Professional Documents

Culture Documents

Blacksmithyshop 140324040517 Phpapp02

Uploaded by

GurjinderSinghDoshanjh0 ratings0% found this document useful (0 votes)

34 views61 pagesd

Original Title

blacksmithyshop-140324040517-phpapp02

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentd

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

34 views61 pagesBlacksmithyshop 140324040517 Phpapp02

Uploaded by

GurjinderSinghDoshanjhd

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 61

Black Smithy Shop

By: Mr Sunil Kumar Ojha

Assistant Professor

Mechanical Engineering Department

JRE Group of Institutions Greater Noida

black" in "blacksmithy" refers to the

black fire scale, a layer of oxides that

forms on the surface of the metal

during heating

The word "smith" derives from an

old word, "smite" (to hit)

Topics to be Covered

Introduction

Forging materials

Heating Devices

Hand Tools and Appliances

Smith Forging Operations

Forging Process

Defects in Forging

Black Smith or forging :work involves heating of

metal stock to a desired temperature, enable it to

acquire sufficient plasticity, followed by the

operations like hammering, bending, pressing etc,

to get desired shape and size.

Blacksmiths produce objects such as gates, grilles, railings, light

fixtures, furniture, sculpture, tools, agricultural implements,

decorative and religious items, cooking utensils, and weapons.

Hand forging: done by hand tools.

Power Forging: done by power hammers.

Drop forging: done by drop hammers.

Machine forging: done by forging machines.

Forging

Forging is defined as the controlled plastic

deformation of metal into predetermined

shapes by pressure or impact blows, or

combination of both.

Forgeability is the relative ability of a

material to deform under a compressive load

without rupture.

Grain Structure

Parts have good strength

High toughness

Forgings require additional heat treating

grain flow (a) casting (b) machining (c) forging

Forging Materials

Any metal or alloy which can be brought into

plastic stage through heating can be forged.

Means those material which have ductile or

malleable property.

Like wrought iron,

carbon steel,

stainless steel,

copper based alloys, nickel-copper alloys,

magnesium alloys etc.

Forging Materials

1. Aluminium alloys

2. Magnesium alloys

3. Copper alloys

4. Low carbon alloy

steel

5. Stainless steel

6. Nickel alloys

7. Titanium alloys

8. Iron based super alloys

9. Cobalt based super

alloys

10. Tantalum alloys

11. Tungsten alloys

12. Beryllium

Forging Process

1. Open Die Forging

TYPES OF OPEN DIE FORGING

Hand forging: Hand forging is done by

hammering the piece of metal, when it is

heated to the proper temperature, on an

anvil.

Power forging

Power Hammer: All power hammers employ the

same general principle of operation, a falling

weight striking the blow, with the entire energy

being absorbed by the work.

Power Press: It is a machine tool which changes

the shape of workpiece by using pressure rather

than blow in previous case.

Forging Process

2. Impression Die Forging

TYPES OF IMPRESSION DIE FORGING

Drop forging: It is done with help of three

types of drop hammers. They are gravity

hammer, air lift hammer and power drop or

steam hammer.

Press forging: It is done in presses rather than

with hammers. The action is relatively slow

squeezing instead of delivering heavy blows

Machine forging: It consists of applying

lengthwise pressure to a hot bar held between

grooved dies to enlarge some section, usually

the end.

Drop forging

Press forging

Machine forging

Forging Process

3. Flashless /Closed Forging

Advantages of Forging Processes

Following are some of the major advantages of forging

processes.

(1) It improves the structure as well as mechanical

properties of the metallic parts.

(2) Forging facilitates orientation of grains in a desired

direction to improve the mechanical properties.

(3) Forged parts are consistent in shape with the

minimum presence of voids and porosities.

(4) Forging can produce parts with high strength to

weight ratio.

(5) Forging processes are very economical for moderate

to high volume productions.

Heating Devices

1. Smiths Hearth

2. Furnace

(i) Box or Batch Type Furnace

(ii) Continuous Type furnace

(iii) Slot type furnace

(iv) Rotary Hearth furnace

(v) Induction Furnace

(vi) Resistance Furnace

Black Smith Forge Hearth

Hearth

Tuyere (nozzle)

Hood

Water Tank

Blower

Chimney

HEATING DEVICES

FORGE:

Types of Furnaces

Box / Batch Type Furnace: this type of furnace is

used for heating small and medium size stock

because they are least expensive. These furnaces

are usually constructed of a rectangular steel

frame lined with insulating and refractory bricks.

Rotary Hearth Furnace: These are doughnut

shaped and are set to rotate so that the stock is

heated to the correct temperature during one

rotation. These are heated by gas or oil.

