Professional Documents

Culture Documents

SIMATIC S7 Totally Integrated Automation

Uploaded by

thaibkproOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIMATIC S7 Totally Integrated Automation

Uploaded by

thaibkproCopyright:

Available Formats

Totally Integrated Automation

SIMATIC

PCS 7

SIMATIC

SIMATIC NET

Software

SIMATIC

HMI

SIMATIC SIMATIC

PC

SIMATIC

WinCC

SIMATIC

DP

SIMATIC

Controller

SIMATIC S7 Date: 04.03.2019

File: 15_.1

Automating with SIMATIC S7

SIMATIC PG SIMATIC

SIMATIC PC SOFTWARE

WIN CC PCS 7

SIEMENS

Standard Tools

PG 740

SIMATIC SIMATIC OP17

4 x 20 Zeichen

8 x 40 Zeichen

SIMATIC OP17

Engineering Tools

Zeichengrößen beliebig mischbar

6/11mm Schrifthöhe

HMI F1

K1

K9 K10

F2

K2

F3

K3

K11

F4

K4

K12

F5

K5

K13

F6

K6

K14

F7

K7

K15

F8

K8

K16

HELP

SHIFT

1

D

A

8

2

E

B

9

3

F

C

0

SHIFT

INS

DEL

HELP

ESC

ACK

ENTER

Runtime Software

OP...OS

MPI Network

SIMATIC NET Industrial Ethernet

PROFIBUS

SIMATIC

Controller

S7-200 S7/M7-300 S7/M7-400 WinAC

PROFIBUS-DP

SIMATIC DP FM

SV

ET200 ASI

SIMATIC S7 Date: 04.03.2019

File: 15_.2

The SIMATIC S7/C7/M7 and WinAC Controllers

modular modular

Upper and

middle

performance

range

SIMATIC S7 - 400 SIMATIC M7 - 400 SIMATIC WinAC Pro

Lower complete

performance modular modular

range

SIMATIC S7 - 300 SIMATIC M7 - 300 SIMATIC C7 - 620 SIMATIC WinAC Basic

Micro PLC compact

SIMATIC S7 - 200

SIMATIC S7 Date: 04.03.2019

File: 15_.3

STEP 7 Software for S7/C7/M7

Neuro Systems

Fuzzy Control

PID Control

TeleService

Standard Tools DOCPRO

Engineering Tools CFC

Runtime Software Tools S7-SCL

S7-Graph

S7-HiGraph

S7-PLCSIM Borland C/C++

S7-PDIAG M7-ProC/C++

STEP 7 Mini

STEP 7 Micro LAD / STL STL LAD FBD STEP 7

LAD / STL Manager Manager

S7-200 S7-300 S7-300 S7-400

Support Support Support Support M7-SYS

S7-200 S7-300 S7-300 S7-400 M7-300

WinAC WinAC M7-400

SIMATIC S7 Date: 04.03.2019

File: 15_.4

Programming Sequence Control Systems with S7- GRAPH

S7-GRAPH: The tool for

programming sequence cascades

Compatible with IEC 1131-3 S1

Designed for the requirements of

production engineering

T1 T4

Graphic division of the process

into steps and transitions

Steps contain actions S2 S5 S6

Transitions check the conditions

for switching to the next step

T2 T5

The following phases of

automation can be S4

optimized with S7-GRAPH:

