Professional Documents

Culture Documents

Starting Methods of DC Motors

Uploaded by

ZealWolf0 ratings0% found this document useful (0 votes)

176 views13 pagesStarting Methods of DC motors

Original Title

Starting Methods of DC motors

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStarting Methods of DC motors

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

176 views13 pagesStarting Methods of DC Motors

Uploaded by

ZealWolfStarting Methods of DC motors

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 13

STARTING METHODS

OF DC MOTOR

WHY DO WE NEED A STARTER??

We know that the voltage equation of a DC

motor is:

V = Eb + Ia.Ra

If the above eqn. is rearranged in terms of

current we have:

Ia = (V Eb)/Ra

At the time of starting the motor speed is zero

as Eb is zero. (=ZNP/60A)

With the rated applied voltage the starting

armature current is therefore Vt

Ra

Since the resistance Ra is much smaller the

motor draws large starting armature current

from the supply mains.

Such a heavy inrush of starting current taken

by the motor may result in:-

1)

2)

3)

4)

Detrimental sparking at the commutators.

Damage to the armature winding.

Deterioration of the insulation due to

overheating.

Large dips in the supply voltage.

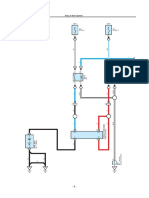

3Point Starters:

This is How the starter looks like:-

OUTER VIEW

INNER VIEW

Various

Parts of a Starter:HANDLE

STUD

S

SOFT IRON

HOLD

ON COIL

OVER

CURRENT

RELEASE COIL

SPRING

3 Point Starter:Fig shown is of 3point starter.

The three terminals marked

A,B,C.

One line is directly connected

to one armature terminal &

one field terminal which are

tied together.

The other line is connected

to point A which is further

connected to the starting arm

L through the over current

release M

To start the motor the main switch is first closed and

starting arm is slowly moved to the right.

As soon as the arm make

contact with stud 1, the

field circuit is directly

connected across the line

and at the same time full

starting resistance R is

placed in series with the

armature.

The starting current drawn by the armature is

I=V/(Ra + Rs)

Where Rs is the starting resistance.

As the arm is further moved, the starting resistance

is gradually cut out till, when the arm reaches the

running position, the resistance is all cut out.

There is a soft iron piece S attached to the arm

which in the full ON or running position is attracted

and held by an electromagnet E energised by the

shunt current. It is variously known as HOLD ON

coil, LOW VOLTAGE release.

Now we will discuss the action of the two protective

devices:-

Hold ON :- The normal

action of this coil is to

hold on the arm in the full

running position. But in

the case of failure of the

supply, it is de-energised,

thereby releasing the arm

which pulled back by the

spring to the OFF

position.

One great advantage of connecting the Hold on coil

in series with the shunt field is that, should the field

circuit became open, the starting arm immediately

springs back to the OFF position thereby preventing

the motor from running away.

Over current release:This consist of an electromagnet

connected in the supply line. If

the motor becomes overloaded

beyond a predetermined value,

then arm D is lifted & short circuits

the electromagnet. Hence the arm is released back to

OFF position.

DISADVANTAGE:

In case of 3 point starter the field coil and the

holding coil are in series.

If the speed above the normal are to obtained the

field current must be reduced .

At certain value of reduced field current, the

electromagnetic pull of the holding coil may

became less than the spring force.

In such case the starter handle returns to the OFF

position and the motor stops working

Thus a 3 point starter cant be used where wide

range of speed control by shunt field control is

required.

4 POINT STARTER:

As the name suggests, it has four terminals (L,L,F,A).

Working is same as that of the 3 point starter.

When compared to the 3 point

starter, it will be noticed that one

important change has been made

ie. The hold On coil has been taken

out of shunt field and has been

connected directly across the line

through a protecting resistance

as shown.

When the armature touches Stud 1,the line current

divides into three parts:

(i) one part goes to the starting resistance Rs.

(ii) The second part passes through the shunt field

and its field resistance.

(iii) Third part goes through the Hold-On coil and

current protecting resistance R.

With this arrangement any change of current in the

shunt field circuit does not at all affect the current

passing through Hold-On coil.

