Professional Documents

Culture Documents

Connection and Bracing (By Abdussalam)

Uploaded by

abdussalam_zahraniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connection and Bracing (By Abdussalam)

Uploaded by

abdussalam_zahraniCopyright:

Available Formats

Introduction

Steps for Design

Geometry Modeling

Loading

Design Parameters

Analysis & Design

Connections & Bracing

Pipe Rack Design Flow Chart

Benefits of Steel Structure

Load Resisting Systems

Frame Types

Concentric / Eccentric Braced Frame

Steel Frame Connection Types

Simple Connection

Moment Connection

EM Connection Capacity Design Flow Chart

Reduced construction time & no seasonal effect.

Light weight and reduced foundation cost.

Durable , Long Lasting and Recyclable.

Easier to modify and reinforce if required.

Fabrication off-site possible (right).

On site erection is a time saving process (left).

Schedule advantage.

Forces

from

Gravity

,wind

and

seismic is imposed on all structures.

Applied vertical forces are gravity

loads.

Forces that act horizontally such as

wind, seismic require a lateral load

resisting

system

to

be

built

in

structure.

When lateral loads are applied to a

structure,

horizontal

diaphragm

transfer the load to the lateral load

resisting system.

Structural steel frame elevation

The type of lateral load (Seismic, Wind, Friction, Thermal ) resisting system to

be used in a Structure Should be taken care in the Earlier Planning Stage.

Braced Frame

Rigid Frame

Common lateral load resisting systems

Rigid frame, utilize the moment connection and this type is preferred where

diagonal or x- bracing is not allowed due to walkway obstruction.

Draw back of rigid frame is more cost than braced frame.

Braced frame is the economical method of resisting wind load in multi storey

structural frame.

Bracing creates triangular configuration in the structures.

Some structures like below picture take the advantage of both rigid and

braced at the same time.

Member or system that provides stiffness

and strength to limit the out of plan

movement of another member at the braced

point. (AISC Spec2010)

Two types of bracing is defined in AISC

(1997) seismic provision in steel structural

building.

A. Concentric Bracing

B. Eccentric Bracing

Concentrically braced frame are those in which the centerlines of members that

meet at a joint intersect at a point to form a vertical truss system that resist

lateral forces.

Commonly used bracing system in steel structure is

X- bracing ( above left)

Chevron (above right)

X- bracing is the most

common system used in steel

buildings.

Connection for X- bracing are

located at beam to column

joint.

Bracing connection may

require large gusset plate at

the beam to column joint.

The members used in chevron bracing

are designed for both compression and

tension

Chevron bracings allows for doorways or

corridors through the bracing lines in a

structure.

CHEVRON

DIAGONAL

ELEVATION WITH SEVERAL BRACING CONFIGURATION

Chevron bracing members use two types

of connections.

The Floor level connection may use a

gusset plate as like in x-braced frame.

The bracing members are connected to

the beam/girder at the top and converge to

a common point.

When gusset plate is used, it in important

to consider their size when laying out any

mechanical equipment pass through

braced bays.

Eccentric brace is commonly used in seismic regions and allow corridors and

walkway through bay frame.

In an eccentrically braced frames, bracing connect to a separate point on

beam/girder.

The beam/girder segment or link between them absorbs energy from seismic

activity through

plastic deformation.

Stiffeners

Link

Beam or Girder

Gusset Plate

Eccentric Brace

E/B with typical brace to beam connection

Adopted AISC 327-05

Eccentrically braced frame looks very similar to chevron bracing.

Eccentric single diagonal brace can also be use to brace a frame.

The specification of structural steel building (AISC 2010) defines two types of

frame connections.

Simple Connection

(below left)

Moment Connection

(below right)

Moment connection are of two types: FR & PR

Simple Connection: Connection that transmit negligible amount of bending

moment between connected members.

Moment Connection: Connection that transmit bending moment between

connected members.

Fully restrained moment connection FR : transfer moments with a negligible

amount of rotation between connected members.

Partially restrained moment connection PR : transfer moments, but rotation

between connected members is not negligible.

Adopted from Vol -II Connection .

Simple connection (A) have rigidity but is assumed to rotate free.

Connection (B & C) are examples of partially restrained moment

connections.

Connection (D & E) are examples of fully restrained moment.

Connection is assumed to be rotation free.

Vertical forces are primary forces transferred by the connection.

For this Connection a separate resisting system is required to design.

