Professional Documents

Culture Documents

Multiple Effect Evaporator

Uploaded by

chemical_yayang2932Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multiple Effect Evaporator

Uploaded by

chemical_yayang2932Copyright:

Available Formats

MULTIPLE EFFECT

EVAPORATOR

Prof.Dr.Ir.Achmad Roesyadi,M.Eng

Step By Step

1. Assume values for the temperatures of the first and second

effects.

2. By means of heat-balance equations across each effect,

determine the evaporation in each effect.

3. By means of the rate equations, calculate the heating surface

needed for each effect.

4. If the heating surfaces so determined are not essentially equal

for the three effects, redistribute the temperature drops and

repeat items 2 and 3 till the heating surfaces are equal.

The second trial can usually be made to give the desired

result, so the method is not unreasonably tedious.

If the liquids has an appreciable boiling-point elevation

(with consequent effects on enthalpies), no rigorous solution is

possible because the relation between concentration, pressure,

boiling-point elevations, and enthalpies cannot be simply

formulated mathematically. A series of approximations makes

the trial-and-error method fairly direct.

1. From the known terminal conditions, find the boiling point and enthalpies

for the last effect

2. Assume the amount of evaporation in the first and second effects. Since

for moderately dilute solutions the slope of the Dhring lines is nearly

unity (the boiling-point elevation is nearly independent of pressure), this

gives approximate compositions and approximate boiling-point

elevations.

3. Since all elevations are now known, the working effective temperature

drop may be determined and distributed among the effects.

4. By means of heat-balance equations, calculate the evaporation in the first

and second effects. If these differ appreciably from those assumed in step

2, repeat steps 2 and 3 with the amounts of evaporation just calculated.

5. By means of rate equations, calculate the surface required

for each effect.

6. If the heating surfaces are not essentially equal for the three

effects, revise the temperature distribution of step 3. Unless

boiling-point elevations are very large, this will not alter

appreciably the elevations assumed in step 2.

7. Repeat these adjustments till the heating surfaces are equal.

The second revision will usually give the required answer.

Example 5-5

A triple-effect forced-circulation evaporator is to concentrate a 10 per cent

solution of sodium hyroxide to 50 per cent. The feed is to be at 100F and

is to be of such an amount as to contain 5 tons NaOH per hour. Steam is

available at 236F (23.2 psia), and a vacuum of 28 in. (referred to a 30-in.

barometer) may be maintained on the last effect. Heat-transfer coefficients

may be assumed to be U

1

= 1100, U

2

= 600, U

3

= 400. Forward feed is to

be used. Radiation losses and losses by entrainment may be neglected.

Condensate may be assumed to leave at he saturation temperature of the

steam. What heating surface must be used (all effects have the same

surfaces) and what is the steam consumption? What is the evaporation per

pound of steam?

F =100,000

X

F

= 0.10

T

F

= 100

h

F

= 60

t

c

1

= 238C

h

c

1

= 204

t

c

2

h

c

2

t

c

3

h

c

3

I II III

L

1

= F V

1

t

L

1

x

1

h

1

L

2

= F V

2

t

L

2

x

2

h

2

L

2

= 20,000

t

L

3

x

3

= 0.50

h

3

= 202

V

1

Y

1 = 0

t

V

1

H

1

V

2

Y

2 = 0

t

V

2

H

2

V

3

Y

3 = 0

t

V

3

H

3

H

S

=1159

t

S

= 236

Solution.

