Professional Documents

Culture Documents

L6 040214

Uploaded by

SrikanthBatnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L6 040214

Uploaded by

SrikanthBatnaCopyright:

Available Formats

Powder Characterizations

Characterizations

Physical

Characteristics

Chemical

Composition

Phase

Composition

Surface

Characteristics

1. Particle size and

distribution

2. Particle shape

3. Degree of

agglomeration

4. Surface area

5. Density and

porosity

6. Flow properties

and granulation

1. Major elements

2. Minor elements

3. Trace elements

(AAS, AES, XRF)

Crystal structure and

phase

composition

1. Surface structure

(LEED, STM, AFM)

2. Surface

composition

(AES, XPS, ESCA,

SIMS)

Physical Characterizations of Powder

Types of Particles

Primary particle

Smallest unit in

the powder with

a clearly defined

surface/isolated

porosity

Agglomerates

Cluster of

primary particles

held together by

surface force

Types: Soft and

Hard

Particles

Small units that

move as a

separate entity

(Coarse particle

1-100 m)

Granules

Large

agglomerates

(Dimension 100-

1000 m)

Physical Characterizations of Powder

Types of Particles

Flocs

Cluster of

particles in a

liquid

suspension

Colloids

Finely divided

phase in a fluid

(Brownian

motion, negligible

sedimentation

under normal

gravity (1 nm 1

m)

Aggregates

Coarse

constituent in a

mixture (pebbles

in concrete)

(> 1 mm)

Definition of Particle Size

Stokes diameter Diameter of the sphere calculated from

Stokes law

Projected area diameter projected area of the particle under

microscope

Ferets diameter/Martins diameter Linear dimension

measured parallel to some fixed direction

(Attached sheet)

Physical Characterizations of Powder

Methods for Measurement of Particle Sizes

Method Range (m)

Microscopy

Optical > 1

SEM > 0.1

TEM > 0.001

Sieving 20 10,000

Sedimentation 0.1 100

Coulter counter 0.5 400

Light Scattering

Scattering intensity 0.1 1000

Brownian motion 0.005 1

X-ray line broadening < 0.1

Physical Characterizations of Powder

Martins Diameter (X

M

) - length of a line that

bisects the area of the particle image

Ferets Diameter (X

F

) - distance between two

tangents on opposite sides of the particle,

parallel to some fixed direction

Projected Area Diameter (X

PA

) - diameter of a

circle having the same area as the two-

dimensional image of the particle

Perimeter Diameter (X

C

) - diameter of the circle

having the same circumference as the perimeter

of the particle

The longest dimension is equal to the maximum

value of Ferets diameter

Measurement of Particle Size by Microscopy

Physical Characterizations of Powder

Methods for Measurement of Particle Sizes

Method Range (m)

Microscopy

Optical > 1

SEM > 0.1

TEM > 0.001

Sieving 20 10,000

Sedimentation 0.1 100

Coulter counter 0.5 400

Light Scattering

Scattering intensity 0.1 1000

Brownian motion 0.005 1

X-ray line broadening < 0.1

Physical Characterizations of Powder

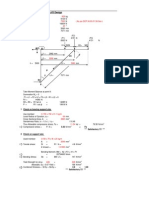

Measurement of Particle Size and Size Distribution by Sieving

Mesh size = the number of wires per

linear inch of the sieve screen, which is

the same as the number of square

apertures per inch.

If mesh number = M, aperture width = a,

wire diameter = w, and the open area =

A, then:

w a

M

+

=

1

w

M

a =

1

2

2

2

) (

) (

Ma

w a

a

A =

+

=

Problem: Find out the wire diameter

and open area of a 400 mesh sieve

with an aperture of 38 m?

Physical Characterizations of Powder

Methods for Measurement of Particle Sizes

Method Range (m)

Microscopy

Optical > 1

SEM > 0.1

TEM > 0.001

Sieving 20 10,000

Sedimentation 0.1 100

Coulter counter 0.5 400

Light Scattering

Scattering intensity 0.1 1000

Brownian motion 0.005 1

X-ray line broadening < 0.1

Physical Characterizations of Powder

Measurement of Particle Size and Size Distribution by Sedimentation

Stokess Law,

av F tq 6 =

F = Frictional force

acting on the particle,

q= Liquid viscosity,

a = particle radius

v = terminal velocity

Stokess Equation,

( )

2 / 1

18

(

=

g d d

v

x

L s

q

x = diameter of the

particle with sphere

shape,

d

s

= particle density

d

L

= liquid density

For non spherical particle,

Limitations

1. Holds good for laminar (non-turbulent) flow

2. No inter-particle collision

3. No interactions between the particles

STK

x x =

Laminar to turbulent flow occurs at some critical velocity,

2 . 0 ~ = =

x d

N

v

L

R

c

q

2 . 0 <

q

x vd

L

2 . 0 >

q

x vd

L

N

R

= Reynolds Number

Laminar Flow

Turbulent Flow

The particle size distribution is determined by measuring

the change in concentration (or density) of the suspension as a function

of time, height along the suspension, or both.

