Professional Documents

Culture Documents

Single Phase Flow Line Sizing

Uploaded by

victorvikram0 ratings0% found this document useful (0 votes)

127 views21 pagesA presentation providing the fundamentals of single-phase line sizing.

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA presentation providing the fundamentals of single-phase line sizing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

127 views21 pagesSingle Phase Flow Line Sizing

Uploaded by

victorvikramA presentation providing the fundamentals of single-phase line sizing.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 21

Single-phase fluid flow

GUIDELINE TO PIPE SIZING FOR SINGLE-PHASE FLOW

AUTHOR: VIKRAM SHARMA

DATE: 7th MARCH 2017

Table of Contents

Introduction

Bernoullis Equation

Friction factor graph

Pressure Drop in Pipe and Fittings

Recommended fluid velocities

Calculation Methodology

References

Introduction

Pipeis a common sight in chemical plant

Pipework & fittings:

20-30% of the total design cost;

10-20% of the total plant investment; and

Other added cost due to maintenance req. & energy

usage in the form of P in the fluids being pumped

Thesize of a pipe (diameter) is expressed in

two ways that are:

Nominal Pipe Size (NPS); and

Diametre Nominal (DN)

NPS is measured in inches, DN is measured in

mm

DN is generally equiv. to NPS multiplied by 25

Introduction (contd)

DNis generally equiv. to NPS multiplied by 25

except:

NPS is DN15

NPS 3 is DN80

Pipe size are designated by two numbers that

are (i) pipe diameter and (ii) thickness

Pipe diameter is generally associated with inside

dia.

Outside dia. is the same for a given size

maintain certain interchangeability of pipe

fittings

NPS 14 and beyond, it is equal to the outside dia.

(OD) in inch.

Introduction (contd)

NPS 14 and beyond, it is equal to the outside

dia. (OD) in inch. (contd)

Pipe wall thickness is referred to pipe

schedule (Sch)

Standardize from 5 to 160 determined by

the service req. like Pressure, Temp., Flow

and corrosion

Pipe wall thickness Pipe Schedule

Bernoullis Equation

P or head loss in a piping system is caused by:

Elevation;

Friction;

Shaft work; and

Turbulence due to sudden change in direction or cross

sectional area

Mechanical Energy Balance (MEB) eq. conservation

of sum of pressure, kinetic and potential energies,

net heat transfer (q), work done by the system (w)

and frictional energy (ef).

efis usually +ve & represents the rate of irreversible

conversion of mech. energy into thermal energy

Sometimes called head loss, friction loss or frictional

pressure drop.

Bernoullis Equation

(contd)

Bernoullis Equation

(contd)

The first 3 terms (pressure, velocity &

elevation) are point functions depend

only on conditions at the inlet & outlet of the

system

w and ef are path functions depend on

what is happening to the system between

the inlet and outlet points

ef loss due to friction and includes losses due

to flow through lengths of pipe, fittings such

as elbows, valves, orifices and pipe

entrances and exits

Bernoullis Equation

(contd)

Kf is the excess head loss due to pipe or pipe

fittings, v is the fluid velocity

Fluids flowing through pipes;

P is the same due to flow is the same

whether the pipe is horizontal, vertical or

inclined

Friction factor

Friction factor is expressed as Moody friction

factor (fM) or Fanning friction factor (fF).

fM = 4fF

Friction factor (contd)

Laminar region (or viscous): Re < 2,000

Critical zone is the transition frm. laminar

to turbulent: 2,000 < Re < 4,000.

Turbulent flow: Re > 4,000

Friction factor is laminar region is not affected

by the relative roughness (/D) but it is

influenced by the fluid viscosity

Friction factor at transition region strongly

depends on both the Re and /D

Friction factor at turbulent region is

independent of Re and is a function of

relative roughness (/D).

Friction factor (contd)

Friction

factor can be computed using two

equations based on the fluid flow regime.

Laminar flow (Re < 2,000) :

Turbulent flow (Re > 4,000):

Reynolds Number:

fD = Darcy friction factor

= Absolute pipe roughness (m):

Carbon Steel = 0.02-0.05 mm

Stainless steel = 0.03 mm

D = Pipe inner diameter (m)

= Fluid density (kg/m3)

= Dynamic viscosity (Ns/m2)

Friction factor (contd)

Colebrooks equation require iteration to

determine the friction factor.