The data given directly are

t

S

= 236F x

F

= 0.10

t

F

= 100F x

1

= 0.50

From the steam tables h

F

= 60 Btu/lb

H

s

= 1159 Btu/lb (latent heat = 955 Btu/lb)

h

3

= 202 Btu/b

TBW III = Saturation temperature (for water) in III = 101F

Weight of feed, thick liquor, and evaporation :

Evaporation = 80,000 lb/hr = V

1

+ V

2

+ V

3

To determine the temperature drop available, it is necessary to know the elevations in

boiling point ; but to determine these he concentrations in I and II must be known

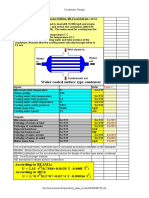

Neraca massa :

Asumsi awal :

< <

anggap :

TBW Tlarutan KTD

DISTRIBUSI

T

F : 100.000 X

f

= 0.1 Ts = 236

I

V

1

: 25.500 F . X

f

= L

1

. X

1

200 209 9 12

L

1

:

74.500 X

1

= 0.134 assumed assumed

II

V

2

: 26.700 F . X

f

= L

2

. X

2

150 165 15 12

L

2

: 47.800 X

2

= 0.218 assumed

V

3

: 27.800 F . X

f

= L

3

. X

3

101 171 70 17

III

L

3

: 20.000 X

3

= 0.5 assumed

TOTAL T 135 - 94 41

T TOTAL KTD = Efektif

Neraca Panas

1

st

Effect

2

nd

Effect

3

rd

Effect

=

=

=

; ;

didapat :

dan

(25.500)

(26.700)

(27.800)

CATATAN : 1) ,H

v

dicari dari Steam Table

2) h

l

dicari dengan grafik Enthalpy Concentration Chart

3) Superheat dihitung : C

p

x KTD

T

Super Heat

+ sp hl Hv Cp T

F sp.

S ke I 236 955 0 955 - 1159

T1 12

T larutan I 224 - - - 171 -

KTD I 9

V1 ke II

215

TBW1 968 4 972 - 1156

T2 12

T larutan II 203 - - - 147 -

KTD II 15

V2 ke III

188

TBW2 985 8 993 - 1149

T3 17

T larutan III 171 - - - 202 -

KTD III 70

V3 ke Kondenser

101

TBW3 1037 31 1069 - 1138

Menghitung Luas

dari

=

=

=

=

Karena maka prosedur distribusi T harus diulang

Catatan : Perubahan T ini tidak banyak mempengaruhi KTD

Kondisi data ditabelkan kembali

CATATAN : 1) ,H

v

dicari dari Steam Table

2) h

l

dicari dengan grafik Enthalpy Concentration Chart

3) Superheat dihitung : C

p

x KTD

T

Super Heat

+ sp hl Hv Cp T

F sp.

S ke I 236 955 0 955 - 1159

T1 10

T larutan I 226 - - - 171 -

KTD I 9

V1 ke II

217

TBW1 967 4 971 - 1156

T2 12

T larutan II 205 - - - 149 -

KTD II 15

V2 ke III

190

TBW2 984 9 993 - 1151

T3 19

T larutan III 171 - - - 202 -

KTD III 70

V3 ke Kondenser

101

TBW3 1037 31 1069 - 1138

Neraca Panas

= 1).

2).

=

3).

=

didapat :

dan

Menghitung A kembali :

(error 3,5% < 5%)

HASIL DAPAT DITERIMA

You might also like

- Calculation For Multiple Effect EvaporatorDocument14 pagesCalculation For Multiple Effect Evaporatormsiregar_3891% (11)

- 2) Multiple Effect Evaporators A) Forward Feed Multiple Effect EvaporatorsDocument12 pages2) Multiple Effect Evaporators A) Forward Feed Multiple Effect EvaporatorsDr-Khalid Al-Shemmari100% (1)

- Evaporator ExcelDocument44 pagesEvaporator ExcelawenskieNo ratings yet

- CEB 2063 Evaporation Process Design and AnalysisDocument28 pagesCEB 2063 Evaporation Process Design and AnalysisScorpion RoyalNo ratings yet

- Evap DesignDocument16 pagesEvap DesignAhmed Ali100% (3)

- Triple Effect EvaporatorDocument9 pagesTriple Effect Evaporatorjnmanivannan100% (1)

- Triple Effect EvaporatorDocument8 pagesTriple Effect Evaporatormfruge7No ratings yet

