Professional Documents

Culture Documents

Thermal Removal of Wax

Uploaded by

pchimanshu27Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Removal of Wax

Uploaded by

pchimanshu27Copyright:

Available Formats

Thermal removal of wax

In thermal technique melting of wax is usually done by the injection of hot oil/hot

water/chemicals.

This technique is simple, low cost and the results are immediate.

Well deposits can vary from a mushy consistency at the upper end of the deposit

to hard, crystalline waxes at the bottom.

The type of wax is a function of the carbon atoms in the molecule.

Soft wax: C12 to C25

hard wax: C25 to C50+

The following is a listing of a few of the wax types that may be encountered in

typical well deposits:

As we can see, The melting temperature increases with the carbon number.

We have to plan our injection time and temperature according to the wax type.

Wax

Component

Carbon

Number

Melting Point

C F

Pentadecane C15 10 50

Hexadecane C16 20 68

Octadecane C18 28 82

Eicosane C20 38 10

Tetracosane C24 51 12

Triacontane C35 75 16

Now, when hot oil/hot water is injected into a well, the heat of the fluids rapidly

transfers to the cooler well bore equipment and waxes in the upper sections of

the well.

As pumping of the hot treating fluid continues the heated zone progresses down

the well bore removing additional deposits.

However, the treatment will not completely clean the well unless the treating

fluid is hot enough and injected long enough to reach the melting point of the

hard waxes at the lower end of the deposit.

Specially designed HOT OIL UNITS are used to heat the lease oil/water to a

temperature of 200 to 500F and either bullhead it into the well or circulate it

through a work string.

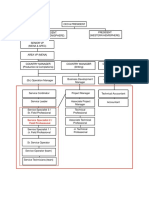

Fig. Hot Oiler

If the paraffin depositing is solid it will often have to be washed out with a work

string.

The CT is an excellent tool used in conjunction with hot oil for the removal of

paraffin.

Process:

- The CTU is rigged up in standard manner.

- A high temperature pack-off rubber should be used in

the pack-off.

- The hot oil trucks discharge line is connected to the

rotating hub of the CTU reel.

- Hot oil/hot water should be circulated through the CT

until the CT is hot prior to going in the hole.

Fig. CTU

Fig. Paraffin removal with Hot Oil

Cautions:

- Circulation of the hot fluid should be maintained from surface to approximately 500

feet below the fresh water zones.

- Circulation should be maintained for at least two hours after reaching the desired

depth. This will ensure melting away all the paraffin rather than simply washing a

hole through it.

- Returns should be monitored to be sure the oil is hot enough to melt the paraffin

before circulation is stopped.

Extreme cautions:

- If the hot oil/chemical should come in contact with someone, it adheres and creates

a much more severe burn than would hot water.

- Extreme care should be used when moving the coiled tubing while circulating hot

fluid.

Advantages:

- CTU provides continuous circulation from surface to bottom.

- CTU has a very effective blowout preventer and pack-off assembly.

- Its operation is fast effective and economical.

You might also like

- Production Operators - Ii Oil Production SafetyDocument50 pagesProduction Operators - Ii Oil Production SafetyZeeshan Jabbar ChanaNo ratings yet

- Overcurrent CoordinationDocument93 pagesOvercurrent CoordinationKumar100% (1)

- VP Construction Real Estate Development in NY NJ Resume Edward CondolonDocument4 pagesVP Construction Real Estate Development in NY NJ Resume Edward CondolonEdwardCondolonNo ratings yet

- Transformer Oil FiltrationDocument21 pagesTransformer Oil Filtrationnicholaslee100% (5)

- Tank Heating DiscussionsDocument26 pagesTank Heating DiscussionsTHERMAX007No ratings yet

- Sony SL HF-900 Owners ManualDocument53 pagesSony SL HF-900 Owners ManualThomas Christoph100% (1)

