Professional Documents

Culture Documents

c4 Crack

Uploaded by

Dustin RobertsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

c4 Crack

Uploaded by

Dustin RobertsonCopyright:

Available Formats

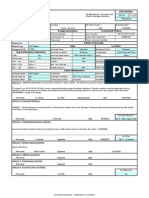

PARAMIT Market

Feedback

23/5/2014

CUST. CUST. PROD. NO. PRM. PROD. NO. COMPLNT RCV DT COMPLAINT

DESCRIPTION

2013/04888 BOSCH 1 607 233 139 900.0258.02C 10-Dec-13 TOOL VIBRATION,

JUST HALF WAVE

SHOWED IN

OSCILLOGRAPH,

DATECODE 25-13

2013/04888 BOSCH 1 607 233 139 900.0258.02C 10-Dec-13 VIBRATION BECOME

NO SOFTSTART,

DATECODE 30-13

2014/01742 BOSCH BSH 1 607 233 139

ASSY

BSH-

900.0258.02@C

21-Apr-14 Vibration

Date code: 07-14

2014/01742 BOSCH BSH 1 607 233 137

ASSY

BSH-

900.0257.02@C

21-Apr-14 Vibration

Date code: 51-13

C4 crack ( found by Bosch)

crack

Latest Feedback

Chronology of Problem

Date 27/3/2013 16/5/2014

Report B7-151a.doc On 10/12/2013 and

21/4/2014

Cause Solder iron touch

capacitor

Countermeasure Solder iron C type

>>F type

Before : C type solder bit

After : flat type solder bit

C type

Flat type

Model : BOSCH 139 PCB ASSY (PORV 39618,39656)

Defect : Micro crack on the chip capacitor- cause by solder iron touch capacitor body

Action : Test run : Change solder iron bit from C type to flat type

No of touch

up IC

Number of

accidental

mark on

capacitor

C Type

Numbe

r of

accide

ntal

mark

on

capacit

or

F type

100 5 0

Previous

complaint

March 2013

COMPLIED

IC short

ICT Test pin

ICT able to check missing or crack component

Not near to affected area

Cause Analysis

Cant detect C4

Can detect C4

10/5/2013 10/12/2013 21/4/2014 Claim

ICT

Solder Iron

C-Type F-Type

17

th

.June 2013

Touch up mark on components

Standard hand soldering spec

All Kaga chip parts but

in the market there are

two types of chip

components

MURATA spec

PARAMIT is using AVX

Study data Temperature Vs Capacitor crack

PWB Temperature Time Remark

1 390 3s OK

2 390 3s OK

3 390 3s crack

4 390 5s OK

5 390 5s OK

6 390 5s OK

7 390 10s OK

8 390 10s OK

9 390 10s OK

When do testing by increase temperature 20C above previous temperature setting

(370C) >390C, one set during 390C/3s having crack problem similar to happen in

customer side

Countermeasure

1) To check with Paramit on specification for part temperature hand soldering spec

2) Temporary use lower temperature ( follow critical part) >>>>>>285~295C

3) Attention sheet at workplace to remind touch up operator of the market claim issue

4) To further study on impact of solder tips temperature change.

as Test study showed that

a) Touch up/soldering of IC is OK even using new temperature 285C.

b) Touch up of RED area is having a problem. >>> TOUCH UP BY TECHNICIAN

OLD Temperature Setting

New Temperature Setting

No Model Job No Qty on line date

1 B139D L95M912 5320 22-May

2 B137D L95B705 800 27-May

3 B139D L95M912 2088 2-Jun

4 B137D L95B705 800 3-Jun

5 B137D L97B706 1634 14-Jul

Total 10642

Cut off lot

Set 1

Set 2

You might also like

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Sov - 1Document1 pageSov - 1biswasdipankar05No ratings yet

- J0263-Ff-El-Dsh-211 Data Sheet For LV Motors (Part Iia)Document7 pagesJ0263-Ff-El-Dsh-211 Data Sheet For LV Motors (Part Iia)jaikolangaraparambilNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- 220 JLD JL10 21051 PDFDocument2 pages220 JLD JL10 21051 PDFFrancisco Antonio Guerrero MonsalvesNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- NCR - SampleDocument7 pagesNCR - SamplecamycaxNo ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- 02 ACSR ZEBRA ConductorDocument37 pages02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- DRG Codes Descr: Sales Order: Item No: Qty: Type: DRG No.: DetailsDocument13 pagesDRG Codes Descr: Sales Order: Item No: Qty: Type: DRG No.: Detailst_syamprasadNo ratings yet

