Professional Documents

Culture Documents

Dosa King's Journey to Standardize India's Favorite Snack

Uploaded by

Ashwani ShastriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dosa King's Journey to Standardize India's Favorite Snack

Uploaded by

Ashwani ShastriCopyright:

Available Formats

Dosa King

Presentation by:-

Ravi Prasad

Sudhir Singh

Shreesh Mani Tiwary

Vinod Kumar

Ashish Joshi

1 Dosa King

Under Guidance of:-

Prof. Abhinav P. Tripathy

Introduction

Before 1992, India did not have any western fast food chain like

KFC, Mc Donald's or Berger King.

R. Narayanan who is the IIM C Post-Graduate and former employee

at Coca Cola & Nestle expected the demand to grow in all major

cities.

This strong belief led to the creation of the IFFL in 1992.

Indian Foods & Fermentation Limited established in order to offer

total Solution to the problem stated above with an objective to

develop an Electronically Controlled Operator Assisted Dosa

Machine(ECOAD).

According to Research in 1992, 20 million dosas consumed every

day.

Dosa King 2

Requirement for Dosa Delivery

System by Dosa Kings team

To design a dosa making machine that could deliver

consisted dosa at 30 seconds interval.

To develop a dosa batter in a dry or wet form so that it

can be transported and used any part of the country.

To develop a potato masala that could be automatically

dispensed from machine as desired.

To deliver the dosa to the customer in a convenient

form such as a roll,

Dosa King 3

User Requirement Analysis

IFFL research shows 90% adults male would eat snack

outside home. Adults male in 16-45 age group formed the

core target audience. Dosa King intended to be a mass

distributed item by 10,000 retail points in 5 year.

Standardization

Although Dosa is a snack/breakfast item, it also served as a

midday meal so the ingredients, the formula and the

expertise is required. Standardization is required in terms

of taste, size and colour.

Delivery of Dosas

Dosa would have to be delivered at the intervals of 30

seconds but customer expectation would be instantaneous.

Dosa King 4

Size of Dosas

Dosa will be served as a roll weighing175 grams in Rs. 10.

All accompaniments to be poured on top of the vertical

dosa similar to other fast food items

The size of the dosa to be 6 Inches diameter.

Accompaniments

Customer expected to have Sambar and chutney not poured

on dosa.

Liquid Chaser

Customer expected to have tea, coffee or soft drink

during/after consumption of dosa

Dosa King 5

System Requirements

Dosa Machine

Dosa machine not to have a footprint of exceeding 6 ft. and it should

be mobile enough.

Dosa Batter

Dosa batter was a fermented product, it has shelf life of 16 hours.

But UDCT found that through the preservatives it can be kept

under refrigerator and use within 4 weeks.

Potato Masala

It is an important ingredients of the masala dosa, Cooked potato

has shelf life of 6 months.

Accompaniments

The Sambar would need to be pre prepared. Coconut chutney is

must to have dosa but it is not available in each part of the

country so dal based chutney would be used, in some instances

mint and chili chutney is used.

Dosa King 6

Standardization

Standardise the product to a level where a customer will

have a masala dosa of a same quality whenever he/she

travelled in the country. In fact standardization was the USP

of IFFL.

Beverages

Vending machine for coffee, tea or soft drink were available

on attracted terms to the IFFL. But the price of beverages

will cost higher than dosa so it was an opportunity to set up

new brand of soft drink.

Packaging

The masala was meant to be eaten on the go. If dosa can be

provided in wrapper but how chutney be provided?

Other Issues

Cooking of dosa produce steam which blacken the ceiling of

store unless some mechanism for trapping and

channelizing out the steam.

Dosa King 7

Product Development Challenges

Project Funding

The project was funded by venture capital. In 1992, the VC

industry in India was in its nascent stage. In fact prior to

1988, the govt. had no policies on VC funds. The guidelines

were restrictive , the funds were restricted to INR 100

million.

Dosa Machine

INR 1 million were assigned for basic design of dosa

machine. The design were assigned to a coffee

manufacturing company which replicated the entire

process of making dosa through a mechanical robot. The

development of machine took 9 months.

Dosa King 8

Dosa Batter

Climatic condition also influenced fermentation

process. The UDCT believed that the wet batter could

preserved after fermentation through preservatives.

The factory location is depended on raw material such

as rice, dal and potatoes.