Planning, Configuring

Programming T3

Debugging

Commissioning

Maintenance, Diagnostics

SIMATIC S7 Date: 04.03.2019

File: 15_.5

Programming using the State Diagram Method with

S7- HiGraph

S7-HiGraph: The tool for Position Index out

programming using Cam-operated switch

State Diagrams 1 2 4 Turn left

Division of the machine into piece

functional units

Creating state diagrams Turn right

for every function unit

Motor Index in

States contain actions Counterbearing

lock/release

State diagrams communicate Index

Motor Counterbearing

using messages

The following phases of

automation can be

optimized with S7-HiGraph: Coordinator

Planning, Configuring

Programming and Debugging

Commissioning

Maintenance, Diagnostics

Supports reuseability

SIMATIC S7 Date: 04.03.2019

File: 15_.6

Programming in the High Level Language S7- SCL

FUNCTION_BLOCK Integrator

S7-SCL: High level language for VAR_INPUT

creating PLC programs Init : BOOL; // Reset output value

x : REAL; // Input value

Compatible with IEC 1131-3Text Ta : TIME; // Sampling interval in ms

(ST=Structered Text)) Ti : TIME; // Integration time in ms

olim : REAL; // Output value upper limit

Certified according to PLCopen ulim : REAL; // Output value lower limit

END_VAR

Base Level

Contains all the typical VAR_OUTPUT

y : REAL:= 0.0; // Initialize output value with 0

elements of a high level END_VAR

language, such as

operands, terms, control BEGIN

IF TIME_TO_DINT(Ti) = 0 THEN // Division by ?

statements OK := FALSE;

PLC specifics are integrated, y := 0.0;

RETURN;

such as I/O access, timers, END_IF;

counters...) IF Init THEN

y:= 0.0;

Advantages: ELSE

y := y+TIME_TO_DINT(Ta)*x/TIME_TO_DINT(Ti);

Well structured, easy to IF y > olim THEN y := olim; END_IF;

understand program IF y < ulim THEN y := ulim; END_IF;

END_IF;

For those knowlegeable in high END_FUNCTION_BLOCK

level langugages

For complex algorithms

SIMATIC S7 Date: 04.03.2019

File: 15_.7

CFC for SIMATIC S7

CFC (Continuous Function Chart):

Tool for graphic creation

of PLC programs

Blocks are placed on

function charts

and interconnected

Interconnection is

possible:

- between I/O fields

- also to blocks in

other charts

Sources and destinations

are managed in the

margins

Advantages

Program creation for

technologists

quick creation, testing

and commissioning times

SIMATIC S7 Date: 04.03.2019

File: 15_.8

Configuring Sequence Control Systems with S7- SFC

S7-SFC: The tool for

programming sequence

cascades

Designed for the require-

ments of process automation

Compatible with IEC 1131-3

Steps assign values to

blocks in the CFC

Transitions check the

conditions for switching to

the next step

Syntax check during

creation

Direct connection to CFC

Acceptance of values using

“Drag&Drop”

Cross reference selections

Visualization within

WinCC

SIMATIC S7 Date: 04.03.2019

File: 15_.9

Process Diagnosis with S7- PDIAG

Process diagnosis: Detection of

faults occurring outside the PLC

Sensor/actuator defective, movement faulty,

...

S7- PDIAG: Tool for configuring

the fault definition in STL, LAD, FBD

Integrated in the development environment

Simple formulation of fault monitoring and

message texts (during and after the

program session)

Fault detection and criteria analysis are Message

conducted automatically

Comprehensive information for the operator

on:

type of fault

location of fault

cause of fault I1.0 I1.1 Q1.0

Reduction of down-time

SIMATIC S7 Date: 04.03.2019

File: 15_.10

Testing User Programs with S7- PLCSIM

S7-PLCSIM: Simulation software

for offline testing of PLC programs

Functional program test

on a simulated CPU

with display/modify I/O

Testing of user blocks in

LAD, FBD, STL, S7-SCL,

S7-GRAPH, S7-HiGraph, CFC

S7-PDIAG, WinCC

Advantages

Faults can be detected early and eliminated

Many tests are already possible in the office

without the final hardware

SIMATIC S7 Date: 04.03.2019

File: 15_.11

Remote Maintenance and Remote Diagnosis with TeleService

TeleService: Makes an online CPU I/O ... CPU

connection to SIMATIC S7/C7

or M7 possible

"Extends" the MPI via

telephone/radio networks

STEP 7 functionality MPI bus

Market standard modems and TS adapter

Fault detection, fault elimination TS adapter

and commissioning from a central

location

system

Advantages: modem

Reduction of maintenance costs

Faster upgrading of the system

Control room with

STEP7 and TeleService

PG/PC

modem

SIMATIC S7 Date: 04.03.2019

File: 15_.12

Creating Plant Documentation with DOCPRO

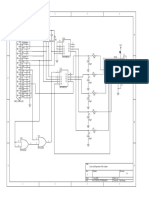

DOCPRO: Creating wiring

manuals for plants

Standardized layout templates,

can be modified to your needs

Generates reference numbers,

generates indexes Layout template

Prints the entire documentation .....................

in one run (e. g. at night) ............................

