Professional Documents

Culture Documents

Aggregate Sales and Operations Planning

Uploaded by

Rahul KhannaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Sales and Operations Planning

Uploaded by

Rahul KhannaCopyright:

Available Formats

Tata McGraw

C

H

A

P

T

E

R

1

6

A

g

g

r

e

g

a

t

e

S

a

l

e

s

a

n

d

O

p

e

r

a

t

i

o

n

s

P

l

a

n

n

i

n

g

Chapter 16

Aggregate Sales and

Operations Planning

Sales and Operations Planning

The Aggregate Operations Plan

Examples: Chase and Level

strategies

OBJECTIVES

16-3

1-4

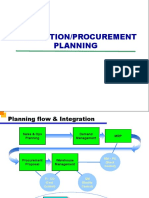

Process planning

Strategic capacity

planning

Sales and operations

(aggregate) planning

Sales

plan

Aggregate

operations

plan

Supply network

planning

Forecasting and

demand management

Master scheduling

Material requirements

planning

Order scheduling

Vehicle capacity

planning

Vehicle loading

Vehicle dispatching

Warehouse

receipt

planning

Weekly

workforce

scheduling

Daily workforce

scheduling

Manufacturing Logistics Services

Long

range

Medium

range

Short

range

16-4

Sales and Operations Planning Activities

Long-range planning

Greater than one year planning horizon

Usually performed in annual increments

Medium-range planning

Six to eighteen months

Usually with weekly, monthly or quarterly

increments

Short-range planning

One day to less than six months

Usually with weekly or daily increments

16-5

The Aggregate Operations Plan

Main purpose: Specify the

optimal combination of

production rate (units

completed per unit of time)

workforce level (number of

workers)

inventory on hand (inventory

carried from previous period)

Product group or broad

category (Aggregation)

This planning is done over an

intermediate-range planning

period of 3 to18 months

16-6

Balancing Aggregate Demand

and Aggregate Production Capacity

0

2000

4000

6000

8000

10000

Jan Feb Mar Apr May Jun

4500

5500

7000

10000

8000

6000

0

2000

4000

6000

8000

10000

Jan Feb Mar Apr May Jun

4500 4000

9000

8000

4000

6000

Suppose the figure to

the right represents

forecast demand in

units

Now suppose this

lower figure represents

the aggregate capacity

of the company to

meet demand

What we want to do is

balance out the

production rate,

workforce levels, and

inventory to make

these figures match up

16-7

Required Inputs to the Production Planning System

Planning

for

production

External

capacity

Competitors

behavior

Raw material

availability

Market

demand

Economic

conditions

Current

physical

capacity

Current

workforce

Inventory

levels

Activities

required

for

production

External

to firm

Internal

to firm

16-8

Key Strategies for Meeting Demand

Chase

Level

Stable workforce

16-9

Aggregate Planning Examples: Unit Demand and Cost Data

Materials $5/unit

Holding costs $1/unit per mo.

Marginal cost of stockout $1.25/unit per mo.

Hiring and training cost $200/worker

Layoff costs $250/worker

Labor hours required .15 hrs/unit

Straight time labor cost $8/hour

Beginning inventory 250 units

Productive hours/worker/day 7.25

Paid straight hrs/day 8

Suppose we have the following unit

demand and cost information:

Demand/mo Jan Feb Mar Apr May Jun

4500 5500 7000 10000 8000 6000

16-10

Jan Feb Mar Apr May Jun

Days/mo 22 19 21 21 22 20

Hrs/worker/mo 159.5 137.75 152.25 152.25 159.5 145

Units/worker 1063.33 918.33 1015 1015 1063.33 966.67

$/worker $1,408 1,216 1,344 1,344 1,408 1,280

Productive hours/worker/day 7.25

Paid straight hrs/day 8

Demand/mo Jan Feb Mar Apr May

Jun

4500 5500 7000 10000 8000

6000

Given the demand and cost information below, what

are the aggregate hours/worker/month, units/worker, and

dollars/worker?

7.25x2

2

7.25x0.15=48.33

&

84.33x22=1063.33

22x8hrsx$8=$140

8

Cut-and-Try Example: Determining

Straight Labor Costs and Output

16-11

Chase Strategy

(Hiring & Firing to meet demand)

Jan

Days/mo 22

Hrs/worker/mo 159.5

Units/worker 1,063.33

$/worker $1,408

Jan

Demand 4,500

Beg. inv. 250

Net req. 4,250

Req. workers 3.997

Hired

Fired 3

Workforce 4

Ending inventory 0

Lets assume our current workforce is 7

workers.

