Professional Documents

Culture Documents

Moldflow Analysis Predicts 15MPa Pressure Drop for Small Part

Uploaded by

baominh007100%(1)100% found this document useful (1 vote)

140 views22 pagesThe analysis aimed to study flow and predict cycle time for part A1309-2. It found that the specified PP material would easily fill the part with an expected 15MPa pressure drop. The overall temperature drop across the part of 1.2C was acceptable. Some weld lines and air traps were predicted. Warpage was expected in all directions, with the main area in the Z direction around 0.3mm. Hot spots were found on the slider side that may require additional cooling.

Original Description:

Original Title

4338322-Moldflow Report.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe analysis aimed to study flow and predict cycle time for part A1309-2. It found that the specified PP material would easily fill the part with an expected 15MPa pressure drop. The overall temperature drop across the part of 1.2C was acceptable. Some weld lines and air traps were predicted. Warpage was expected in all directions, with the main area in the Z direction around 0.3mm. Hot spots were found on the slider side that may require additional cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

140 views22 pagesMoldflow Analysis Predicts 15MPa Pressure Drop for Small Part

Uploaded by

baominh007The analysis aimed to study flow and predict cycle time for part A1309-2. It found that the specified PP material would easily fill the part with an expected 15MPa pressure drop. The overall temperature drop across the part of 1.2C was acceptable. Some weld lines and air traps were predicted. Warpage was expected in all directions, with the main area in the Z direction around 0.3mm. Hot spots were found on the slider side that may require additional cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 22

Moldflow Analysis Report

Cool, Flow & Warp Analysis Of Small base Part

AG10-07, 07 JULY 2010 Page 1

Moldflow Analysis Report

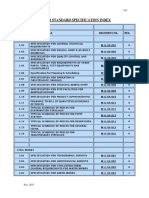

Contents

1. Summary 03

2. Material Properties 04

3. Part thickness 05 -06

4. Processing Condition & Runner Layout 07

5. Results 08 - 21

AG10-07, 07 JULY 2010 Page 2

Moldflow Analysis Report

Summary

ANALYSIS AIMS

To study the flow and predict the cycle time of the A1309-2 part.

ANALYSIS APPROACH

The cavity and the cold runner sections are modeled.

And a Fusion Cool + Flow + Warp analysis was conducted.

The specified material is PP (grade is specified BP RPP 2009 GK BLK, which is not listed in

the moldflow database, so we used Polypropylene PPC 5660 from TOTAL Petrochemicals) to

running the analysis .

This may effect the actual values obtained in the analysis (e.g. shrinkage values, pressure

requirements), but it can still be used to observe the general trends in the results (e.g. filling

pattern, warpage shape etc).

CONCLUSION

A pressure drop of 15MPa is expected across the system which indicating this material can

easy to fill this part.

The over all melt front temperature drop is C across the part, which is acceptable.

The weld lines might be visible to eye due to zero degree of two melt.

The part is expected to have warpage in X,Y,Z direction, the particular data of warpage please

refer to page 20 to 23.

The hot spots in the slider side due to the placement of the cooling channel, these area need

to add cooling circuit or beryllium insert if we can (refer to page 19).

AG10-07, 07 JULY 2010 Page 3

Moldflow Analysis Report

Material : PP

Similar Material

Trade Name: Polypropylene PPC 5660 Manufacturer : TOTAL Petrochemicals

Material Family: PP

Recommend processing temperature

Melt : 200C – 260C Mold : 20 C – 60 C

Characteristics : Amorphous Material Viscosity Index : VI(240)0111

others: Melt mass –Flow Rate(MFR)(230C/2.16kg) 7.0g/10min

Conductivity : 0.1762 W/m/C (at 230C)

Specific Heat : 2618.6 J/kg/ C (at 230 C)

Melt Density : 0.74577 g/cm^3

Absolute Max Temp : 300 C

Ejection Temperature : 95C

Max Shear Stress : 0.25MPa

Max Shear Rate : 100,000 l/s

PVT Plot

Viscosity Plot

AG10-07, 07 JULY 2010 Page 4

Moldflow Analysis Report

Part thickness

Use different color to show the thickness.

AG10-07, 07 JULY 2010 Page 5

Moldflow Analysis Report

Part thickness

Use different color to show the thickness.

AG10-07, 07 JULY 2010 Page 6

Moldflow Analysis Report

Processing Condition & Runner Layout

The Processing Conditions used was as

follows:

Filling Time : Auto, 4.6 sec.