Hence the desirable speed control can be easily

attained.

You might also like

- 3 Point Starter Working Principle & ConstructionDocument6 pages3 Point Starter Working Principle & ConstructionsuryavigneNo ratings yet

- Study of StartersDocument6 pagesStudy of StartersGANESH KUMAR B eee2018No ratings yet

- 3 Point or 4 Point StarterDocument5 pages3 Point or 4 Point StarterAmar PandaNo ratings yet

- 1.to Find Voltage Regulation of Single Phase TransformerDocument7 pages1.to Find Voltage Regulation of Single Phase Transformershahabrandhawa50% (2)

- Hopkinson Test On DC Shunt MotorDocument5 pagesHopkinson Test On DC Shunt MotorVarun VadluriNo ratings yet

- Single Phase Current Transformer LabDocument6 pagesSingle Phase Current Transformer LabHumayun ArshadNo ratings yet

- Two Point StarterDocument4 pagesTwo Point StarterudhayabarathiNo ratings yet

- 5.AC Phase Control Using SCRDocument8 pages5.AC Phase Control Using SCRabcdefgNo ratings yet

- Exp1 The Single Phase TransformerDocument8 pagesExp1 The Single Phase Transformernaveen rajNo ratings yet

- DC Generator Principles ExplainedDocument15 pagesDC Generator Principles ExplainedAjay Talajiya0% (1)

- Heaven's light guides polarity testDocument3 pagesHeaven's light guides polarity testAbdul Mubin100% (2)

- Wireless Stepper Motor ControlDocument2 pagesWireless Stepper Motor ControlHarsha100% (1)

- Problems Chapter 5 1Document7 pagesProblems Chapter 5 1Siva KumarNo ratings yet

- Determine Phase SequenceDocument5 pagesDetermine Phase SequenceZAIN UL ABIDENNo ratings yet

- Tube Light ManualDocument2 pagesTube Light ManualSwaroop MallickNo ratings yet

- What Is The Use of Choke in Florescent TubesDocument7 pagesWhat Is The Use of Choke in Florescent Tubessumanta1981100% (2)

- 02 Power ElectronicsDocument212 pages02 Power Electronicsmarkschurer223453No ratings yet

- Experiment 1 - Single Phase TransformerDocument9 pagesExperiment 1 - Single Phase TransformerKhairul Islam HimelNo ratings yet

- Enerzio Product Catalog 2019-2020 New PDFDocument16 pagesEnerzio Product Catalog 2019-2020 New PDFHarvinder Singh HarryNo ratings yet

- Typical Rod Gap ArresterDocument11 pagesTypical Rod Gap ArresterMuhammad Asif Iqbal100% (1)

- DC GeneratorDocument38 pagesDC Generatoraswardi8756No ratings yet

- EEL2026-LabsheetDocument23 pagesEEL2026-LabsheetchandraNo ratings yet

- Short Transmission LineDocument18 pagesShort Transmission LineNaga AnanthNo ratings yet

- Electrical and Electronics Lab Manual For Mechanical EngineeringDocument21 pagesElectrical and Electronics Lab Manual For Mechanical EngineeringSreerag Kunnathu SugathanNo ratings yet

- 1338184181.7817effects of Voltage Unbanlance On Induction MotorsDocument4 pages1338184181.7817effects of Voltage Unbanlance On Induction MotorsRAPRATSINNo ratings yet

- Unit 1: The Power System Overview and ModelingDocument8 pagesUnit 1: The Power System Overview and ModelingIhuhwa Marta TauNo ratings yet

- Electromechanical InstrumentsDocument17 pagesElectromechanical Instrumentsอภิฌาน กาญจนวาปสถิตย์No ratings yet

- EE8411 - EM 2 LabDocument6 pagesEE8411 - EM 2 LabVengatNo ratings yet

- AC CircuitsDocument20 pagesAC CircuitsNikhil GobhilNo ratings yet

- Machies Singly ExcitedDocument15 pagesMachies Singly ExcitedMohamed ElfekyNo ratings yet

- Injection of EMF in The Rotor CircuitDocument3 pagesInjection of EMF in The Rotor CircuitAbhishekGuptaNo ratings yet