Potato Masala and Accompaniments

Potatoes from different parts of the country tested

different.

IFFL decided to dehydrate the potatoes along with the

masalas and other ingredients.

IFFL also wanted to negotiate with coca cola, Pepsico,

Brooke Bond, nestle and Rasna.

Dosa King 9

Project Risk

The dosa machine had not been standardized.

Delivery of dosa in vertical format assumed that crisp

enough dosa could be delivered that not sag while

holding potato masala in place in center.

Making 90 gram dosa against 175 gram industry size.

This decision was taken because 175 gram dosa could

not stand upright.

Dosa King 10

Decisions

Nagpur was chosen location on the basis of availability

of potatoes, dal, rice powder and other ingredients.

A retort packaging facility was sourced from Mumbai

based manufacturer.

Development of chutney outsourced to Hyderabad

based food manufacturer

IFFL decide to test market with original specifications.

Dried dosa batter will suffice for test market.

A mix of onions and other spice preserved in brine was

developed for potato masala.

Dosa King 11

Test Market

Dosa did not perform in test market, there were no consistency

between 2 dosas.

Customer expected to eat the dosa on the go but actual dosas

were limp and sagged.

Demand for sambar accelerated.

Dosa deliver in every 90 seconds and every 3

rd

dosa would turn

out damaged.

Potato masala could not be tested as the product gave the smell of

chemical preservatives. Later Product was withdrawn.

Frequent power cuts resulted in interruptions in dosa making

process.

How IFFL response to test market

results

The size of dosa revised to 110 grams.

The enzyme to accelerate the process of making dosa

batter was finalized.

The software on the electronics was redone including

sensor.

The footprint of machine to be reduced 6 sq. feet.

Delivery time to be accelerated to 30 seconds.

Dosa King 12

Final Launch

A fabricated drum drier for potato flakes was deployed

as final one was delayed due to delay in placing the

order.

During the period of development , several

commitments were made to funding institutions about

launch date.

Then final deadline of 6 months was fixed.

The IFFL opened 250 outlets in Mumbai,

Ahmadabad and Chennai.

Dosa King 13

Conclusion

Dosa king set up to provide standardized dosa for

every Indian, this aim faced many challenges at early

stage.

Procuring raw material and other ingredients was the

main problem while setting up an location for

manufacturing.

IFFLs USP was standardization of dosa.

They were lacking proper financial support.

Accompaniments was also the problem as customer

have different taste in different regions.

Dosa King 14

Dosa King 15

You might also like

- New Pair of Glasses Part 1Document18 pagesNew Pair of Glasses Part 1John Ashton80% (50)

- Time MagazineDocument128 pagesTime MagazineSubhabrat Padhi80% (10)

- Personal Spaceship User Guide - En-USDocument36 pagesPersonal Spaceship User Guide - En-USsumit_vishwkarmaNo ratings yet

- Mobile Catering Business Plan TemplateDocument45 pagesMobile Catering Business Plan TemplateBill Humphreys100% (4)

- MDCM Case Write UpDocument16 pagesMDCM Case Write UpKurt MarshallNo ratings yet

- Cultural Values in Indian Cosmetic BrandsDocument16 pagesCultural Values in Indian Cosmetic BrandsRajdeep Roy Chowdhury0% (1)

- Emulsification and Encapsulation Pocket GuideDocument2 pagesEmulsification and Encapsulation Pocket GuideIngredion Knowledge BankNo ratings yet

- Group 10 - Sec BDocument10 pagesGroup 10 - Sec BAshishKushwahaNo ratings yet

- Strategic Mangaement PepsiCoDocument14 pagesStrategic Mangaement PepsiCoDwayneOliwaNo ratings yet

- Business Analytics-Bharti Airtel: Group 7 Members: Rajani Nair Akansha Dwivedi Moumita Basak Jayasekharan UnnikrishnanDocument7 pagesBusiness Analytics-Bharti Airtel: Group 7 Members: Rajani Nair Akansha Dwivedi Moumita Basak Jayasekharan UnnikrishnanRajani Nair (PGPMX-2019 Batch 1)No ratings yet

- Cottle-Taylor: Expanding The Oral Care Group in India: Submitted By: Group B32Document7 pagesCottle-Taylor: Expanding The Oral Care Group in India: Submitted By: Group B32Janani Ramanathan0% (1)

