Professional Documents

Culture Documents

Types and Uses of Ropes on Ships

Uploaded by

Vijay Damley0 ratings0% found this document useful (0 votes)

74 views14 pagesRopes continue to play an important role on ships and come in various types. Natural fiber ropes are made by twisting fibers like manila, sisal or hemp into yarns and strands with opposite directions of lay. Synthetic ropes made of materials like nylon or polypropylene are stronger than natural fibers. Wire ropes are mainly used for cargo gear and cranes, consisting of wires, strands and a heart core. Proper maintenance of ropes is important to ensure coating and lubrication.

Original Description:

Original Title

Ropes.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRopes continue to play an important role on ships and come in various types. Natural fiber ropes are made by twisting fibers like manila, sisal or hemp into yarns and strands with opposite directions of lay. Synthetic ropes made of materials like nylon or polypropylene are stronger than natural fibers. Wire ropes are mainly used for cargo gear and cranes, consisting of wires, strands and a heart core. Proper maintenance of ropes is important to ensure coating and lubrication.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views14 pagesTypes and Uses of Ropes on Ships

Uploaded by

Vijay DamleyRopes continue to play an important role on ships and come in various types. Natural fiber ropes are made by twisting fibers like manila, sisal or hemp into yarns and strands with opposite directions of lay. Synthetic ropes made of materials like nylon or polypropylene are stronger than natural fibers. Wire ropes are mainly used for cargo gear and cranes, consisting of wires, strands and a heart core. Proper maintenance of ropes is important to ensure coating and lubrication.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 14

Ropes

Ropes of many different types and sizes have continued to play a

major role in the working of ships throughout history

In spite of modernization, ropes have not disappeared from ships

Today ropes are used for moorings, general purpose and LSA.

On cargo ships ropes are used for lifting gear

Ropes

Ropes are made from mainly 2 types of fibres

Natural and synthetic

All natural fibre rope is manufactured from manila, sisal, hemp,

coir, cotton or flax fibres.

The process of manufacture consists of twisting the fibres into

yarns and turning the yarns in an opposite direction to

establish the strands

Strands are laid into rope. Mainly ropes are right hand lay.

It is essential to realise that each of the components is turned

(twisted) up in an opposite direction to that of its

predecessor, e.g. in right-hand lay, strands are laid up right-

handed (clockwise), yarns laid up left-handed, and fibres laid

up right-handed.

There are many types of lays

Normally ships use 3 strand right hand lay ropes for general

purpose

Ropes

Synthetic ropes

Made from synthetic materials like Nylon, Polypropylene and

polyester.

They are much stronger than natural fibre ropes for same size

Ships use various lays of synthetic ropes

Ropes

Ropes

Synthetic Rope Advantages

Superior lifting/pulling strength versus natural fiber rope

Outstanding strength to weight ratio (ease of handling)

Pliant and grips the load well without marring surfaces

Electrically non-conductive (eliminates potential for

electrocution when used as tag line)

Inherently safer than wire rope with a breakage due to lighter

weight

Safe, cost-efficient alternative to wire rope for some

applications

Ropes

Synthetic Rope Disadvantages

Limited to light load applications

Exhibits substantial elongation under load

Looses strength when subjected to temperatures greater that 65

C

Melts when subjected to temperatures exceeding 150 C, friction

points for example

Ropes

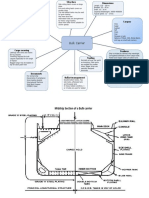

Wire ropes

Mainly used for cargo gear, lifeboats and engine room crane

A steel wire rope is composed of three parts wires, strands

and the heart.

The heart is made of natural fibre, though recently synthetic

fibre has been used when resistance to crushing is required.

Modern ropes are designed with specific tasks in mind and their

construction varies accordingly. However, all wire ropes are

affected by wear and bending, especially so when the ropes are

operated around drum ends or sheaves.

Ropes

Ropes

All wires should be governed by a planned maintenance system to

ensure that they are coated with lubricant at suitable intervals

throughout their working life. Internal lubrication will occur if

the wire has a natural fibre heart, for when the wire comes under

tension, the heart will expel its lubricant into the wires, so

causing the desired internal lubrication.

If synthetic material is used for the heart of a wire, this also

acts to reduce corrosion. Being synthetic, the heart is impervious

to moisture; consequently, should the rope become wet, any

moisture would be expelled from the interior of the wire as weight

and pressure are taken up.

