Professional Documents

Culture Documents

Process Innovation

Uploaded by

Aanchal GuptaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Innovation

Uploaded by

Aanchal GuptaCopyright:

Available Formats

PROCESS

INNOVATION

By:-

Kriti Mathur- 76

Abhishek Kumar- 85

Nishant Tyagi- 86

Manisha Shrestha- 95

What Is Process?

A Process is combination of facilities, skills and technologies

that are used to produce products or provide services.

What is Process Innovation?

Process innovation combines adopting a process

view of business functions with the application of

new ideas and technology.

Process innovation depends on the transfer of

knowledge and information.

For improving productivity.

Increase employee job satisfaction.

Deliver enhanced product or service value

to the customer.

For controlling and reducing process

wastage.

For controlling and reducing work in

process inventories.

For reducing processing time & costs.

Need For Process Innovation?

Process innovations builds an adaptive

business process management system (BPMS).

For manufacturing companies.

For service companies.

Focus

Steps in Process Innovation

Successful process innovation requires the

following:

Proper Planning.

Creating a multifunctional team of Technical,

Production and Maintenance Department.

Continued

Selecting a small group of operators and

workers, seeking their participation in

process innovation through

communication, counselling, training and

rewards etc.

Pilot run of the new process.

Observations and improvements.

Large scale training of entire work force.

Commercial use of new Process.

Attributes of Innovative

Processes

1. Elimination or decrease in manual processes.

2. Coordination of processes across distances.

3. Change of process sequence; allow parallel

processes.

4. Capturing process information to understand

process better.

5. Improved analysis of information and decision

making.

6. Capture and distribute organizational

information.

7. Monitoring process status.

8. Coordination of tasks and processes

(cross functional).

Tools For Process Innovation

Developing Assembly Charts for studying conceptual

framwork of material flow .

Developing Process Charts for studying conceptual

framwork of process flow.

Computer Aided Designing (CAD), Computer

Simulation.

Time Study for comparing time taken for various

operations and tasks.

Value Engineering and Analysis.

Business Process Reengineering.

Benchmarking.

Using Change Management Strategies.

Financial Appraisal.

Innovation Strategies

Automation

1. More web information.

2. Improve IVR service.

3. Increase self-service.

4. Reduce access to files.

Process Sequence

1. Parallel processing.

2. Virtual linkages.

3. Simultaneous entry

and review.

Geographic

1. Multiple sites on

campus.

2. Coordination with other

departments.

Tracking

1. Transaction volume.

2.Document management.

3. Priority processing.

4. Transaction type.

Continued

Integration

1. Coordination of activities.

2. Policy and process

alignment.

3. Scheduling and planning.

Information

1. Process cycle times.

2. Peak processing.

3. Customer profiles.

Analysis

1. Management

Information.

2. Scheduling,

staffing, process

design.

Knowledge

1. Knowledge Management.

2. Standard operating

procedures.

3. Regulation and statutory

changes.

Techniques Of

Process

Innovation

1. BPR

Business process re-engineering is also known as business

process redesign, business process change management.

Business process re-engineering (BPR) is a technique by

which organizations fundamentally rethink how they do

their work in order to dramatically improve customer

service, cut operational costs, and become world-class

competitors.

It is more than just business improvising.

A key stimulus for re-engineering has been the

continuing development and deployment of sophisticated

information systems and networks.

Continued

Reengineering assumes the current process is largely

irrelevant - it shall not work on future, it's broke, forget it.

Start afresh. Such a clean slate perspective enables the

designers of business processes to disassociate themselves

from today's process, and focus on a new process.

Reengineering starts with a high-level assessment of the

organization's mission, strategic goals, and customer needs

Re-engineering identifies, analyzes, and re-designs an

organization's core business processes with the aim of

achieving dramatic improvements in critical performance

measures, such as cost, quality, service, and speed

Continued

2. TQM

Total: Make up of the whole. . Quality: Degree of

excellence a product or service provides. Management:

Act, art, or manner of handling, controlling, directing, etc.

Therefore, TQM is the art of managing the whole to achieve

excellence. TQM is defined as both a philosophy and a set of

guiding principles that represent the foundation of a

continuously improving organization.

It is the application of quantitative methods and human

resources to improve all the processes within an

organization and exceed customer needs now and in the

future.

TQM integrates fundamental management techniques,

existing improvement efforts, and technical tools under a

disciplined approach.