Single plate Connection

( Shear Tab)

A plate is welded to the supporting

member and bolted to the web of the

supported beam.

Double Angle Connection

The in plane pair of legs are attached to

the web of the supported member and out

of plane pair of legs attached to the

supporting beam web or flange.

Shear

end

connection

plate

A plate is welded perpendicular to the

end of supported web and bolted to

supporting beam.

Seated connection

An angle is mounted with one leg vertical

against the supporting column & the other

leg provides a seat upon which the beam

is mounted ,a stabilizer connection is

provided at top of the web.

Designed as rigid connection with little or no rotation.

Moment and vertical shear forces are transferred through the

connection.

Two types of moment connection are allowed:

1.

Partially restrained moment connection.

2.

Fully restrained moment connection.

Fully restrained (FR)Connection

Partially restrained (PR)Connection

Have sufficient strength to transfer moment

Have sufficient strength to transfer

with negligible rotation between connected

moments with rotation between

members.

connected members.

Welded flange plate connection

Bolted flange plate connection

Top and bottom flange plates connect the flanges of supported member to the supporting

column.

A single plate is used to transfer the vertical shear force.

*With column web

Bolted extended end plate

connection

Welded flange connection

Complete joint penetration groove

welds directly top and bottom

flanges of the supported member

to supporting column.

A shear connection at web is used

to transfer the vertical shear force.

A plate is welded to the end of

supported beam and bolted to the

supporting column flange.

*With column

PR moment connection

A double angle simple connection

transfers vertical shear forces while top

and bottom flange plates resist moment

forces produced by wind.

Top and bottom angle with shear

end plate connection

Angles are bolted or welded to the top

and bottom flanges of the supported

member and to the supporting column.

A shear end plate on the web is used to

transfer vertical shear forces.

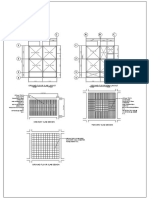

SAFE LOAD OF CONNECTION

End Moment

Connection

Ma =min.(Mm,Mw,Mb,Mp,Mst) (kN-m)

Ta = min.(Tm,Tw,Tb,Tp,Tst) (kN)

Va = min. (Vm,Vw,Vb) (kN)

(5) STIFFENER DESIGN

(1) MEMBER

Mm = 0.6Fy x Sx (kN-m)

Vm = 0.4Fy x Awn (kN)

Tm = 0.6Fy x 2Af (kN)

Af = bfb x tfb (mm2)

Awn = ( d1 - 2tfb ) x twb

(mm2)

(2) HIGH STRENGTH BOLT

Mb = n1 x Qt x ( d1 - tfb ) (kN-m)

Vb = n2 x Qs (kN)

Tb = 2 x n1 x Qt (kN)

n1= Number of tension bolts

n2= Total Number of bolts

(4) END PLATE

Mp = Ff x ( d1 - tfb ) (kN-m)

Tp = 2 x Ff (kN)

Ff = 4 x Me / ( m x Pe ) (kN)

Me = bp x 0.75Fy x tp2 / 6 (kN-m)

m = Ca x Cb x (Af / Aw)1/3 x (Pe /

db)1/4

Pe = Pf - (db / 4) - 0.707S1 (mm)

Ca = 1.13

Cb = ( bfb / bp )1/2

db = (mm)

Aw = twb x (d1 - 2tfb) (mm2)

(3) WELD

Mw = Ff x ( d1 - tfb ) (kN-m)

Ff = Fw x Awf (kN)

Vw = Fw x Aww(kN)

Tw = Fw x 2Awf

Awf = 0.707 x S1 x (2bfb+2tfb-twb )

(mm2) Aww = 0.707 S2 x ( d1 / 2 - tfb ) x

2 (mm2)

(5-1) COLUMN FLANGE BENDING

STRENGTH

Fcap = 4 x Me /( m x Pe )

Me = bs x 0.75Fy x tfc2 / 6 (kN)

bs= 2.5 x ( Pf + tfb + Pf ) (kN-m)

Pe = g / 2 - db / 4 - k1 (mm)

m = Ca x Cb x ( Af / Aw )1/3 x ( Pe / db )1/4

(mm)

Af / Aw = 1.0

min Mst = Ff x ( d1 - tfb ) (kN-m)

Ff = Fcap + Fst (kN)

min Tst = 2Ff (kN)

(5-2) TENSION CAPACITY OF STIFFENER

PLATE

Fst = 0.6Fy x Ast (kN)

