Professional Documents

Culture Documents

Perencanaan Tambang

Uploaded by

Ersyad Fikriansyah0 ratings0% found this document useful (0 votes)

36 views19 pagesperencanaan tambang

Original Title

PERENCANAAN TAMBANG

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentperencanaan tambang

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views19 pagesPerencanaan Tambang

Uploaded by

Ersyad Fikriansyahperencanaan tambang

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 19

EKI MARUCI 1202070

MARDHATILLAH AULIA 1203146

IKKE PUTRA LANDUPA 1206356

FIKRIANSYAH ERSYAD 1206358

SRI YANA RAHMAWATI 1206366

WIKE AFLIZA RAHMAWATI 1206368

RIDHO YOVANDA 1209514

Introduction Functional Design

Wearing Course Material Selection

Placement and Compaction

The Selection and Application Of Dust Palliatives

Wearing Course

This is the layer of material on the top of the road - also called

surfacing or sheeting. For mine roads it is often an (unbound) gravel

mixture - but exactly what that mixture comprises is important -

because the wearing course controls how the road performs and how

the road-user interacts with the road (skid resistance, traction, etc.).

Both safety and productivity are influenced by the wearing course

'performance'. When a road is 'maintained' or bladed (scraped), it is

the wearing course we work with, to restore it to its original

condition and remove surface defects which, in part, contribute to

rolling resistance. Selection and placement of this layer is based on

the Functional Design Specifications.

Wearing course selection and blending

Critical Service Defects

Rolling Resistance Progression

Maintenance Frequency Suitable

Desain fungsional dipusatkan pada pemilihan pemakaian

jalan yang dipilih sesuai dengan persyaratannya dimana

untuk memperkecil rate of Degeneration, atau

peningkatan Rolling Resistance di permukaan jalan.

A road with many defects often has a high

rolling ressitance

Spesifikasi Desain Fungsional dipusatkan pada lapisan pemakaian

jalan. Material yang digunakan adalah Kompak.

Tujuan Functional Design untuk mengurangi Rolling Resistance

- Permasalahan yang sering timbul dalam Fungsional Desain ( Misal

: poorly,soft, too loose layer (Friable atau ravelling).

Ketebalan dalam penimbunan lapisan : 200 mm.

Tampilan batuan yang baik dalam proses penghancuran

untuk digunakan, ukurannya lebih kecil dari 40 mm dan

tidak begitu halus ( lolos ayakan kurang dari 20 % atau

lebih halus kurang dari 0.425 mm ).

Terlihat tidak adanya ikatan yang halus diantara

material.

Ketika material dipadatkan, material tersebut tidak

akan saling menyatu.

Material yang identik digunakan berupa kerikil atau campuran batuan yang telah

di crusher yang disetarakan pada pertimbangan safety,

operasional,lingkungan,dan ekonomi.

Material yang digunakan memiliki Rolling Resistance kecil dan Koeffisisen daya

rekat yang tinggi.

Persyaratan ideal dalam Pembangunan jalan angkut Tambang

Mampu menyediakan keadaan yang aman dalam penggunaan kendaraan tanpa

membutuhkan perbaikan yang berlebihan

Mampu berkendara dalam kondisi basah dan kering

Mampu dalam menampung air tanpa erosi yang berlebih

Tahan terhadap perilaku pengupasan jalan

Bebas dari debu yang berlebihan dalam cuaca panas

Bebas dari licin yang berlebihan dalam cuaca hujan

Low cost dan pemeliharaannya mudah

Meminimalisir pengaruh Kerusakan yang paling umum

dijumpai dalam jalan angkut tambang yang identik

dengan :

Tahanan Gelincir (slip ) Basah

Tahanan Gelincir (slip) - Kering

Masalah Debu

Material lepas

Jalan Bergelombang

Jalan Berbatu Lepas

Jalan Berlubang

Jalan Berjejak

Jalan Berbatu terikat

Jalan Retak - licin

Moisture ontent and Compaction

In the case of the wearing course (and other

layerworks), the material(s) used here possess

optimum densities that ensure adequate

support, stability, and strength.

As the wearing course compacts, the voids are

reduced and this causes the dry density to

increase to a point, but then fall because

achievable compaction is limited by the volume

occupied by pore water (the zero air void line

(ZAV)). There is not time during compaction for

water to be squeezed out. When the wearing

course or other constructed layer approaches the

ZAV line (which gives the maximum dry density

for a given moisture content), a maximum dry

density is reached and the moisture content at

this maximum is called the optimum moisture

content (OMC).

Pengurangan emisi debu dapat dilakukan dengan penyemprotan air, namun banyak

memberikan dampak dari segi kelangkaan dan erosi yang ditimbulkan, dan tingkat

penguapan yang tinggi.

Penyiraman lebih efektif menggunakan semprot-bar dan nozel dipasang dekat dengan

permukaan jalan (0.5litres / m2).

Results can be further improved by:

integrating truck speed with water delivery rate, to prevent over-watering

ramps, etc; and

using a 50m on 50m off (intermittent) spray pattern on the roads and

allowing truck tyres to carry water over to the dry section. This also

improves safety on ramp segments, especially on down grade higher

speed hauls where the truck may be in retard and skid resistance is at a

premium.

Jika dilihat lebih dekat bagaimana debu terbentuk di jalan tambang,

Debu dihasilkan melalui proses mengudaranya material halus.