Advantages of TQM

Encourages a strategic approach to

management at the operational level

Provides high return on investment through

improving efficiency

Works equally well for service and

manufacturing sectors

Allows organizations to take advantage of

developments that enable managing

operations as cross-functional processes

Fits an orientation toward inter-

organizational collaboration and strategic

alliances through establishing a culture of

collaboration among different departments

within organization

Diff between BPR vs TQM

Approaches

Davenport points out that the Major difference between

BPR and other approaches to organization development

(OD), especially the continuous improvement (Kaizen)

or TQM movement, is: Today firms seek not fractional,

but multiplicative levels of improvement (10times)

rather than 10%.

Continued

Johansson

provides a description of BPR relative to other

process-oriented views, such as TQM and JIT as under:

"Business Process Reengineering, although a close

relative, seeks radical rather than merely continuous

improvement. It escalates the efforts of JIT and TQM to

make process orientation a strategic tool and a core

competence of the organization. BPR concentrates on

core business processes, and uses the specific techniques

within the JIT and TQM toolboxes as enablers, while

broadening the process vision."

3. Lean Production System

It is the western term for Toyota Production

System. This production philosophy is now

widely used in auto industry around the

world. This system has been modified

everywhere in the auto industry, adapted to

some extent on the local industrial situation

or practices, however its core principles

remain the same. This system is not only used

in auto industry but also in other non-

auto industries involved in assembling

process.

Benefits of Lean Production

System

Waste Reduction.

Production Cost Reduction.

Manufacturing Cycle Reduction.

Labor Reduction.

Inventory Reduction.

Production Capacity Increase.

4. Kaizen

Japanese strategy for continuous

improvement

Not a single day should go without any

improvement

Customer driven strategy for improvement

Quality first, not profit first

Consists of two major components

Maintenance

Improvement

Benefits of Kaizen

Reduces Waste.

Improves.

Immediate Results.

5. 5S Concept

Refers to the five words:

Seiri.

Seiton.

Seiso.

Seiketsu.

Shitsuke .

6. Six Sigma

Six Sigma focuses on making

improvements in all operations within a

process, producing results more rapidly

and effectively.

EXAMPLES OF PROCESS INNOVATION

1. The Float Glass process developed by Alistair

Pilkington, in which plate glass is manufactured by

drawing glass out across a bed of molten tin (Quinn,

1991). Prior to the introduction of this process

innovation, plate glass used for shop windows and

office windows was expensive and of poor quality

largely because the only way of getting a flat

surface was to grind it and polish it. The Float Glass

process at a stroke eliminated the need for time

consuming grinding and polishing it, leading to a

dramatic fall in costs. The result can be seen in the

public buildings constructed in the last thirty years,

where everything from office blocks and hotels to

airports and shopping malls now employ large

expanses of glass

Continued

2 .Precision Ring Makers (PRM) made components

to high specifications,largely for the aircraft

industry. Its main development work was focused

upon process improvements. It had developed

low cost tooling techniques which resulted in

great savings: for example, tooling changes for

thin guage shims using conventional techniques

cost about 4000, while with PRMs technique the

cost was about 30. It had purchased CNC

machines for milling and engraving, and was

planning to network the CNC machines to its

computer system so that programmes could be

transmitted directly to production.

Continued

3. The humble photocopier, developed by Chester

Carlson, may not sound like a spectacular

innovation, and yet it had a big impact on the

way in which administrative systems in offices are

organised.

4.Fabrication and Assembly Company (FAC) was

primarily interested in welding technology. A

recent example of process improvement was the

application of plasma cutting instead of drilling,

in the manufacture of heat exchangers and

plates. A flushing system to prevent the build-up

of sludge in the air chambers of the water tables

which were being manufactured, was also

developed to assist the introduction of plasma

cutting.

You might also like

- International Strategic Management A Complete Guide - 2020 EditionFrom EverandInternational Strategic Management A Complete Guide - 2020 EditionNo ratings yet

- PPC Cha - 3Document44 pagesPPC Cha - 3antehenNo ratings yet

- Production And Operations Management A Complete Guide - 2020 EditionFrom EverandProduction And Operations Management A Complete Guide - 2020 EditionNo ratings yet

- Mcqs Ethics and CSR)Document9 pagesMcqs Ethics and CSR)Maida TanweerNo ratings yet

- ENF123 Lecture 3Document8 pagesENF123 Lecture 3Dave N100% (1)

- Productivity and Reliability-Based Maintenance Management, Second EditionFrom EverandProductivity and Reliability-Based Maintenance Management, Second EditionNo ratings yet