- Micom p139 Over Current RelayDocument4 pagesMicom p139 Over Current Relayanoop_jan139885100% (1)

- 28 LaDocument3 pages28 Lagsinghal121No ratings yet

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Document12 pagesPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNo ratings yet

- MAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER DATA SHEET-Rev.C PDFDocument14 pagesMAGNETIC LEVEL GAUGE WITH LEVEL TRANSMITTER DATA SHEET-Rev.C PDFNguyễnQuíTrọngNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Welding Process Control Sheet: Weld Joint & Process DetailsDocument4 pagesWelding Process Control Sheet: Weld Joint & Process DetailsalokbdasNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- Revise Insp Report - 1 PDFDocument4 pagesRevise Insp Report - 1 PDFShankar RajNo ratings yet

- Cathodic Protection System MMO Grid of Tank Quality Control and Inspection Report FormDocument5 pagesCathodic Protection System MMO Grid of Tank Quality Control and Inspection Report Formjamal2877No ratings yet

- Data Sheet & SLDDocument22 pagesData Sheet & SLDvaithy2011100% (1)

- Unique 4Document23 pagesUnique 4kavitapatil12No ratings yet

- 1510 Side Mounted Level Switch Cat498Document4 pages1510 Side Mounted Level Switch Cat498thotalnNo ratings yet

- Mc7447/Mc7457 Microprocessor Mos-13 Hip7Soi Qualification ReportDocument9 pagesMc7447/Mc7457 Microprocessor Mos-13 Hip7Soi Qualification ReportStrawichDanielNo ratings yet

- Volume3A MechDocument321 pagesVolume3A MechAdeel JamilNo ratings yet

- BB.G VSP Pve Ed 20 Me Das 004 - 0Document9 pagesBB.G VSP Pve Ed 20 Me Das 004 - 0Luong AnhNo ratings yet

- AirspeedDocument9 pagesAirspeednabawi24No ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- LV-110120-110220 35-35112 3in ANSI 300Document12 pagesLV-110120-110220 35-35112 3in ANSI 300mggz_15No ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- EQT ChecklistDocument5 pagesEQT Checklistvijayachidu100% (1)

- 9952T 1311 F0001 PD2 A CDocument169 pages9952T 1311 F0001 PD2 A CBarbara HowellNo ratings yet

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- Welding Inspector Interview QuestionsDocument5 pagesWelding Inspector Interview QuestionsValli Raju91% (23)

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Document6 pagesZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarNo ratings yet

- CBT Questions: (2) Peel TestDocument18 pagesCBT Questions: (2) Peel TestMOHAMEDNo ratings yet

- LGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetDocument37 pagesLGDD ZZ ITTDSXS 00 45671233 0 Instrument DatasheetuyaiekanemNo ratings yet

- Welding Manual Nov 2010Document187 pagesWelding Manual Nov 2010Sumit Chaurasia100% (4)

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- HT Motor DatasheetDocument62 pagesHT Motor DatasheetShantanu Dutta100% (2)

- 00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Document11 pages00-GRC-EDA-100038-33 (Technical Submittal For Instruments) Rev02Alaa RamadanNo ratings yet

- HD Valvulas de ControlDocument5 pagesHD Valvulas de ControlIsmaelCruzNo ratings yet

- SPC-0804.02-99.90 Rev D3 BEDDDocument23 pagesSPC-0804.02-99.90 Rev D3 BEDDTimothy LeonardNo ratings yet

- Tank DatasheetDocument4 pagesTank DatasheetAlvin Smith60% (5)

- Welding Procedure Specification SampleDocument5 pagesWelding Procedure Specification SampleAdiNo ratings yet

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocument10 pagesA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaNo ratings yet

- Field Inspection Dg345Document9 pagesField Inspection Dg345zat572000No ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- 00DF1BA3Document25 pages00DF1BA3Tecnico ID LedNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961100% (1)

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- Check List PipeDocument18 pagesCheck List PipeGeorge MadisonNo ratings yet