- Single Effect EvaporaterDocument16 pagesSingle Effect EvaporaterdebdeepNo ratings yet

- Design of Triple Effect EvaporatorDocument37 pagesDesign of Triple Effect EvaporatorI. Murali Krishna0% (1)

- Multi Effect EvaporatorDocument32 pagesMulti Effect EvaporatorAradhana Kanchan Saxena100% (3)

- Excel Crop Care Limited: "Multi Effect Evaporator Plant"Document9 pagesExcel Crop Care Limited: "Multi Effect Evaporator Plant"Sparsh ShukalNo ratings yet

- 08-Falling Film Evaporator - by Bma GermanyDocument30 pages08-Falling Film Evaporator - by Bma GermanyFarooq Ameer Jordan Wala100% (1)

- Shell Diameter Calculation and Heat Exchanger DesignDocument26 pagesShell Diameter Calculation and Heat Exchanger Designpavan100% (1)

- Mechanical vapor recompression and multiple effect evaporator system reduces steam usageDocument13 pagesMechanical vapor recompression and multiple effect evaporator system reduces steam usageMariAle Droz CastroNo ratings yet

- Heat CapacityDocument2 pagesHeat CapacityAbhijit MokashiNo ratings yet

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationVirendra Bhagat100% (1)

- 1981 - Addison - Large Falling Film EvaporatorsDocument3 pages1981 - Addison - Large Falling Film EvaporatorsshondabagueNo ratings yet

- Design and Simulation of a Multiple Effect Evaporator System for Black Liquor ConcentrationDocument68 pagesDesign and Simulation of a Multiple Effect Evaporator System for Black Liquor ConcentrationAhmed AliNo ratings yet

- Calculations On An Adiabatic Continuous DryerDocument11 pagesCalculations On An Adiabatic Continuous DryerCaleb Somai0% (1)

- Evaporator DesignDocument5 pagesEvaporator DesignSaurab DevanandanNo ratings yet

- EvaporationDocument50 pagesEvaporationRajNo ratings yet

- Single Effect Evaporation (SEE) ProcessesDocument28 pagesSingle Effect Evaporation (SEE) ProcessesAl- Dhaheri0% (1)

- Noniterative Design of Multiple Effect Evaporators Using Excel Add InsDocument10 pagesNoniterative Design of Multiple Effect Evaporators Using Excel Add InsGalang Hanif AbdulahNo ratings yet

- Cebu Institute of Technology: UniversityDocument10 pagesCebu Institute of Technology: UniversityArchie HisolerNo ratings yet

- Falling Film Evaporator-MEng-ThesisDocument206 pagesFalling Film Evaporator-MEng-ThesisElza Febrianty AngrainiNo ratings yet

- Evaporator: Department of Chemical EngineeringDocument16 pagesEvaporator: Department of Chemical EngineeringspidyNo ratings yet

- Condenser DesignDocument12 pagesCondenser Designbirendrajee100% (1)

- Energy Reduction Schemes For Multiple Effect Evaporator SystemsDocument10 pagesEnergy Reduction Schemes For Multiple Effect Evaporator Systemskishna009No ratings yet

- Multiple Effect Evaporator Online CalculationsDocument1 pageMultiple Effect Evaporator Online CalculationsRajdeepsinhNo ratings yet

- MVR Writeup 2016Document13 pagesMVR Writeup 2016Abhijeet Jhankal100% (1)

- Forced Circulation Evaporator Final ReportDocument40 pagesForced Circulation Evaporator Final ReportManvi SharmaNo ratings yet

- Coalmix & Biomix - PresentationDocument47 pagesCoalmix & Biomix - PresentationchandravadiyaketanNo ratings yet

- Cooling Tower FinalDocument10 pagesCooling Tower Finalmkha87100% (4)