Ast = ts x ( bfc - twc - 2 x 5 - 2 x 25 ) (mm2)

(5-3) SHEAR CAPACITY OF STIFFENER

PLATE

Fst = 0.4Fy x Ast (kN)

(5-4) STIFFENER WELD CAPACITY OF

COLUMN FLANGE

Fst = fw x Ast (kN)

Ast = 0.707 x lw x Sflg (mm

(5-5) STIFFENER WELD CAPACITY OF

COLUMN WEB

Fst = fw x Ast (kN)

Ast = 0.707 x lw x Sweb (mm2)

lw = 4 x (dc/2 - tfc - 25 - Sweb) : HALF

lw = 4 x (dc - 2tfc - 2x25 - 2xSweb) : FULL

AISC VOLUME-II CONNECTION

CONNECTION TEACHING TOOLKIT (AISC)

AISC 327-05 SEISMIC DESIGN MANUAL

AISC 2010 SPECIFICATION FOR STRUCTURAL

STEEL BLDGS

You might also like

- 18 Desing of Support For Pressure VesselDocument27 pages18 Desing of Support For Pressure VesselAmit KananiNo ratings yet

- DLRB Design ReportDocument61 pagesDLRB Design ReportRaviTeja100% (2)

- Composite Steel Beam DesignDocument4 pagesComposite Steel Beam Designmagi100% (1)

- Emad GadDocument34 pagesEmad GadRichoNo ratings yet

- Raft FoundationDocument11 pagesRaft Foundationcapstone111100% (2)

- 15 Years of Geotechnical Limit State Design in Australia: Foundations and Pile GroupsDocument6 pages15 Years of Geotechnical Limit State Design in Australia: Foundations and Pile Groupsprashanth c.nNo ratings yet

- Civil Engineering Column Design and Behavior AnalysisDocument58 pagesCivil Engineering Column Design and Behavior AnalysisAnonymous nQ9Rqm100% (1)

- Grameenphone 32m Guy Supported Mast SpecsDocument7 pagesGrameenphone 32m Guy Supported Mast Specsashraf04_ceNo ratings yet

- Chevron BracingDocument4 pagesChevron Bracingapi-369789750% (2)

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDocument5 pagesGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VNo ratings yet

- Calculation Sheets NZS 3604Document5 pagesCalculation Sheets NZS 3604Sam LeungNo ratings yet

- Structural Calculation LLPH Operation Shelter (N) : Upgrade Buildings For Risk Mitigation at Ras Tanura RefineryDocument121 pagesStructural Calculation LLPH Operation Shelter (N) : Upgrade Buildings For Risk Mitigation at Ras Tanura Refineryimri ssNo ratings yet

- Bondek IIDocument24 pagesBondek IIumtancw100% (3)

- DDA 3164 BEAM Shear Deflection and CrackDocument20 pagesDDA 3164 BEAM Shear Deflection and CrackZayyan RomjonNo ratings yet

- Reinforcing Steel in Slabs On Grade - tcm45-346883Document3 pagesReinforcing Steel in Slabs On Grade - tcm45-346883Ralf SnellNo ratings yet

- Reinforced Concrete BeamsDocument28 pagesReinforced Concrete BeamsEdriane Jude MalemNo ratings yet

- Lower cost FRP baffle panel for structural wallsDocument2 pagesLower cost FRP baffle panel for structural wallsLoay Al-SabbaghNo ratings yet

- T01-1 MasterFrame Tutorial - The BasicsDocument68 pagesT01-1 MasterFrame Tutorial - The BasicsMartinNo ratings yet

- Lecture of FootingDocument195 pagesLecture of FootingMonirul IslamNo ratings yet

- HW Retaining WallDocument76 pagesHW Retaining Wallrutuja100% (1)

- Chapter 3 Column and Compression MembersDocument60 pagesChapter 3 Column and Compression Membersbihanba100% (1)

- UWS CompositeBeam ShearConnectionDocument15 pagesUWS CompositeBeam ShearConnectionMuhammad AsroriNo ratings yet

- Factors Affecting Strength of Epoxy Repaired TimberDocument15 pagesFactors Affecting Strength of Epoxy Repaired TimberJosé PeNo ratings yet

- Bracing Connection Work Point PDFDocument2 pagesBracing Connection Work Point PDFaams_sNo ratings yet

- RAPT Beam AnalysisDocument16 pagesRAPT Beam Analysisvikramjain66No ratings yet

- Dev LengthDocument5 pagesDev LengthdghtghfgjhhjjhnNo ratings yet

- Con 1302Document12 pagesCon 1302Sanket Arun More100% (1)