First, calculate net requirements for

production, or 4500-250=4250 units

Then, calculate number of workers

needed to produce the net

requirements, or

4250/1063.33=3.997 or 4 workers

Finally, determine the number of

workers to hire/fire. In this case we

only need 4 workers, we have 7, so

3 can be fired.

16-12

Jan Feb Mar Apr May Jun

Days/mo 22 19 21 21 22 20

Hrs/worker/mo 159.5 137.75 152.25 152.25 159.5 145

Units/worker 1,063 918 1,015 1,015 1,063 967

$/worker $1,408 1,216 1,344 1,344 1,408 1,280

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250

Net req. 4,250 5,500 7,000 10,000 8,000 6,000

Req. workers 3.997 5.989 6.897 9.852 7.524 6.207

Hired 2 1 3

Fired 3 2 1

Workforce 4 6 7 10 8 7

Ending inventory 0 0 0 0 0 0

Below are the complete calculations for the remaining

months in the six month planning horizon

16-13

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250

Net req. 4,250 5,500 7,000 10,000 8,000 6,000

Req. workers 3.997 5.989 6.897 9.852 7.524 6.207

Hired 2 1 3

Fired 3 2 1

Workforce 4 6 7 10 8 7

Ending inventory 0 0 0 0 0 0

Jan Feb Mar Apr May Jun Costs

Material $21,250.00 $27,500.00 $35,000.00 $50,000.00 $40,000.00 $30,000.00 203,750.00

Labor 5,627.59 7,282.76 9,268.97 13,241.38 10,593.10 7,944.83 53,958.62

Hiring cost 400.00 200.00 600.00 1,200.00

Firing cost 750.00 500.00 250.00 1,500.00

$260,408.62

Below are the complete calculations for the remaining months in

the six month planning horizon with the other costs included

16-14

Level Workforce Strategy (Surplus and Shortage Allowed)

Jan

Demand 4,500

Beg. inv. 250

Net req. 4,250

Workers 6

Production 6,380

Ending inventory 2,130

Surplus 2,130

Shortage

Lets take the same problem as

before but this time use the

Level Workforce strategy

This time we will seek to use

a workforce level of 6 workers

16-15

Jan Feb Mar Apr May Jun

Demand 4,500 5,500 7,000 10,000 8,000 6,000

Beg. inv. 250 2,130 2,140 1,230 -2,680 -1,300

Net req. 4,250 3,370 4,860 8,770 10,680 7,300

Workers 6 6 6 6 6 6

Production 6,380 5,510 6,090 6,090 6,380 5,800

Ending inventory 2,130 2,140 1,230 -2,680 -1,300 -1,500

Surplus 2,130 2,140 1,230

Shortage 2,680 1,300 1,500

Note, if we recalculate this sheet with 7 workers

we would have a surplus

Below are the complete calculations for the remaining

months in the six month planning horizon

16-16

Jan Feb Mar Apr May Jun

4,500 5,500 7,000 10,000 8,000 6,000

250 2,130 10 -910 -3,910 -1,620

4,250 3,370 4,860 8,770 10,680 7,300

6 6 6 6 6 6

6,380 5,510 6,090 6,090 6,380 5,800

2,130 2,140 1,230 -2,680 -1,300 -1,500

2,130 2,140 1,230

2,680 1,300 1,500

Jan Feb Mar Apr May Jun

$8,448 $7,296 $8,064 $8,064 $8,448 $7,680 $48,000.00

31,900 27,550 30,450 30,450 31,900 29,000 181,250.00

2,130 2,140 1,230 5,500.00

3,350 1,625 1,875 6,850.00

$241,600.00

Below are the complete calculations for the

remaining months in the six month planning

horizon with the other costs included

Note, total

costs under

this strategy

are less than

Chase at

$260.408.62

Labor

Material

Storage

Stockout

16-17

Question Bowl

Sales and Operations Planning

activities are usually conducted

during which planning time

horizon?

a. Long-range

b. Intermediate-range

c. Short-range

d. Really short-range

e. None of the above

Answer: b. Intermediate-range (i.e., 6 to

18 months)