- FOI Homepage - Online Liturgy: Booklet: by Olivia RobertsonDocument5 pagesFOI Homepage - Online Liturgy: Booklet: by Olivia RobertsonskaluNo ratings yet

- Dosa King CaseDocument8 pagesDosa King CaseManohar PalavalasaNo ratings yet

- Samantha Seetaram IENG3003 Assignment1Document15 pagesSamantha Seetaram IENG3003 Assignment1Samantha SeetaramNo ratings yet

- Project Assessment at Railways FinalDocument5 pagesProject Assessment at Railways FinaldebojyotiNo ratings yet

- Xiaomi: Designing An Ecosystem For The "Internet of Things"Document5 pagesXiaomi: Designing An Ecosystem For The "Internet of Things"Shubham SinhaNo ratings yet

- Coca-Cola IndiaDocument11 pagesCoca-Cola IndiaLakshmi Satya RayasamNo ratings yet

- Investment Analysis ExercisesDocument4 pagesInvestment Analysis ExercisesAnurag SharmaNo ratings yet

- Emirates Airline Success Behind Solid GrowthDocument1 pageEmirates Airline Success Behind Solid GrowthChRehanAliNo ratings yet

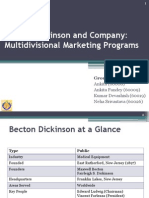

- Becton Dickinson and CompanyDocument19 pagesBecton Dickinson and CompanyAmitSinghNo ratings yet

- CP 5Document1 pageCP 5Mohammad Sameed Zaheer100% (1)

- OTISLINE PresentationDocument5 pagesOTISLINE PresentationRajgopal IyengarNo ratings yet

- Cottle-Taylor Expanding The Oral Care Group in India Group-6Document17 pagesCottle-Taylor Expanding The Oral Care Group in India Group-6ayush singlaNo ratings yet

- Print OutDocument17 pagesPrint OutRobin BishwajeetNo ratings yet

- PGP12101 B Akula Padma Priya DADocument20 pagesPGP12101 B Akula Padma Priya DApadma priya akulaNo ratings yet

- State Bank of India: Transforming A State Owned GiantDocument18 pagesState Bank of India: Transforming A State Owned GiantSahil NagpalNo ratings yet

- The Power of Direct Sales Growth Through Motivation and TrainingDocument8 pagesThe Power of Direct Sales Growth Through Motivation and TrainingSaurabh PalNo ratings yet

- Harrington Collection Explores Growth in Active-Wear MarketDocument13 pagesHarrington Collection Explores Growth in Active-Wear MarketPoonam Chauhan100% (2)

- Age Experience in SF Overall Work Ex Region Positives NegativesDocument6 pagesAge Experience in SF Overall Work Ex Region Positives NegativesireneNo ratings yet

- Oversight Systems AnswersDocument4 pagesOversight Systems AnswersRitika SharmaNo ratings yet

- Group 9 - SDMDocument50 pagesGroup 9 - SDMPRASHANT KUMARNo ratings yet

- Exercise 1 SolnDocument2 pagesExercise 1 Solndarinjohson0% (2)

- Shobhit Saxena - CSTR - Assignment IDocument4 pagesShobhit Saxena - CSTR - Assignment IShobhit SaxenaNo ratings yet

- Atlantic Computers: A Bundle of Pricing OptionsDocument4 pagesAtlantic Computers: A Bundle of Pricing OptionsFree GuyNo ratings yet

- Striders: Running Away or Towards The Growth (Group 8)Document1 pageStriders: Running Away or Towards The Growth (Group 8)Rashi VajaniNo ratings yet

- Case Analysis - Wright Line, Inc. (A)Document8 pagesCase Analysis - Wright Line, Inc. (A)ayush singlaNo ratings yet

- Cottle Taylor Case StudyDocument10 pagesCottle Taylor Case StudyParth DhingraNo ratings yet

- Boots Hair Case Sales Promotion CaseDocument44 pagesBoots Hair Case Sales Promotion CasePHANEENDRA SAINo ratings yet

- Question-Set 2: How Did You Handle The Ambiguity in Your Decision-Making? What WasDocument6 pagesQuestion-Set 2: How Did You Handle The Ambiguity in Your Decision-Making? What WasishaNo ratings yet

- Cottle Taylor Case AnalysisDocument22 pagesCottle Taylor Case AnalysisRALLAPALLI VISHAL VIJAYNo ratings yet