Mold Temperature : 40 C

Melt Temperature : 230 C

Velocity/Pressure switchover at 98.5% volume fill

Packing Pressure : 80% of Max Injection Pressure

Hot Gate

size:

Ф2.5mm

AG10-07, 07 JULY 2010 Page 7

Moldflow Analysis Report

Filling Pattern

Fig 1 Fig 2

The last filling area

Fig 3 Fig 4

AG10-07, 07 JULY 2010 Page 8

Moldflow Analysis Report

Filling Time (Flash)

AG10-07, 07 JULY 2010 Page 9

Moldflow Analysis Report

Filling Time (Flash)

AG10-07, 07 JULY 2010 Page 10

Moldflow Analysis Report

Pressure drop

A pressure drop of 15MPa is expected across the system,

this indicated that the material is easy to fill this part.

AG10-07, 07 JULY 2010 Page 11

Moldflow Analysis Report

Temperature at flow front

The plastics material enters the runners at 230 C.

The overall temperature drop is about 1.2C,

which is acceptable.

AG10-07, 07 JULY 2010 Page 12

Moldflow Analysis Report

Weld Lines

The weld lines (color curve) might be visible to

eye, due to the zero degree of the two melts.

AG10-07, 07 JULY 2010 Page 13

Moldflow Analysis Report

Air traps

The air traps (pink mark ) location are as show.

AG10-07, 07 JULY 2010 Page 14

Moldflow Analysis Report

Cooling Channels : Temperature Rise

The coolant is specified as water at 25 C, and with turbulent flow in each channels

(Reynold Number = 10,000).

The outlet temperature of each channels is exceed 0.66C, this indicate the cooling

channels are efficient.

Cavity Core cooling

AG10-07, 07 JULY 2010 Page 15

Moldflow Analysis Report

Cooling Channels : Temperature Rise

Slider cooling

AG10-07, 07 JULY 2010 Page 16

Moldflow Analysis Report

Mould Surface Temperature

Total Cycle time: 105 sec.

( Auto Injection + Packing + Cooling Times = 100 sec. Mold open time = 5 sec.)

Core side

Cavity side

Hot spot

Slider Slider

AG10-07, 07 JULY 2010 Page 17

Moldflow Analysis Report

Warpage in X direction

AG10-07, 07 JULY 2010 Page 18

Moldflow Analysis Report

Warpage in Y direction

AG10-07, 07 JULY 2010 Page 19

Moldflow Analysis Report

Warpage in Z direction

AG10-07, 07 JULY 2010 Page 20

Moldflow Analysis Report

Warpage in Z direction

Z direction The main warpage area

3 gates, the warpage of Z direction just

reduce about 0.1mm compare to 1 gate.

AG10-07, 07 JULY 2010 Page 21

Moldflow Analysis Report

END

AG10-07, 07 JULY 2010 Page 22

You might also like

- Solar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsFrom EverandSolar Optical Materials: Applications & Performance of Coatings & Materials in Buildings & Solar Energy SystemsM. G. HutchinsNo ratings yet

- LG 42lh40ed (-Sa) 42lh45ed (-SB) Chassis Lj92jDocument76 pagesLG 42lh40ed (-Sa) 42lh45ed (-SB) Chassis Lj92jJose Fco. Aleman Arriaga100% (1)

- Vacuum CastingDocument23 pagesVacuum Castingdeep555820% (1)

- Part 1-Introduction Manufacturing - # 1Document53 pagesPart 1-Introduction Manufacturing - # 1mohan ladiNo ratings yet

- Gates Actros MP4 PDFDocument101 pagesGates Actros MP4 PDFSarl BprNo ratings yet

- Pe Actros - 2015Document86 pagesPe Actros - 2015Dan RosoiuNo ratings yet

- Mercedes Gearbox Replacement Parts CatalogDocument212 pagesMercedes Gearbox Replacement Parts Catalogmarcosluna68No ratings yet

- 3d Systems Cimatron 15 WhatsnewDocument4 pages3d Systems Cimatron 15 WhatsnewLily CuellarNo ratings yet

- MCP Rapid ToolingDocument14 pagesMCP Rapid ToolingsferrandNo ratings yet

- Konpar 2018 KatalogDocument92 pagesKonpar 2018 KatalogEndeveurs AlienNo ratings yet