16-18

Question Bowl

Which of the following are

Production Planning Strategies

can involve trade-offs among the

workforce size, work hours,

inventory, and backlogs?

a. Chase strategy

b. Stable workforce-variable work

hours

c. Level strategy

d. All of the above

e. None of the above

Answer: d. All of the above

16-19

Question Bowl

Which of the following are considered

relevant costs in the Aggregate

Production Plan?

a. Costs associated with changes in

the production rate

b. Inventory holding costs

c. Backordering costs

d. Basic production costs

e. All of the above

Answer: e. All of the above

16-20

Question Bowl

Which of the following Aggregate

Planning Techniques can be

performed using simple

spreadsheets?

a. Cut-and-try

b. Linear programming

c. Transportation method

d. All of the above

e. None of the above

Answer: a. Cut-and-try (The other two involve more

complex computational effort than simple

spreadsheets.)

16-21

End of Chapter 16

16-22

You might also like

- sales and operations planning A Complete Guide - 2019 EditionFrom Everandsales and operations planning A Complete Guide - 2019 EditionNo ratings yet

- Demand PlanningDocument17 pagesDemand PlanningArijit SamantaNo ratings yet

- Sales Operation PlanningDocument19 pagesSales Operation Planningmunishchawla100% (1)

- Demand forecasting A Complete Guide - 2019 EditionFrom EverandDemand forecasting A Complete Guide - 2019 EditionRating: 5 out of 5 stars5/5 (1)

- Sales and Operations Planning - APICS Exam WarehouseDocument6 pagesSales and Operations Planning - APICS Exam Warehousevishalyerawar100% (1)

- Cpim - MPR (Sop & MPS)Document118 pagesCpim - MPR (Sop & MPS)Mohammad S. Abu SbeihNo ratings yet

- Inventory Management System A Complete Guide - 2019 EditionFrom EverandInventory Management System A Complete Guide - 2019 EditionNo ratings yet

- CPIM (Certified in Production and Inventory Management)Document9 pagesCPIM (Certified in Production and Inventory Management)TannelsNo ratings yet

- BSCM 2 PDFDocument56 pagesBSCM 2 PDFduytay94No ratings yet

- Bolton - Sales and Operations PlanningDocument39 pagesBolton - Sales and Operations Planningeternal_rhymes6972No ratings yet

- Sales & Operations PlanningDocument41 pagesSales & Operations PlanningShubham Gupta0% (1)

- Demand Management and ForecastingDocument51 pagesDemand Management and ForecastingRahul KhannaNo ratings yet

- SMR NotesDocument30 pagesSMR Noteslyb119No ratings yet

- Sales and Operations Planning in SAPDocument13 pagesSales and Operations Planning in SAPNeelesh100% (1)

- Sales And Operations Planning A Complete Guide - 2020 EditionFrom EverandSales And Operations Planning A Complete Guide - 2020 EditionRating: 4 out of 5 stars4/5 (1)

- Apics Cpim Pt+1 Mod+1 SecgDocument29 pagesApics Cpim Pt+1 Mod+1 SecgHisham Ahmed FouadNo ratings yet

- Material Requirements Planning in A Demand Driven World: Carol PtakDocument32 pagesMaterial Requirements Planning in A Demand Driven World: Carol PtakWill Jin0% (1)

- Evolution of Sales and OperationsDocument11 pagesEvolution of Sales and OperationsShikhar Saxena100% (1)

- S&OP Grid - FOR STUDENTSDocument6 pagesS&OP Grid - FOR STUDENTSumair talashNo ratings yet

- Detailed Capacity Planning ContinuedDocument35 pagesDetailed Capacity Planning Continuedzakria100100100% (2)

- Demand Planning and ForecastingDocument10 pagesDemand Planning and Forecastingskabbas1No ratings yet

- CPIM Part 1 Section ADocument2 pagesCPIM Part 1 Section ASaurabhNo ratings yet

- CPIM Master Planning of Resources Prep UpdatedDocument10 pagesCPIM Master Planning of Resources Prep Updatedcarolina_ikeNo ratings yet

- Detailed Scheduling and Planning (Lesson 1)Document34 pagesDetailed Scheduling and Planning (Lesson 1)Pharmacotherapy100% (9)