- 271 - PH8252 Physics For Information Science - Notes UNIT IV OPTICAL PROPERTIES OF MATERIALS PDFDocument66 pages271 - PH8252 Physics For Information Science - Notes UNIT IV OPTICAL PROPERTIES OF MATERIALS PDFHari100% (1)

- EEM328 Electronics Laboratory - Report4 - BJT BiasingDocument4 pagesEEM328 Electronics Laboratory - Report4 - BJT Biasingdonatello84No ratings yet

- Electrical Circuit Lab ManualDocument38 pagesElectrical Circuit Lab Manualecessec67% (3)

- Experiment No. 2.4 - The Squirrel-Cage Induction Motor ObjectiveDocument3 pagesExperiment No. 2.4 - The Squirrel-Cage Induction Motor ObjectiveKristine AldayNo ratings yet

- Sheet 3Document3 pagesSheet 3geo_bi100% (1)

- EE6201 Circuit Theory Regulation 2013 Lecture Notes PDFDocument257 pagesEE6201 Circuit Theory Regulation 2013 Lecture Notes PDFVenkatesan Swamy100% (1)

- Stop & Start System Circuit DiagramDocument19 pagesStop & Start System Circuit DiagramEdik Bonifacio MamaniNo ratings yet

- Transformer PPT For First YearDocument42 pagesTransformer PPT For First YearDhairya PathakNo ratings yet

- Measure AC Voltages Using an AC PotentiometerDocument3 pagesMeasure AC Voltages Using an AC PotentiometerNh Chuminda Yapa100% (1)

- AC Quantities ExplainedDocument7 pagesAC Quantities Explainedsrinivas100% (1)

- V and Inverted V Curves of Synchronous MotorDocument7 pagesV and Inverted V Curves of Synchronous Motorkarthikeyan249No ratings yet

- Experiment No.3Document6 pagesExperiment No.3justinepunzalan250% (1)

- Synchronous Generator Transient AnalysisDocument15 pagesSynchronous Generator Transient AnalysisRoshan AkaravitaNo ratings yet

- Experiment No. 6 Programmable Unijunction Transistor (PUT)Document5 pagesExperiment No. 6 Programmable Unijunction Transistor (PUT)WILL100% (1)

- Internship Report FOR AP GENCODocument65 pagesInternship Report FOR AP GENCORajesh KalyanamNo ratings yet

- EE743 Induction Machines Torque-Speed CharacteristicsDocument22 pagesEE743 Induction Machines Torque-Speed CharacteristicsGogioman Myhay100% (1)

- Me I 18 TutorialDocument7 pagesMe I 18 TutorialArkadebSenguptaNo ratings yet

- No Load and Block Rotor Tests for 3-Phase Induction MotorDocument11 pagesNo Load and Block Rotor Tests for 3-Phase Induction MotorKsr Akhil100% (1)

- Step-Down Cycloconverter Explained - Electrical ConceptsDocument5 pagesStep-Down Cycloconverter Explained - Electrical ConceptsMohammad HamamdNo ratings yet

- Electrical 4Document2 pagesElectrical 4Puran Singh LabanaNo ratings yet

- Lab ReportDocument15 pagesLab Reportaeoliano0% (1)

- EE6201 Circuit Theory Regulation 2013 Lecture Notes PDFDocument251 pagesEE6201 Circuit Theory Regulation 2013 Lecture Notes PDFrajNo ratings yet

- DC MOTOR STARTER TYPESDocument6 pagesDC MOTOR STARTER TYPESGANESH KUMAR B eee2018No ratings yet

- DC Motor StartersDocument6 pagesDC Motor StartersAreeb KhanNo ratings yet

- 3 Point StarterDocument2 pages3 Point StarterAkash ANo ratings yet

- Topic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByDocument16 pagesTopic: Starter of Engine Branch: Electrical Engineering: Prepared By:-Guided ByTanvi KhuranaNo ratings yet

- Three Point and Four Point StarterDocument7 pagesThree Point and Four Point Starterkaran nirmala gajanan shindeNo ratings yet

