Professional Documents

Culture Documents

A3 Report

Uploaded by

Faye Alonzo0 ratings0% found this document useful (0 votes)

138 views19 pagesToyota's new domestic plant expansion has massive technical requirements that must be translated from Japanese documents to English. The size and complexity of the projects are creating errors and delays. The A3 thinking process aims to create an organization full of thinking, learning problem solvers.

Original Description:

Original Title

A3 Report.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentToyota's new domestic plant expansion has massive technical requirements that must be translated from Japanese documents to English. The size and complexity of the projects are creating errors and delays. The A3 thinking process aims to create an organization full of thinking, learning problem solvers.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

138 views19 pagesA3 Report

Uploaded by

Faye AlonzoToyota's new domestic plant expansion has massive technical requirements that must be translated from Japanese documents to English. The size and complexity of the projects are creating errors and delays. The A3 thinking process aims to create an organization full of thinking, learning problem solvers.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 19

The A3 REPORT

Developing an Organization of Thinking

Problem Solvers

Topic Outline

Introduction

The A3 Thinking Process

Toyotas SECRET:

The A3 REPORT

I. Background

II. Current Conditions

III. Goals/ Targets

IV. Cause Analysis

V. Proposed Countermeasures

VI. Plan

VII. Follow-up

New domestic plant expansion has massive technical

requirements that must be translated from Japanese

documents to English. The size and complexity of the

projects are creating errors & delays.

I. Background

Cost overruns, delays and errors due to:

Sheer volume of documents

Multiple & varied vendors (pricing, quality, ease)

Involvement of various departments & working

style.

II. Current Conditions

Simplify and standardize the process

Reduce costs by 10%

III. Goals/ Targets

Challenge of translating from Japanese to English

Multiple varied vendors create a complex, non-

standard process

Overall improvement can be defined by reduction

in cost overruns

IV. Cause Analysis

Simplify and improve process performance by

choosing one vendor based on competitive bid

process.

V. Proposed Countermeasures

Evaluate current vendor.

Identify new vendor candidates

Develop bid package and distribute.

VI. Plan

Monitor cost to proposal

Review performance at the end of one year.

Put contract up for bid again if performance fails

VII. Follow-up

Create Robust Process for Translating Documents

Goals

1. Get decisions made.

2. Distribute authority to the level needed for good decision

3. Align people and teams on common goals and learn for

constant improvement.

4. Solve the problem at hand

5. Make the process of problem solving transparent

6. Make the process of problem solving teachable in a

manner that creates an organization full of thinking,

learning problem solvers

V. Proposed Countermeasures

VII. Follow-up

Support Launch Objectives with Accurate, Timely Document Translation

II. Current Conditions

Quality: 0 Defect at Launch

Delivery: 100% on-time

- Level weekly volume (Heijunka)

- Consistent short lead time with

predictable delivery

Cost: 10% decrease Rework down; overtime down

III. Goals/ Targets

I. Background

IV. Cause Analysis

VI. Plan

II. Current Conditions

I. Background

New domestic plant expansion has massive technical

requirements that must be translated from Japanese

documents to English. The size and complexity of the

projects are creating errors & delays.

I. Background

Cost overruns, delays and errors due to:

Sheer volume of documents

Multiple & varied vendors (pricing, quality, ease)

Involvement of various departments & working

style.

II. Current Conditions

The A3 can be used as a mechanism

to prevent from jumping ahead to a

solution. We can simply be an

investigator and let the needs and facts

of the situation speak for themselves.

Rather than the answer, we must

simply state succinctly, What is the

Problem?

II. Current Conditions

I. Background

An A3 tells a complete story, with a

beginning, a middle and an end.

Every A3 is no more than a visual

manifestation of a problem-solving

thought process involving continual

dialogue between the owner of an

issue and others in an organization.

Current conditions are always

based on facts derived from the

gemba the place where the work

takes place. Real facts about the

real work are derived from careful

investigation on the part of the

author.