- Forecasting APICSDocument52 pagesForecasting APICSGnanamoorthi SubramaniamNo ratings yet

- Introduction To Forecasting and Demand PlanningDocument70 pagesIntroduction To Forecasting and Demand Planningakosumchi80% (5)

- Warehouse AnalyticsDocument62 pagesWarehouse AnalyticsMary Williams100% (1)

- Sales & Operations Planning - How Good Is Your Game PlanDocument43 pagesSales & Operations Planning - How Good Is Your Game PlanLowell Harper100% (1)

- 01 BSCM v3.1 PPT MasterDocument55 pages01 BSCM v3.1 PPT Masterprasadjahagirdar1No ratings yet

- APICS MPR Practice QuestionsDocument14 pagesAPICS MPR Practice QuestionsNeville Dastoor0% (2)

- Cpim - Eco QuestionDocument18 pagesCpim - Eco QuestionPharmacotherapy100% (1)

- SupplyChainPlanningAndControl BA enDocument310 pagesSupplyChainPlanningAndControl BA enrajivbiNo ratings yet

- APICS CPIM Self-Study Resources: CPIM Exam Content ManualDocument16 pagesAPICS CPIM Self-Study Resources: CPIM Exam Content ManualvivansharmaNo ratings yet

- Oracle - Integrated Business Planning Linking Demantra S&OP and Hyperion Financial Planning (1-Managing-risk-And-uncertainty-wit-129208-Zhs)Document38 pagesOracle - Integrated Business Planning Linking Demantra S&OP and Hyperion Financial Planning (1-Managing-risk-And-uncertainty-wit-129208-Zhs)Jose LaraNo ratings yet

- S&OP - Glide PathDocument4 pagesS&OP - Glide PathVidit GuptaNo ratings yet

- Supply Chain Planning - Leading Practices PDFDocument55 pagesSupply Chain Planning - Leading Practices PDFvupro219No ratings yet

- Index: CPIM Exam - Basics of Supply Chain Management Practice Study SheetDocument31 pagesIndex: CPIM Exam - Basics of Supply Chain Management Practice Study SheetSH ZHOUNo ratings yet

- Top 10 Success Factors For Sales and Operations PlanningDocument28 pagesTop 10 Success Factors For Sales and Operations PlanningRamesh PoshalaNo ratings yet

- Sales and Operations Planning RapidResponseDocument4 pagesSales and Operations Planning RapidResponseking arjunNo ratings yet

- My APICS CPIM MPR NotesDocument45 pagesMy APICS CPIM MPR NotesMarkusTruelove100% (1)

- 10 Commandments of Inventory ManagementDocument6 pages10 Commandments of Inventory ManagementJayesh BaldotaNo ratings yet

- Basics of Inventory Management PDFDocument22 pagesBasics of Inventory Management PDFakay0505No ratings yet

- Sales & Operations Planning ProcessDocument38 pagesSales & Operations Planning ProcessAminur Rahaman100% (1)

- APICS CSCP Module 1 Topic 2 SummaryDocument1 pageAPICS CSCP Module 1 Topic 2 SummaryJohnatas MontezumaNo ratings yet

- Detailed Scheduling and Planning (Lesson 9)Document42 pagesDetailed Scheduling and Planning (Lesson 9)Pharmacotherapy100% (4)

- S&op and Master SchedulingDocument79 pagesS&op and Master Schedulingeternal_rhymes6972No ratings yet

- Apics Cpim Pt+1 Mod+1 SechDocument27 pagesApics Cpim Pt+1 Mod+1 SechHisham Ahmed FouadNo ratings yet

- S&OPDocument34 pagesS&OPestudiosa25No ratings yet

- 02SMR Ses2 Ver 1-2Document52 pages02SMR Ses2 Ver 1-2rajatgayal100% (1)

- APICS CPIM 5th Module-SMR Session 1,2,3,4Document155 pagesAPICS CPIM 5th Module-SMR Session 1,2,3,4Vipin Rajput100% (6)

- Aggregate PlanningDocument19 pagesAggregate PlanningPiyush MathurNo ratings yet

- Aggregate (Sales & Operations) PlanningDocument23 pagesAggregate (Sales & Operations) Planning199388No ratings yet

- CH7 Demand ManagementDocument43 pagesCH7 Demand ManagementRahul Khanna0% (1)