- Operations ManagementDocument35 pagesOperations ManagementAung Mon ChanNo ratings yet

- Business Process Engineering A Complete Guide - 2020 EditionFrom EverandBusiness Process Engineering A Complete Guide - 2020 EditionNo ratings yet

- Chapter 2 (Financial Analysis)Document46 pagesChapter 2 (Financial Analysis)Mahmudul HasanNo ratings yet

- People Capability Maturity Model A Complete Guide - 2021 EditionFrom EverandPeople Capability Maturity Model A Complete Guide - 2021 EditionNo ratings yet

- Auto Plant Location FactorsDocument6 pagesAuto Plant Location Factorsankujai88No ratings yet

- Chapter 7 STRDocument10 pagesChapter 7 STRmedrekNo ratings yet

- Operations Management: Aggregate PlanningDocument16 pagesOperations Management: Aggregate PlanningArun MishraNo ratings yet

- 4th Year Course OutlineDocument18 pages4th Year Course OutlineEbsa AdemeNo ratings yet

- Exploiting Networks: Topic 10Document15 pagesExploiting Networks: Topic 10Siti AishahNo ratings yet

- Chapter 5Document40 pagesChapter 5Rashid Al-MansouriNo ratings yet

- Stability StrategyDocument22 pagesStability StrategySid GargNo ratings yet

- Ethics/Social Responsibility/ SustainabilityDocument21 pagesEthics/Social Responsibility/ SustainabilityNur AmirahNo ratings yet

- Operation ResearchDocument25 pagesOperation Researchmahmoud khaterNo ratings yet

- Assignment 2Document2 pagesAssignment 2Giselle SantosNo ratings yet

- Opertions Research Note From CH I-V RevisedDocument150 pagesOpertions Research Note From CH I-V RevisedISRAELNo ratings yet

- Measuring Performance of Responsibility CentersDocument30 pagesMeasuring Performance of Responsibility CentersRajat SharmaNo ratings yet

- Organizational Structure BreakdownDocument25 pagesOrganizational Structure BreakdownKing HeniNo ratings yet

- Mp482 Product Development and Design (Careeryuga)Document2 pagesMp482 Product Development and Design (Careeryuga)Subahani HaneefaNo ratings yet

- Chapter 1 - Overview of OBDocument31 pagesChapter 1 - Overview of OBPrerna AroraNo ratings yet

- STRATEGIC MANAGEMENT Unit 3Document97 pagesSTRATEGIC MANAGEMENT Unit 3Social MediaNo ratings yet

- TBChap 001Document193 pagesTBChap 001Arizza RiveraNo ratings yet

- QuizDocument55 pagesQuizMuhammad Ben Mahfouz Al-ZubairiNo ratings yet

- Project1 3Document89 pagesProject1 3eyob yohannes100% (1)

- Forecasting: I See That You Will Get An A From This CourseDocument60 pagesForecasting: I See That You Will Get An A From This CourseTalemaNo ratings yet

- Strategic Management Spring 2015 First Asignment Mintzberg and WaltersDocument7 pagesStrategic Management Spring 2015 First Asignment Mintzberg and WaltersIlko KacarskiNo ratings yet

- BUS COM. - Chapter - 1Document48 pagesBUS COM. - Chapter - 1Rubayet HasanNo ratings yet

- Obtaining Technology - PlanningDocument37 pagesObtaining Technology - PlanningputerimatunNo ratings yet

- ForecastDocument48 pagesForecastnoxiousfireNo ratings yet

- StudentDocument16 pagesStudentJayne Carly CabardoNo ratings yet

- Business CommunicationDocument206 pagesBusiness Communicationbq3410No ratings yet

- Module 3-: Marketing Innovation ProductsDocument129 pagesModule 3-: Marketing Innovation ProductsRohan v ChandgadkarNo ratings yet

- Case Study: 3M Rethinking InnovationDocument3 pagesCase Study: 3M Rethinking InnovationIngwang Diwang KatonNo ratings yet

- MGT4001 Entrepreneurship InnovationDocument31 pagesMGT4001 Entrepreneurship Innovations225830100% (1)

- MBA 624 Fall 2015 Project Analysis SyllabusDocument7 pagesMBA 624 Fall 2015 Project Analysis SyllabusChaitanyaVallurupalliNo ratings yet

- Bus 206 Sample Questions Chapters 1-4Document40 pagesBus 206 Sample Questions Chapters 1-4tableroof100% (1)