Box / Batch Type Furnace

Rotary Hearth Furnace

Rotary Hearth Furnace

Types of Furnaces

Continuous/ Conveyor Furnace: They are generally

used to heat one end of the larger workpiece. They had

an air or oil operated cylinder to push stock end to end

through a narrow furnace.

Induction Furnace: In induction furnace the stocks are

passed through induction coils in the furnace. An

induction furnace greatly reduces scale formation doe

to oxidation.

Resistance Furnace: These furnaces are faster than

induction furnace and are often automated. In this

furnace the stock is connected into the circuit of step

down transformer and is heated due to resistance in

circuit.

Continuous/ Conveyor Furnace

Induction Furnace

Resistance Furnace

Heating: Hearth or in Furnace

Holding: Tongs

Beating : by Hammers over Anvil

Portable tools: Fullers, Chisels, Swages etc

Tools and Equipments required for

Hand Forging

Black Smith Forge Hearth

Anvil

Swage Block

Hammers

Tongs

Chisels

Punches

Drifts

Fullers

Swages

Flatters

Set Hammers

Black Smith Forge Hearth

Hearth

Tuyere (nozzle)

Hood

Water Tank

Blower

Chimney

Anvil

Swage Block

( made of cast iron or cast Steel)

It carrying a number of slots of different

shapes and sizes along its four side faces. The

job is to be given a desired shape is kept

similar shaped slot.

Hammers

Ball Peen Hammer

Sledge Hammer

(i) straight peen sledge Hammer

(ii)Cross peen sledge Hammer

(iii)Double Faced Sledge Hammer

Tongs

Tongs are used for holding and turning hot metal pieces. Depending upon

their use tongs are classified as below

Square Hollow tong

Pincer tong

Close flat tong

Chisel tong

Pick up tong

Round hollow tong

Chisels

Chisels are used for cutting the metal pices in hot and cold

state.

(a) Hot Chisel

(b)Cold Chisel

(c) Hardie Set

Punchs: are made up of high carbon steel and are used for

making rough holes in hot metal pieces

Drift: is a large size punch used to enlarge a hole.

Fullers

Fullers are used for necking down, grooving and drawing a

piece of work. These are made in two pieces (Lower and

Upper). Lower piece is mounted on anvil and upper is held in

and from a wire handle. These are made of high carbon steel

and medium carbon steel. These are used for hot work only.

Swages

swages are used for increasing the length of a circular

rod or for finishing the circular surface of job after

forging. Swages are made of high carbon steel in two

parts called top and bottom swage. Their working

faces carry circular grooves to suit the size of work

SWAGES

A)Top Swage B) Bottom Swage

Flatters or Smoothers

Flatters are used for levelling and finishing a flat surface after

drawing out or any other forging operation. The are made of

high carbon steel and consists of square body , fitted with handle

and flat square bottom (face).

Set Hammers

it is used for the finishing the corners, formed by two

adjacent surfaces at right angles. The job is supported

on the anvil and tool is hammered from the top.

Forging Operations

1. Upsetting

2. Drawing Down

3. Setting Down

4. Punching

5. Drifting

6. Bending

7. Fullering

8. Flattening

9. Swaging

10. Forge Welding

11. Cutting

12. Drop Forging

Upsetting

Upsetting is the process through which the crossection of metal piece

is increased with a corresponding reduction in length.

In this process first of all the work is heated to the required

temperature then heavy blow is given by hand hammer. The swelling

of work takes place at the hot portion.

Cogging/Drawing Down/Drawing out

It is the process of reducing the crossection of a bar and

increasing its length.

The operation of is carried out in three steps:-

(a) first Hammering with Cross peen Hammer

(b) then pair of Fullers used

(c) Then the curved top of work is leveled off with set hammers

and finally finished with flatters

Setting Down

It is the process of local thinning down effect by the set hammers.

Punching

It is the process of producing the holes by forcing the

punch through the work.

Drifting

By this process punched hole enlarged

Bending

It is an important operation in forging and is very frequently used. The

bends may be either sharp cornered, angle bends or they may be

composed of more gradual curve. The angle bend may be made by

hammering the metal over the edge of the anvil,

or over a block of metal helds in the hardie hole

Fig 1

Fig 2

Fig 3

Fullering

In Fullering operation material crossection is decreased and length is

increased. The fullering operation is carried out with the help of pair of

fullers and anvil. Bottom fuller is kept in anvil hole and heated work

peice is kept in between bottom and top fullers. The fullers locate and

concentrate the hammer blow , causing the metal to be drawn out

more rapidly.

Flattening

The flattening is carried out after drawing out, fullering

or any other operation to remove the fullering marks

for leveling and finishing flat surfaces

Swaging

Swaging is the operation of changing the

shape of cross-section of job to some specific

shapes such as round, square, hexagonal etc.