- DistributionDocument32 pagesDistributionRahul KhannaNo ratings yet

- Operations Consulting and ReengineeringDocument28 pagesOperations Consulting and ReengineeringRahul Khanna100% (1)

- Supply Chain RelationshipsDocument34 pagesSupply Chain RelationshipsRahul KhannaNo ratings yet

- Process Capability and SPC : Operations ManagementDocument43 pagesProcess Capability and SPC : Operations ManagementRahul KhannaNo ratings yet

- Product and Service DesignDocument17 pagesProduct and Service DesignRahul KhannaNo ratings yet

- Project ManagementDocument42 pagesProject ManagementRahul KhannaNo ratings yet

- Manufacturing ProcessesDocument14 pagesManufacturing ProcessesRahul KhannaNo ratings yet

- Strategic Capacity ManagementDocument36 pagesStrategic Capacity ManagementRahul KhannaNo ratings yet

- Materials Requirements PlanningDocument34 pagesMaterials Requirements PlanningRahul KhannaNo ratings yet

- Demand Management and ForecastingDocument51 pagesDemand Management and ForecastingRahul KhannaNo ratings yet

- Inventory Control: Operations ManagementDocument43 pagesInventory Control: Operations ManagementRahul KhannaNo ratings yet

- Lean Manufacturing: Operations ManagementDocument37 pagesLean Manufacturing: Operations ManagementRahul KhannaNo ratings yet

- Supply Chain StrategyDocument25 pagesSupply Chain StrategyRahul KhannaNo ratings yet

- Training - Human Resource ManagementDocument26 pagesTraining - Human Resource ManagementRahul KhannaNo ratings yet

- Organisation Design and ChangeDocument16 pagesOrganisation Design and ChangeRahul KhannaNo ratings yet

- Organizational EffectivenessDocument30 pagesOrganizational EffectivenessRahul KhannaNo ratings yet

- Wipro Report - Report On Strike in Jhansi FacilityDocument14 pagesWipro Report - Report On Strike in Jhansi FacilityRahul KhannaNo ratings yet

- Inventory ManagementDocument75 pagesInventory ManagementRahul KhannaNo ratings yet

- Collecting Information and Forecasting DemandDocument28 pagesCollecting Information and Forecasting DemandRahul Khanna100% (1)

- Smart Locker Inc Final Business PlanDocument29 pagesSmart Locker Inc Final Business Planapi-449150694100% (5)

- Course Outline Soc Sci 1 Ss Ay 11 12Document6 pagesCourse Outline Soc Sci 1 Ss Ay 11 12Aldren RebaLdeNo ratings yet

- Term PaperDocument9 pagesTerm PaperAlyssa EspinosaNo ratings yet

- Stages of Bengali TheatreDocument8 pagesStages of Bengali Theatreanirwandatta100% (1)

- Gabriel v. PangilinanDocument2 pagesGabriel v. PangilinanMit SkroNo ratings yet

- Dunn. J - The Living WordDocument200 pagesDunn. J - The Living Wordvffinder100% (2)

- Segmented Reporting Investment Center Evaluation and Transfer PricingDocument42 pagesSegmented Reporting Investment Center Evaluation and Transfer PricingAyu Dian SetyaniNo ratings yet

- Rosetta Stone of Women BehaviourDocument11 pagesRosetta Stone of Women Behaviourgift2umaNo ratings yet

- Case Study: Professional Pay Structure: Student Name: DateDocument4 pagesCase Study: Professional Pay Structure: Student Name: DateSarfraz AshrafNo ratings yet

- Practice Test 9 - 1Document9 pagesPractice Test 9 - 1Phuong DaoNo ratings yet

- Anxiety ROLE PLAY ScriptDocument3 pagesAnxiety ROLE PLAY ScriptMayanda UtamiNo ratings yet

- Granting Global Agency For Muslim Military / United Muslim Management Agency (Umma)Document17 pagesGranting Global Agency For Muslim Military / United Muslim Management Agency (Umma)GOVERNMENT OF USICNo ratings yet

- Assignment 1 Cittizenship & DiversityDocument2 pagesAssignment 1 Cittizenship & Diversitynickoh28No ratings yet

- Consti Law Cases Chapters 1 To 3Document6 pagesConsti Law Cases Chapters 1 To 3Gervilyn Macarubbo Dotollo-SorianoNo ratings yet

