Professional Documents

Culture Documents

Hydraulic Brakes

Uploaded by

prateekg92Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Brakes

Uploaded by

prateekg92Copyright:

Available Formats

SAE Road Show II

Mini Baja

BRAKE SYSTEMS 101

Energy Conversion Management

Presented by Paul S. Gritt

BRAKE SYSTEMS 101

3

Topics To Be Presented

The Basic Concepts

Hydraulic layouts

Component functions

Brake Balance

Stopping Distance and Fade

Formula SAE vs. Mini Baja

Lessons Learned

The Rules

Questions

BRAKE SYSTEMS 101

4

The Basic Concepts

Kinetic energy = heat

F = ma

Newton is always right!

Do the calculations first

When all else fails see rule 3.

BRAKE SYSTEMS 101

5

Energy Conversion

The brake system converts the kinetic

energy of vehicle motion into heat

BRAKE SYSTEMS 101

6

Energy Conversion

A vehicle weighing 290 kg. (639 lbs.)

At 90 kph (55.9 mph) has kinetic energy of:

Stopping the vehicle at .9G takes 2.9 Seconds

This is equal to 31 kilowatts (42 HP).

OR 90,770 N-M.

BRAKE SYSTEMS 101

7

Kinetic Energy as a Function of Speed and Mass

0

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

30 60 90 120

Speed kph

E

n

e

r

g

y

N

-

M

200 kg

250 kg

290 kg

BRAKE SYSTEMS 101

8

F = ma

The Key Question!

How do you calculate F?

BRAKE SYSTEMS 101

9

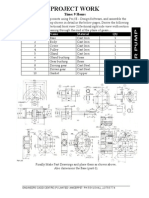

Basic System Model

Brake Force

BRAKE SYSTEMS 101

10

Hydraulic System Configurations

There are two layouts of hydraulic brake systems used

in cars and light trucks.

Front/Rear hydraulic split:

Also called axle by axle, vertical, and some times black

and white.

Diagonal Split:

Also called criss-cross.

The type of split is only significant in the

event of a hydraulic system failure.

BRAKE SYSTEMS 101

11

Front/rear Hydraulic Split

Front Axle

Rear Axle

Primary System

Secondary System

BRAKE SYSTEMS 101

12

Diagonal Split System

In a diagonal split system, one brake line is run to

each rear brake and one to each front brake.

The connections are such that the left front and

the right rear brake are on one circuit and the right

front and left rear are on the other circuit

BRAKE SYSTEMS 101

13

Typical Diagonal Split System

Right front

left rear

Left front

right rear

BRAKE SYSTEMS 101

14

Brake Component Function

BRAKE SYSTEMS 101

15

Four Sub-systems

Actuation sub-system

Foundation sub-system

Parking brake sub-system

ABS & ESP (electronic stability

program) sub-system

BRAKE SYSTEMS 101

16

Actuation Sub-system

Brake Pedal

Master Cylinder

Proportioning Valves

Brake Lines

16

BRAKE SYSTEMS 101

17

The Brake Pedal

Driver Input

Output to master cylinder

100 N and 144 mm

400 N and 36 mm

4:1 Nominal

Pedal Ratio

BRAKE SYSTEMS 101

18

Master Cylinders

Output Pressure

Input Force

A master cylinder is just a simple piston

inside a cylinder

BRAKE SYSTEMS 101

19

M/C Unapplied

BRAKE SYSTEMS 101

20

M/C Applied

BRAKE SYSTEMS 101

21

Primary System Failure

Operated

Mechanically

Bottoms Against

Secondary Piston

Pressure for

Normal

Secondary

System

Function

BRAKE SYSTEMS 101

22

Secondary System Failure

Bottoms at End of Cylinder Bore

Pressure for Normal Primary System Function

BRAKE SYSTEMS 101

23

Proportioning Valves

TYPICALPROPVALVEPERFORMANCECURVE

02004006008001,000

0

200

400

600

800

FrontBrakePressure

R

e

a

r

B

r

a

k

e

P

r

e

s

s

u

r

e

Split Point

Slope

Hard Stops

Reduce the pressure to

the rear brakes

Diagonal systems

require two

Split and slope are

changed to create

proper balance

BRAKE SYSTEMS 101

24

Adjustable Proportioning valves

Wilwood Tilton

Only the split points are adjustable

BRAKE SYSTEMS 101

25

Brake Lines

Double wall steel tubing (Bundy Tubing) is industry

standard.