II. Current Conditions

I. Background

A3s employ visual methods to share

information and thinking. This

helps condense key facts into

meaningful visual shorthand

storytelling tools that help pack a

great deal of data into an elegant

presentation

II. Current Conditions

Defining the problem simply and

powerfully represents the most

important part of any A3.

Effective A3s persuade others by

capturing the right story with facts (not

abstractions) and communicating the

meaning effectively.

Quality: 0 Defect at Launch

Delivery: 100% on-time

- Level weekly volume (Heijunka)

- Consistent short lead time with

predictable delivery

Cost: 10% decrease Rework down; overtime down

III. Goals/ Targets

Cost overruns, delays and errors due to:

Sheer volume of documents

Multiple & varied vendors (pricing, quality, ease)

Involvement of various departments & working

style.

II. Current Conditions

Simplify and standardize the process

Reduce costs by 10%

III. Goals/ Targets

A problem is something that presents

itself as a barrier to the organization

achieving its goal. Articulating this

problem requires the author to identify

the gap between current state and the

desired performance at any given time.

The root cause or reason the gap exists is

identified through examining the way the

work is currently being performed and

asking why the problem occurs. If the

root cause is clearly defined, effective

countermeasures can be easily developed.

IV. Cause Analysis

Challenge of translating from Japanese to English

Multiple varied vendors create a complex, non-

standard process

Overall improvement can be defined by reduction

in cost overruns

IV. Cause Analysis

V. Proposed Countermeasure

Simplify and improve process

performance by choosing one vendor

based on competitive bid process.

V. Proposed Countermeasures

KS

8/8/08

DP

8/7/08

A3 proposals typically use the word

countermeasure rather than

solution. Countermeasure refers to

the way that proposed actions are

directly addressed to existing conditions.

More importantly, the wording

recognizes that even apparent

solutions inevitably create new

problems. Once a countermeasure is in

place, it will create a new situation, with

its own set of problems that will require

their countermeasures.

V. Proposed Countermeasure

Simplify and improve process

performance by choosing one vendor

based on competitive bid process.

V. Proposed Countermeasures

KS

8/8/08

DP

8/7/08

The A3s process explores a set of

potential countermeasures rather

than just one solution. By

examining a range of potential

choices, individuals uncover a

broader and more meaningful

basis for dialogue, analysis and

agreement.

V. Proposed Countermeasure

Simplify and improve process

performance by choosing one vendor

based on competitive bid process.

V. Proposed Countermeasures

KS

8/8/08

DP

8/7/08

Note that effective

countermeasures can be produced

only by speaking with everyone

who touches the work. And so

producing a viable plan requires

meaningful input from everyone.

V. Proposed Countermeasure

Simplify and improve process

performance by choosing one vendor

based on competitive bid process.

V. Proposed Countermeasures

KS

8/8/08

DP

8/7/08

All A3s include the initials or

names of the author and manager.

The Value of the A3 process to the

manager cannot be overemphasized.

The manager now has a tool to

mentor and establish alignment.

The individual now has the means to

propose answers to problems that he/

she owns, to create authorization to

act and to manufacture the

authorization needed to see the

proposal carried out.

VI. Plan

KS

8/8/08

DP

8/7/08

Producing a realistic plan through

the A3 process shifts the basis of

decision making from formal

authority to ownership of the

problem itself. By developing a

mastery of the issues at hand and

involving the players in the process,

the A3 author earns the authority to

propose and move forward an

effective plan.

Evaluate current vendor.

Identify new vendor candidates

Develop bid package and distribute.

VI. Plan

VI. Plan

Every action plan includes a schedule for hansei, or reflection to identify problems,

develop new countermeasures and communicate improvements to the rest of the

organization. A3s are part of a learning cycle of continuous improvement which is

why a key Toyota saying is,

No problem is a problem.

Midterm review

Prelaunch review

Ensure ongoing collaboration

Monitor system weekly. All

metrics', especially quality

and delivery

Monitor cost to proposal

Review performance at the end of one year.