- PDF Created With Pdffactory Pro Trial VersionDocument28 pagesPDF Created With Pdffactory Pro Trial Versionmasterpro666No ratings yet

- Noise From Front of CarDocument3 pagesNoise From Front of CarVrn SitaramNo ratings yet

- BumperDocument3 pagesBumperkerrenNo ratings yet

- Cam Design - Pt1Document29 pagesCam Design - Pt1JC ZayasNo ratings yet

- SAW D ManualDocument16 pagesSAW D ManualjlmansillaNo ratings yet

- Mercedes-Benz On Highway ApplicationDocument24 pagesMercedes-Benz On Highway Applicationfdpc1987100% (1)

- Aypars Radiator Hose CatalogueDocument131 pagesAypars Radiator Hose CatalogueAypars Spare PartsNo ratings yet

- Tool Based Micro MachiningDocument8 pagesTool Based Micro MachiningAnmol SatsangiNo ratings yet

- Unit 3 Vehicle and Their SpecificationsDocument48 pagesUnit 3 Vehicle and Their Specificationssiddh2805No ratings yet

- Arburg Multi-Component 522771 en GB PDFDocument16 pagesArburg Multi-Component 522771 en GB PDFmedamineNo ratings yet

- CETOL Tutorial Table PDFDocument27 pagesCETOL Tutorial Table PDFHenrique OliveiraNo ratings yet

- Tech Doc Def Iso22241 Jul2022Document1 pageTech Doc Def Iso22241 Jul2022Wael MohammedNo ratings yet

- Arocs 4146 K 8x4 en (5aa)Document3 pagesArocs 4146 K 8x4 en (5aa)Benjamin Musa ダNo ratings yet

- Ama WB NX PDFDocument36 pagesAma WB NX PDFirinaNo ratings yet

- Innovation by Aluminium Castings, KSM PDFDocument31 pagesInnovation by Aluminium Castings, KSM PDFsengcan100% (1)

- Manual 38731 PDFDocument79 pagesManual 38731 PDFMartín AlonsoNo ratings yet

- Dieffenbacher Product Catalog 052019 EN-minDocument73 pagesDieffenbacher Product Catalog 052019 EN-minЕвгений ТокаревNo ratings yet

- UPVC Window QuotationDocument7 pagesUPVC Window QuotationSàrthàk SrìvàstàvàNo ratings yet

- EPA04 MBE 900 Operator's Manual: DDC-SVC-MAN-0055Document121 pagesEPA04 MBE 900 Operator's Manual: DDC-SVC-MAN-0055АндрейNo ratings yet

- Z-DQ GuideDocument18 pagesZ-DQ GuideDragomir EleonoraNo ratings yet

- Power Assisted Gear ShiftingDocument25 pagesPower Assisted Gear ShiftingPramodPradhanNo ratings yet

- DesignTipsVol1 Web Download PDFDocument14 pagesDesignTipsVol1 Web Download PDFJeffNo ratings yet

- Wheel Hub Design DocumentationDocument4 pagesWheel Hub Design DocumentationPratikRoyNo ratings yet

- Mentor Graphics Procedure OverviewDocument49 pagesMentor Graphics Procedure Overviewsai prasadNo ratings yet

- Armi Truck Parts MercedesDocument294 pagesArmi Truck Parts MercedesArmi Otomotiv Truck PartsNo ratings yet

- Mesh Quality and Advenced VNDocument37 pagesMesh Quality and Advenced VNRE ACNo ratings yet

- Sheet Metal Design and Press Selection GuideDocument92 pagesSheet Metal Design and Press Selection GuideVishalNaranjeNo ratings yet

- AnyCasting PDFDocument26 pagesAnyCasting PDFSimon Risteski100% (1)

- Slam TestDocument17 pagesSlam Testtoyota952No ratings yet

- Deloitte Challenges of Additive ManufacturingDocument32 pagesDeloitte Challenges of Additive Manufacturingwachid yahyaNo ratings yet

- Intro To Tol Stack Up March2014 PDFDocument33 pagesIntro To Tol Stack Up March2014 PDFshaikameedNo ratings yet

- Voith History en 2016Document76 pagesVoith History en 2016khabiran100% (1)

- Auto Noise Vibration Harshness Analysis Full VehicleDocument5 pagesAuto Noise Vibration Harshness Analysis Full VehicleManeesh M KaimalNo ratings yet

- 004 GHB Oxy-Fuel Cutting TechniquesDocument191 pages004 GHB Oxy-Fuel Cutting TechniquesMilan DurcovicNo ratings yet