3/16 o.d. is standard size.

Very robust, can take a lot of abuse

Use SAE 45 inverted flare (J533 and J512) joints

if you can.

BRAKE SYSTEMS 101

26

Foundation Brake Sub-system

Disc Brakes

Linings

BRAKE SYSTEMS 101

27

Front Disc Brake

BRAKE SYSTEMS 101

28

Front Disc Brake

BRAKE SYSTEMS 101

29

Brake Linings

Brake linings are probably the most mis-understood part

of a brake system.

The output of any brake is directly related to the

coefficient of friction () between the lining and the disc

or drum.

The challenge is knowing what the instantaneous value

of is during any given stop.

Any design calculations you do, go right out the window

if the lining you use does not have the value you

assumed.

BRAKE SYSTEMS 101

30

Brake Linings

Remember the equation for a disc brake

The best method for determining the actual value of for

a given lining is from a dynamometer test.

BRAKE SYSTEMS 101

31

Brake Balance

BRAKE SYSTEMS 101

32

Both Front Wheels Locked:

Not good if you are on a curved road

You cant steer

OK, if you must hit something

The vehicle goes straight

BRAKE SYSTEMS 101

33

Both Rear Wheels Locked:

The front wheels track straight ahead

Then the rear wheels deviate to the side

Until the vehicle cant track straight any

longer and the rear starts to spin around the

front

BRAKE SYSTEMS 101

34

vs. % Wheel Slip

0 10 20 30 40 50 60 70 80 90 100

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

% Wheel Slip

M

u

(

D

e

c

e

l

e

r

a

t

i

o

n

)

Typical Dry Surface

Steering

Braking

BRAKE SYSTEMS 101

35

Front Lock

If there is more front brake torque than dynamic front weight

The front wheels will lock up before the rears

20%

80%

40%

60%

Brake torque

distribution

Dynamic weight

distribution

BRAKE SYSTEMS 101

36

Rear Lock

If there is more rear brake torque than dynamic rear weight;

The rear wheels will lock up before the fronts

40%

60%

20%

80%

Brake torque

distribution

Dynamic weight

distribution

BRAKE SYSTEMS 101

37

Optimum Braking

Optimum braking is achieved when brake torque

distribution matches dynamic weight distribution

Weight Distribution

No Braking

Hard Braking

40%

60%

20%

80%

BRAKE SYSTEMS 101

38

Calculating Dynamic Weight Transfer

BRAKE SYSTEMS 101

39

Ideal Vs Actual Torque

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

Front Torque

R

e

a

r

T

o

r

q

u

e

Ideal

60/40 Actual

70/30 Actual

With a prop valve

BRAKE SYSTEMS 101

40

Stopping Distance

Does not Depend on:

Type of brakes

Size of brakes

Does Depend on:

Tire to road friction

Vehicle balance

Skill of driver

System Reaction Time

BRAKE SYSTEMS 101

41

vs. % Wheel Slip

0 10 20 30 40 50 60 70 80 90 100

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

% Wheel Slip

M

u

(

D

e

c

e

l

e

r

a

t

i

o

n

)

Typical Dry Surface

Braking

BRAKE SYSTEMS 101

42

Brake Fade

Brake fade is the loss of performance resulting

from the lining friction decreasing as the lining

and rotor or drum rises in temperature

BRAKE SYSTEMS 101

43

Formula SAE

vs.