- CH 05Document50 pagesCH 05haiirinnisaNo ratings yet

- Shree Swami Atmanand Saraswati Institute of Technology: Subject: OR (2171901) Class: 7 Sem. (Mech)Document7 pagesShree Swami Atmanand Saraswati Institute of Technology: Subject: OR (2171901) Class: 7 Sem. (Mech)VIPULNo ratings yet

- Code 1Document7 pagesCode 1Temesgen GashuNo ratings yet

- Lecture Notes Topic 7 Management and LeadershipDocument9 pagesLecture Notes Topic 7 Management and LeadershipS MNo ratings yet

- IKEA Financial Risk in China CaseDocument10 pagesIKEA Financial Risk in China CaseErlinda SusilowatiNo ratings yet

- Concept of Innovation: UNIT-2 (KHU702) InnovationsDocument7 pagesConcept of Innovation: UNIT-2 (KHU702) InnovationsArpitNo ratings yet

- Business Plan ENTREPRENEURSHIPDocument32 pagesBusiness Plan ENTREPRENEURSHIPHitesh JoshiNo ratings yet

- Lecture 1 (Final) - Chapter 1 - Introduction To Quantitative AnalysisDocument24 pagesLecture 1 (Final) - Chapter 1 - Introduction To Quantitative Analysisvivi AnNo ratings yet

- Assignment Supplier Relationship ManagementDocument2 pagesAssignment Supplier Relationship Managementeeit_nizam100% (1)

- Seven Sources of Innovation OpportunityDocument9 pagesSeven Sources of Innovation Opportunitydilip504No ratings yet

- Business Research Methods Unit 1Document26 pagesBusiness Research Methods Unit 1pooja gupta100% (1)

- Chapter No.1 Introduction To Opretional ResearchDocument76 pagesChapter No.1 Introduction To Opretional Researchsuraj mauryaNo ratings yet

- Evolution of Management Theories in 40 CharactersDocument7 pagesEvolution of Management Theories in 40 CharactersSrinath RavindranNo ratings yet

- Risk Management and Derivatives - 2Document43 pagesRisk Management and Derivatives - 2mahesh8169No ratings yet

- SCRIBD - 3M InnovationDocument5 pagesSCRIBD - 3M InnovationsumiannaNo ratings yet

- BA12N Chap004Document148 pagesBA12N Chap004Katherine SalvatoreNo ratings yet

- CH 5 - D. H. HoltDocument36 pagesCH 5 - D. H. Holtdanial001No ratings yet

- Leadership Issues in Globalization: Submitted By: Shivani (082) NameeshaDocument11 pagesLeadership Issues in Globalization: Submitted By: Shivani (082) NameeshaAanchal GuptaNo ratings yet

- Ethical Issues in International BusinessDocument14 pagesEthical Issues in International BusinessAanchal GuptaNo ratings yet

- CUSTOMER EXPECTATIONS OF SERVICEDocument21 pagesCUSTOMER EXPECTATIONS OF SERVICEAanchal Gupta100% (1)

- Electronic Payment SystemDocument20 pagesElectronic Payment SystemAanchal GuptaNo ratings yet

- FD PresentationDocument20 pagesFD PresentationAanchal GuptaNo ratings yet

- Advertising Appeal FinalDocument26 pagesAdvertising Appeal FinalAanchal Gupta0% (1)

- Electronic Payment SystemDocument20 pagesElectronic Payment SystemAanchal GuptaNo ratings yet

- Industrial Relations and Technological ChangeDocument11 pagesIndustrial Relations and Technological ChangeAanchal Gupta94% (18)

- Innovation ModelsDocument32 pagesInnovation ModelsAanchal GuptaNo ratings yet

- Management GuruDocument28 pagesManagement GuruAanchal GuptaNo ratings yet

- Process InnovationDocument29 pagesProcess InnovationAanchal Gupta100% (8)

- Role of Marketing in A Developing EconomyDocument23 pagesRole of Marketing in A Developing EconomyAanchal GuptaNo ratings yet

- Reconciliation of Cost and Financial AccountsDocument1 pageReconciliation of Cost and Financial AccountsAanchal GuptaNo ratings yet

- HazardsDocument1 pageHazardsAanchal GuptaNo ratings yet

- Business ResearchDocument15 pagesBusiness ResearchAanchal GuptaNo ratings yet

- Questionnaire For The Analysis of Employee EngagementDocument1 pageQuestionnaire For The Analysis of Employee EngagementAanchal GuptaNo ratings yet

