Professional Documents

Culture Documents

4 TurbulentFlow

Uploaded by

cristianbenitesfOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 TurbulentFlow

Uploaded by

cristianbenitesfCopyright:

Available Formats

Drilling Engineering

Drilling Engineering PE 311

Turbulent Flow in Pipes and Annuli

Prepared by: Tan Nguyen

Drilling Engineering

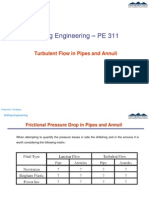

Frictional Pressure Drop in Pipes and Annuli

When attempting to quantify the pressure losses in side the drillstring and in the annulus it is

worth considering the following matrix:

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Introduction

Laminar Flow: In this type of flow, layers of fluid move in streamlines. There is no microscopic or

macroscopic intermixing of the layers. Laminar flow systems are generally represented

graphically by streamlines.

Turbulent Flow: In turbulent flow, there is an irregular random movement of fluid in transverse

direction to the main flow. This irregular, fluctuating motion can be regarded as superimposed on

the mean motion of the fluid.

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Definition of Reynolds Number

Reynolds number, Re, is a dimensionless number that gives a measure of the ratio of inertial

forces to viscous forces. Reynolds number is used to characterize different flow regimes, such

as laminar or turbulent flow. Laminar occurs at low Reynolds number, where viscous forces are

dominant, and is characterized by smooth, constant fluid motion; turbulent flow occurs at high

Reynolds number and is dominated by inertial forces, which tend to produce chaotic eddies,

vortices and other flow instabilities.

_

For pipe

In field unit:

_

Re

928 u d

Prepared by: Tan Nguyen

Re

ud

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Determination of Laminar/Turbulent Flow

_

Re

928 u d

where fluid density, lbm/gal

u avg. fluid velocity, ft/s

d pipe I.D., in

viscosity of fluid, cp.

If

Re < 2,100

Laminar flow

Re = 2,100 4,000

Transition flow

Re > 4,000

Turbulent

Note that this critical Reynolds number is correct only for Newtonian fluids

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Determination of Friction Factor - Laminar Flow

Relationship between shear stress and friction factor:

Pipe flow under laminar conditions:

Therefore,

Newtonian fluids flow in pipe under laminar flow conditions:

Hence,

This equation will be used to calculate the friction factor of Newtonian fluids flow in pipe under

laminar flow conditions.

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Determination of Friction Factor - Turbulent Flow

For turbulent flow, the friction factor can be calculated by using Colebrook correlation.

1

1.255

4 log 0.269 / d

f

N Re f

Where is the absolute roughness. /d is the relative roughness.

For smooth pipe, the relative roughness /d < 0.0004, the following equations can be used to

calculate the friction factor in turbulent flow

Re = 2,100 100,000:

Blasius approximation:

Re = 2,100 100,000:

Prepared by: Tan Nguyen

1

4 log N Re

f

0.0791

0.25

N Re

f 0.395

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Determination of Friction Factor

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Determination of Friction Factor

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Determination of the Frictional Pressure Loss

From equation:

In field unit:

, an equation of dp/dL can be expressed as

. This equation can be used to calculate the frictional pressure drop

gradient for Newtonian and non-Newtonian fluids.

Combining this equation and the Blasius approximation gives

dp 0.75u1.75 0.25 0.75 q1.75 0.25

0.25

dL

1800d

8624d 4.75

u 2

0.0791

dp

25.8d

dL 928 vd 0.25

Note that the Moody friction factor is four times higher than the Fanning friction factor.

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Example

Example: Determine the frictional pressure drop in 10000ft of 4.5-in commercial steel drillpipe

having an internal diameter of 3.826in. If a 20 cp Newtonian fluid having a density of 9 lbm/gal is

pumped through the drillpipe at a rate of 400 gal/min

Solution:

Mean velocity:

q

400

11.16 ft / s

2.488d 2 2.488 * 3.826 2

_

Reynolds number:

Re

928 u d

928 * 9 *11.16 * 3.826

17831

20

Since Re > 2,100, the flow is under turbulent flow conditions.

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Example

From table 4.5, the absolute roughness for commercial steel pipe is = 0.000013 inches.