.........................

.................................

Advantage: ........................

Convenient creation ...........

of documents Reference number

Project

SIMATIC S7 Date: 04.03.2019

File: 15_.13

Runtime Software for Closed-loop Control Engineering Tasks

Confi- Basic SW

gura- or

Overview tion option

tool package

PID Controller No Basic SW

Basic SW PID Control Yes Basic SW

Standard PID Control Yes Option

Modular PID Control Yes Option

Fuzzy Control Yes Option

Neuro Systems Yes Option

FM 355 / 455 Yes

S7-200 S7-300 S7-400 C7 M7

SIMATIC S7 Date: 04.03.2019

File: 15_.14

Borland C/C++, M7- ProC/C++ and M7- SYS RT for M7-Automation

Computers

Borland C/C++

Creation of C/C++ programs

for M7

M7- ProC/C++

Integration of Borland C/C++

in STEP 7

Powerful debugger for

user-friendly program testing

M7- SYS RT

RMOS operating system C

for the computer pro M7-SYS RT

real-time capable

multitasking

Advantage: SIEMENS

Technological functions STEP7

BorlandC/C++

can be programmed M7-ProC/C++

PG 740

Extreme time-critical tasks

SIMATIC S7 Date: 04.03.2019

File: 15_.15

Communicating with SIMATIC NET

Industrial Ethernet Manage-

ment level

Cell level

PROFIBUS

Field level

Actuator Actuator-

Sensor- sensor

Interface level

SIMATIC S7 Date: 04.03.2019

File: 15_.16

Operator Control and Process Monitoring with SIMATIC HMI

Process visualization

system

SIMATIC WinCC

Configuration and

visualization software

SIMATIC ProTool

SIMATIC Panels

SIMATIC S7 Date: 04.03.2019

File: 15_.17

Consistent Configuration with SIMATIC ProTool

PC-based Systems

Graphic Display Panels

Text Display Panels

SIMATIC S7 Date: 04.03.2019

File: 15_.18

Process Visualization and Operator Control with WinCC

SIMATIC S7 Date: 04.03.2019

File: 15_.19

Process Automation with SIMATIC PCS 7

Engineering System Process terminal 1 Process terminal 2 Process terminal 3

Terminal bus

WinCC OS WinCC OS-Server

System bus

S7-400 as

central unit

FM

SV DP

ET 200M

FM

SV DP

Field devices

SIMATIC S7 Date: 04.03.2019

File: 15_.20

Summary

WinCC PCS 7

NET

Engineering

SIMATIC S7

NET

Instrum. Drives

M

SIMATIC S7 Date: 04.03.2019

File: 15_.21

You might also like

- SERV1 01e SystemFamilyDocument19 pagesSERV1 01e SystemFamilyNeagoe CristianNo ratings yet

- SIMATIC S7 System Family OverviewDocument165 pagesSIMATIC S7 System Family OverviewelectrineerNo ratings yet

- PRO1 01e SystemFamilyDocument19 pagesPRO1 01e SystemFamilyanunNo ratings yet

- PLC TrainingDocument161 pagesPLC Trainingmeftah.youssef08No ratings yet

- The SIMATIC S7 System FamilyDocument31 pagesThe SIMATIC S7 System Familyhwhhadi100% (1)

- Manual s7 Basico PDFDocument280 pagesManual s7 Basico PDFSagar PawarNo ratings yet

- r1 SYSTEM UBERBLICKDocument15 pagesr1 SYSTEM UBERBLICKVadimNo ratings yet

- PRO1 01E SystemFamily PDFDocument38 pagesPRO1 01E SystemFamily PDFJJ PedroNo ratings yet