Mini Baja

The brake system design must

match the vehicle objectives

BRAKE SYSTEMS 101

44

Formula SAE

Absolute reliability

High Speeds

Maximum possible decel without locking

Consistent balance with changing temperatures

Mini Baja

Absolute reliability

Low Speeds

Very hostile environment

Brake must work when wet and muddy

BRAKE SYSTEMS 101

45

Mini Baja, Hostile Environment

Will your master cylinder fill up with water?

How does you brake lining work when it is wet?

BRAKE SYSTEMS 101

46

Lessons Learned

BRAKE SYSTEMS 101

47

Dont Do Something Because:

The other guys do it.

All the race cars have it.

It looks really cool

BRAKE SYSTEMS 101

48

Design to a Specific Objective:

Do the math first

Verify your assumptions

Take the easy solution (KISS)

BRAKE SYSTEMS 101

49

Lessons Learned

Lesson Number 1 - Keep it SIMPLE

BRAKE SYSTEMS 101

50

Lessons Learned

Lesson Number 2 - Keep it light; but not too light.

90% of the braking energy goes into the rotor

If the rotor is too light it gets very hot

If the temperatures get too high very nasty things

can happen.

BRAKE SYSTEMS 101

51

Too light

2006 DCAE program involved a Hemi powered

Grand Cherokee.

One team used much smaller rear brakes and rotors

to save a few pounds on a 3200 lb vehicle with 500

hp.

The vehicle went off the end of the main straight at

over 100 mph on the third lap because of brake

failure.

BRAKE SYSTEMS 101

52

BRAKE SYSTEMS 101

53

BRAKE SYSTEMS 101

54

Lessons Learned

Lesson Number 3 - Packaging and Integration drive

90% of design

Lesson Number 4 - Read the rules

Lesson Number 5 - Allow enough time for

details and testing

BRAKE SYSTEMS 101

55

Brake rules

- The car must have four wheel brakes operated by a single

control.

- It must have two independent hydraulic circuits with independent fluid

reserves.

- The brake system must be capable of locking all four (4)

wheels, and stopping the vehicle in a straight line

The braking systems must be protected with scatter shields from

failure of the drive train (FSAE only)

- A brake pedal over-travel switch must be installed. This switch must

kill the ignition and cut the power to any electrical fuel pumps. (FSAE

only)

- The car must be equipped with a red brake light that illuminates when

ever the brakes are applied

BRAKE SYSTEMS 101

56

Any Questions

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- WELDING - InspectionDocument15 pagesWELDING - Inspectionprateekg92No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Weld SymbolsDocument37 pagesWeld Symbolsprateekg92No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- ONGC Mechanical QuestionDocument27 pagesONGC Mechanical QuestionNavlesh SharmaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- ONGC Reasoning QuestionsDocument6 pagesONGC Reasoning Questionsprateekg92No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Vedic AstrologyDocument2 pagesVedic AstrologySuryasukra100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 5S LearningDocument30 pages5S Learningprateekg92No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GD&T Reference ChartDocument1 pageGD&T Reference ChartChinna ThiruNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Install WF5 1Document11 pagesInstall WF5 1fernandojNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Understanding Springs, Shocks and Suspension Motion RatiosDocument8 pagesUnderstanding Springs, Shocks and Suspension Motion Ratiosprateekg92No ratings yet

- ONGC Reasoning QuestionsDocument6 pagesONGC Reasoning Questionsprateekg92No ratings yet

- Mech Eng Handbook ONGCDocument220 pagesMech Eng Handbook ONGCMadhusudan BarotNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Title Block Tutorial in CATIA V5Document2 pagesTitle Block Tutorial in CATIA V5prateekg92No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CATIA V5 - Mold Tooling Design CourseDocument2 pagesCATIA V5 - Mold Tooling Design Courseprateekg92No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Challan Form Gen/OBCDocument1 pageChallan Form Gen/OBCprateekg92No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Equivalent Analysis of Honecomb PanelsDocument5 pagesEquivalent Analysis of Honecomb Panelsprateekg92No ratings yet

- Maruti Swift Crash Test ResultDocument1 pageMaruti Swift Crash Test ResultRushLaneNo ratings yet