- What Are The Important Stipulations in Magna Carta For Teachers and The Code of Ethics For Professional Teachers?Document1 pageWhat Are The Important Stipulations in Magna Carta For Teachers and The Code of Ethics For Professional Teachers?Junnel CasanovaNo ratings yet

- 2016 Financial Industry Cybersecurity Report: SecurityscorecardDocument22 pages2016 Financial Industry Cybersecurity Report: SecurityscorecardHiba AfanehNo ratings yet

- Alfonso v. Land Bank of The Phils. - MendozaDocument1 pageAlfonso v. Land Bank of The Phils. - MendozaDonna Mendoza100% (1)

- The Cultural Politics of Markets (Anthropology, Culture & Society) (PDFDrive)Document255 pagesThe Cultural Politics of Markets (Anthropology, Culture & Society) (PDFDrive)Yana ArsyadiNo ratings yet

- M.Ed Entrance Sample Model Question Paper Ans ErsDocument19 pagesM.Ed Entrance Sample Model Question Paper Ans Erssubhas9804009247No ratings yet

- Test Bank to Accompany Microeconomics Se-đã Chuyển ĐổiDocument31 pagesTest Bank to Accompany Microeconomics Se-đã Chuyển ĐổiThiện Lê ĐứcNo ratings yet

- MGVCLDocument160 pagesMGVCLhavejsnjNo ratings yet

- Republic Act No. 8472: General Provisions Title City of TagumDocument37 pagesRepublic Act No. 8472: General Provisions Title City of TagumPiayaNo ratings yet

- C - TSCM62 - 67 LatestDocument15 pagesC - TSCM62 - 67 LatestPooja SinghNo ratings yet

- Chapter Two: Cost of Capital & Capital Structure TheoriesDocument17 pagesChapter Two: Cost of Capital & Capital Structure TheoriesBaharu AbebeNo ratings yet

- Challenge 7.1Document5 pagesChallenge 7.1JamRickNo ratings yet

- Corporate Loyalty PDFDocument12 pagesCorporate Loyalty PDFMayuraNo ratings yet

- Joy Global Inc: FORM 10-QDocument44 pagesJoy Global Inc: FORM 10-QfiahstoneNo ratings yet

- Exam 2019 Questions and AnswersDocument19 pagesExam 2019 Questions and AnswersĐạt NguyễnNo ratings yet

- Business Com MM Final LL LLLLLDocument16 pagesBusiness Com MM Final LL LLLLLSamihaSaanNo ratings yet

- ZEALANDIA Wedding BrochureDocument20 pagesZEALANDIA Wedding Brochurezealandia100% (1)

- High Road Leadership: Bringing People Together in a World That DividesFrom EverandHigh Road Leadership: Bringing People Together in a World That DividesNo ratings yet

- Summary of Noah Kagan's Million Dollar WeekendFrom EverandSummary of Noah Kagan's Million Dollar WeekendRating: 5 out of 5 stars5/5 (2)

- Summary of Steven Bartlett's The Diary of a CEOFrom EverandSummary of Steven Bartlett's The Diary of a CEORating: 5 out of 5 stars5/5 (4)

- The Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverFrom EverandThe Coaching Habit: Say Less, Ask More & Change the Way You Lead ForeverRating: 4.5 out of 5 stars4.5/5 (186)

- Millionaire Mindset: Accept That Your Own Life Choices Led to Who You Are Today. If You Can Accept This Then You Can Learn to Change Your Mindset and Habits to Match Those of Today's Millionaires and Effortlessly Lead the Way to Your Own Success!From EverandMillionaire Mindset: Accept That Your Own Life Choices Led to Who You Are Today. If You Can Accept This Then You Can Learn to Change Your Mindset and Habits to Match Those of Today's Millionaires and Effortlessly Lead the Way to Your Own Success!Rating: 4.5 out of 5 stars4.5/5 (17)

- The First Minute: How to start conversations that get resultsFrom EverandThe First Minute: How to start conversations that get resultsRating: 4.5 out of 5 stars4.5/5 (57)

- The Effective Executive by Peter Drucker - Book Summary: The Definitive Guide to Getting the Right Things DoneFrom EverandThe Effective Executive by Peter Drucker - Book Summary: The Definitive Guide to Getting the Right Things DoneRating: 4.5 out of 5 stars4.5/5 (19)