- CSD 366 Concrete: Topics: 5 Two Way Slabs On Columns 6 ShearDocument55 pagesCSD 366 Concrete: Topics: 5 Two Way Slabs On Columns 6 ShearChan Nov100% (1)

- Braced Frames: From Steelconstruction - InfoDocument18 pagesBraced Frames: From Steelconstruction - Infojohnsmith1980No ratings yet

- Structural Analysis of Transmission Structures: 1.problem DescriptionDocument69 pagesStructural Analysis of Transmission Structures: 1.problem DescriptionMahesh ANo ratings yet

- Composite Beam DesignDocument33 pagesComposite Beam DesignihpeterNo ratings yet

- The Behavior of Cold Formed Steel Structure Connections PDFDocument11 pagesThe Behavior of Cold Formed Steel Structure Connections PDFg1n2No ratings yet

- Column Design Procedure PDFDocument26 pagesColumn Design Procedure PDFTamilNo ratings yet

- Fema 356Document121 pagesFema 356Girijesh Prasad Sah100% (1)

- Pile Cap Design - Structural GuideDocument6 pagesPile Cap Design - Structural GuideA KNo ratings yet

- Bolted Connections BearingDocument21 pagesBolted Connections Bearingkamad0naNo ratings yet

- HB Ground Improvement Solutions MatrixDocument3 pagesHB Ground Improvement Solutions MatrixSheik Mohamed LiakathNo ratings yet

- Design Model For Simple Column Bases - Axially Loaded I Section ColumnsDocument17 pagesDesign Model For Simple Column Bases - Axially Loaded I Section Columnshooky1100% (2)

- Designing structural steelwork to BS5950Document8 pagesDesigning structural steelwork to BS5950Reef20No ratings yet

- Shear Walls - An OverviewDocument6 pagesShear Walls - An OverviewTabish IslamNo ratings yet

- What Are The Types of Ties Used in Building ConstructionDocument4 pagesWhat Are The Types of Ties Used in Building ConstructioncarmeloNo ratings yet

- Composite Member EI ValueDocument4 pagesComposite Member EI ValueArjun RajaNo ratings yet

- Ramset AnchorsDocument60 pagesRamset Anchorsmercab15No ratings yet

- A Five Story Precast Concrete Test Building For Seismic Conditions - Design DetailsDocument8 pagesA Five Story Precast Concrete Test Building For Seismic Conditions - Design Detailswrite2eddyNo ratings yet

- Macalloy Tension Rod SystemsDocument25 pagesMacalloy Tension Rod Systemsakajsi0% (1)

- Reinforced and Post Tensioned Rapt Software Design Workshop 1 Day PDFDocument1 pageReinforced and Post Tensioned Rapt Software Design Workshop 1 Day PDFUtsav ShrivastavaNo ratings yet

- Composite Construction Design GuideDocument23 pagesComposite Construction Design Guiderameshbabu_1979No ratings yet

- MasterSeries Student Masonry Retaining EtcDocument21 pagesMasterSeries Student Masonry Retaining EtcekaNo ratings yet

- RCC Slab Reinforcement GuideDocument22 pagesRCC Slab Reinforcement GuidelakshitaNo ratings yet

- Pile Cap Design - Structural GuideDocument9 pagesPile Cap Design - Structural Guidedhan singhNo ratings yet

- Apex HaunchDocument34 pagesApex HaunchDanny ArimaNo ratings yet

- OneSteel Design Booklet DB1.1 - Design of Simply Supported Composite BeamsDocument54 pagesOneSteel Design Booklet DB1.1 - Design of Simply Supported Composite Beamsdirk.price635No ratings yet

- Load Difference in NZ CodeDocument7 pagesLoad Difference in NZ CodeAslam KyonNo ratings yet

- Column Design GuideDocument8 pagesColumn Design GuideegozenovieNo ratings yet

- Con3001 PDFDocument3 pagesCon3001 PDFManimaran JayarajNo ratings yet

- Example Flat Slab Design - CarDocument31 pagesExample Flat Slab Design - CarRayGaintNo ratings yet

- Ramset Specifiers Resource Book 09Document244 pagesRamset Specifiers Resource Book 09GarryNo ratings yet

- Everdure Waterstop - Page1Document1 pageEverdure Waterstop - Page1Jefferd AlicanNo ratings yet