The relative roughness /d = 0.000013/3.826 = 0.0000034 < 0.0004 --> smooth pipe

1

1.255

4 log 0.269 / d

f

N re f

Solve this equation for the Fanning friction factor: f = 0.00666

Thus the frictional pressure loss can be obtained by

2

dp

f v

0.00666 * 9 *11.16 2

p f

D

D

*10000 756 psi

dL

25.8d

25.8 * 3.826

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Example

Using Blasius approximation

0.0791 ,the equation

0.25

N Re

v

0.0791

dp

25.8d

dL 928 vd 0.25

1.75

dp 0.75 v 0.25

0.0777 psi / ft

0.25

dL

1800d

Pressure drop: DP = dp/dL x D = (0.0777)(10,000) = 777 psi

Prepared by: Tan Nguyen

becomes

Drilling Engineering

Turbulent Flow in Pipes Newtonian Fluids

Example

Using Blasius approximation

0.0791 ,the equation

0.25

N Re

v

0.0791

dp

25.8d

dL 928 vd 0.25

1.75

dp 0.75 v 0.25

0.0777 psi / ft

0.25

dL

1800d

Pressure drop: DP = dp/dL x D = (0.0777)(10,000) = 777 psi

Prepared by: Tan Nguyen

becomes

Drilling Engineering

Turbulent Flow in Pipes/Annuli NonNewtonian Fluids

Equivalent Diameter for Annular Geometry Hydraulic Diameter Method

Hydraulic diameter is defined as:

Equivalent diameter by using hydraulic diameter method:

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Equivalent Diameter for Annular Geometry From Momentum Equation

From the momentum equation, frictional pressure drop for Newtonian fluid in the annulus is

dp f

dL

d d

1,500 d 22 d12

d2

ln

d1

2

2

2

1

For pipe flow, d1 --> 0 then

dp f

dL

u

1,500d 2

Comparing these two equations, the equivalent diameter an annulus can be obtained

d 22 d12

de d d

ln d 2 d1

2

2

Prepared by: Tan Nguyen

2

1

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Equivalent Diameter for Annular Geometry Narrow Slot Approximation

From the narrow slot approximation, frictional pressure drop for Newtonian fluid in the annulus is

For pipe flow

dp f

dL

u

1,500d 2

Comparing these two equations, the equivalent diameter an annulus can be obtained

d e 0.816 d 2 d1

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Equivalent Diameter for Annular Geometry Crittendon Correlation

A fourth expression for the equivalent diameter of an annulus was developed by Crittendon.

When using Crittendon correlation, a fictitious average velocity also must be used in describing

the flow system.

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Bingham Plastic Model

1. Obtain apparent viscosity by combining the frictional pressure loss in

pipe (or annulus) for both Newtonian and Bingham Plastic models

or

a p

6.66 y d

a p

pv

y

a v

1500d 2 1500d 2 225d

( Pipe)

5 y (d 2 d1 )

v

( Annulus )

2. Use apparent viscosity to determine Reynolds Number

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Bingham Plastic Model

Another way to determine the flow regime (critical Reynolds number) is to use the Hedstrom number

N HE

y d 2

p2

In field unit

N HE

Prepared by: Tan Nguyen

37100 y d 2

p2

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Bingham Plastic Model

Turbulent

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Power Law Model

Apparent Viscosity for use in the Reynolds Number is obtained by comparing the laminar flow

equations for Newtonian and Power Law fluids

Pipe flow:

n

a v

Kv

3 1/ n

1500d 2 144000d (1 n ) 0.0416

Kd (1 n ) 3 1 / n

a

(1 n )

0

.

0416

96v

( Pipe)

Annular flow:

n

a v

Kv

2 1/ n

1000(d 2 d1 ) 2 144000(d 2 d1 ) (1 n ) 0.0208

K (d 2 d1 ) (1 n ) 2 1 / n

a

(1 n )

0

.