- Plasma Cutting AssignmentDocument7 pagesPlasma Cutting AssignmentMuziKhumalo0% (1)

- Introduction To Injection Mold Design: Learning ObjectivesDocument82 pagesIntroduction To Injection Mold Design: Learning ObjectivesVignesh WaranNo ratings yet

- 2016 Audi q3 71223 PDFDocument252 pages2016 Audi q3 71223 PDFSaša MarinNo ratings yet

- Begin Your Journey as a 3D Design Engineer with SOLIDWORKS TrainingDocument4 pagesBegin Your Journey as a 3D Design Engineer with SOLIDWORKS TrainingETSNo ratings yet

- Edu Cat e GSD FX V5R8Document150 pagesEdu Cat e GSD FX V5R8Madhusudhan D100% (3)

- Rail Interiors Magazine-2011Document84 pagesRail Interiors Magazine-2011Jaijith ...100% (2)

- SOLIDWORKS Inspection CMM Calypso PDFDocument5 pagesSOLIDWORKS Inspection CMM Calypso PDFJosephRomeraloNo ratings yet

- M35160 Ug Rev 3Document19 pagesM35160 Ug Rev 3FreezzbyNo ratings yet

- SC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHDocument60 pagesSC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHadrianahoukiNo ratings yet

- Design and Manufacturing of Special Purpose Machine For DrillingDocument4 pagesDesign and Manufacturing of Special Purpose Machine For DrillingInternational Journal of Innovative Science and Research Technology100% (1)

- Tutorial Gearbox 2012 enDocument33 pagesTutorial Gearbox 2012 enSathish KumarNo ratings yet

- Small Base Moldflow Analysis ReportDocument24 pagesSmall Base Moldflow Analysis ReportSreedhar PugalendhiNo ratings yet

- JI2048-977-MS-DAT-0041 - Rev002 (T-1020)Document9 pagesJI2048-977-MS-DAT-0041 - Rev002 (T-1020)Tech DesignNo ratings yet

- Baterias Concorde PDFDocument34 pagesBaterias Concorde PDFESAVENo ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet

- Giáo Trình NX Mold Wizard Design ProcessDocument156 pagesGiáo Trình NX Mold Wizard Design Processbaominh007No ratings yet

- An Optimization of Plastic Injection Mol PDFDocument6 pagesAn Optimization of Plastic Injection Mol PDFКонстантин ГавриловNo ratings yet

- NX 10 For Engineering Design PDFDocument207 pagesNX 10 For Engineering Design PDFAnonymous EVAzqFeburNo ratings yet

- Mold Layout: Professor Joseph GreeneDocument34 pagesMold Layout: Professor Joseph GreeneBa BuNo ratings yet

- An Optimization of Plastic Injection Mol PDFDocument6 pagesAn Optimization of Plastic Injection Mol PDFКонстантин ГавриловNo ratings yet

- Weld Lines PDFDocument6 pagesWeld Lines PDFbaominh007No ratings yet

- Moldex Six Successful Case Studies 2018Document34 pagesMoldex Six Successful Case Studies 2018baominh007No ratings yet

- Mould Cooling SystemDocument15 pagesMould Cooling SystemIqbal FauziNo ratings yet

- Part and Mold Design Guide (2005)Document174 pagesPart and Mold Design Guide (2005)naitikpanchal100% (4)

- Mitsubishi Molding PDFDocument17 pagesMitsubishi Molding PDFbaominh007No ratings yet

- Trouble Shooting For Injection Moulding 2014 PDFDocument24 pagesTrouble Shooting For Injection Moulding 2014 PDFchemikas8389No ratings yet

- Delrin Mold Guide 11 06Document48 pagesDelrin Mold Guide 11 06ibmufnman100% (2)

- 101 Plastic Injection Molding Engineering ManufacturingDocument3 pages101 Plastic Injection Molding Engineering Manufacturingbaominh007No ratings yet

- Injection Molding TroubleshootingDocument4 pagesInjection Molding Troubleshootingbaominh007No ratings yet

- 6 Defect Identification and Troubleshooting: 6.1 Defects TableDocument4 pages6 Defect Identification and Troubleshooting: 6.1 Defects Tablebaominh007No ratings yet