- MitsucablesDocument4 pagesMitsucablesambresh.09No ratings yet

- ST-TIA BasisDocument359 pagesST-TIA Basissmradpera100% (1)

- Rewiring A User Program: Simatic S7Document16 pagesRewiring A User Program: Simatic S7Neagoe CristianNo ratings yet

- Mag Pi 64Document1 pageMag Pi 64Adam MikitzelNo ratings yet

- LattpschDocument1 pageLattpschhanif khanNo ratings yet

- PGP Glass Staking ModelDocument13 pagesPGP Glass Staking ModelSolanki SamarthNo ratings yet

- Introduction to PROFIBUS DP and HMI Operator PanelDocument31 pagesIntroduction to PROFIBUS DP and HMI Operator Panelhaftu gideyNo ratings yet

- 3288.0-18 MHZ ReceiverDocument2 pages3288.0-18 MHZ ReceiverJoy MukherjiNo ratings yet

- TenguDocument1 pageTenguIrpiri WillkaNo ratings yet

- HC04a PCB Top ViewDocument1 pageHC04a PCB Top ViewAitorNo ratings yet

- Pcs 7Document34 pagesPcs 7Josh JoshNo ratings yet

- MC#1 Turret-WS Manual1Document25 pagesMC#1 Turret-WS Manual1prithwirajroyNo ratings yet

- PRO1 02E TrainingUnits and AddressingDocument33 pagesPRO1 02E TrainingUnits and AddressingING. OSCAR PACHECONo ratings yet

- Simatic Pcs 7: System OverviewDocument34 pagesSimatic Pcs 7: System OverviewAbel MogesNo ratings yet

- PRSERV - 05E - SW Commissioning and TroubleshootingDocument12 pagesPRSERV - 05E - SW Commissioning and TroubleshootingNeagoe CristianNo ratings yet

- Piano Tiles Super Auto PlayerDocument1 pagePiano Tiles Super Auto PlayerLautaro DíazNo ratings yet

- Simatic pcs7 Traing Course PDFDocument34 pagesSimatic pcs7 Traing Course PDFmiraNo ratings yet

- Titan20 - Block - Diagram - XT2073 - Motorola One FusionDocument1 pageTitan20 - Block - Diagram - XT2073 - Motorola One FusionTecnicos GeveyNo ratings yet

- Toshiba Satellite M305D - Quanta - Bu2 - R1a - DB8F0A0BU2M - SchematicsDocument36 pagesToshiba Satellite M305D - Quanta - Bu2 - R1a - DB8F0A0BU2M - SchematicsDaniel Norberto DemariaNo ratings yet

- HP G56 - G42 - G62 Schematics  - Compaq Presario CQ56 - CQ62 Schematics  - 31AX2MB00D0  - DA0AX2MB6E0  - DA0AX2MB6E1  - AX2 - AX7 Motherboard SchematicsDocument42 pagesHP G56 - G42 - G62 Schematics  - Compaq Presario CQ56 - CQ62 Schematics  - 31AX2MB00D0  - DA0AX2MB6E0  - DA0AX2MB6E1  - AX2 - AX7 Motherboard Schematicsjuan manuel sierra solis25% (4)

- ESQUEMA Termostato SOLDADORDocument1 pageESQUEMA Termostato SOLDADORCarlos Alberto AmichettiNo ratings yet

- MY - 3-1-6 Specification - Slim Low Static Ducted Twenty Series PDFDocument1 pageMY - 3-1-6 Specification - Slim Low Static Ducted Twenty Series PDFAbipraya UNRINo ratings yet

- Mist13 PCBDocument1 pageMist13 PCBDoug HodsonNo ratings yet

- MC 1458Document8 pagesMC 1458كردن سيدي محمدNo ratings yet

- COM Except XT1806 MB Schematics Central Do TécnicoDocument30 pagesCOM Except XT1806 MB Schematics Central Do TécnicoCarlos Eduardo RodriguesNo ratings yet