0208

144v

Prepared by: Tan Nguyen

( Annulus)

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Power Law Model

Reynolds number for power law fluids in pipe:

N Re

89100 v

( 2 n )

0.0416d

3 1/ n

Reynolds number for power law fluids In annulus:

N Re

109000 v

( 2 n )

0.0208(d 2 d1 )

2 1/ n

Friction factor for power law fluids under turbulent flow conditions

1/ f

Prepared by: Tan Nguyen

4.0

0.395

1 n / 2

log(

N

f

)

Re

n 0.75

n 1 .2

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Power Law Model

Prepared by: Tan Nguyen

Drilling Engineering

Summary

Prepared by: Tan Nguyen

Drilling Engineering

Summary

Newtonian Model

Prepared by: Tan Nguyen

Bingham Plastic Model

Power Law Model

Drilling Engineering

Summary

Newtonian Model

Prepared by: Tan Nguyen

Bingham Plastic Model

Power Law Model

Drilling Engineering

Summary

Newtonian Model

Prepared by: Tan Nguyen

Bingham Plastic Model

Power Law Model

Drilling Engineering

Example Newtonian Fluid in Annulus

Example 1: A 9.0 lbm/gal brine having a viscosity of 1.0 cp is being circulated in a well at a rate

of 200 gal/min. Apply the all the criteria for computing equivalent diameter. Determine the flow

pattern and frictional pressure gradient. The drillpipe has an external diameter of 5.0 in. and the

hole has a diameter of 10 in.

Solution:

Prepared by: Tan Nguyen

Drilling Engineering

Example Newtonian Fluid in Annulus

Prepared by: Tan Nguyen

Drilling Engineering

Example Newtonian Fluid in Annulus

Prepared by: Tan Nguyen

Drilling Engineering

Example Newtonian Fluid in Annulus

Hydraulic Method

Momentum Mothod

Narrow Slot Method

Crittendon Method

Note that the Crittendon correlation is applied for the fourth method. In this

method, we need to calculate the equivalent diameter based on Crittendon

correlation and the fictitious average velocity.

Prepared by: Tan Nguyen

Drilling Engineering

Example BHF - Annulus

Example 2: A 10 lbm/gal mud having a plastic viscosity of 40 cp and a yield point of 15 lbf/100ft 2

is circulated at a rate of 600 gal/min. Estimate the frictional pressure loss in the annulus opposite

the drill collars if the drill collars are in a 6.5-in hole, have a length of 1,000 ft, and a 4.5 in. OD.

Check for turbulence using both the apparent viscosity concept and the Hedstrom number

approach. Use an narrow slot equivalent diameter to represent the annular geometry.

Prepared by: Tan Nguyen

Drilling Engineering

Example BHF - Annulus

Equivalent diameter using narrow slot approximation

Reynolds number based on apparent viscosity

Prepared by: Tan Nguyen

Drilling Engineering

Example BHF - Annulus

Reynolds number for a plastic viscosity of 40 cp

Using the graph for Hedstrom number, the critical Reynolds number is 3,300. The flow is turbulent

Prepared by: Tan Nguyen

Drilling Engineering

Example BHF - Annulus

Using Blasius approximation with Re = 3,154, the friction factor is f = 0.0098

Frictional pressure loss is given:

Prepared by: Tan Nguyen

Drilling Engineering

Example BHF - Annulus

Prepared by: Tan Nguyen

Drilling Engineering

Example PL - Annulus

Example 3: A 15.6 lbm/gal cement slurry having a consistency index of 335 eq cp and a flow

behavior index of 0.67 is being pumped at a rate of 672 gal/min between a 9.625-in. hole and a

7.0-in.casing. Determine the frictional pressure loss per 100 ft of slurry. Use the equivalent

diameter based on the narrow slot approximation.

Solution:

The mean velocity:

Reynolds number:

Prepared by: Tan Nguyen

Drilling Engineering

Turbulent Flow in Pipes/Annuli nonNewtonian Fluids

Power Law Model

Prepared by: Tan Nguyen

Drilling Engineering

Example PL - Annulus

Prepared by: Tan Nguyen

You might also like

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Agl FLDDocument2 pagesAgl FLDrarunr1No ratings yet

- Predicting well temperatureDocument3 pagesPredicting well temperatureArun KumarNo ratings yet

- Pump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test MeasurementsDocument13 pagesPump Intake Pressure Determined From Fluid Levels Dynamometers and Valve Test Measurementsenriqueg_53No ratings yet

- 1 Presentation Echometer QRod Quick Rod DesignDocument23 pages1 Presentation Echometer QRod Quick Rod DesignNIno Lenin Yupanqui SanchezNo ratings yet