Ropes

Ropes

Ropes

Ropes

Ropes

Thank You

You might also like

- Tahoe Magazine 2012-13Document166 pagesTahoe Magazine 2012-13Sierra Nevada Media GroupNo ratings yet

- Rigging KNOTSDocument13 pagesRigging KNOTSDexter FernandezNo ratings yet

- Knots and How To Tie Them Boy Scouts of Americapdf PDFDocument32 pagesKnots and How To Tie Them Boy Scouts of Americapdf PDFEulin RjayNo ratings yet

- Net Making Made Simple - A Guide to Making Nets for Sport and HomeFrom EverandNet Making Made Simple - A Guide to Making Nets for Sport and HomeNo ratings yet

- Catalogue Fall Protection EquipmentDocument2 pagesCatalogue Fall Protection EquipmentBea MokNo ratings yet

- Shell and Deck PlatingDocument22 pagesShell and Deck PlatingVijay DamleyNo ratings yet

- Shell and Deck PlatingDocument22 pagesShell and Deck PlatingVijay DamleyNo ratings yet

- Wire and Fiber Rope Guide for Safe Use & InspectionDocument20 pagesWire and Fiber Rope Guide for Safe Use & InspectionGabrielNo ratings yet

- Ship Building MaterialsDocument11 pagesShip Building MaterialsVijay DamleyNo ratings yet

- Week 4 Day 1 INTRO TO MOUNTAINEERINGDocument24 pagesWeek 4 Day 1 INTRO TO MOUNTAINEERINGPaola Pelle RosalNo ratings yet

- One Move Too Many-Injuries+Overuse Syndroms-2003Document117 pagesOne Move Too Many-Injuries+Overuse Syndroms-2003mr_raccoonNo ratings yet

- Illustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringFrom EverandIllustrated Seamanship: Ropes & Ropework, Boat Handling & AnchoringNo ratings yet

- Lifting and Crane Safety GuideDocument41 pagesLifting and Crane Safety GuideSarferi AbdullahNo ratings yet

- KnottingDocument29 pagesKnottingazeela22No ratings yet

- Marlinespike - Introduction: Types of Rope ConstructionDocument23 pagesMarlinespike - Introduction: Types of Rope Constructiondavidantis100% (1)

- Pedh-2122 Week 11-20 (Ama Source)Document42 pagesPedh-2122 Week 11-20 (Ama Source)Danrey De Castro Gutierrez58% (24)

- Rock Climbing Basics - VDiff ClimbingDocument13 pagesRock Climbing Basics - VDiff ClimbingVDiff ClimbingNo ratings yet

- How to Choose the Right Sewing ThreadDocument6 pagesHow to Choose the Right Sewing ThreadAshraf Ali0% (1)

- Army Mountain Warfare SchoolDocument222 pagesArmy Mountain Warfare Schooljcuscatuga100% (1)

- Yarns Fabric KnowledgeDocument15 pagesYarns Fabric Knowledgeishajain11No ratings yet

- Narrow Fabrics: G.Maheswaran Assistant Professor Department of Textile Technology PSG College of Technology CoimbatoreDocument22 pagesNarrow Fabrics: G.Maheswaran Assistant Professor Department of Textile Technology PSG College of Technology Coimbatoremahes_tex100% (2)

- Yarn Classification & TerminologyDocument82 pagesYarn Classification & TerminologyRAHUL16398No ratings yet

- On Ropes and CordagesDocument30 pagesOn Ropes and CordagesHimanshu Verma100% (2)

- 2 - DSM Notes Hoisting MechanismDocument13 pages2 - DSM Notes Hoisting MechanismsanketNo ratings yet

- WireRopeBasics ClassificationFeaturesDocument5 pagesWireRopeBasics ClassificationFeaturesbibin2010No ratings yet

- Knits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKDocument23 pagesKnits: - Prepared by - P.Lakshmana Kanth, Senior Faculty - IFTKP. LakshmanakanthNo ratings yet

- Touching The Void RevisionDocument8 pagesTouching The Void RevisionZeeshanAliNo ratings yet

- 1 - Ropes PDFDocument12 pages1 - Ropes PDFClarence PieterszNo ratings yet

- Fibre and Wire Ropes GuideDocument25 pagesFibre and Wire Ropes GuidesabeerNo ratings yet

- Shipboard Mooring Equipment: Course No. 12Document39 pagesShipboard Mooring Equipment: Course No. 12Dan CobeliNo ratings yet

- Rib KnitDocument21 pagesRib Knitn.t50% (2)