- XT1806 SchematicsDocument30 pagesXT1806 SchematicsCarlos Eduardo RodriguesNo ratings yet

- E-Diagram 28V ConverterDocument1 pageE-Diagram 28V ConverterJulio BaldoyNo ratings yet

- SN 74 Ls 148Document26 pagesSN 74 Ls 148Felipe vergaraNo ratings yet

- D D D D: 4 5 6 7 8 C B GND V NC D 3 2 1 9 A 4 5 6 7 Ei A2 A1 GND V E0 GS 3 2 1 0 A0Document24 pagesD D D D: 4 5 6 7 8 C B GND V NC D 3 2 1 9 A 4 5 6 7 Ei A2 A1 GND V E0 GS 3 2 1 0 A0Juan Manuel Calderon TrujilloNo ratings yet

- 01Document29 pages01Hải Nguyễn KhắcNo ratings yet

- Programme de Revision Des Equipements Annee - 2024: Page 1/1 Indice: 01 Date:31/12/2023 Enafor Smi - QhseDocument1 pageProgramme de Revision Des Equipements Annee - 2024: Page 1/1 Indice: 01 Date:31/12/2023 Enafor Smi - QhseYassineNo ratings yet

- TIA Portal V17: Webinar LaunchDocument53 pagesTIA Portal V17: Webinar Launchali rif100% (1)

- Nokia C2Document9 pagesNokia C2philipingote69100% (1)

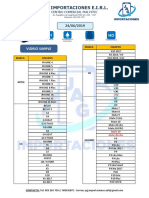

- Jag Importaciones E.I.R.L.: Vidrio SimpleDocument4 pagesJag Importaciones E.I.R.L.: Vidrio SimpleJhon Ramón HuariNo ratings yet

- Serv1 - 11e - Introduction To Profibus DP and HmiDocument28 pagesServ1 - 11e - Introduction To Profibus DP and HmiAhmed KhairiNo ratings yet

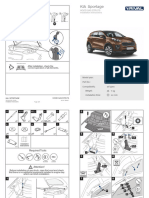

- Silownik SportageDocument2 pagesSilownik SportageB rgNo ratings yet

- SERV1 04e SIMATICManagerDocument18 pagesSERV1 04e SIMATICManagerNeagoe CristianNo ratings yet

- Proface Catalog2009v2Document18 pagesProface Catalog2009v2Beltazor HellboyNo ratings yet

- Daihatsu Type k3 Engine Service Manual No9737 No9332 No 9237 Ignition SystemDocument10 pagesDaihatsu Type k3 Engine Service Manual No9737 No9332 No 9237 Ignition SystemJoko Mardiyanto100% (1)

- Gain 5V Sense Ant: 80 Metre ARDF Radio Sport ReceiverDocument1 pageGain 5V Sense Ant: 80 Metre ARDF Radio Sport Receivererin salomeNo ratings yet

- Sitrain Sitrain: Pleas Scroll Down For English VersionDocument7 pagesSitrain Sitrain: Pleas Scroll Down For English VersioncuonghuynhjrNo ratings yet

- TE1 Block Diagram: IntelDocument40 pagesTE1 Block Diagram: IntelRian05 AntalNo ratings yet

- Siemens - Guia Kits EducativosDocument149 pagesSiemens - Guia Kits EducativosOSCAR ELIECER MESA MARTINEZNo ratings yet

- Tia Portal V17 Technical HighlightsDocument50 pagesTia Portal V17 Technical HighlightsSérgio SilvaNo ratings yet

- Sony Vaio PCG-K13 Quanta JE2Document38 pagesSony Vaio PCG-K13 Quanta JE2luckyman7No ratings yet

- SimaticHmiOptionPlus V10 DOC enDocument104 pagesSimaticHmiOptionPlus V10 DOC enthaibkproNo ratings yet

- Simatic Visualization Architect (Sivarc) - Getting Started: Tia Portal V14Document33 pagesSimatic Visualization Architect (Sivarc) - Getting Started: Tia Portal V14gayip94718100% (1)