- Correlations StandingDocument14 pagesCorrelations StandingIngrid GarciaNo ratings yet

- Wi XXXX-PXX Rev. x1 Pump TestingDocument14 pagesWi XXXX-PXX Rev. x1 Pump TestingJessie MazonNo ratings yet

- Tarea 19 - Metodo API Rp11lDocument12 pagesTarea 19 - Metodo API Rp11lMelo GutiérrezNo ratings yet

- Downhole Gas Separator Performance Simulation Software Paper SWPSC 2014Document15 pagesDownhole Gas Separator Performance Simulation Software Paper SWPSC 2014angeles mendozaNo ratings yet

- Semilog Analysis for Oil Wells - WTADocument32 pagesSemilog Analysis for Oil Wells - WTAChai CwsNo ratings yet

- Part 7 - Wellbore Storage EffectsDocument5 pagesPart 7 - Wellbore Storage EffectsChai CwsNo ratings yet

- Horizontal/Slant/Vertical Wells: SPE 24352 Analysis of L Nflow Performance Simulation of Solution-Gas Drive ForDocument10 pagesHorizontal/Slant/Vertical Wells: SPE 24352 Analysis of L Nflow Performance Simulation of Solution-Gas Drive FormaharabdNo ratings yet

- Me 262 Lecture 8Document25 pagesMe 262 Lecture 8toaniltiwariNo ratings yet

- API 47 275 StandingDocument14 pagesAPI 47 275 StandingHamza AliNo ratings yet

- Christopher Franklin - Handbook of Oil and Gas Operations PDFDocument281 pagesChristopher Franklin - Handbook of Oil and Gas Operations PDFHaitham AbdulrazzakNo ratings yet

- Ask ECHOMETER - 20 - QRod - Quick - Rod - DesignDocument93 pagesAsk ECHOMETER - 20 - QRod - Quick - Rod - DesignMohamed ben halimaNo ratings yet

- Part 15 Slug DST MDT IpttDocument15 pagesPart 15 Slug DST MDT IpttChai CwsNo ratings yet

- F. J. Garber, SPE, University of Southwestern Louisiana And, J. G. Osorio, University National de ColombiaDocument10 pagesF. J. Garber, SPE, University of Southwestern Louisiana And, J. G. Osorio, University National de ColombiaAndres CalvoNo ratings yet

- Part 2 Add Note On Permeability and CompressibilityDocument3 pagesPart 2 Add Note On Permeability and CompressibilityChai CwsNo ratings yet

- API Standard Pump Assemblies GuideDocument20 pagesAPI Standard Pump Assemblies GuidejulianosatlerNo ratings yet

- Hydraulic Jet PumpDocument3 pagesHydraulic Jet Pumpvictor javier nuñezNo ratings yet

- PB Lecture Notes 2017Document59 pagesPB Lecture Notes 2017ganeshNo ratings yet

- Spe-6788-Pa-Hv (1) SpeDocument13 pagesSpe-6788-Pa-Hv (1) SpeNixon AyalaNo ratings yet

- 05 Traps PDFDocument17 pages05 Traps PDFDevinaacsNo ratings yet

- Agl DSNDocument4 pagesAgl DSNR NilandNo ratings yet

- Co2 Injection Wells.009Document11 pagesCo2 Injection Wells.009Shio WenzanNo ratings yet

- 1 2 Dynamometer Basic LoadsDocument37 pages1 2 Dynamometer Basic LoadsRodrigo DacolNo ratings yet

- The Flowing Material Balance Procedure L. Mattar R. Mcneil: This Article Begins On The Next PageDocument14 pagesThe Flowing Material Balance Procedure L. Mattar R. Mcneil: This Article Begins On The Next PageAmr HegazyNo ratings yet

- Spe 8206 Pa PDFDocument12 pagesSpe 8206 Pa PDFSuci Nur HidayahNo ratings yet

- CAP6 Whitson Phase BehaviorDocument21 pagesCAP6 Whitson Phase BehaviorMaría José MartínezNo ratings yet

- Rmo Wellbore FlowDocument34 pagesRmo Wellbore FlowAnonymous 3cS5mPzkT0No ratings yet