- CrackingDocument20 pagesCrackingNiaz Ali KhanNo ratings yet

- Electrical Estimate Template PDFDocument1 pageElectrical Estimate Template PDFMEGAWATT CONTRACTING AND ELECTRICITY COMPANYNo ratings yet

- Incinerator: Make: Sunflame Type: OSVDocument40 pagesIncinerator: Make: Sunflame Type: OSVravilullaNo ratings yet

- Heater TreatersDocument9 pagesHeater TreatersDeepak Shakya100% (2)

- Turbine Lub Oil System: A Chemical Approach)Document33 pagesTurbine Lub Oil System: A Chemical Approach)Sanjit SahooNo ratings yet

- QCM Part 145 en Rev17 310818 PDFDocument164 pagesQCM Part 145 en Rev17 310818 PDFsotiris100% (1)

- Gravity Based Foundations For Offshore Wind FarmsDocument121 pagesGravity Based Foundations For Offshore Wind FarmsBent1988No ratings yet

- Transformer Dry Out ProcedureDocument4 pagesTransformer Dry Out ProcedurePedada AdityaNo ratings yet

- Scavenge FireDocument3 pagesScavenge FireVishu SharmaNo ratings yet

- Thermal CrackingDocument24 pagesThermal Crackingmihir kumar100% (1)

- Turbine OperationDocument62 pagesTurbine OperationNIHAR BEHERA100% (3)

- Coal Mill Safety K ChandaDocument12 pagesCoal Mill Safety K Chandanarasimhamurthy414No ratings yet

- ADU Desalting PDFDocument100 pagesADU Desalting PDFHARSHA DEEPTHI GUNANA (N150434)No ratings yet

- Cloud & Pour PointsDocument9 pagesCloud & Pour PointsMuhammed Fuad100% (1)

- Thermia BDocument4 pagesThermia Bsofian juniardiNo ratings yet

- Refinery 3Document53 pagesRefinery 3Patel AshokNo ratings yet

- Crude Distillation: Petroleum Refining Engineering 2012 - 2013Document22 pagesCrude Distillation: Petroleum Refining Engineering 2012 - 2013die_1No ratings yet

- The 2 Stroke Diesel CycleDocument14 pagesThe 2 Stroke Diesel CycleBharatiyulam100% (1)

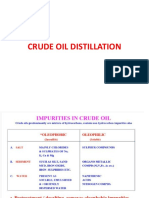

- Crude Oil DistillationDocument109 pagesCrude Oil Distillationshreshth chawlaNo ratings yet

- Oily Water SeperatorsDocument38 pagesOily Water Seperatorsakusuper67% (3)

- 4269chapter 4 Crude DistillationDocument19 pages4269chapter 4 Crude DistillationJuan Carlos Barrera Quijano100% (1)

- Thermal CrackingDocument24 pagesThermal Crackingzubi0585No ratings yet

- 6 Crude Oil RefiningDocument57 pages6 Crude Oil RefiningAkashNo ratings yet

- C 7Document183 pagesC 7Liza Cabalquinto LorejoNo ratings yet

- CHE 1014 Petroleum Technology: Unit 2 Petroleum (CRUDE OIL) Topic: Crude Oil DistillationDocument26 pagesCHE 1014 Petroleum Technology: Unit 2 Petroleum (CRUDE OIL) Topic: Crude Oil DistillationpranavNo ratings yet

- 9 Visbreaking 09 Sep 2019material I 09 Sep 2019 2. VISBREAKINGDocument7 pages9 Visbreaking 09 Sep 2019material I 09 Sep 2019 2. VISBREAKINGRashmi KumariNo ratings yet

- Thermal EDocument43 pagesThermal EMohanad HussienNo ratings yet

- Thermal Eor 1673792137Document25 pagesThermal Eor 1673792137بهزاد نايف الملكوNo ratings yet