- TIAPortalSivarcenUS en-USDocument236 pagesTIAPortalSivarcenUS en-USRafael GagoNo ratings yet

- July 2018: Fernando AlmeidaDocument63 pagesJuly 2018: Fernando AlmeidathaibkproNo ratings yet

- Data Acquisition and Reporting Software For GE iFIX HMI SystemsDocument52 pagesData Acquisition and Reporting Software For GE iFIX HMI SystemsthaibkproNo ratings yet

- Why Do Other WinCC Stations Not Appear in The Network Environment On The Windows 7 and Windows Server 2008 PCsDocument11 pagesWhy Do Other WinCC Stations Not Appear in The Network Environment On The Windows 7 and Windows Server 2008 PCsthaibkproNo ratings yet

- WINDOWS FORMS .Net en CDocument25 pagesWINDOWS FORMS .Net en CPaul Diaz ChireNo ratings yet

- SPPA-3000 Basic ManualDocument407 pagesSPPA-3000 Basic ManualHanEol Kim71% (14)

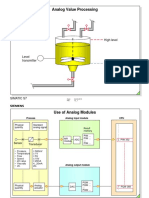

- 12 Analog Value Processing - R02Document11 pages12 Analog Value Processing - R02thaibkproNo ratings yet

- 13 Documenting, Saving, Archiving - R01Document16 pages13 Documenting, Saving, Archiving - R01thaibkproNo ratings yet

- July 2018: Fernando AlmeidaDocument63 pagesJuly 2018: Fernando AlmeidathaibkproNo ratings yet

- 09 Functions and Function Blocks - R01Document27 pages09 Functions and Function Blocks - R01thaibkproNo ratings yet

- Digital Operations OptimizationDocument30 pagesDigital Operations OptimizationthaibkproNo ratings yet

- 05 Binary Operations - R01Document14 pages05 Binary Operations - R01thaibkproNo ratings yet

- 10 Troubleshooting - R01Document35 pages10 Troubleshooting - R01thaibkproNo ratings yet

- Pcs7 Compendium Part B en US en-USDocument17 pagesPcs7 Compendium Part B en US en-USthaibkproNo ratings yet

- 14 Communication - R01Document27 pages14 Communication - R01thaibkproNo ratings yet

- 08 Data Storage in Data Blocks - R01Document18 pages08 Data Storage in Data Blocks - R01thaibkproNo ratings yet

- PCS7 Mini V81 enDocument70 pagesPCS7 Mini V81 enthaibkproNo ratings yet

- 11 Organization Blocks - R01Document15 pages11 Organization Blocks - R01thaibkproNo ratings yet

- Symbols and Addressing in SIMATIC S7Document14 pagesSymbols and Addressing in SIMATIC S7thaibkproNo ratings yet

- Pcs7 Compendium Part B en US en-USDocument148 pagesPcs7 Compendium Part B en US en-USWahyudi PrajitnoNo ratings yet

- Configuring Siemens PCS7 To Use PLCSIM - 0Document25 pagesConfiguring Siemens PCS7 To Use PLCSIM - 0alpha1ahNo ratings yet

- 04 Editing Blocks - R01Document27 pages04 Editing Blocks - R01thaibkproNo ratings yet

- 03 Hardware Configuration and Memory Concept - R01Document22 pages03 Hardware Configuration and Memory Concept - R01thaibkproNo ratings yet

- 02 Simatic Manager - r01Document17 pages02 Simatic Manager - r01thaibkproNo ratings yet

- pcs7 Compendium Part A en-US PDFDocument320 pagespcs7 Compendium Part A en-US PDFthaibkproNo ratings yet

- PCS7 Mini V81 en PDFDocument120 pagesPCS7 Mini V81 en PDFthaibkproNo ratings yet

- Addendum Proyek Konstruksi Jalan Di Kota Palangka: Analisis Faktor Penyebab, Akibat, Dan Proses Contract RayaDocument13 pagesAddendum Proyek Konstruksi Jalan Di Kota Palangka: Analisis Faktor Penyebab, Akibat, Dan Proses Contract RayaFahmi AnwarNo ratings yet