- Decision Models and Optimization: Sample-Endterm-with SolutionsDocument6 pagesDecision Models and Optimization: Sample-Endterm-with SolutionsYash NyatiNo ratings yet

- ISM Case Analysis (Cisco Systems) : Group 13 Section - ADocument6 pagesISM Case Analysis (Cisco Systems) : Group 13 Section - AManish Kumar BansalNo ratings yet

- TiVo Case StudyDocument3 pagesTiVo Case StudyMuskan PuriNo ratings yet

- Wrightline Inc. Case Study: Group-6Document6 pagesWrightline Inc. Case Study: Group-6sili coreNo ratings yet

- Optimizing Soda Promotional SpendingDocument10 pagesOptimizing Soda Promotional SpendingzqasimNo ratings yet

- Summary and AnswersDocument9 pagesSummary and Answersarpit_nNo ratings yet

- B2B Marketing - Jyoti - Sagar - P19052Document5 pagesB2B Marketing - Jyoti - Sagar - P19052JYOTI TALUKDARNo ratings yet

- Magnet Beauty Products Leasing Decision ImpactDocument11 pagesMagnet Beauty Products Leasing Decision ImpactFiqri100% (1)

- Managing Change at Disney's European OperationsDocument11 pagesManaging Change at Disney's European OperationsGiskardNo ratings yet

- Coffee Wars: CCD vs Starbucks in IndiaDocument3 pagesCoffee Wars: CCD vs Starbucks in IndiaSreeda PerikamanaNo ratings yet

- Emami Case StudyDocument4 pagesEmami Case StudyMridul GreenwoldNo ratings yet

- Case Reliance Baking SodaDocument2 pagesCase Reliance Baking Sodajaimaharashtra100No ratings yet

- Godrej Problem Case StudyDocument1 pageGodrej Problem Case StudysamacsterNo ratings yet

- Demand forecasting perishable homemade food ID FreshDocument2 pagesDemand forecasting perishable homemade food ID FreshPoornima SaiNo ratings yet

- Chestnut FoodsDocument2 pagesChestnut FoodsDebanu MahapatraNo ratings yet

- The Morning Star Company: Self-Management at WorkDocument8 pagesThe Morning Star Company: Self-Management at WorkRomali DasNo ratings yet

- Dwo PHD01003 Harshad Savant Term2 EndtermDocument8 pagesDwo PHD01003 Harshad Savant Term2 EndtermHarshad SavantNo ratings yet

- "The New Science of Salesforce Productivity": Reading SummaryDocument2 pages"The New Science of Salesforce Productivity": Reading SummarypratyakshmalviNo ratings yet

- Does IT Payoff? Strategies of Two Banking Giants: Submitted By: Group 4, Section BDocument5 pagesDoes IT Payoff? Strategies of Two Banking Giants: Submitted By: Group 4, Section BNeha Bhomia GuptaNo ratings yet

- Arogya Parivar Case Analysis Group 4 Sec - CDocument5 pagesArogya Parivar Case Analysis Group 4 Sec - CMuktesh SinghNo ratings yet

- Whtsapp DealDocument3 pagesWhtsapp DealvishalbiNo ratings yet

- QMDocument87 pagesQMjyotisagar talukdarNo ratings yet

- Dosa King CaseDocument7 pagesDosa King Casevivek lukeNo ratings yet

- Industrial Training Report of Parle-G: Bvoc - FST 3 Year Submitted By: Aaisha Dav College Sector 10DDocument62 pagesIndustrial Training Report of Parle-G: Bvoc - FST 3 Year Submitted By: Aaisha Dav College Sector 10DAaisha SanaNo ratings yet

- Coke and Pepsi Learn To Compete in India.: IM Case StudyDocument12 pagesCoke and Pepsi Learn To Compete in India.: IM Case StudySiddharth GuptaNo ratings yet

- KFC's Supply Chain and Operational Strategy in IndiaDocument23 pagesKFC's Supply Chain and Operational Strategy in IndiaharshNo ratings yet

- PGDM Students Must Have at Least 2 Years Work Experience". Start From Explaning The PostDocument3 pagesPGDM Students Must Have at Least 2 Years Work Experience". Start From Explaning The PostAshwani ShastriNo ratings yet

