeeppoliticsforumEmil-Wendtland100% (1)

- The Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaDocument7 pagesThe Great Eggscape: Corey Kelvin Group 73 Nizam Umayr PatriciaLegendaryNNo ratings yet

- EXER2Document12 pagesEXER2Angelus Vincent GuilalasNo ratings yet

- RT80 Parts Manual 053-1271Document165 pagesRT80 Parts Manual 053-1271Abdellah NajmNo ratings yet

- BIFFI RHPS CatalogueDocument11 pagesBIFFI RHPS CatalogueblloewyNo ratings yet

- Midterm Exam VibrationDocument12 pagesMidterm Exam VibrationKobeNo ratings yet

- Midterm JavaDocument4 pagesMidterm Javaمحمد سمورNo ratings yet

- Introduction To Web TechnologiesDocument8 pagesIntroduction To Web TechnologiesManeela SiriNo ratings yet

- AdaptationsDocument17 pagesAdaptationsJanusz PocińskiNo ratings yet

- Lecture 03Document42 pagesLecture 03Laís Medeiros100% (1)

- Cavitation - ANSYS CFD PDFDocument4 pagesCavitation - ANSYS CFD PDFMohsen SalehiNo ratings yet

- IAMI Revision Questions Motor and GeneralDocument8 pagesIAMI Revision Questions Motor and GeneralStewart LongNo ratings yet

- PS1800 Centrifugal Pumping Systems: General Data and Sizing TablesDocument12 pagesPS1800 Centrifugal Pumping Systems: General Data and Sizing TablesSINES FranceNo ratings yet

- RT MDocument6 pagesRT MShikhar NigamNo ratings yet

- PythonDocument66 pagesPythoncredtechNo ratings yet

- Online Shopping Portal Project ReportDocument33 pagesOnline Shopping Portal Project ReportSagar Chauhan50% (2)

- Technical Data: 1. DescriptionDocument6 pagesTechnical Data: 1. DescriptionAnthonyNo ratings yet

- PM Trailer 16T General Purpose RevBDocument60 pagesPM Trailer 16T General Purpose RevBHANNESNo ratings yet

- ENG - B1.1.0106S Talking On The Phone PDFDocument23 pagesENG - B1.1.0106S Talking On The Phone PDFankira78No ratings yet

- ITIL Cobit MappingDocument16 pagesITIL Cobit Mappingapi-383689667% (3)

- Yokota MhiDocument35 pagesYokota MhiElliott Russell100% (1)

- Panel Simplex 2008Document86 pagesPanel Simplex 2008JhonyLazoNo ratings yet

- Netsure-731-A41-User-Manual (Manual) PDFDocument38 pagesNetsure-731-A41-User-Manual (Manual) PDFRoger Alfaro GNo ratings yet

- Six SigmaDocument92 pagesSix SigmaJan Karina Lapeña PadlaNo ratings yet

- SR5 TOOL Equipment, Drones (Buyable), Compiled ListDocument3 pagesSR5 TOOL Equipment, Drones (Buyable), Compiled ListBeki LokaNo ratings yet

- HYPRODocument1 pageHYPROhumberto zamarNo ratings yet

- Unit-3 Embedded Software 23. Multitasking and Process ManagementDocument8 pagesUnit-3 Embedded Software 23. Multitasking and Process ManagementSoundarya SvsNo ratings yet

- 3 Complaint LettersDocument6 pages3 Complaint LettersCarolina Sorto CastañonNo ratings yet