Swaging operation is carried out with pair of

swages or by swage block.

Forge Welding

It is the process of joining the two surfaces of

metal under pressure after they are heated to

the correct temperature.

Cutting

It is a form of chiseling where a long piece of

stock is cut into several required lengths.

Notches is made and chisel is placed over notch

then hammered then turn 180 Degree and chisel

placed opposite the metal cut-off in two pieces.

Drop Forging

When mass production of identical articles is

required by forging, the method of drop forging or

stamping is used. This is performed by a special

type hammer know as drop hammer or drop stamp.

Accurately made steel dies are used for this

purpose.

Defects in Forging

1. Cold Shut or Lap

2. Cracks

3. Scale Pits

4. Unfilled Sections

5. Mismatch Sections

6. Ruptured Fibers Flow lines

7. Fins and Rags

8. Burnt and Overheated Metal

Forging Defects

Unfilled Section: In this some section of the die

cavity are not completely filled by the flowing

metal.

Cold Shut: This appears as a small cracks at the

corners of the forging.

Scale Pits: This is seen as irregular depurations on

the surface of the forging.

Die Shift or Miss-match Forging : This is caused by

the miss alignment of the die halve, making the

two halve of the forging to be improper shape.

Flakes: These are basically internal ruptures

caused by the improper cooling of the large

forging.

Improper Grain Flow or rupture fiber flow

lines: This is caused by the improper design of

the die, which makes the flow of the metal

not flowing the final interred direction.

Forging Defects

Fins and rags : These are small projections or

pices of loose metal driven into metal surface.

Burnt and Overheated Metal: heating the

metal at high temperature or for too long time

burn the metal

Forging Defects

You might also like

- Blacksmithy Shop: By: Manoj YadavDocument49 pagesBlacksmithy Shop: By: Manoj YadavvijaykumarNo ratings yet

- Black Smithy ShopDocument31 pagesBlack Smithy ShopArun kumar rouniyarNo ratings yet

- Surya Black SmithyDocument11 pagesSurya Black Smithy2K20B671 Shivam GargNo ratings yet

- Smithy & Forging ShopDocument24 pagesSmithy & Forging Shopashok junapudiNo ratings yet

- Forging 2Document39 pagesForging 2ssukhmeet551No ratings yet

- Chapter 14.1 To 14.4,14.6Document20 pagesChapter 14.1 To 14.4,14.6Lhekha RaviendranNo ratings yet

- Metal FormingDocument40 pagesMetal Formingsreeeram100% (1)

- Smithy ManualDocument11 pagesSmithy ManualSeattle MountaineerNo ratings yet

- Blacksmithy or Forging NoteDocument4 pagesBlacksmithy or Forging NoteSomnath MondalNo ratings yet

- Final Unit 3 Manufacturing Processes PDFDocument227 pagesFinal Unit 3 Manufacturing Processes PDFHardik ChhabraNo ratings yet

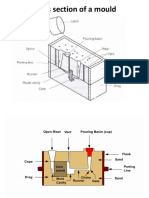

- Cross Section of A MouldDocument54 pagesCross Section of A MouldkanishkNo ratings yet

- Forging Die of SpannerDocument16 pagesForging Die of Spannervirendra pawarNo ratings yet

- Unit Iii Bulk Processes Bulk DeformationDocument77 pagesUnit Iii Bulk Processes Bulk DeformationAkash akNo ratings yet

- Cross Section of A MouldDocument56 pagesCross Section of A MouldALOKSRKNo ratings yet

- Engineering Workshop Lab Manual (Smithy Shop)Document8 pagesEngineering Workshop Lab Manual (Smithy Shop)Sumit Chauhan0% (2)

- 1) - Introduction:: Metal Forming ProcessesDocument10 pages1) - Introduction:: Metal Forming Processesphysics a2No ratings yet

- Forging NotesDocument20 pagesForging NotesDheeraj JoshiNo ratings yet

- Black Smithy ShopDocument3 pagesBlack Smithy ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)No ratings yet

- Laboratory Manual: Chandigarh Engineering College, Landran (Mohali)Document15 pagesLaboratory Manual: Chandigarh Engineering College, Landran (Mohali)Jay PandeyNo ratings yet

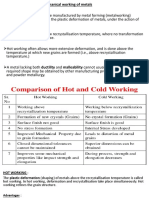

- Hot Cold WorkingDocument40 pagesHot Cold Workingpatel ketanNo ratings yet

- Forging Design ConsiderationsDocument81 pagesForging Design ConsiderationssuneethaNo ratings yet

- Foundry &forging Viva 3&4th Sem VtuDocument11 pagesFoundry &forging Viva 3&4th Sem VtuMahesh B R Mysore100% (11)