- 2.008 03im 05S PDFDocument13 pages2.008 03im 05S PDFsilversky09No ratings yet

- 6 Defect Identification and Troubleshooting: 6.1 Defects TableDocument4 pages6 Defect Identification and Troubleshooting: 6.1 Defects Tablebaominh007No ratings yet

- 01 BasicsDocument8 pages01 Basicsbaominh007No ratings yet

- 4plas Troubleshooting Guide Id111 PDFDocument12 pages4plas Troubleshooting Guide Id111 PDFJohn WayneNo ratings yet

- 500 câu luyện từ vựng - cô Mai Phương - Ngoại ngữ 24hDocument29 pages500 câu luyện từ vựng - cô Mai Phương - Ngoại ngữ 24hnguoitronggiangho2k1100% (1)

- Product Comparison Master RevisedDocument1 pageProduct Comparison Master Revisedbaominh007No ratings yet

- Mechanics - Fluid Dynamics: K. Suresh Senanayake 1Document2 pagesMechanics - Fluid Dynamics: K. Suresh Senanayake 1mangsureshNo ratings yet

- Production Range: EUROPIPE. The World Trusts UsDocument8 pagesProduction Range: EUROPIPE. The World Trusts UsIslam-Lotfi Hadj-ArabNo ratings yet

- Sub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)Document2 pagesSub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)estelauNo ratings yet

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedDocument3 pagesDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.No ratings yet

- Flamanville France Nuclear Power Plant WallchartDocument1 pageFlamanville France Nuclear Power Plant WallchartArzu AkarNo ratings yet

- R6.3 TR-XXL Parameter Settings ReleaseDocument493 pagesR6.3 TR-XXL Parameter Settings Releasemishu35No ratings yet

- Caliber Modulo PCM PinoutDocument7 pagesCaliber Modulo PCM PinoutManuel Suarez100% (3)

- ECU MS 3 Sport GT3 Cup Manual Setup GuideDocument26 pagesECU MS 3 Sport GT3 Cup Manual Setup GuideAngel LópezNo ratings yet

- Ncert Summary Class 12th PhysicsDocument29 pagesNcert Summary Class 12th Physicsmeghraj.socialNo ratings yet

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Document5 pagesCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723No ratings yet

- 937 Letter AttchamentDocument8 pages937 Letter AttchamentNeeta RautelaNo ratings yet

- Specification For Smoke Bomb Test PDFDocument4 pagesSpecification For Smoke Bomb Test PDFARUNNo ratings yet

- Ethics IndividualDocument3 pagesEthics IndividualJustin JJNo ratings yet

- Various Configurations of Co2 CaptureDocument16 pagesVarious Configurations of Co2 CaptureMaythee SaisriyootNo ratings yet

- Hydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Document22 pagesHydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Thulasidasan JeewaratinamNo ratings yet

- Programator Orar - 292555GB-03Document16 pagesProgramator Orar - 292555GB-03Daniel EneaNo ratings yet

- Lumidor Minimax XTDocument4 pagesLumidor Minimax XTPaky PakicNo ratings yet

- 42SL80 TrainingDocument93 pages42SL80 Trainingvmalvica67% (3)

- Spe 21970 MSDocument13 pagesSpe 21970 MSasu jaranNo ratings yet

- Enatel's microCOMPACT Power SystemDocument2 pagesEnatel's microCOMPACT Power SystemomarpatNo ratings yet

- Ceiling Mounted Chilled Water UnitDocument2 pagesCeiling Mounted Chilled Water UnitPrinces Katherine VergaraNo ratings yet

- Operation Manual - WSRF-50Document175 pagesOperation Manual - WSRF-50eduardo100% (2)

- WM2077CW Service ManualDocument44 pagesWM2077CW Service ManualMichael David SharkeyNo ratings yet

- Galcon ProductDocument69 pagesGalcon Productapi-36492444No ratings yet

- Sungris BrochureDocument8 pagesSungris Brochurechemasi123No ratings yet

- Universal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysDocument21 pagesUniversal Gen Controller Manual - Digital Display, 8 Inputs, 4 RelaysBrianHazeNo ratings yet

- Damper mechanism details for Atlas Copco rock drills under 40 charactersDocument27 pagesDamper mechanism details for Atlas Copco rock drills under 40 characterssalvador341100% (2)

- Scope of Work Doc-Fire Hydrant SystemDocument2 pagesScope of Work Doc-Fire Hydrant SystemMauliNo ratings yet

- SGP Chapter-1Document81 pagesSGP Chapter-1Shashank ReddyNo ratings yet