Put contract up for bid again if performance

fails

VII. Follow-up

V. Proposed Countermeasures

VII. Follow-up

Support Launch Objectives with Accurate, Timely Document Translation

II. Current Conditions

Quality: 0 Defect at Launch

Delivery: 100% on-time

- Level weekly volume (Heijunka)

- Consistent short lead time with

predictable delivery

Cost: 10% decrease Rework down; overtime down

III. Goals/ Targets

I. Background

IV. Cause Analysis

VI. Plan

You might also like

- A3 Process Guide for Improving Patient TransportDocument14 pagesA3 Process Guide for Improving Patient TransportJayantRKNo ratings yet

- A3 Thinking and ReportingDocument23 pagesA3 Thinking and ReportingDaniel WuNo ratings yet

- Kaizen: Concepts and SystemsDocument76 pagesKaizen: Concepts and SystemsLastine AdaNo ratings yet

- Going LeanDocument54 pagesGoing LeanShubham GuptaNo ratings yet

- Black Belt Training - Module 2 - Day 1Document89 pagesBlack Belt Training - Module 2 - Day 1haythemNo ratings yet

- A3 TemplateDocument8 pagesA3 TemplateDnl SalgadoNo ratings yet

- Smed PDFDocument17 pagesSmed PDFVinay BansalNo ratings yet

- TPS A3 ReportDocument44 pagesTPS A3 ReportTonmok SonNo ratings yet

- The Lean A3 Method for Problem SolvingDocument14 pagesThe Lean A3 Method for Problem SolvingAshokNo ratings yet

- Kaizen CharterDocument3 pagesKaizen CharterDebashishDolonNo ratings yet

- Kaizen - Group 5 Present ItDocument46 pagesKaizen - Group 5 Present ItreezcoolrizNo ratings yet

- Continuous Improvement Toolkit: A3 ThinkingDocument60 pagesContinuous Improvement Toolkit: A3 ThinkingAmit Kumar SinghNo ratings yet

- Lean Daily Management SystemDocument8 pagesLean Daily Management SystemNg Yievia100% (1)

- Lean OutlineDocument2 pagesLean OutlineTee Hor ChangNo ratings yet

- Value Stream MappingDocument40 pagesValue Stream Mappingjinyue7302No ratings yet

- Visual Factory (Actually Used in Factories)Document19 pagesVisual Factory (Actually Used in Factories)monu9999100% (2)

- Kaizen Event CharterDocument4 pagesKaizen Event CharterManuel Dos SantosNo ratings yet

- Hoshin Kanri Planning BookDocument30 pagesHoshin Kanri Planning BookMarco Antonio Figueroa RamírezNo ratings yet

- Leader Standard Work V1.0Document3 pagesLeader Standard Work V1.0SudhagarNo ratings yet

- Linda Linnus, MA / LSSBB / ISO 9001Document88 pagesLinda Linnus, MA / LSSBB / ISO 9001Anonymous G5vlroDv100% (2)

- Lean Tool Glosary - Top 25Document3 pagesLean Tool Glosary - Top 25funchesitoNo ratings yet

- Basic Concepts On 5s Kaizen TQMDocument19 pagesBasic Concepts On 5s Kaizen TQMRodj Eli Mikael Viernes-IncognitoNo ratings yet

- What Is Business Process MappingDocument8 pagesWhat Is Business Process Mappingsheebakbs5144No ratings yet

- JIT - JidokaDocument23 pagesJIT - JidokaViraj DhuriNo ratings yet

- 5S Shapes GameDocument2 pages5S Shapes GameAsrizal asrizalNo ratings yet

- Presentation On TPS - JIT KanbanDocument93 pagesPresentation On TPS - JIT KanbanManish RajdevNo ratings yet

- Lean Six Sigma Fundamentals Lecture on DMAIC MethodologyDocument21 pagesLean Six Sigma Fundamentals Lecture on DMAIC Methodologyzoyamalik27100% (1)

- Standardized Work: Creating Continuous FlowDocument13 pagesStandardized Work: Creating Continuous FlowHisar SimanjuntakNo ratings yet