- Install Grub Bootloader on UEFI SystemDocument3 pagesInstall Grub Bootloader on UEFI SystemSalvatore BonaffinoNo ratings yet

- 2011 06 14 AVKS LDAP SSO Integration PDFDocument28 pages2011 06 14 AVKS LDAP SSO Integration PDFsaicharan3979No ratings yet

- PSD To Statistically Equivalent TransientDocument4 pagesPSD To Statistically Equivalent TransientDasaka BrahmendraNo ratings yet

- Labureader Plus 2: Semi-Automated Urine Chemistry AnalyzerDocument2 pagesLabureader Plus 2: Semi-Automated Urine Chemistry AnalyzerCARLOSNo ratings yet

- Bank Monitoring SAPDocument33 pagesBank Monitoring SAPdavender kumarNo ratings yet

- MRP An ImplementationDocument13 pagesMRP An ImplementationmishrarNo ratings yet

- Ansys Fensap-Ice ViewmericalDocument66 pagesAnsys Fensap-Ice ViewmericalEDIZONNo ratings yet

- MC Manual Final Modified PDFDocument62 pagesMC Manual Final Modified PDFhghjbjhbjhbjNo ratings yet

- Midterm QuestionsDocument5 pagesMidterm Questionsapi-300838237No ratings yet

- VBA FIND ALL FUNCTIONDocument16 pagesVBA FIND ALL FUNCTIONYamini ShindeNo ratings yet

- Java Programming For Human BeingsDocument80 pagesJava Programming For Human BeingsMiguel León NogueraNo ratings yet

- Simulation of Recirculating FlowsDocument10 pagesSimulation of Recirculating FlowsPrince Israel EboigbeNo ratings yet

- Hspice RFDocument452 pagesHspice RFSandeep SriramNo ratings yet

- AntelopeDocument71 pagesAntelopeMarian Jusko0% (1)

- For 252 Esxi 51 To 65Document5 pagesFor 252 Esxi 51 To 65mandeepmailsNo ratings yet

- Project On PLC For Color Mixer ConveyorDocument37 pagesProject On PLC For Color Mixer ConveyorJunaid Ulla KhasimNo ratings yet

- HECHMS Manual-All FinDocument48 pagesHECHMS Manual-All FinTulips Loric Vernon100% (7)

- Python Quick Reference CardDocument17 pagesPython Quick Reference CardSérgio Luiz Araújo Silva94% (16)

- Meynard de Leon LascanoDocument3 pagesMeynard de Leon LascanoDimple MacalaNo ratings yet

- Swot AnalysisDocument4 pagesSwot AnalysisAnonymous Cy9amWA9No ratings yet

- TIB TRA 5.9.0 RelnotesDocument152 pagesTIB TRA 5.9.0 Relnoteseden4872No ratings yet

- My Learning Journey ReflectionDocument2 pagesMy Learning Journey Reflectionapi-486217715No ratings yet

- Non Functional RequirementsDocument7 pagesNon Functional RequirementsSrinivasa GarlapatiNo ratings yet

- Assignment 2nd - 566 - Computer ApplicationDocument36 pagesAssignment 2nd - 566 - Computer ApplicationM Hammad ManzoorNo ratings yet

- Computer NetworksDocument47 pagesComputer NetworksJeena Mol AbrahamNo ratings yet

- C++ Copy Constructors ExplainedDocument2 pagesC++ Copy Constructors ExplainedSanjay MunjalNo ratings yet

- Cs 1.6 ServerDocument3 pagesCs 1.6 ServerAlen KurcinakNo ratings yet

- Vishu - Numerical AnalysisDocument15 pagesVishu - Numerical Analysisayushi28No ratings yet

- Personal Skills Worksheet for Coding Career OptionsDocument2 pagesPersonal Skills Worksheet for Coding Career OptionsLucky ManNo ratings yet