- ForgingDocument16 pagesForgingAeshwrya PandaNo ratings yet

- Mechanical Working of Metals MaterialDocument40 pagesMechanical Working of Metals MaterialRoyalmechNo ratings yet

- Design of Dies - Unit 4Document149 pagesDesign of Dies - Unit 4210 SureshNo ratings yet

- L8 - Bulk Deformation ProcessingDocument70 pagesL8 - Bulk Deformation ProcessingAstha PantNo ratings yet

- FR ManualDocument10 pagesFR ManualMuhd Shabeeb ANo ratings yet

- Blacksmithy: Engineering Work Shop Department of Mechanical EngineeringDocument4 pagesBlacksmithy: Engineering Work Shop Department of Mechanical EngineeringSourabh DhavalaNo ratings yet

- Unit IIIDocument114 pagesUnit IIIManoj Kumar SNo ratings yet

- Black Smithy Shop: 1-Supporting Tools: Leg ViceDocument10 pagesBlack Smithy Shop: 1-Supporting Tools: Leg ViceAashish KushwahaNo ratings yet

- ForgingDocument38 pagesForgingapi-26546070100% (2)

- Performing Hand Forging: LO1: Analyze and Plan HandDocument21 pagesPerforming Hand Forging: LO1: Analyze and Plan HandZimbelachew Emawoy100% (2)

- L5 - Ta201p (05.07.2021)Document84 pagesL5 - Ta201p (05.07.2021)quick winnerNo ratings yet

- Smithy: Applications of ForgingDocument8 pagesSmithy: Applications of Forginghuman kindNo ratings yet

- Mechanical Working of MetalsDocument53 pagesMechanical Working of Metalsmurari100% (3)

- Forging DefectDocument4 pagesForging DefectRashmi Bhatt NautiyalNo ratings yet

- Forging and Its TypesDocument9 pagesForging and Its TypesHarinath GowdNo ratings yet

- Forging Is ADocument5 pagesForging Is ASahilNo ratings yet

- Metallurgy CH 12 and 13 Lecture NotesDocument6 pagesMetallurgy CH 12 and 13 Lecture Notesayaan.works76No ratings yet

- Teknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Document62 pagesTeknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Aszhari AszhariNo ratings yet

- Lecture 11Document22 pagesLecture 11Huraira AbidNo ratings yet

- Experiment 6Document3 pagesExperiment 6Subhasis BiswalNo ratings yet

- Casting, Rolling, Forging, ExtrusionDocument60 pagesCasting, Rolling, Forging, ExtrusionHARIKRISHNAN SRNo ratings yet

- Chapter 3 Metal Forming ProcessesDocument103 pagesChapter 3 Metal Forming Processesdagimawgchew777No ratings yet

- Forging MaterialDocument51 pagesForging MaterialRoyalmechNo ratings yet

- Selection of Manufacturing Methods For Machine Element S For Toggle JackDocument16 pagesSelection of Manufacturing Methods For Machine Element S For Toggle JackPrayag GiteNo ratings yet

- Metal FormingDocument20 pagesMetal FormingPrashant ShreshthaNo ratings yet

- Manufacturing Process 1 2Document70 pagesManufacturing Process 1 2MD Al-Amin100% (1)

- MFG II 3182 Chapter 1Document58 pagesMFG II 3182 Chapter 1Naol EmanaNo ratings yet

- Background/ Profile of CompanyDocument8 pagesBackground/ Profile of Companyethiopia ethiopiaNo ratings yet

- Forging - The Process: Metal Forging Is A Metal Forming Process That Involves ApplyingDocument25 pagesForging - The Process: Metal Forging Is A Metal Forming Process That Involves ApplyingAdityasinh DesaiNo ratings yet

- Rolling of MetalsDocument22 pagesRolling of MetalsraniksrNo ratings yet

- Course Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDocument21 pagesCourse Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDinesh Killada50% (2)

- Forging Process PDFDocument15 pagesForging Process PDFSantoshNo ratings yet

- Metal RollingDocument22 pagesMetal RollingNishith100% (2)

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Mensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeFrom EverandMensuration for Sheet Metal Workers - As Applied in Working Ordinary Problems in Shop PracticeNo ratings yet

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Takin' Care of Business:: The Georgia Tech WorkshopDocument33 pagesTakin' Care of Business:: The Georgia Tech WorkshopMohsen SaidiNo ratings yet

- Cupola and Blast FurnaceDocument26 pagesCupola and Blast FurnaceGurjinder SinghNo ratings yet

- MR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaDocument61 pagesMR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaGurjinderSinghDoshanjhNo ratings yet

- Cupola and Blast FurnaceDocument26 pagesCupola and Blast FurnaceGurjinder SinghNo ratings yet

- Casting DefectsDocument9 pagesCasting DefectsVIBHAV83% (6)