- Here We Want To Test The Null Hypothesis That The No. of Employees Does Not Depends Upon The Store SizeDocument3 pagesHere We Want To Test The Null Hypothesis That The No. of Employees Does Not Depends Upon The Store SizeAshwani ShastriNo ratings yet

- IndustryDocument5 pagesIndustryAshwani ShastriNo ratings yet

- Report WritingDocument26 pagesReport WritingScott HarmonNo ratings yet

- ReportDocument44 pagesReportAshwani ShastriNo ratings yet

- Ques. 1-5Document4 pagesQues. 1-5Ashwani ShastriNo ratings yet

- Questionaire of RBDocument3 pagesQuestionaire of RBAshwani ShastriNo ratings yet

- Analysis of Emulsifier in Food Using Chromatographic TechniquesDocument6 pagesAnalysis of Emulsifier in Food Using Chromatographic TechniquesMaria SiahaanNo ratings yet

- Nursing Care Plan: Name: Client V.P.B. Age: 38 Years Old. Gender: FemaleDocument1 pageNursing Care Plan: Name: Client V.P.B. Age: 38 Years Old. Gender: FemaleWild RoseNo ratings yet

- Experiment No.1: Extraction of Caffeine From CoffeeDocument5 pagesExperiment No.1: Extraction of Caffeine From CoffeeYnuehSolomonNo ratings yet

- Motivation and Purpose:: Secondary ResearchDocument4 pagesMotivation and Purpose:: Secondary ResearchMarvellous mbanjoNo ratings yet

- The Contemporary World: Activity 4-Global EconomyDocument15 pagesThe Contemporary World: Activity 4-Global EconomyReynamae TicanoNo ratings yet

- Project Plan#3 (4th QTR)Document3 pagesProject Plan#3 (4th QTR)Rosann RosannNo ratings yet

- Visiting Sap AG WalldorfDocument14 pagesVisiting Sap AG WalldorfIza ŠušteršičNo ratings yet

- Filipino Sweet Macaroni SaladDocument5 pagesFilipino Sweet Macaroni SaladJennifer R. JuatcoNo ratings yet

- PepsiCoâ ™s Distribution & Logistics OperationsDocument16 pagesPepsiCoâ ™s Distribution & Logistics OperationsPriyesh DoshiNo ratings yet

- Find The Correct Conditions (Types of If-Clauses) - Mind The Underlined Verb FormsDocument2 pagesFind The Correct Conditions (Types of If-Clauses) - Mind The Underlined Verb FormshaldanmihaelaNo ratings yet

- ExperimentDocument4 pagesExperimentShahfizah EzyanNo ratings yet

- Nestlé: Usama AhmadDocument26 pagesNestlé: Usama AhmadMuhammad Usama MunirNo ratings yet

- BOQ For Kitchen Equipment (Mahadev Palace at Jodhpur)Document10 pagesBOQ For Kitchen Equipment (Mahadev Palace at Jodhpur)Aakash VijayNo ratings yet

- CB Group 3 Final Report - OreoDocument45 pagesCB Group 3 Final Report - OreoNaman Ladha100% (1)

- CL2010 Film Lions ShortlistDocument11 pagesCL2010 Film Lions ShortlistsaumyavishNo ratings yet

- The Lord's Supper Proclaims Christ As The Source and Sustenance of Our LifeDocument2 pagesThe Lord's Supper Proclaims Christ As The Source and Sustenance of Our LifeGrace Church ModestoNo ratings yet

- Coffee Day Beverages - Sales Trainee 2022 BatchDocument2 pagesCoffee Day Beverages - Sales Trainee 2022 Batchfaizan shaikhNo ratings yet

- Evening Street Review Number 40Document250 pagesEvening Street Review Number 40Barbara BergmannNo ratings yet

- TQM 2nd Assignment On NestleDocument25 pagesTQM 2nd Assignment On NestleSalman Ahmad Khan67% (3)

- Detour Cafe MenuDocument2 pagesDetour Cafe MenuMarcus LaceyNo ratings yet

- Lakelovers 2012 BrochureDocument412 pagesLakelovers 2012 BrochuresunnysallyNo ratings yet

- Extemporaneous Dispensing - Procedures PDFDocument2 pagesExtemporaneous Dispensing - Procedures PDFDr.Ramkaran SainiNo ratings yet

- Log and Supply ChainDocument7 pagesLog and Supply ChainjamilNo ratings yet