- TPM Road MapDocument4 pagesTPM Road Map01dynamicNo ratings yet

- 5S KAIZEN TQM Healthcare ImprovementDocument33 pages5S KAIZEN TQM Healthcare Improvementsandeep singhNo ratings yet

- Reliability of Continuous ImprovementDocument20 pagesReliability of Continuous ImprovementMohamed ElnagdyNo ratings yet

- Toyota's 5-Step Process for Continuous Improvement ImplementationDocument6 pagesToyota's 5-Step Process for Continuous Improvement Implementationdbryant1435100% (1)

- 5S Support Functions FaureciaDocument21 pages5S Support Functions Faureciapedro_euNo ratings yet

- The Lean Stack - Part 1Document15 pagesThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyNo ratings yet

- SMED Training Material PDFDocument35 pagesSMED Training Material PDFEr Jagadish MandalNo ratings yet

- Making Materials Flow ForewordDocument6 pagesMaking Materials Flow ForewordZeeshanSajidNo ratings yet

- Quick Changeover BasicsDocument44 pagesQuick Changeover BasicsSergio Prieto SerranoNo ratings yet

- Visual Management: Using Visual Elements To Control Work and Monitor StatusDocument9 pagesVisual Management: Using Visual Elements To Control Work and Monitor StatusFran JimenezNo ratings yet

- Kaizen Desk Reference Standard PDFDocument466 pagesKaizen Desk Reference Standard PDFAwadhut MaliNo ratings yet

- TPM in Assembly LineDocument15 pagesTPM in Assembly LineSagar Yadav100% (1)

- Six Sigma and Lean OperationsDocument66 pagesSix Sigma and Lean Operationsjitendrasutar1975No ratings yet

- Participant Workbook Integrated TemplateDocument74 pagesParticipant Workbook Integrated TemplateLaura RomanNo ratings yet

- Kaizen Event Implementation Manual by Mika, GeoffreyDocument169 pagesKaizen Event Implementation Manual by Mika, GeoffreyEduardo favelaNo ratings yet

- 0-3-2 E-KanbanDocument33 pages0-3-2 E-Kanbanprasetyo ilhamNo ratings yet

- Lean Kaizen Charter WorksheetDocument9 pagesLean Kaizen Charter Worksheetdefreyn100% (1)

- 10 Days Nos TrainingDocument511 pages10 Days Nos Trainingdayat hidayatNo ratings yet

- 8D Problem Solving 8: Consumer Lifestyle May 21st, 2009 Paul Van Den Kerkhoff (Updated by Ronny Schepmans)Document79 pages8D Problem Solving 8: Consumer Lifestyle May 21st, 2009 Paul Van Den Kerkhoff (Updated by Ronny Schepmans)petergogNo ratings yet

- Yamada Concepts14aDocument30 pagesYamada Concepts14aPedro Apodaca SamNo ratings yet

- Understanding Value Stream MappingDocument12 pagesUnderstanding Value Stream Mappinggandi shrtnNo ratings yet

- A Strategy For Performance ExcellenceDocument73 pagesA Strategy For Performance Excellenceravi.youNo ratings yet

- Lean Lab 2Document41 pagesLean Lab 2Jonas LeoNo ratings yet

- Handbook of Industrial EngineeringDocument24 pagesHandbook of Industrial EngineeringRanachetan SinghNo ratings yet

- Value Stream MappingDocument54 pagesValue Stream MappingQuynh Chau TranNo ratings yet

- Optimize lean thinking processes with value stream mappingDocument23 pagesOptimize lean thinking processes with value stream mappingEko DiptyoadiNo ratings yet

- Gemba KaizenDocument64 pagesGemba KaizenJohnson Gitonga Nderi100% (3)

- Kaizen: The Key To Japan's Competitive SuccessDocument48 pagesKaizen: The Key To Japan's Competitive Successyudha witantoNo ratings yet

- Hoshin X MatrixDocument6 pagesHoshin X MatrixIndira Prastika ArifiandithaNo ratings yet

- Six Sigma DMAIC Quick ReferenceDocument9 pagesSix Sigma DMAIC Quick ReferenceTrey Martin-EllisNo ratings yet