- Thermal EorDocument42 pagesThermal EorPetroleum PetroleumNo ratings yet

- Fuel SystemDocument31 pagesFuel SystemX SxUxGxAxR XNo ratings yet

- Module-3: Prepared by Suchisnata Pradhani Department of Chemical EngineeringDocument9 pagesModule-3: Prepared by Suchisnata Pradhani Department of Chemical EngineeringSadhan PadhiNo ratings yet

- CDUDocument17 pagesCDUmitpgandhiNo ratings yet

- A Study On Process Optimization and Refinery Operations at A Petroleum IndustryDocument23 pagesA Study On Process Optimization and Refinery Operations at A Petroleum Industryvinothvinoth272002No ratings yet

- Operational Information Scavenge FiresDocument9 pagesOperational Information Scavenge FiresSiva RamanNo ratings yet

- Visbreaking, Thermal Cracking, and Coking: Mercaptan ExtractionDocument4 pagesVisbreaking, Thermal Cracking, and Coking: Mercaptan ExtractionChetan CherryNo ratings yet

- Module 8.2 Fuel Oil TreatmentDocument5 pagesModule 8.2 Fuel Oil Treatmentdepedromarjan05No ratings yet

- 14-17 ConversionDocument16 pages14-17 ConversionLakshya SaxenaNo ratings yet

- Crude DistillationDocument32 pagesCrude DistillationIzziyyahNo ratings yet

- Combustion PDFDocument79 pagesCombustion PDFKranthi ReddyNo ratings yet

- Abhishek Report UpdatedDocument43 pagesAbhishek Report UpdatedYash ChouDharyNo ratings yet

- Shell Thermia B Pds PDFDocument3 pagesShell Thermia B Pds PDFBoon Kuan LimNo ratings yet

- Liquid Fuels: Origin of PetroleumDocument14 pagesLiquid Fuels: Origin of PetroleumAdnan MaqboolNo ratings yet

- Types of Conversion ProcessesDocument5 pagesTypes of Conversion ProcessesLakshya SaxenaNo ratings yet

- Texatherm: Industrial Heat Transfer OilDocument2 pagesTexatherm: Industrial Heat Transfer OilCharith LiyanageNo ratings yet

- Distillation of HerbsDocument10 pagesDistillation of HerbscrimsonredNo ratings yet

- Hot Light OilDocument3 pagesHot Light OilhosihosiannaNo ratings yet

- Action To Taken During Scavange FireDocument7 pagesAction To Taken During Scavange FireVinothen RajNo ratings yet

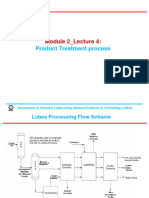

- Module2 Lect4Document28 pagesModule2 Lect4srirajgirish7No ratings yet

- Fuel Systems Onboard ShipsDocument22 pagesFuel Systems Onboard ShipsluswagamasasiNo ratings yet

- Danol XHTDocument1 pageDanol XHTpalraj_suriNo ratings yet

- Techno Economic Report of Oil TreatmentDocument5 pagesTechno Economic Report of Oil TreatmentZain Ul AbedinNo ratings yet

- Des AlterDocument5 pagesDes Altersagarchawla13No ratings yet

- Thermal Cracking:: Stream Number Stream Make SourceDocument3 pagesThermal Cracking:: Stream Number Stream Make SourcejohnNo ratings yet

- Decarb Sop Final PDFDocument7 pagesDecarb Sop Final PDFchemeng1No ratings yet

- What Is Heavy Fuel Oil Used ForDocument10 pagesWhat Is Heavy Fuel Oil Used ForWaqar Younas NumberdarNo ratings yet

- Figure 1 (A) : Timing Diagram of 4-Stroke EngineDocument6 pagesFigure 1 (A) : Timing Diagram of 4-Stroke EngineManamohanNo ratings yet

- Adu & VduDocument19 pagesAdu & Vduvijetakumari.201ch059No ratings yet

- TB011-Technical Brief - Heat Transfer Systems GulfSea HT Oil 32-V1Document7 pagesTB011-Technical Brief - Heat Transfer Systems GulfSea HT Oil 32-V1magadali7814No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Satsang Diksha Guj-Sanskrit-EngDocument274 pagesSatsang Diksha Guj-Sanskrit-Engpchimanshu27No ratings yet