Author propose Churchill (1977) equation

that allows engineers to determine the

friction factor for both laminar and turbulent

flows.

Pressure Drop in Pipe and

Fittings

P

for straight pipe run:

Pressure drop for fittings can be computed

using resistance coefficient method (K).

This could be done via Darby 3-K method for

fittings

Why Darby 3-K method is preferred?

Accounts directly for the effect of both Re & fitting

size on the loss coefficient.

Pressure Drop in Pipe and

Fittings (contd)

Other option: The Equivalent Length Method (Leq/D)

The Leq/D method assumes that:

Size of fittings of a given type can be scaled corresponding to a given dia.

Reynolds number on the friction loss is the same as the pipe loss

The above assumptions are incorrect. Why?

The laminar or turbulent flow within a valve or a

fitting is generally quite different from that of

straight pipe.

With this, there is an uncertainty when determining

the effect of Re on the loss coefficients.

Leq/D method does not account for the lack of exact

scaling for valves and fittings

Pressure Drop in Pipe and

Fittings (contd)

For Darby 3-K constants, refer to:

https://neutrium.net/fluid_flow/pressure-loss-from-f

ittings-3k-method/

For

other fittings such as sudden pipe

contractions, square reduction, tapered

reduction, sharp orifice, square expansion,

tapered expansion, thick orifice and pipe

reduce, refer to Coker (2007)

Recommended fluid velocities

Typical velocities and pressure drop:

Liquid (pumped, not viscous): 1-3 m/s, 0.5 kPa/m

Liquid (gravity flow): - m/s , 0.05 kPa/m

Gases & vapours: 15-30 m/s, 0.02 % of the line

pressure

HP steam (> 8 bar): 30-60 m/s, - kPa/m

Typical

velocities at pump suction and

discharge lines:

Recommended fluid velocities

(contd)

Typicalvelocities and pressure drop for

single-phase gas process lines:

Calculation Methodology

Obtain the piping layout from PFD, P&IDs or Piping

Isometrics

Obtain data at fluid inlet of the pipe corresponding to

inlet temperature and pressure. Info req. are mass

flow, , , T & P.

Select a pipe size and material (Refer to Slide #5)

Calc. the fluid velocity. Ensure it comply with the fluid

req. (Refer to Slide #17)

Calc. Re Laminar or Turbulent (Refer to Slide #12)

Calc. the fD Churchills (1977) eq. (Refer to Slide

#13)

Calc. the Pbar/100m of the straight pipe. Include

elevation (Refer to Slide #14).

Calc. Pbar by multiplying with pipe straight length

Calculation Methodology (contd)

Calc. P of fittings. Use Darby 3-K method and

Coker (2007) (Refer to Slide #16 and Slide

#14)

Calc. P of other items such as process

equipment etc.

Calc. the total pressure drop of the system (P)

PT = Pfriction + Pfittings + Pother items

Check if downstream pressure P2 is as per

specifications.

P2 = P1 - PT

Ifnot, repeat the above calc. by selecting a

different pipe size

References

Bahadori, A. (2014). Process pipe sizing for plants

location. In Natural Gas Processing: Technology and

Engineering Design (p. 83). Oxford: Gulf Professional

Publishing.

Murty, K. K. (2010). Sizes, Schedules, And Standards.

In All-in-One Manual of Industrial Piping Practice and

Maintenance On-The-Job Solutions, Tips and Insights

(p. 52). New York: Industrial Press.

Native Dynamics. (2012, May 19). Neutrium. Retrieved

March 7, 2017, from Absolute Roughness of Pipe

Material: https://neutrium.net/fluid_flow/absolute-

roughness/

Sinnot, R. K. (2005). Piping and Instrumentation. In

Chemical Engineering Design (Vol. 6, p. 218). Oxford:

Elsevier.