- Role of Cooperative Sin Community Devp.Document4 pagesRole of Cooperative Sin Community Devp.Faye AlonzoNo ratings yet

- 05 Gregor and The Code of ClawDocument621 pages05 Gregor and The Code of ClawFaye Alonzo100% (7)

- Pre-Feasibility Study DEPARTMENTAL STOREDocument27 pagesPre-Feasibility Study DEPARTMENTAL STOREmuhammad jasimNo ratings yet

- Coop Pesos PaperDocument46 pagesCoop Pesos Paperkhasper_d100% (5)

- Approval Sheet 1Document9 pagesApproval Sheet 1Faye AlonzoNo ratings yet

- Philippines - Cooperatives (FAQ)Document5 pagesPhilippines - Cooperatives (FAQ)KAKKAMPI100% (12)

- Nihongo ProjectDocument6 pagesNihongo ProjectFaye Alonzo100% (1)

- Computerized Inventory SystemDocument68 pagesComputerized Inventory SystemFaye Alonzo69% (36)

- BankruptcyDocument2 pagesBankruptcyFaye Alonzo100% (1)

- Probability of Financial DistressDocument34 pagesProbability of Financial DistressFaye AlonzoNo ratings yet

- DFD1Document1 pageDFD1Faye AlonzoNo ratings yet

- Level 0 DFDDocument1 pageLevel 0 DFDFaye AlonzoNo ratings yet

- Bank Failure Prediction Using Two-Step Survival Time ApproachDocument26 pagesBank Failure Prediction Using Two-Step Survival Time ApproachFaye AlonzoNo ratings yet

- Five Components AIS Importance ITDocument2 pagesFive Components AIS Importance ITFaye AlonzoNo ratings yet

- UntitledDocument3 pagesUntitledJaime CaguiclaNo ratings yet

- Partnership Part 1Document19 pagesPartnership Part 1Archilyn Holotba Macumao AbeciaNo ratings yet

- 060 218 Icm2011 Pg0804 0837 Multipurpose CooperativesDocument34 pages060 218 Icm2011 Pg0804 0837 Multipurpose CooperativesFaye Alonzo0% (1)

- Chapter 13 Capital Structure and LeverageDocument16 pagesChapter 13 Capital Structure and LeverageFaye Alonzo100% (6)

- My PrinceDocument570 pagesMy Princekaislen75% (20)

- Other Topics in Capital Budgeting: Multiple Choice: ConceptualDocument33 pagesOther Topics in Capital Budgeting: Multiple Choice: ConceptualAileen CempronNo ratings yet

- Organizing Business ActivitiesDocument51 pagesOrganizing Business ActivitiesFaye Alonzo80% (5)

- Chapter 11 Cash Flow Estimation and Risk AnalysisDocument80 pagesChapter 11 Cash Flow Estimation and Risk AnalysisFaye Alonzo86% (7)

- Mewujudkan Insan Indonesia Cerdas Komprehensif Dan KompetitifDocument8 pagesMewujudkan Insan Indonesia Cerdas Komprehensif Dan KompetitifImam RifaiNo ratings yet

- IELTS Reading - MCQ 1 - Questions PDFDocument2 pagesIELTS Reading - MCQ 1 - Questions PDFJai GurudevNo ratings yet

- Psychotraumatology Güz 2018Document5 pagesPsychotraumatology Güz 2018NESLİHAN ORALNo ratings yet

- Module 6-9. BLDNG & EnhancingDocument40 pagesModule 6-9. BLDNG & EnhancingJuzzelMarie De-GuzmanNo ratings yet

- MOCK JOB INTERVIEW (Sample Questions & Answers)Document6 pagesMOCK JOB INTERVIEW (Sample Questions & Answers)Cha Eun WooNo ratings yet

- Opposing Viewpoint - OverthinkingDocument5 pagesOpposing Viewpoint - Overthinkingapi-547815782No ratings yet

- Suzanne Assignment Part 1 Task 1 Last Edit 1Document20 pagesSuzanne Assignment Part 1 Task 1 Last Edit 1api-590858093No ratings yet