- Technological Developments in Yarn IndustryDocument28 pagesTechnological Developments in Yarn Industrymahek ajugiaNo ratings yet

- Knit Fabric ProcessingDocument42 pagesKnit Fabric Processingahmer adnan95% (21)

- Pinnacle Pull-Off Boulder IngDocument6 pagesPinnacle Pull-Off Boulder Ingjut780No ratings yet

- Classification of Yarns PDFDocument27 pagesClassification of Yarns PDFArvindhanRathinaswamy100% (1)

- TRT Class 03 Rope Construction & Knots PDFDocument51 pagesTRT Class 03 Rope Construction & Knots PDFromanNo ratings yet

- MD Mazbah Uddin Bangladesh University of Textiles Yarn Engineering Department Batch 08Document48 pagesMD Mazbah Uddin Bangladesh University of Textiles Yarn Engineering Department Batch 08AliaNo ratings yet

- Beep 6 Unit 5Document30 pagesBeep 6 Unit 5Robert Smith Acaro Castillo100% (4)

- MontserratDocument69 pagesMontserratencadenaravistaNo ratings yet

- Climbing PortugalDocument11 pagesClimbing Portugalhattori_gonzo0% (1)

- RopesDocument34 pagesRopesabhishekverma86No ratings yet

- Rope WorkDocument5 pagesRope WorkcommandoNo ratings yet

- Fibre Ropes, Knots, HitchesDocument26 pagesFibre Ropes, Knots, HitchesMaricris de GuzmanNo ratings yet

- Ropes and Wires Construction GuideDocument21 pagesRopes and Wires Construction GuideJames MonishNo ratings yet

- ROPES AND WIRES GUIDEDocument13 pagesROPES AND WIRES GUIDEPrinceNo ratings yet

- RopesDocument2 pagesRopesPetralina NaibahoNo ratings yet

- تقرير فاينل صناعية ١Document9 pagesتقرير فاينل صناعية ١سجاد المالكيNo ratings yet

- Derivatives of Warp KnittingDocument19 pagesDerivatives of Warp KnittingVikash KumarNo ratings yet

- Conveyor BeltDocument54 pagesConveyor BeltDhruv PanchalNo ratings yet

- Integrated Term Project: Submitted By: Nikhil Sharma Seemta ChoudharyDocument24 pagesIntegrated Term Project: Submitted By: Nikhil Sharma Seemta ChoudharyNikhil Sharma75% (4)

- Deck-Equipment-And-Marlinspike-Seamanship Week 8Document36 pagesDeck-Equipment-And-Marlinspike-Seamanship Week 8Hannah DuyagNo ratings yet

- Sewing ThreadDocument55 pagesSewing Threadচৌদ্দগ্রাম পৌর আমজনতা0% (1)

- AGV & RopesDocument48 pagesAGV & RopesSaru ArjunanNo ratings yet

- Staple or FilamentDocument30 pagesStaple or Filamentapi-232403733No ratings yet

- Novelty Yarns FundamentalsDocument37 pagesNovelty Yarns FundamentalsRS DEVAJATHANo ratings yet

- Staple or Filament1Document29 pagesStaple or Filament1Vachan Abhilekh ThakurNo ratings yet

- Understanding Wire Rope Components and ConstructionDocument12 pagesUnderstanding Wire Rope Components and ConstructionZachNo ratings yet

- Ropes, Wires & Chains GuideDocument8 pagesRopes, Wires & Chains GuideArunim ChandolaNo ratings yet

- Woven Fabric Formation Technique - Part 1Document29 pagesWoven Fabric Formation Technique - Part 1ramstexNo ratings yet

- Cast Net GlossaryDocument1 pageCast Net GlossaryklingonNo ratings yet

- Threads: Training & Development/Od Shahi Exports PVT LTDDocument30 pagesThreads: Training & Development/Od Shahi Exports PVT LTDVarun MehrotraNo ratings yet

- Special YarnDocument42 pagesSpecial YarnMd. Nasir UddinNo ratings yet

- Sewing ThreadsDocument18 pagesSewing ThreadsSahlu Klemewerk DagetNo ratings yet

- SEAMANSHIP (1 and 2)Document11 pagesSEAMANSHIP (1 and 2)Maria Kris Joaquin Capati100% (1)

- MarlinspikeDocument30 pagesMarlinspikeMitchell WillieNo ratings yet

- Rigging and HoistingDocument106 pagesRigging and HoistingLijo JohnNo ratings yet