- Satsang Diksha Hindi-SanskritDocument132 pagesSatsang Diksha Hindi-Sanskritpchimanshu27No ratings yet

- Service Specialist 2 / Field ProfessionalDocument1 pageService Specialist 2 / Field Professionalpchimanshu27No ratings yet

- Basin Plan Nov2012Document265 pagesBasin Plan Nov2012pchimanshu27No ratings yet

- Chi-Square Test PresentationDocument28 pagesChi-Square Test Presentationpchimanshu27No ratings yet

- LT1256X1 - Revg - FB1300, FB1400 Series - EnglishDocument58 pagesLT1256X1 - Revg - FB1300, FB1400 Series - EnglishRahma NaharinNo ratings yet

- Danube Coin LaundryDocument29 pagesDanube Coin LaundrymjgosslerNo ratings yet

- STM Series Solar ControllerDocument2 pagesSTM Series Solar ControllerFaris KedirNo ratings yet

- Audit Certificate: (On Chartered Accountant Firm's Letter Head)Document3 pagesAudit Certificate: (On Chartered Accountant Firm's Letter Head)manjeet mishraNo ratings yet

- 1.mukherjee - 2019 - SMM - Customers Passion For BrandsDocument14 pages1.mukherjee - 2019 - SMM - Customers Passion For BrandsnadimNo ratings yet

- Unit 13 - Business Hotels and Sales ConferencesDocument24 pagesUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNo ratings yet

- Defeating An Old Adversary Cement Kiln BallsDocument5 pagesDefeating An Old Adversary Cement Kiln BallsManish KumarNo ratings yet

- Writing Task The Strategy of Regional Economic DevelopementDocument4 pagesWriting Task The Strategy of Regional Economic DevelopementyosiNo ratings yet

- Oxygen BarrierDocument20 pagesOxygen BarrierKarina ArdizziNo ratings yet

- CEA 4.0 2022 - Current Draft AgendaDocument10 pagesCEA 4.0 2022 - Current Draft AgendaThi TranNo ratings yet

- Caso Kola RealDocument17 pagesCaso Kola RealEvelyn Dayhanna Escobar PalomequeNo ratings yet

- Aluminium Extrusion Industry in IndiaDocument3 pagesAluminium Extrusion Industry in Indiakalan45No ratings yet

- MCoal Coal July Investor SlidesDocument26 pagesMCoal Coal July Investor SlidesMCoaldataNo ratings yet

- Lemon AidDocument17 pagesLemon AidJade Anne Mercado BalmesNo ratings yet

- Mobile Based IVR SystemDocument17 pagesMobile Based IVR SystemIndraysh Vijay [EC - 76]No ratings yet

- PanasonicDocument35 pagesPanasonicAsif Shaikh0% (1)

- Frigidaire Parts and Accessories CatalogDocument56 pagesFrigidaire Parts and Accessories CatalogPedro RuizNo ratings yet

- Question Bank For Vlsi LabDocument4 pagesQuestion Bank For Vlsi LabSav ThaNo ratings yet

- Projects: Term ProjectDocument2 pagesProjects: Term ProjectCoursePinNo ratings yet

- 88 - 02 Exhaust Manifold Gasket Service BulletinDocument3 pages88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerNo ratings yet

- Digital Documentation Class 10 NotesDocument8 pagesDigital Documentation Class 10 NotesRuby Khatoon86% (7)

- EE1000 DC Networks Problem SetDocument7 pagesEE1000 DC Networks Problem SetAmit DipankarNo ratings yet

- Risk Analysis and Management - MCQs1Document7 pagesRisk Analysis and Management - MCQs1Ravi SatyapalNo ratings yet

- Algorithm - WikipediaDocument34 pagesAlgorithm - WikipediaGilbertNo ratings yet