You might also like

- Project Engineering Change Management ProcedureDocument17 pagesProject Engineering Change Management Procedurevictorvikram100% (1)

- Computer Application in Hydraulic Engineering-7th EditionDocument4 pagesComputer Application in Hydraulic Engineering-7th Editionkawser zaman0% (1)

- PromaxDocument20 pagesPromaxehsan_sa405100% (1)

- Jacket-Side Nusselt Number: Isaac LehrerDocument6 pagesJacket-Side Nusselt Number: Isaac LehrerJimmy Miranda100% (1)

- Simple Dew Point Control With Propane Loop For Chilling (HYSYS V8.6)Document32 pagesSimple Dew Point Control With Propane Loop For Chilling (HYSYS V8.6)JesusNo ratings yet

- EN 1092-1-Flange PDFDocument18 pagesEN 1092-1-Flange PDFSimona Adriana100% (1)

- Dimensional Analysis of Pipe Flow PDFDocument34 pagesDimensional Analysis of Pipe Flow PDFuzair shakeelNo ratings yet

- Knock Out Drums and SeparatorsDocument2 pagesKnock Out Drums and SeparatorsAhmed RedaNo ratings yet

- Lecture 5 - Materials Selection For Pipings - 99Document80 pagesLecture 5 - Materials Selection For Pipings - 99shahin azNo ratings yet

- Line Sizing SlidesDocument24 pagesLine Sizing Slideskrishna106738100% (1)

- Korf BrochureDocument1 pageKorf Brochurelhphong021191No ratings yet

- Code General Design GuideDocument12 pagesCode General Design Guidec_nghiaNo ratings yet

- Hydrogen Storage 2Document18 pagesHydrogen Storage 2JoostGoNo ratings yet

- High Gas Volume Vertical Knock-Out Drum Liquid RemovalDocument3 pagesHigh Gas Volume Vertical Knock-Out Drum Liquid RemovalArynda Dimas SadewoNo ratings yet

- Viscous Flow in Pipes: OverviewDocument40 pagesViscous Flow in Pipes: OverviewPaulo BuenoNo ratings yet

- Flow Assurance IntroductionDocument71 pagesFlow Assurance IntroductionClement ChimaNo ratings yet

- Equivalent MethodDocument8 pagesEquivalent MethodAjaykumar TiwariNo ratings yet

- Boiler Water Treatment: Deposit ControlDocument5 pagesBoiler Water Treatment: Deposit ControlKrishna RayuduNo ratings yet

- Velocity and Pressure Drop in PipesDocument5 pagesVelocity and Pressure Drop in PipesManojkumar ThilagamNo ratings yet

- Gas Hydraulic PipelineDocument5 pagesGas Hydraulic PipelineJuanNo ratings yet

- Technical & economical comparison of multi-phase meters vs test separatorsDocument10 pagesTechnical & economical comparison of multi-phase meters vs test separatorsPovenesan KrishnanNo ratings yet

- Flow AssuranceDocument10 pagesFlow Assurancesri9987No ratings yet

- Chlorine PropertiesDocument16 pagesChlorine PropertiesVel MuruganNo ratings yet

- Hydraulic Study of GRE Piping Using Pipenet SimulationDocument5 pagesHydraulic Study of GRE Piping Using Pipenet SimulationpsycopaulNo ratings yet

- Vibration Analysis 2Document6 pagesVibration Analysis 2Loxman ZahariNo ratings yet

- GoyalDocument3 pagesGoyalVan LeNo ratings yet

- طراحی پایپینگ اطراف پمپ هاDocument25 pagesطراحی پایپینگ اطراف پمپ هاMorteza DianatfarNo ratings yet

- BDV to Flare System SizingDocument4 pagesBDV to Flare System SizingIOCPC100% (1)

- Efficient slug catcher separates two-phase flow under 40 charsDocument3 pagesEfficient slug catcher separates two-phase flow under 40 charswkhan_55No ratings yet

- Design Shell TubeDocument3 pagesDesign Shell TubeAKSHEYMEHTANo ratings yet

- Interview Questions 1 TCSDocument3 pagesInterview Questions 1 TCSSrinivas TumpalaNo ratings yet