A light beam or an x-ray beam is projected at a known height through a

glass cell containing the suspension.

The intensity of the transmitted beam is measured by a photocell or an

x-ray detector located at the opposite side.

The intensity I of the transmitted beam will increase as,

) exp(

0

KACy I I =

I

0

= Intensity of the incident beam

K = Extinction coefficient

A = Projected area per unit mass of the

particle

C = Concentration by mass of the particle

y = Optical path length through the

suspension

The particle size distribution [e.g., the cumulative mass percent finer

(CMPF) versus the Stokes diameter] is deconvoluted from the measured intensity

ratio, I/Io, coupled with Stokes Eq.

Physical Characterizations of Powder

Methods for Measurement of Particle Sizes

Method Range (m)

Microscopy

Optical > 1

SEM > 0.1

TEM > 0.001

Sieving 20 10,000

Sedimentation 0.1 100

Coulter counter 0.5 400

Light Scattering

Scattering intensity 0.1 1000

Brownian motion 0.005 1

X-ray line broadening < 0.1

Physical Characterizations of Powder

Measurement of Particle Size and Size Distribution by Coulter Counter

As a particle passes through the orifice,

it displaces an equivalent volume of the

electrolyte and causes a change in the

electrical resistance, the magnitude of which

is proportional to the volume of the particle.

The changes in resistance are converted to

voltage pulses, which are amplified, sized,

and counted to produce data for the particle

size distribution of

the suspended particles.

Since the number and volume of the

particles are measured in this technique, the

particle size distribution will consist of the

CNPF (or CNPL) versus the volume diameter

x

V

Disadvantage

Blocking of the orifice by bigger particle

You might also like

- Absorption Spectrum of YSZDocument9 pagesAbsorption Spectrum of YSZSrikanthBatnaNo ratings yet

- Pressure Raman Variation With DFTDocument12 pagesPressure Raman Variation With DFTSrikanthBatnaNo ratings yet

- Paper On UV Visible SpectrosDocument6 pagesPaper On UV Visible SpectrosSrikanthBatnaNo ratings yet

- Temperature Dependence of Yttria Stabilized Zirconia Raman SpectrumDocument7 pagesTemperature Dependence of Yttria Stabilized Zirconia Raman SpectrumSrikanthBatnaNo ratings yet

- Which Transducer Array Is BestDocument14 pagesWhich Transducer Array Is BestSrikanthBatnaNo ratings yet

- Harvard-Notes On Stresses and Failure Modes in Thin Films PDFDocument47 pagesHarvard-Notes On Stresses and Failure Modes in Thin Films PDFSrikanthBatnaNo ratings yet

- Introduction to Using FullProf for Rietveld AnalysisDocument34 pagesIntroduction to Using FullProf for Rietveld AnalysisSrikanthBatnaNo ratings yet

- Stress - Polycrystalline Ceramics - ClarkeDocument8 pagesStress - Polycrystalline Ceramics - ClarkeSrikanthBatnaNo ratings yet

- LeverDAC MaxiDocument1 pageLeverDAC MaxiSrikanthBatnaNo ratings yet

- Bruker 2d XRDDocument15 pagesBruker 2d XRDSrikanthBatnaNo ratings yet

- In (AB)Document7 pagesIn (AB)SrikanthBatnaNo ratings yet

- Thick Wall Vessel Limit - IMECS2009 - pp1649-1654Document6 pagesThick Wall Vessel Limit - IMECS2009 - pp1649-1654chuckhsu1248No ratings yet

- Determination of Residual Stresses by X-Ray - Diffraction - Issue 2Document77 pagesDetermination of Residual Stresses by X-Ray - Diffraction - Issue 2Roman MinikayevNo ratings yet

- Addition of Rare Earth Oxide Stabilizers Into YtDocument4 pagesAddition of Rare Earth Oxide Stabilizers Into YtSrikanthBatnaNo ratings yet

- Quant Anal of 3yztpDocument6 pagesQuant Anal of 3yztpSrikanthBatnaNo ratings yet

- Plasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401Document9 pagesPlasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401balajeemech2010No ratings yet

- CIVA 2016 simulation and analysis tool enhancementsDocument3 pagesCIVA 2016 simulation and analysis tool enhancementsSrikanthBatnaNo ratings yet

- Plasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401Document9 pagesPlasticity: R. Chandramouli Associate Dean-Research SASTRA University, Thanjavur-613 401balajeemech2010No ratings yet

- Yield CriteriaDocument23 pagesYield CriteriaJuan MNo ratings yet

- Machine Vise Working DrawingDocument5 pagesMachine Vise Working DrawingSrikanthBatnaNo ratings yet

- 13 Management ScienceDocument38 pages13 Management Scienceakram75zaaraNo ratings yet

- Registration 1Document1 pageRegistration 1SrikanthBatnaNo ratings yet

- Material Characterisation Using Lamb Waves and ANNDocument6 pagesMaterial Characterisation Using Lamb Waves and ANNSrikanthBatnaNo ratings yet