- DCDocument1 pageDCBuvan BsgNo ratings yet

- 26 - 1 - 1 - 8 2015Document11 pages26 - 1 - 1 - 8 2015Mohit kolliNo ratings yet

- Mukundpur - Yamuna Vihar (Line 7) - ModelDocument1 pageMukundpur - Yamuna Vihar (Line 7) - ModelZealWolfNo ratings yet

- Ggsipu CollegesDocument12 pagesGgsipu CollegesZealWolfNo ratings yet

- Janakpuri West - Kalindikunj (Line 8) - ModelDocument1 pageJanakpuri West - Kalindikunj (Line 8) - ModelZealWolfNo ratings yet

- Opamp CircuitsDocument19 pagesOpamp CircuitsZealWolfNo ratings yet

- Advertisement - 61 Shortlist ResultDocument2 pagesAdvertisement - 61 Shortlist ResultZealWolfNo ratings yet

- Central Secretariat To Kashmere Gate-ModelDocument1 pageCentral Secretariat To Kashmere Gate-Modeltejashraj93No ratings yet

- Electro Mechanical Energy Conversion-I (End Term) - 2008Document2 pagesElectro Mechanical Energy Conversion-I (End Term) - 2008ZealWolfNo ratings yet

- The Night Sky ConstellationsDocument10 pagesThe Night Sky ConstellationsZealWolfNo ratings yet

- A77 India Micromax ManualDocument65 pagesA77 India Micromax ManualZealWolfNo ratings yet

- 3 Programmable ConfigurationsDocument5 pages3 Programmable Configurationstabani_shaikNo ratings yet

- PrepositionsDocument9 pagesPrepositionsZealWolfNo ratings yet

- Organizational Behaviour QuestionsDocument4 pagesOrganizational Behaviour QuestionsZealWolfNo ratings yet

- Dmbsvivaqsem 5Document19 pagesDmbsvivaqsem 5Is EverNo ratings yet

- Analog Electronics Lab ManualDocument68 pagesAnalog Electronics Lab ManualZealWolfNo ratings yet

- Ae Lab Ivsem EceDocument60 pagesAe Lab Ivsem EceNavneet KumarNo ratings yet

- 9back EmfDocument9 pages9back EmfSafin BiswasNo ratings yet

- True or False Statements and Fill in the Blanks QuestionsDocument3 pagesTrue or False Statements and Fill in the Blanks Questionsashushaktiman100% (1)

- Study of Reverse Charracteristics of Zener DiodeDocument3 pagesStudy of Reverse Charracteristics of Zener DiodeZealWolfNo ratings yet

- Power System Mit LectureDocument25 pagesPower System Mit LecturejyotiblossomsNo ratings yet

- Analog Electronics QuestionsDocument3 pagesAnalog Electronics QuestionsZealWolfNo ratings yet

- Viva Voce Questions On Communication SystemsDocument3 pagesViva Voce Questions On Communication SystemsZealWolf100% (3)

- Opamp CircuitsDocument19 pagesOpamp CircuitsZealWolfNo ratings yet

- U.K.Singh Manufacturing ProcessesDocument290 pagesU.K.Singh Manufacturing ProcessesGirish Dey100% (7)

- 9back EmfDocument9 pages9back EmfSafin BiswasNo ratings yet

- CommutationDocument9 pagesCommutationPooja TiwariNo ratings yet

- 12 XmerDocument10 pages12 Xmercuteb8No ratings yet

- 14 Transformer PhasorsDocument13 pages14 Transformer PhasorsShahnawaz AhmadNo ratings yet

- The Fireye E110 FLAME MONITOR System PDFDocument48 pagesThe Fireye E110 FLAME MONITOR System PDFIng. Bendryx BelloNo ratings yet

- ACL LabDocument30 pagesACL LabPaola Andrea Beniz NaipánNo ratings yet

- DS POSITION INDICATOR EN Rev01Document3 pagesDS POSITION INDICATOR EN Rev01Ronak PatelNo ratings yet

- How Computers Work & Their Daily UseDocument3 pagesHow Computers Work & Their Daily UserezaNo ratings yet