- High Road Leadership: Bringing People Together in a World That DividesFrom EverandHigh Road Leadership: Bringing People Together in a World That DividesNo ratings yet

- Brain Rules (Updated and Expanded): 12 Principles for Surviving and Thriving at Work, Home, and SchoolFrom EverandBrain Rules (Updated and Expanded): 12 Principles for Surviving and Thriving at Work, Home, and SchoolRating: 4 out of 5 stars4/5 (702)

- The Millionaire Fastlane: Crack the Code to Wealth and Live Rich for a LifetimeFrom EverandThe Millionaire Fastlane: Crack the Code to Wealth and Live Rich for a LifetimeRating: 4.5 out of 5 stars4.5/5 (2)

- How to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobFrom EverandHow to Talk to Anyone at Work: 72 Little Tricks for Big Success Communicating on the JobRating: 4.5 out of 5 stars4.5/5 (37)

- Leadership and Self-Deception: Getting out of the BoxFrom EverandLeadership and Self-Deception: Getting out of the BoxRating: 5 out of 5 stars5/5 (156)

- TED Talks: The Official TED Guide to Public SpeakingFrom EverandTED Talks: The Official TED Guide to Public SpeakingRating: 4.5 out of 5 stars4.5/5 (211)

- Extreme Ownership by Jocko Willink and Leif Babin - Book Summary: How U.S. Navy SEALS Lead And WinFrom EverandExtreme Ownership by Jocko Willink and Leif Babin - Book Summary: How U.S. Navy SEALS Lead And WinRating: 4.5 out of 5 stars4.5/5 (75)

- How to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersFrom EverandHow to Lead: Wisdom from the World's Greatest CEOs, Founders, and Game ChangersRating: 4.5 out of 5 stars4.5/5 (95)

- The Introverted Leader: Building on Your Quiet StrengthFrom EverandThe Introverted Leader: Building on Your Quiet StrengthRating: 4.5 out of 5 stars4.5/5 (35)

- Scaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0From EverandScaling Up: How a Few Companies Make It...and Why the Rest Don't, Rockefeller Habits 2.0Rating: 5 out of 5 stars5/5 (2)

- Think Remarkable: 9 Paths to Transform Your Life and Make a DifferenceFrom EverandThink Remarkable: 9 Paths to Transform Your Life and Make a DifferenceNo ratings yet

- The 7 Habits of Highly Effective PeopleFrom EverandThe 7 Habits of Highly Effective PeopleRating: 4 out of 5 stars4/5 (2568)

- Think Like Amazon: 50 1/2 Ideas to Become a Digital LeaderFrom EverandThink Like Amazon: 50 1/2 Ideas to Become a Digital LeaderRating: 4.5 out of 5 stars4.5/5 (62)

- Summary of Leaders Eat Last: Why Some Teams Pull Together and Others Don't by Simon SinekFrom EverandSummary of Leaders Eat Last: Why Some Teams Pull Together and Others Don't by Simon SinekRating: 4.5 out of 5 stars4.5/5 (142)

- How to Win Friends and Influence People: Updated For the Next Generation of LeadersFrom EverandHow to Win Friends and Influence People: Updated For the Next Generation of LeadersRating: 4.5 out of 5 stars4.5/5 (151)

- Billion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsFrom EverandBillion Dollar Lessons: What You Can Learn from the Most Inexcusable Business Failures of the Last Twenty-five YearsRating: 4.5 out of 5 stars4.5/5 (52)

- Spark: How to Lead Yourself and Others to Greater SuccessFrom EverandSpark: How to Lead Yourself and Others to Greater SuccessRating: 4.5 out of 5 stars4.5/5 (132)

- Follow The Leader: A Collection Of The Best Lectures On LeadershipFrom EverandFollow The Leader: A Collection Of The Best Lectures On LeadershipRating: 5 out of 5 stars5/5 (122)

- Cultures of Growth: How the New Science of Mindset Can Transform Individuals, Teams, and OrganizationsFrom EverandCultures of Growth: How the New Science of Mindset Can Transform Individuals, Teams, and OrganizationsNo ratings yet

- The Catalyst: How to Change Anyone's MindFrom EverandThe Catalyst: How to Change Anyone's MindRating: 4.5 out of 5 stars4.5/5 (277)