- Design Memorandum For LP Chemcial Dosing System (Rev-1)Document12 pagesDesign Memorandum For LP Chemcial Dosing System (Rev-1)suparnabhoseNo ratings yet

- Gas/Liquid Separators: Quantifying Separation Performance - Part 1Document10 pagesGas/Liquid Separators: Quantifying Separation Performance - Part 1sara25dec689288No ratings yet

- PSV SizingDocument18 pagesPSV SizingGo IELTSNo ratings yet

- Indus - PGD Process Design EngineeringDocument2 pagesIndus - PGD Process Design EngineeringAmarjeet SandhuNo ratings yet

- Models - Ssf.convection Porous MediumDocument10 pagesModels - Ssf.convection Porous MediumArih FadiNo ratings yet

- 05 OilCharacterizationDocument16 pages05 OilCharacterizationMohammed Abubakar EllemanNo ratings yet

- Design Review of AbsorbersDocument46 pagesDesign Review of AbsorbersAngelik MoralesNo ratings yet

- Heat Transfer Equipment 1. Heat ExchangersDocument44 pagesHeat Transfer Equipment 1. Heat ExchangersInamullah KhanNo ratings yet

- Process and Instrumentation Diagram Development for Water and Waste Water TreatmentDocument14 pagesProcess and Instrumentation Diagram Development for Water and Waste Water TreatmentATUL SONAWANENo ratings yet

- Models For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationDocument11 pagesModels For Analysis of Water Hammer in Piping With Entrapped Air - Chaiko - 2002 - PPL CorporationElias TascaNo ratings yet

- CE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasDocument41 pagesCE4105 Surface Production Operations: Operasi Produksi Permukaan Hidrokarbon / Operasi Hulu Minyak Dan GasRickyWisaksonoNo ratings yet

- Pipline EngineerDocument19 pagesPipline Engineermohammed9k9albhadlyNo ratings yet

- Dynamic SimulationDocument22 pagesDynamic SimulationUsama IqbalNo ratings yet

- Lecture 1 IntroductionDocument26 pagesLecture 1 IntroductionRozh SartipNo ratings yet

- 10 CFD Simulation of Hydrocyclone in Absense of An Air Core 2012Document10 pages10 CFD Simulation of Hydrocyclone in Absense of An Air Core 2012Jair GtzNo ratings yet

- Design of Long Distance Oil PipelineDocument21 pagesDesign of Long Distance Oil PipelineHaseeb Khawaja100% (1)

- Symbol OdsDocument26 pagesSymbol OdsAnjana NairNo ratings yet

- FDP01 MDM3 Asyyy 14 343015 0001 01Document77 pagesFDP01 MDM3 Asyyy 14 343015 0001 01Khánh TrầnNo ratings yet

- Flare NetDocument2 pagesFlare NetPetrol SollyNo ratings yet

- Optimization and Design of Dehydration Unit and NGL ProcessDocument51 pagesOptimization and Design of Dehydration Unit and NGL ProcessHoracio RodriguezNo ratings yet

- K.O DrumDocument7 pagesK.O DrumsaririskihasibuanNo ratings yet

- Line SizingDocument20 pagesLine SizingAhmed HassanNo ratings yet

- Engineered Spring SupportsDocument43 pagesEngineered Spring SupportsNestor Barranco RadaNo ratings yet

- Ch1-Flow of Fluids in Pipes - StudentDocument112 pagesCh1-Flow of Fluids in Pipes - Studentmelki blair kamga nougoueNo ratings yet

- IFP Materials PDFDocument2 pagesIFP Materials PDFProcess EngineerNo ratings yet

- Pipeline LosessDocument23 pagesPipeline Losessasl91No ratings yet

- Assignment LabDocument19 pagesAssignment LabHidayah HumairaNo ratings yet

- Ductwork Design ProgramDocument69 pagesDuctwork Design Programsalmaan khanNo ratings yet

- Fluid Engineering - Flow in PipesDocument6 pagesFluid Engineering - Flow in PipesSherif Abdel Hamid FakhryNo ratings yet

- Pressure Loss in PipesDocument1 pagePressure Loss in Pipessj_scribdNo ratings yet