- 1 Connection and BracingDocument33 pages1 Connection and BracingCe WinNo ratings yet

- BracingDocument30 pagesBracingshailiza velaniNo ratings yet

- Steel ResearchDocument33 pagesSteel ResearchMohamed HaggagNo ratings yet

- Some Info On TrussesDocument9 pagesSome Info On TrussesameensderajNo ratings yet

- Types of Truss Member Sections: Bolted Angles To Form Lightweight, Long-Span TrussesDocument6 pagesTypes of Truss Member Sections: Bolted Angles To Form Lightweight, Long-Span TrussesjustineNo ratings yet

- Connections and Bracing - PresentationDocument32 pagesConnections and Bracing - PresentationAndreea NanNo ratings yet

- Seismic Bracing For Fire Fighting SystemDocument29 pagesSeismic Bracing For Fire Fighting SystemSree S100% (1)

- MTech Structural Engineering Question Bank on Advanced Steel StructuresDocument12 pagesMTech Structural Engineering Question Bank on Advanced Steel StructuresravirainbowNo ratings yet

- Poured Joint With Backer Rod 21110Document2 pagesPoured Joint With Backer Rod 21110جميل عبد الله الحماطيNo ratings yet

- Natural Red Clay Interlocking PantileDocument6 pagesNatural Red Clay Interlocking PantileArnisNo ratings yet

- Reinforcing Bar Couplers LRDocument16 pagesReinforcing Bar Couplers LRNessa NesschtNo ratings yet

- S. Suresh: Fatigue of Materials (Cambridge Solid State Science Series)Document20 pagesS. Suresh: Fatigue of Materials (Cambridge Solid State Science Series)Akshay YarlapatiNo ratings yet

- Slab Design CalculationsDocument21 pagesSlab Design CalculationsLucas Construction SolutionsNo ratings yet

- Lenton CouplersDocument20 pagesLenton CouplersSherief MagdyNo ratings yet

- Final Internship ReportDocument39 pagesFinal Internship ReportKirubel AyeleNo ratings yet

- BRIDGE Cat + Exams-01Document14 pagesBRIDGE Cat + Exams-01SHOTURU PNo ratings yet

- Purlin section design beam displacement analysisDocument7 pagesPurlin section design beam displacement analysisIjaz AhmedNo ratings yet

- Two-way slab design layoutDocument1 pageTwo-way slab design layoutMark Anthony TajonNo ratings yet

- Shear and Diagonal Tension in BeamsDocument13 pagesShear and Diagonal Tension in Beamsdilnessa azanawNo ratings yet

- TENSACCIAI - Slab Post-Tensioning SystemDocument0 pagesTENSACCIAI - Slab Post-Tensioning Systemnovakno1No ratings yet

- Introduction To Masonry StructuresDocument33 pagesIntroduction To Masonry StructuresNiraj JhaNo ratings yet

- Internship ReportDocument39 pagesInternship ReportAman HoodaNo ratings yet

- Design of RC Beam (GB) : GeometryDocument5 pagesDesign of RC Beam (GB) : GeometryJake CortezNo ratings yet

- C-HW09 Simpson CatalogDocument44 pagesC-HW09 Simpson CatalogLee WinklerNo ratings yet

- Hume Pipe Culvert EstimateDocument6 pagesHume Pipe Culvert EstimateChandu NaniNo ratings yet

- Experimental and Numerical Studies On The BehaviouDocument13 pagesExperimental and Numerical Studies On The Behavioupradeep kankeriNo ratings yet

- Seismic Analysis of Structures by Etabs in BS Code PDFDocument12 pagesSeismic Analysis of Structures by Etabs in BS Code PDFKirti Chandra JoshiNo ratings yet

- 1082 Rawlplug en R Hptii ZF Zinc Flake ThroughboltDocument8 pages1082 Rawlplug en R Hptii ZF Zinc Flake Throughboltmaniamjad321No ratings yet

- Cumbia. Theory and GuideDocument44 pagesCumbia. Theory and GuideElias RojanoNo ratings yet

- Concrete Construction Article PDF - Isolation and Expansion Joints in Concrete PavementsDocument2 pagesConcrete Construction Article PDF - Isolation and Expansion Joints in Concrete PavementsMaria RosaNo ratings yet

- Construction and Building Materials: Gourab Saha, Krishna Prapoorna BiligiriDocument10 pagesConstruction and Building Materials: Gourab Saha, Krishna Prapoorna Biligirithanhnhat5521No ratings yet