- An Evaluation of Critical Multiphase Flow Performance Through Wellhead ChokesDocument8 pagesAn Evaluation of Critical Multiphase Flow Performance Through Wellhead ChokesAhmed Khalil JaberNo ratings yet

- Inflow relationships for slanted/horizontal solution-gas drive wellsDocument8 pagesInflow relationships for slanted/horizontal solution-gas drive wellsNACHO AVIÑANo ratings yet

- Inertial Calcul PDFDocument10 pagesInertial Calcul PDFatesarikNo ratings yet

- Part 7a - Manual Log-Log Analysis WBS IARF ModelDocument14 pagesPart 7a - Manual Log-Log Analysis WBS IARF ModelChai CwsNo ratings yet

- 2009 EngelderLashUzcategui (AAPG)Document33 pages2009 EngelderLashUzcategui (AAPG)Fatima Rodriguez EstevezNo ratings yet

- Slide 1 /140Document142 pagesSlide 1 /140Dede PratamaNo ratings yet

- API 11-S4 RP Well Data SheetDocument17 pagesAPI 11-S4 RP Well Data Sheetlutfi awnNo ratings yet

- Jet Pumps and EjectorsDocument1 pageJet Pumps and EjectorsamitkrayNo ratings yet

- Part 16 Horizontal Well TestingDocument16 pagesPart 16 Horizontal Well TestingChai CwsNo ratings yet

- Sucker Rod Pumping Workshop TopicsDocument31 pagesSucker Rod Pumping Workshop TopicsRodrigo DacolNo ratings yet

- Part 13 Gas Well TestingDocument47 pagesPart 13 Gas Well TestingChai CwsNo ratings yet

- SPE-29342 Gas Migration RatesDocument7 pagesSPE-29342 Gas Migration RatesRyan HengNo ratings yet

- 2 5 QRod Quick Rod DesignDocument49 pages2 5 QRod Quick Rod DesignJonathan AvilaNo ratings yet

- Spe 184834 MSDocument11 pagesSpe 184834 MSSSNo ratings yet

- Gas lift spacing designDocument3 pagesGas lift spacing designashrafsaberNo ratings yet

- Mathcad - Gorilla VII Mud Pump CalcsDocument2 pagesMathcad - Gorilla VII Mud Pump CalcsMohamed SaeedNo ratings yet

- Handout 1 Derivation Radial Diffusivity Equation PCB3013Document4 pagesHandout 1 Derivation Radial Diffusivity Equation PCB3013Chai CwsNo ratings yet

- Choke Sizing & Propiedaes de Los FluidosDocument149 pagesChoke Sizing & Propiedaes de Los FluidosJose RojasNo ratings yet

- OOT PulsFrac Input Request - OEF-1000-001 TPN-211Document5 pagesOOT PulsFrac Input Request - OEF-1000-001 TPN-211Christian BimoNo ratings yet

- Advances in Dynamometer TechnologyDocument17 pagesAdvances in Dynamometer Technologysalakhid100% (1)

- Rig PI-316 specificationsDocument17 pagesRig PI-316 specificationsAnonymous JMoXMYMnNo ratings yet

- Boiling Heat Transfer and Two-Phase Flow PDFDocument441 pagesBoiling Heat Transfer and Two-Phase Flow PDFll_pabilonaNo ratings yet

- Spe 146394 MSDocument5 pagesSpe 146394 MSDr-Jitendra Vaish100% (1)

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Turbulent flow pipes annuli drilling engineeringDocument40 pagesTurbulent flow pipes annuli drilling engineeringHENDRIK2011100% (1)

- Drilling Hydraulics FormulaeDocument3 pagesDrilling Hydraulics FormulaeAngel NgoNo ratings yet

- OCW Drilling Hydraulics LectureDocument59 pagesOCW Drilling Hydraulics Lecturefreelancer2earn100% (1)

- Aircraft Lateral Static StabilityDocument16 pagesAircraft Lateral Static StabilityMatthew AustinNo ratings yet

- 03 U4 Reading1Document5 pages03 U4 Reading1api-292718088No ratings yet

- FLUID MACHINERY TURBINE CHARACTERISTIC CURVESDocument2 pagesFLUID MACHINERY TURBINE CHARACTERISTIC CURVESsarathkumararasu007No ratings yet