- Energy Losses Due To Friction1Document25 pagesEnergy Losses Due To Friction1Rey VicencioNo ratings yet

- Screw Screw Screw Screw Pump Pump Pump PumpDocument2 pagesScrew Screw Screw Screw Pump Pump Pump PumpvictorvikramNo ratings yet

- CompPerform PDFDocument6 pagesCompPerform PDFFabian MederosNo ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- 1) Experimental Evaluation of RBD Palm Olein As Lubricant in Low Temperature - Syahrullail-1Document10 pages1) Experimental Evaluation of RBD Palm Olein As Lubricant in Low Temperature - Syahrullail-1victorvikramNo ratings yet

- Echivalenta INCH METRIC For Bolt Stud Dimensions For Ansi FlangesDocument1 pageEchivalenta INCH METRIC For Bolt Stud Dimensions For Ansi FlangesVasilica Barbarasa100% (1)

- Tenaris Line PipeDocument2 pagesTenaris Line PipeAnonymous 7I5qQ0eAxgNo ratings yet

- Rec Hi TempDocument1 pageRec Hi TempvictorvikramNo ratings yet

- cs5 2ch1Document60 pagescs5 2ch1sitipertiwiNo ratings yet

- Pipe Schedule and Thickness PDFDocument2 pagesPipe Schedule and Thickness PDFskychurch100% (1)

- Catalogue Pipe Hangers SupportsDocument111 pagesCatalogue Pipe Hangers SupportsIlija Runjajic100% (1)

- 2539 00 JSD 1300-01-0 Piping Class PDFDocument194 pages2539 00 JSD 1300-01-0 Piping Class PDFvictorvikramNo ratings yet

- Flexej Elaflex Erv G 1116Document2 pagesFlexej Elaflex Erv G 1116victorvikramNo ratings yet

- cd-6 Bulletin 714 1Document2 pagescd-6 Bulletin 714 1victorvikramNo ratings yet

- OISD Standard 244 DraftDocument94 pagesOISD Standard 244 DraftSuresh GanesanNo ratings yet

- Oisd 118Document27 pagesOisd 118Priyanka RazdanNo ratings yet

- Appendix 3 D1 Calculation Cobbins Nursery 070415Document1 pageAppendix 3 D1 Calculation Cobbins Nursery 070415victorvikramNo ratings yet

- API 650 Storage Tank Code GuideDocument15 pagesAPI 650 Storage Tank Code GuideDylan RamasamyNo ratings yet

- Protect Centrifugal Pumps From Low Flows PDFDocument12 pagesProtect Centrifugal Pumps From Low Flows PDFicingrockNo ratings yet

- GAPS Plant LayoutDocument11 pagesGAPS Plant Layoutvb_pol@yahooNo ratings yet

- Electricmotors 1Document101 pagesElectricmotors 1musewejamesoumaNo ratings yet

- DOE MalaysiaDocument82 pagesDOE Malaysiaednavilod67% (3)

- CompressorsDocument8 pagesCompressorsgunjan_88No ratings yet

- 2 SteamPipeDocument4 pages2 SteamPipebugerkngNo ratings yet

- ASEE 2011 Spreadsheet Draft Jan21 2011Document12 pagesASEE 2011 Spreadsheet Draft Jan21 2011haffaNo ratings yet

- Section E - Irrigation Bill of QuantitiesDocument24 pagesSection E - Irrigation Bill of QuantitiesvictorvikramNo ratings yet

- Open Cooling Tower Design ConsiderationsDocument5 pagesOpen Cooling Tower Design ConsiderationsvictorvikramNo ratings yet

- Check Valve Selection Guide: FCD ADAMS8007-00Document4 pagesCheck Valve Selection Guide: FCD ADAMS8007-00Mohamed NabilNo ratings yet

- ANSI Flanges Dimensions Specs Grades ClassesDocument23 pagesANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharNo ratings yet

- SESCO.L90.D.501-12 - List of Material Machinery Part - Rev00 - 14-10-2013Document74 pagesSESCO.L90.D.501-12 - List of Material Machinery Part - Rev00 - 14-10-2013Quyet PhungNo ratings yet