- JNEC Man-Made Fibers GuideDocument23 pagesJNEC Man-Made Fibers GuideKhushboo ThakurNo ratings yet

- General Information On Ropes in Underground MiningDocument4 pagesGeneral Information On Ropes in Underground Miningntyba16No ratings yet

- Canada Cordage Inc-RopeDocument7 pagesCanada Cordage Inc-RopeTagor SianiparNo ratings yet

- Sewing Thread Types and CharacteristicsDocument10 pagesSewing Thread Types and CharacteristicsKhurram IftikharNo ratings yet

- Simpul & IkatanDocument47 pagesSimpul & IkatannewrainNo ratings yet

- 08 Wrap - YarnDocument39 pages08 Wrap - YarnShashwata BhowmikNo ratings yet

- YARN and Its PropertiesDocument49 pagesYARN and Its PropertiesYongho LouisNo ratings yet

- Salvage & Its TypeDocument12 pagesSalvage & Its Typerashmi jainNo ratings yet

- MS2 Chapter 3Document41 pagesMS2 Chapter 3Bacquial, Phil Gio E. (Phil Gio)No ratings yet

- Structure and features of bulk carriersDocument2 pagesStructure and features of bulk carriersVijay Damley100% (1)

- Ship Hull Definitions GuideDocument19 pagesShip Hull Definitions GuideVijay DamleyNo ratings yet

- RopesDocument14 pagesRopesVijay DamleyNo ratings yet

- Ship Hull Definitions GuideDocument19 pagesShip Hull Definitions GuideVijay DamleyNo ratings yet

- IMU GSK IntroductionDocument53 pagesIMU GSK IntroductionVijay DamleyNo ratings yet

- IMU Load Line MarkingsDocument16 pagesIMU Load Line MarkingsVijay DamleyNo ratings yet

- IMU Load Line MarkingsDocument16 pagesIMU Load Line MarkingsVijay DamleyNo ratings yet

- IMU GSK IntroductionDocument53 pagesIMU GSK IntroductionVijay DamleyNo ratings yet

- Chartwork Q1Document1 pageChartwork Q1Vijay DamleyNo ratings yet

- Youth & Adventure TourismDocument18 pagesYouth & Adventure TourismSaurabh GanganiNo ratings yet

- The Story of Aged Mother: A Japanese Folktale Conveyed Through MusicDocument6 pagesThe Story of Aged Mother: A Japanese Folktale Conveyed Through MusicWensky RagpalaNo ratings yet

- Answer Keys: Richmond Practice Tests For FlyersDocument6 pagesAnswer Keys: Richmond Practice Tests For FlyerssirkhuongNo ratings yet

- Unit 4 Voices 3Document4 pagesUnit 4 Voices 3Anonymous 7xhhVAWCXNo ratings yet

- TechDocument49 pagesTechAgostefNo ratings yet

- B52 InstDocument2 pagesB52 InstDougNewNo ratings yet

- MountaineeringDocument2 pagesMountaineeringRochie RoasaNo ratings yet

- ACTIVITY 2 - MountaineeringDocument4 pagesACTIVITY 2 - MountaineeringMhyka CandelariaNo ratings yet

- Halimbawa NG Mga Larong PinoyDocument5 pagesHalimbawa NG Mga Larong Pinoykikhay11No ratings yet

- Extreme SportDocument7 pagesExtreme SportharsimranbhullarNo ratings yet

- Student's Book Answer KeyghgbDocument51 pagesStudent's Book Answer KeyghgbYaskoNo ratings yet

- Colorado Fun FactsDocument2 pagesColorado Fun FactsDenverCOHomeNo ratings yet

- Video Worksheet 1ADocument2 pagesVideo Worksheet 1ATeng Savat Vathanak តេង សាវ៉ាតវឌ្ឍនៈNo ratings yet

- An Extraordinaire Expedition To Buaya Sangkut Waterfall, Endau-Rompin National Park, Johor Darul TakzimDocument9 pagesAn Extraordinaire Expedition To Buaya Sangkut Waterfall, Endau-Rompin National Park, Johor Darul TakzimEmran Mohd TamilNo ratings yet

- SDP Apti PaperDocument5 pagesSDP Apti PaperpankimehtaNo ratings yet

- Rezolvari EnglezaDocument6 pagesRezolvari EnglezaAna Maria RusuNo ratings yet

- Europa: Swing Parts ListDocument1 pageEuropa: Swing Parts ListIshmael WoolooNo ratings yet