- Culture Eats StrategyDocument16 pagesCulture Eats StrategyPrateek KatekarNo ratings yet

- (Selected Components Only) Group Members: Miguel Martin V. Lopez Miguel Mangalindan Odessa Mae de Guzman Gloria Agagon Bianca DomingoDocument3 pages(Selected Components Only) Group Members: Miguel Martin V. Lopez Miguel Mangalindan Odessa Mae de Guzman Gloria Agagon Bianca DomingoSergio ConjugalNo ratings yet

- Bobo DollDocument8 pagesBobo DollSa KeynaNo ratings yet

- Edu 3460-Lesson PlanDocument8 pagesEdu 3460-Lesson PlanKat2234No ratings yet

- Persuasive Writing BreakdownDocument25 pagesPersuasive Writing Breakdownella100% (1)

- Z. J. Lipowski (Auth.), P. Pichot, P. Berner, R. Wolf, K. Thau (Eds.) - Biological Psychiatry, Higher Nervous Activity-Springer US (1985)Document928 pagesZ. J. Lipowski (Auth.), P. Pichot, P. Berner, R. Wolf, K. Thau (Eds.) - Biological Psychiatry, Higher Nervous Activity-Springer US (1985)cc vereNo ratings yet

- List of Verbs, Nouns, Adjectives, and AdverbsDocument12 pagesList of Verbs, Nouns, Adjectives, and AdverbsNickLooNo ratings yet

- 2022 - YLI National Program - Essay TopicDocument4 pages2022 - YLI National Program - Essay Topichappier everNo ratings yet

- Community Policing Program for Deportees in TrinidadDocument12 pagesCommunity Policing Program for Deportees in TrinidadsemigemiNo ratings yet

- Lesson 1 Knowing OneselfDocument67 pagesLesson 1 Knowing OneselfCarl Anthony Lague PahuyoNo ratings yet

- Responsible Social Media UseDocument4 pagesResponsible Social Media UseKay BelgaNo ratings yet

- Interviews Extra: Intermediate Unit 1Document4 pagesInterviews Extra: Intermediate Unit 1Alex FilatovNo ratings yet

- Four Types of Power in Ir PDFDocument25 pagesFour Types of Power in Ir PDFoanabrandaNo ratings yet

- The Railway ChildrenDocument2 pagesThe Railway ChildrenTheKhoteeNo ratings yet

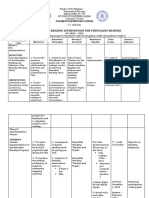

- Action Plan On Reading Intervention For Struggling Readers: Nazareno Elementary SchoolDocument3 pagesAction Plan On Reading Intervention For Struggling Readers: Nazareno Elementary SchoolLoida Jonson99% (69)

- Jan 12 C1 - Exercise 2Document5 pagesJan 12 C1 - Exercise 2Minh LaiNo ratings yet

- How WWI Poetry Conveys Horrors of WarDocument2 pagesHow WWI Poetry Conveys Horrors of WarItzel Ahelyn Ríos RubioNo ratings yet

- Research problem and questionsDocument8 pagesResearch problem and questionsKurt TanNo ratings yet

- Real Analysis Notes For CSIR-NET ExamDocument416 pagesReal Analysis Notes For CSIR-NET ExamAnandNo ratings yet

- Gatsby EssayDocument2 pagesGatsby EssayMatúš NeczliNo ratings yet

- Beyond The Dopamine Hypothesis of Schizophrenia To Three Neural Networks of Psychosis Dopamine Serotonin and GlutamateDocument5 pagesBeyond The Dopamine Hypothesis of Schizophrenia To Three Neural Networks of Psychosis Dopamine Serotonin and Glutamaterap 2treyNo ratings yet

- Dokkodo (The Way of Walking Alone)Document1 pageDokkodo (The Way of Walking Alone)bionicras67% (6)

- Historical Setting Whole KS2 PompeiiDocument2 pagesHistorical Setting Whole KS2 Pompeiirebecca_cosgrave4286100% (2)