- Tower HMBDocument26 pagesTower HMBAnkur KoulNo ratings yet

- Evaporation 1Document23 pagesEvaporation 1nontando sogaNo ratings yet

- Evaporator (D-1) Design ExcelDocument7 pagesEvaporator (D-1) Design ExceldiRkdARyLNo ratings yet

- Types of EvaporatorsDocument12 pagesTypes of Evaporatorsapi-377437388% (8)

- EvaporatorsDocument66 pagesEvaporatorsnaval chaudhary83% (12)

- Spray Drying Design and Operation Guide Under 40 CharactersDocument24 pagesSpray Drying Design and Operation Guide Under 40 CharactersHOMAYOUN KHADIVINo ratings yet

- EvaporatorDocument4 pagesEvaporatorVipul PrakashNo ratings yet

- EvaporatorDocument5 pagesEvaporatorLimanto Lee89% (9)

- Japan-Philippine Steel Manufacturing Corporation: Acid Fumes ScrubberDocument84 pagesJapan-Philippine Steel Manufacturing Corporation: Acid Fumes ScrubberLuis UrzoNo ratings yet

- Boiler Feed Water Treatment & BlowdownDocument6 pagesBoiler Feed Water Treatment & BlowdownnurulNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- Condenser Design Calculation SummaryDocument11 pagesCondenser Design Calculation SummaryAlMakhie0% (1)

- Latest Technologies Knowledge Sharing Session 4Document38 pagesLatest Technologies Knowledge Sharing Session 4Tajuddin ShaikNo ratings yet

- Guid To Design of EvaporatorDocument40 pagesGuid To Design of Evaporatorscranderi100% (2)

- Evaporator EfficiencyDocument15 pagesEvaporator EfficiencySanjaySinghAdhikariNo ratings yet

- Fundamental Principles of DryingDocument32 pagesFundamental Principles of DryingSaber Chemkhi100% (1)

- Evaporation: Types, Design, Calculation and ProcessesDocument86 pagesEvaporation: Types, Design, Calculation and ProcessesArgha TalukderNo ratings yet

- Tripple Effect Evaporator Design CalculationDocument6 pagesTripple Effect Evaporator Design CalculationCathal McKeownNo ratings yet

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Spray Dryer PDFDocument12 pagesSpray Dryer PDFAhmad Zaidi100% (1)

- Heat Exchanger Design CalculationsDocument6 pagesHeat Exchanger Design CalculationsryanarthurNo ratings yet

- Key Process Indicators-Falling Film EvaporatorsDocument20 pagesKey Process Indicators-Falling Film Evaporatorscgoveia3No ratings yet

- Chapter Five PDFDocument24 pagesChapter Five PDFعبدالله رعد حران 32No ratings yet

- Lecture 8Document20 pagesLecture 8Bradee DoodeeNo ratings yet

- Simulation of A Multiple-Effect EvaporatorDocument36 pagesSimulation of A Multiple-Effect EvaporatorSamsouma SoumiaNo ratings yet

- P (Atm.) : Solution of Problem No. 3 Compression and Expansion of A Two Gases SystemDocument4 pagesP (Atm.) : Solution of Problem No. 3 Compression and Expansion of A Two Gases SystemPopovici DraganNo ratings yet

- Shell and Tube Heat Exchanger Sample Problem and SolutionDocument9 pagesShell and Tube Heat Exchanger Sample Problem and Solutionlouisealfonzo.chanNo ratings yet

- Catalysis & Catalysts - Impregnation and Reaction MechanismDocument19 pagesCatalysis & Catalysts - Impregnation and Reaction MechanismZamri Fadilah IINo ratings yet

- Technical Science Notes Students VersionDocument22 pagesTechnical Science Notes Students VersionAriff AziziNo ratings yet

- DSC Q100 ManualDocument76 pagesDSC Q100 ManualKaanNo ratings yet

- Flinn Lab 1: Atomic Structure & Periodic Trends: Observe Part 1Document7 pagesFlinn Lab 1: Atomic Structure & Periodic Trends: Observe Part 1Angelo RayesNo ratings yet