- Selecting and Designing in The Right Schottky Rectifier International Rectifier An968Document2 pagesSelecting and Designing in The Right Schottky Rectifier International Rectifier An968abcdNo ratings yet

- How To Prepare For Quantitative AptitudeDocument4 pagesHow To Prepare For Quantitative AptitudePardha SaradhiNo ratings yet

- Cisco Model EPC3925 8x4 EuroDOCSIS 3.0Document3 pagesCisco Model EPC3925 8x4 EuroDOCSIS 3.0irfaneng76No ratings yet

- SBGR Ils-T-Rwy-28r Iac 20220908Document1 pageSBGR Ils-T-Rwy-28r Iac 20220908jcndrckz4qNo ratings yet

- Siemens Simatic S7-300 SM338 6ES7338-4BC00 - 0AB0 Positioning Module PDFDocument2 pagesSiemens Simatic S7-300 SM338 6ES7338-4BC00 - 0AB0 Positioning Module PDFmicaNo ratings yet

- T1004M6R012Document1 pageT1004M6R012АлександрNo ratings yet

- Icom IC-M710 Instruction ManualDocument28 pagesIcom IC-M710 Instruction ManualYayok S. Anggoro100% (1)

- Battery Charger CTEK - MXS 5.0 - ENDocument6 pagesBattery Charger CTEK - MXS 5.0 - ENVladimirNo ratings yet

- 1 KW Traction Controller Reference Design For 3-Phase BLDC Motors For Light Electric VehiclesDocument7 pages1 KW Traction Controller Reference Design For 3-Phase BLDC Motors For Light Electric VehiclesAhmar Hayat KhanNo ratings yet

- media-2063038-OM 7.76 Help PDFDocument362 pagesmedia-2063038-OM 7.76 Help PDFmicrajacutNo ratings yet

- Lab 2 - Electro-Pneumatic SystemDocument9 pagesLab 2 - Electro-Pneumatic SystemSiti Sarah100% (1)

- Aurasemi - Timing BU - Main - PresentationDocument72 pagesAurasemi - Timing BU - Main - PresentationAnindyaSahaNo ratings yet

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionDocument4 pagesDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileNo ratings yet

- Seminar On Virtual Private Network: Prepared byDocument36 pagesSeminar On Virtual Private Network: Prepared bypranesh_patelNo ratings yet

- مكبرات العمليات PDFDocument55 pagesمكبرات العمليات PDFmahmoud DawoodNo ratings yet

- TL321Document4 pagesTL321poupoutosNo ratings yet

- 2nd Order Band Pass Chebyshev 0.5 DB Active Filter Design Assignment 2 KHZ - 4 KHZDocument7 pages2nd Order Band Pass Chebyshev 0.5 DB Active Filter Design Assignment 2 KHZ - 4 KHZBuddhiNo ratings yet

- Baofeng UV-5R - Reference 4x6Document8 pagesBaofeng UV-5R - Reference 4x6compte emailNo ratings yet

- Backend GTLDocument16 pagesBackend GTLcarver_uaNo ratings yet

- WAGO Profibus DP SlaveDocument2 pagesWAGO Profibus DP SlavewhateverzxzNo ratings yet

- Georgita Radio1 BA PTDocument292 pagesGeorgita Radio1 BA PTHjac CarvalhoNo ratings yet

- XZone Service Manual 1.2Document20 pagesXZone Service Manual 1.2Abraham BongòNo ratings yet

- ODA-150 Towards A More Generic Slice Template GST - 5GROTS CatalystDocument19 pagesODA-150 Towards A More Generic Slice Template GST - 5GROTS CatalystAndrea StefanelliNo ratings yet

- Shannon-Weaver Model of Communication - 7 Key Concepts (2020)Document10 pagesShannon-Weaver Model of Communication - 7 Key Concepts (2020)Afif Kim100% (1)

- Service Manual: NSX-AJ310 NSX-SZ310 NSX-SZ315 NSX-SZ510Document42 pagesService Manual: NSX-AJ310 NSX-SZ310 NSX-SZ315 NSX-SZ510miguel_olmos_18No ratings yet

- Fuji Ceramics CorporationDocument2 pagesFuji Ceramics CorporationTan SoNo ratings yet