- PT and Fittings Exam 4Document7 pagesPT and Fittings Exam 4Panitan MungsongNo ratings yet

- Jawai Original Proposal MapDocument1 pageJawai Original Proposal MapRituparna NathNo ratings yet

- P200 Series: Portable Hydrostatic TesterDocument8 pagesP200 Series: Portable Hydrostatic TesterAwo Ni Orumila OsarosoNo ratings yet

- Senr4280 00Document2 pagesSenr4280 00SERVICE & REPAIR MANUALNo ratings yet

- V20920 Bx220imDocument32 pagesV20920 Bx220imjajsjxbxcbcbxNo ratings yet

- 4VP01Document4 pages4VP01Lakshmi KishoreNo ratings yet

- Spar Plumbing Equipments and Pipes-1Document34 pagesSpar Plumbing Equipments and Pipes-1Emilienne Laure NgahaneNo ratings yet

- PUMP CALCDocument2 pagesPUMP CALCElias EliasNo ratings yet

- SS316Document2 pagesSS316Girish PanchalNo ratings yet

- Provisional Time Table - IPPL 2023 - MS As On 10-08-2023Document2 pagesProvisional Time Table - IPPL 2023 - MS As On 10-08-2023Kahah gdaubNo ratings yet

- MAST2776B Process Instrumentation TS Lesson 4 Rev.00Document60 pagesMAST2776B Process Instrumentation TS Lesson 4 Rev.00Hassan Al-HasanNo ratings yet

- BNG Usaha Industri 2017Document12 pagesBNG Usaha Industri 2017NadeNo ratings yet

- 750 Double Interlock Preaction System, Type D, 2 To 8 InchesDocument30 pages750 Double Interlock Preaction System, Type D, 2 To 8 InchesAhmad SalahNo ratings yet

- PL2012 SDDocument98 pagesPL2012 SDJorge DiazNo ratings yet

- Water Feature 1,2,3Document15 pagesWater Feature 1,2,3Anonymous 6HjnToW6No ratings yet

- Darcy'S Law: Groundwater Hydraulics Daene C. MckinneyDocument42 pagesDarcy'S Law: Groundwater Hydraulics Daene C. MckinneyJúlio Gabriel Queiroz dos SantosNo ratings yet

- Metec Design and Construction Engineers India (P) LTD: Itc LimitedDocument21 pagesMetec Design and Construction Engineers India (P) LTD: Itc LimitedBalaNo ratings yet

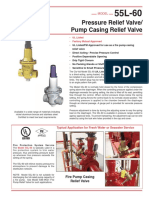

- Fire Pump Casing Relief Valve BrochureDocument2 pagesFire Pump Casing Relief Valve Brochureramon duldulaoNo ratings yet

- Fluid System 05 - Pompa SentrifugalDocument58 pagesFluid System 05 - Pompa SentrifugalSelviya AvaurumNo ratings yet

- General notes and referencesDocument1 pageGeneral notes and referencesdian yuristiaNo ratings yet

- Copper Pipe Leak Test and VacuumDocument2 pagesCopper Pipe Leak Test and Vacuumalone160162l100% (1)

- Barksdale Controls Valves RegulatorsDocument42 pagesBarksdale Controls Valves Regulatorsuldarico lozanoNo ratings yet

- Well Completion (2) Model AnswerDocument4 pagesWell Completion (2) Model Answermissaoui0% (1)

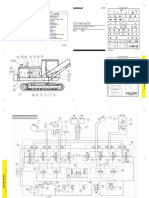

- 312D Hyd PDFDocument2 pages312D Hyd PDFMbahdiro Kolenx100% (3)

- Use With 731 Hoses. Visual Index: Catalog 4400 USDocument9 pagesUse With 731 Hoses. Visual Index: Catalog 4400 USAndreiNo ratings yet

- Control Valve FazriDocument17 pagesControl Valve FazriZul FazriNo ratings yet

- Pricelist 1Document78 pagesPricelist 1sandeepbhallaNo ratings yet

- Good Water Warehouse CatalogDocument184 pagesGood Water Warehouse CatalogNEFTALI VARGAS MANDUJANONo ratings yet