- Valuation of InventoriesDocument27 pagesValuation of InventoriesAanchal Gupta100% (1)

- Project Employee Training DevelopmentDocument15 pagesProject Employee Training DevelopmentHimanshu KshatriyaNo ratings yet

- Role of Marketing in A Developing EconomyDocument23 pagesRole of Marketing in A Developing EconomyAanchal GuptaNo ratings yet

- Stand Cons T DetailsDocument164 pagesStand Cons T DetailsmirfanjpcgmailcomNo ratings yet

- Comb Manual IM 106 6888QSDocument36 pagesComb Manual IM 106 6888QSsathish2829No ratings yet

- CS As Corporate Saviour - Oil and Gas Industry PDFDocument48 pagesCS As Corporate Saviour - Oil and Gas Industry PDFBalraj JNo ratings yet

- Time Table Spring 2017 18Document10 pagesTime Table Spring 2017 18SuvamNo ratings yet

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteDocument4 pagesAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzNo ratings yet

- Properties of LPGDocument33 pagesProperties of LPGmukund madhav100% (2)

- Maximum Power Tracking System for Solar Panels Using Automatic ControlDocument79 pagesMaximum Power Tracking System for Solar Panels Using Automatic ControlHarish VarmaNo ratings yet

- Control Valve and Steam Line PDFDocument19 pagesControl Valve and Steam Line PDFRofi MuhammadNo ratings yet

- PL-BRICK HP 2850 740 2X6: Product DatasheetDocument4 pagesPL-BRICK HP 2850 740 2X6: Product DatasheetAbhilash ThomasNo ratings yet

- Cutting A GemDocument18 pagesCutting A Gemmobsivac100% (1)

- Sasirekha Computer ProjectDocument90 pagesSasirekha Computer ProjectAkurati RupendraNo ratings yet

- P613 HW # 2 Solutions for a 2D Electron GasDocument4 pagesP613 HW # 2 Solutions for a 2D Electron GasRakeshNo ratings yet

- EASA Part 66 Module 7 MCQ and Essay QuestionsDocument4 pagesEASA Part 66 Module 7 MCQ and Essay QuestionsazadairNo ratings yet

- Ejercicios Propuestos Temas Hasta Primer PrevioDocument2 pagesEjercicios Propuestos Temas Hasta Primer PrevioJuan De DiosNo ratings yet

- Vienna ModernDocument85 pagesVienna ModernZain ZulfiqarNo ratings yet

- NX Training Syllabus Module IDocument5 pagesNX Training Syllabus Module IDharaiya HardikNo ratings yet

- Freezing pipes-FPSDocument2 pagesFreezing pipes-FPSBinu SulochananNo ratings yet

- DWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingDocument1 pageDWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingSumit ChakravartyNo ratings yet

- Installation Tools and Equipment - ACCC Pasadena.Document12 pagesInstallation Tools and Equipment - ACCC Pasadena.EDGARDO DIAZGRANADOSNo ratings yet

- Data Collector 2.03.00Document20 pagesData Collector 2.03.00vyaskingNo ratings yet

- Zw3d2022 Lite Vs Cadbro 2022Document4 pagesZw3d2022 Lite Vs Cadbro 2022Carlos LimaNo ratings yet

- Genesis of Spalling in Tandem Mill Work-RollsDocument9 pagesGenesis of Spalling in Tandem Mill Work-Rolls54321qazNo ratings yet

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Purushothaman.V Head-Technical 9500118390: Kind Attn: Ln. RDocument9 pagesPurushothaman.V Head-Technical 9500118390: Kind Attn: Ln. RsramkmNo ratings yet

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- Calibration of A Pressure GaugeDocument6 pagesCalibration of A Pressure GaugeThapelo100% (2)

- WTS 12 ElectrodynamicsDocument28 pagesWTS 12 ElectrodynamicsTondani100% (1)

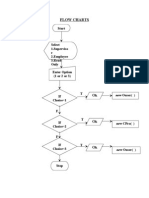

- Flow Charts Option: StartDocument13 pagesFlow Charts Option: StartbalabooksNo ratings yet

- Wind Load CompututationsDocument31 pagesWind Load Compututationskim suarezNo ratings yet

- Mechanical Testing of MaterialsDocument38 pagesMechanical Testing of MaterialsAanand Rishabh DagaNo ratings yet