- Report Stirling Engine CompleteDocument28 pagesReport Stirling Engine CompleteNurul Nadia33% (3)

- Metrology Unit 3 PPT 3Document34 pagesMetrology Unit 3 PPT 3Punith RajNo ratings yet

- Distillation EfosaDocument36 pagesDistillation EfosaEmonbeifo EfosasereNo ratings yet

- Nuclear ReactionsDocument3 pagesNuclear ReactionsErica Alviyanti BastiandNo ratings yet

- Ikpeka Et Al-2018-Journal of Petroleum Exploration and Production TechnologyDocument24 pagesIkpeka Et Al-2018-Journal of Petroleum Exploration and Production TechnologyNwakile ChukwuebukaNo ratings yet

- Concentration Terms (Basic Sheet)Document3 pagesConcentration Terms (Basic Sheet)ParthNo ratings yet

- Ammonia Mass BalanceDocument34 pagesAmmonia Mass Balanceaskaridumbo82% (17)

- Solution Manual For Human Biology 16th Edition Sylvia Mader Michael WindelspechtDocument36 pagesSolution Manual For Human Biology 16th Edition Sylvia Mader Michael Windelspechtoverspinmeetklac40100% (46)

- Exp17 Pstest LR v09022017 Chapter 1Document30 pagesExp17 Pstest LR v09022017 Chapter 1Malek MahmoudNo ratings yet

- PARTICLE PROPERTIES OF WAVESDocument27 pagesPARTICLE PROPERTIES OF WAVESDikshit AjitsariaNo ratings yet

- L3 Equilibrium ConversionDocument17 pagesL3 Equilibrium ConversionChristopher RamosNo ratings yet

- Lesson 3 Properties of Liquids and IMFDocument47 pagesLesson 3 Properties of Liquids and IMFHillary Faith GregoryNo ratings yet

- British Patent for Orbitally Rearranged Monoatomic ElementsDocument24 pagesBritish Patent for Orbitally Rearranged Monoatomic ElementsSean ReevesNo ratings yet

- SLES Concentration Effect On The Rheolog TraducidoDocument22 pagesSLES Concentration Effect On The Rheolog TraducidoJose GamezNo ratings yet

- J - Am. Chem. SOC1.9 92, 114, 5530 ArduengoDocument5 pagesJ - Am. Chem. SOC1.9 92, 114, 5530 ArduengoLissette JimenezNo ratings yet

- View Eval ReportDocument5 pagesView Eval ReportmadhavNo ratings yet

- Lab Report 5Document5 pagesLab Report 5mamoona noreenNo ratings yet

- Refresher 3 PipeDocument11 pagesRefresher 3 PipeKira YagamiNo ratings yet

- Notes Lecture 2 - Scanning-Transmission Electron Microscope (STEM)Document16 pagesNotes Lecture 2 - Scanning-Transmission Electron Microscope (STEM)Anirban BasuNo ratings yet

- 13 Wet Scrubbing: A. Arrowsmith and N. F. AshtonDocument2 pages13 Wet Scrubbing: A. Arrowsmith and N. F. AshtonDHAVALESH AMNo ratings yet

- Synthesis of Mesoporous Carbon MaterialsDocument7 pagesSynthesis of Mesoporous Carbon MaterialsMaria IgnatNo ratings yet

- Fuels and CombustionDocument63 pagesFuels and CombustionKenneth DilancoNo ratings yet

- The Rate and Extent of Chemical ChangeDocument11 pagesThe Rate and Extent of Chemical ChangeKirsten AntonioNo ratings yet

- Hvac CalculationsDocument8 pagesHvac CalculationsJads CayabyabNo ratings yet

- Textile Chemical Brochure 8.6.22 - 031Document1 pageTextile Chemical Brochure 8.6.22 - 031NIKESH PRAKASHNo ratings yet