- Manual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukDocument11 pagesManual Ultrasonic Inspection of Thin Metal Welds: Capucine - Carpentier@twi - Co.ukSrikanthBatnaNo ratings yet

- Mcs Exam enDocument9 pagesMcs Exam enSrikanthBatnaNo ratings yet

- Xray ProdDocument25 pagesXray ProdSrikanthBatnaNo ratings yet

- Imaging With PADocument6 pagesImaging With PASrikanthBatnaNo ratings yet

- Olymp TrainngDocument8 pagesOlymp TrainngSrikanthBatnaNo ratings yet

- Introduction to the Six Most Common NDT MethodsDocument34 pagesIntroduction to the Six Most Common NDT MethodsNanditha Mandava ChowdaryNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ref 1Document5 pagesRef 1Diego Alejandro Roa CalaNo ratings yet

- Lecture Notes - Measurement of Fluid FlowDocument11 pagesLecture Notes - Measurement of Fluid Flowneji hyuugaNo ratings yet

- Polymer Project For Class 12thDocument11 pagesPolymer Project For Class 12thVinod KaushikNo ratings yet

- Fabrication and Characteriation of P-N Junction DiodeDocument11 pagesFabrication and Characteriation of P-N Junction Diode12343567890No ratings yet

- Module 10: Solved ProblemsDocument2 pagesModule 10: Solved ProblemscaptainhassNo ratings yet

- Brochure Interbond 1202UPC US - 301111Document2 pagesBrochure Interbond 1202UPC US - 301111King SabiNo ratings yet

- ASM Subject Guide - HeatTreating PDFDocument7 pagesASM Subject Guide - HeatTreating PDFJhon Alexander VilladaNo ratings yet

- Expanded Polystyrene Geofoam in Pavement ConstructionDocument11 pagesExpanded Polystyrene Geofoam in Pavement Constructionminsara madtNo ratings yet

- Mechanics of Materials - IiDocument43 pagesMechanics of Materials - IiSaAhRaNo ratings yet

- Column Design AnalysisDocument18 pagesColumn Design AnalysisSurya FahmiNo ratings yet

- Design Notes For ALL Memebres - Sefi ForumDocument17 pagesDesign Notes For ALL Memebres - Sefi ForumcoolkaisyNo ratings yet

- QuestionDocument5 pagesQuestionsumeetsharma27No ratings yet

- Mass Transfer PartDocument31 pagesMass Transfer Partoctoviancletus100% (2)

- IIT Bearing DesignDocument19 pagesIIT Bearing Designmadanpal29No ratings yet

- Aws ChartDocument3 pagesAws ChartSaran KumarNo ratings yet

- Compacted Graphite Iron - Mechanical and Physical Properties For Engine DesignDocument22 pagesCompacted Graphite Iron - Mechanical and Physical Properties For Engine DesignThanhluan NguyenNo ratings yet

- Ternary Phase DiagramDocument9 pagesTernary Phase DiagramFabiha SheikhNo ratings yet

- Trihal TRI1250245297IP210Document2 pagesTrihal TRI1250245297IP210Aryo BayuNo ratings yet

- Versatility at work in cast iron turningDocument24 pagesVersatility at work in cast iron turningAchmad Arifudin HidayatullohNo ratings yet

- Bolted JointsDocument20 pagesBolted JointsNurcahyo Djati WNo ratings yet

- Platform - Bracing SupportDocument12 pagesPlatform - Bracing Supportpandiangv100% (1)

- Alsaeab FiniteelementmodellingofanchoragetoconcreteDocument513 pagesAlsaeab Finiteelementmodellingofanchoragetoconcretedoomflare2000xNo ratings yet

- Dissimilar Friction Stir Welding of 6061 Aluminum Alloy and AZ31 Magnesium Alloy Assisted With Ultrasonic PDFDocument4 pagesDissimilar Friction Stir Welding of 6061 Aluminum Alloy and AZ31 Magnesium Alloy Assisted With Ultrasonic PDFSantiago EscobarNo ratings yet

- Communication Register Map of EN8400Document5 pagesCommunication Register Map of EN8400NM GroupNo ratings yet

- RC DesignDocument11 pagesRC DesignZul FadzliNo ratings yet

- 3 Materials Prperties7Document10 pages3 Materials Prperties7ArthurNo ratings yet

- Work Sheet Science 9 Module 4Document8 pagesWork Sheet Science 9 Module 4jan lawrence panganibanNo ratings yet

- Diagram FasaDocument53 pagesDiagram FasaZeoliteNo ratings yet

- Adsorption Isotherm Models - Classification, PhysicalDocument79 pagesAdsorption Isotherm Models - Classification, PhysicalAnis SuffiNo ratings yet

- Microstructure and Fatigue Resistance of Carburized Steels PDFDocument10 pagesMicrostructure and Fatigue Resistance of Carburized Steels PDFyh1.yuNo ratings yet