- CFD simulation of turbulence downstream of a large diameter square knife gate valveDocument5 pagesCFD simulation of turbulence downstream of a large diameter square knife gate valveRaef kobeissiNo ratings yet

- 1718SEM1Document6 pages1718SEM1Benedict ChinNo ratings yet

- LE10-Aulas 14 e 15-Escoamento Viscoso em Condutos-PME3238 PDFDocument3 pagesLE10-Aulas 14 e 15-Escoamento Viscoso em Condutos-PME3238 PDFMalu NevesNo ratings yet

- UPRT profile load factor drag controls stall recoveryDocument30 pagesUPRT profile load factor drag controls stall recoverygabriel sigifredo bolaños barreraNo ratings yet

- Pressure in Flowing FluidsDocument10 pagesPressure in Flowing FluidsIan SorzNo ratings yet

- Hydraulics Secttion4Document7 pagesHydraulics Secttion4Rezeile RoxasNo ratings yet

- Friction QsDocument2 pagesFriction QsicgsoftwareNo ratings yet

- Fluid Mechanics and Hydraulic Machine PDFDocument3 pagesFluid Mechanics and Hydraulic Machine PDFChaudhary Rahul SinghNo ratings yet

- The Particle Image Velocimetry - Characteristics Limits and Possible ApplicationsDocument398 pagesThe Particle Image Velocimetry - Characteristics Limits and Possible ApplicationsAdrian DavidNo ratings yet

- Mechanical Properties of Fluid - 04 (Of Lec-08) - Yakeen 2.0 2024 (Legend)Document3 pagesMechanical Properties of Fluid - 04 (Of Lec-08) - Yakeen 2.0 2024 (Legend)shubhamshekhar2003No ratings yet

- Wellbore CalculationsDocument34 pagesWellbore Calculationsbaskr82100% (1)

- Tutorial PackedBedDocument2 pagesTutorial PackedBedtejkiranNo ratings yet

- WR3Document8 pagesWR3Chris AdaminovicNo ratings yet

- Hydraulics Chapter 2 Problem SetDocument6 pagesHydraulics Chapter 2 Problem SetjosephussucoNo ratings yet

- Gravitation Revision Notes (JEE Mains)Document33 pagesGravitation Revision Notes (JEE Mains)SHREYANo ratings yet

- Hydraulic Engineering Lab ManualDocument34 pagesHydraulic Engineering Lab ManualK YNo ratings yet

- Fluidic Elements based on Coanda EffectDocument10 pagesFluidic Elements based on Coanda EffectAswith R ShenoyNo ratings yet

- 8 Air Pocket 8 Air Pocket 8. Air Pocket 8. Air Pocket: The ProblemDocument5 pages8 Air Pocket 8 Air Pocket 8. Air Pocket 8. Air Pocket: The ProblemBhavya JainNo ratings yet

- The Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE PublishersDocument10 pagesThe Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE Publishersdishku100% (1)

- (JPP-1) - (JEE 3.0) - Kinematics 2D - 3rd June.Document36 pages(JPP-1) - (JEE 3.0) - Kinematics 2D - 3rd June.gangadaran buvanaNo ratings yet

- CVEN 3323 Weirs LabDocument5 pagesCVEN 3323 Weirs LabJJ Sean CruzNo ratings yet

- Centrifugal Pumps TipsDocument34 pagesCentrifugal Pumps TipsFaizan AbbasiNo ratings yet

- Boundary Layer Theory 9Document20 pagesBoundary Layer Theory 9Sunil BagadeNo ratings yet

- Flow-Induced Vibration (FIV) Analysis (Vortex Shedding) - BETA Machinery AnalysisDocument3 pagesFlow-Induced Vibration (FIV) Analysis (Vortex Shedding) - BETA Machinery AnalysisGuilherme Augusto de Oliveira100% (1)

- Developmentofa Simulation Modelfor Propeller PerformanceDocument142 pagesDevelopmentofa Simulation Modelfor Propeller PerformanceorsoytNo ratings yet

- ABS Valve Flow CharacteristicsDocument6 pagesABS Valve Flow CharacteristicsNyoman RakaNo ratings yet

- Schem SPI Sizing EquationsDocument62 pagesSchem SPI Sizing EquationsRAJAVIGNESH SNo ratings yet