Jumlah debu yang akan dihasilkan berasal dari dua factor :

spray-on application with deep penetration (the ability to penetrate compacted

materials), or mix-in applications with minimal site preparation (rip, mix-in and

recompact);

straight-forward applications requiring minimal supervision, not sensitive nor requiring

excessive maintenance or closely controlled re-applications;

the road should be trafficable within a maximum of 24 hours (short product curing

period);

availability in sufficient quantity at reasonable prices;

adequate proven or guaranteed durability, efficiency and resistance to deterioration by

leaching, evaporation, ultra-violet light and chemical reaction with wearing course or

spillage on road;

effective over both wet and dry seasons;

evaluated against local and international safety standards and environmentally

acceptable.

You might also like

- LANDSATDocument22 pagesLANDSATErsyad FikriansyahNo ratings yet

- MAGMATIKDocument50 pagesMAGMATIKErsyad FikriansyahNo ratings yet

- Tugas 02 Ganesa MineralDocument8 pagesTugas 02 Ganesa MineralErsyad FikriansyahNo ratings yet

- Tugas-1 Mineralogi Dan Kosentrasi Mineral PDFDocument45 pagesTugas-1 Mineralogi Dan Kosentrasi Mineral PDFErsyad FikriansyahNo ratings yet

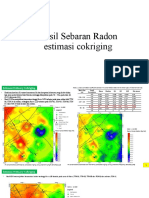

- Hasil Sebaran Radon Estimasi CokrigingDocument5 pagesHasil Sebaran Radon Estimasi CokrigingErsyad FikriansyahNo ratings yet

- Cover BPJS Kesehatan FixDocument2 pagesCover BPJS Kesehatan FixErsyad FikriansyahNo ratings yet

- TUGAS 03 Geostatistik - Fikriansyah Ersyad - 22119304Document11 pagesTUGAS 03 Geostatistik - Fikriansyah Ersyad - 22119304Ersyad FikriansyahNo ratings yet

- 2020 TA5103 Materi 00 SAPDocument16 pages2020 TA5103 Materi 00 SAPErsyad FikriansyahNo ratings yet

- Parameter Inversi TEM SEMUADocument17 pagesParameter Inversi TEM SEMUAErsyad FikriansyahNo ratings yet

- Tugas 02 Ganesa MineralDocument8 pagesTugas 02 Ganesa MineralErsyad FikriansyahNo ratings yet

- Tugas-1 Mineralogi Dan Kosentrasi Mineral PDFDocument45 pagesTugas-1 Mineralogi Dan Kosentrasi Mineral PDFErsyad FikriansyahNo ratings yet

- Tugas 01 Geostatistik - Fikriansyah ErsyadDocument36 pagesTugas 01 Geostatistik - Fikriansyah ErsyadErsyad FikriansyahNo ratings yet

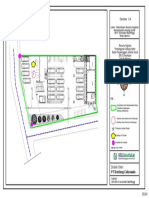

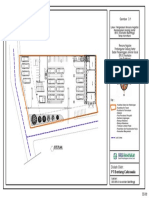

- Gambar 3.4 - III 85 Peta UPL OperasiDocument1 pageGambar 3.4 - III 85 Peta UPL OperasiErsyad FikriansyahNo ratings yet

- Gambar 3.1 - III 82 Peta UKL KonstruksiDocument1 pageGambar 3.1 - III 82 Peta UKL KonstruksiErsyad FikriansyahNo ratings yet

- MATRIK UKL-UPL BPJS Kesehatan BukittinggiDocument20 pagesMATRIK UKL-UPL BPJS Kesehatan BukittinggiErsyad FikriansyahNo ratings yet

- Gambar 3.1 - III 82 Peta UKL KonstruksiDocument1 pageGambar 3.1 - III 82 Peta UKL KonstruksiErsyad FikriansyahNo ratings yet

- Kata PengantarDocument1 pageKata PengantarErsyad FikriansyahNo ratings yet

- Gambar 3.1 - III 82 Peta UKL KonstruksiDocument1 pageGambar 3.1 - III 82 Peta UKL KonstruksiErsyad FikriansyahNo ratings yet

- Bab Iv-IpplhDocument1 pageBab Iv-IpplhErsyad FikriansyahNo ratings yet

- UKL-UPL Gedung BPJSDocument6 pagesUKL-UPL Gedung BPJSErsyad FikriansyahNo ratings yet

- TAMBANG TIMAHDocument20 pagesTAMBANG TIMAHNanda Dwi CahyaNo ratings yet

- Bab I-Pendahuluan NewDocument8 pagesBab I-Pendahuluan NewErsyad FikriansyahNo ratings yet

- Bab IiDocument7 pagesBab IiErsyad FikriansyahNo ratings yet

- Curah Hujan Tahun 2012Document8 pagesCurah Hujan Tahun 2012Ersyad FikriansyahNo ratings yet

- Metoda Pembuatan Blok ModelDocument1 pageMetoda Pembuatan Blok ModelErsyad FikriansyahNo ratings yet

- Bab I PendahuluanDocument34 pagesBab I PendahuluanErsyad FikriansyahNo ratings yet

- TAMBANG TIMAHDocument20 pagesTAMBANG TIMAHNanda Dwi CahyaNo ratings yet

- Bab I PendahuluanDocument5 pagesBab I PendahuluanErsyad FikriansyahNo ratings yet

- 7 Daftar IsiDocument2 pages7 Daftar IsiErsyad FikriansyahNo ratings yet