- Modal Analysis of Honeycomb Structure With Variation of Cell SizeDocument3 pagesModal Analysis of Honeycomb Structure With Variation of Cell Sizeprateekg92No ratings yet

- MHRD Internship AnnexureDocument3 pagesMHRD Internship Annexureprateekg92No ratings yet

- Anola Seed Removing MachineDocument10 pagesAnola Seed Removing Machineprateekg92No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gandhi Naked AmbitionDocument2 pagesGandhi Naked AmbitionShailendra Pratap Singh100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- OpenGL Programs For Various Geometric TransformationsDocument11 pagesOpenGL Programs For Various Geometric Transformationsprateekg92No ratings yet

- Civil Services Examination 2014 PDFDocument30 pagesCivil Services Examination 2014 PDFjairaj321No ratings yet

- Detailed Solution of GATE 2013 ME PaperDocument78 pagesDetailed Solution of GATE 2013 ME Paperprateekg92100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Pune University 2008 Civil Engineering Exam ResultsDocument182 pagesPune University 2008 Civil Engineering Exam Resultsprateekg92No ratings yet

- Off-Road TiresDocument8 pagesOff-Road Tiresprateekg92No ratings yet

- Workshop On Mvat Circular Enrolment - 2012-13Document2 pagesWorkshop On Mvat Circular Enrolment - 2012-13prateekg92No ratings yet

- Mechanical Project - Gear PumpDocument6 pagesMechanical Project - Gear Pumpprateekg92No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- TRUCK TIRE TYPES AND ROAD CONTACT PRESSURES - Yap PDFDocument20 pagesTRUCK TIRE TYPES AND ROAD CONTACT PRESSURES - Yap PDFebastien2No ratings yet

- Dometic RM 7390Document30 pagesDometic RM 7390Zoran Prokic100% (1)

- Manual - Aztec THDDocument112 pagesManual - Aztec THDCesar Augusto100% (1)

- NAV MB7 840 ExamsDocument7 pagesNAV MB7 840 ExamsRahul DhandNo ratings yet

- Hydrotesting Quad Joint PipesDocument15 pagesHydrotesting Quad Joint PipesTrust EmmaNo ratings yet

- Hydraulic Lab 1Document12 pagesHydraulic Lab 1Afiq HamidiNo ratings yet

- Airaya AI108-4958-On Wireless Bridge ReviewDocument7 pagesAiraya AI108-4958-On Wireless Bridge ReviewSynworks Development GroupNo ratings yet

- Mobile IPv6 SeminarDocument34 pagesMobile IPv6 SeminarTinsu M Babu100% (1)

- Grove-GMK7550 Product GuideDocument56 pagesGrove-GMK7550 Product GuideabguyNo ratings yet

- Thrush S2R R-1340 Maintenence ManualDocument227 pagesThrush S2R R-1340 Maintenence Manualarizonaflyer1_732976100% (1)

- The Water Supply Regulations 2009Document22 pagesThe Water Supply Regulations 2009triggs1971No ratings yet

- New IEC 61850-Based Solutions: Client Functionality On All Device FamiliesDocument8 pagesNew IEC 61850-Based Solutions: Client Functionality On All Device FamiliesHung Cuong PhamNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Acceptance SamplingDocument35 pagesAcceptance SamplingParas ThakurNo ratings yet

- en Operating Instructions VEGABAR 28 Two Wire 4 20 MADocument56 pagesen Operating Instructions VEGABAR 28 Two Wire 4 20 MAVegard SømliøyNo ratings yet

- LIS Communication Setting InstructionDocument15 pagesLIS Communication Setting InstructionDiệt ThầnNo ratings yet

- Determination of Water-Cement Ratio of HardenedDocument6 pagesDetermination of Water-Cement Ratio of HardenedMárcio AlvesNo ratings yet

- Construction Manager Resume: 20+ Years ExperienceDocument5 pagesConstruction Manager Resume: 20+ Years ExperienceRavi YadavNo ratings yet

- Industrial Series BrochureDocument16 pagesIndustrial Series BrochureLitarmjNo ratings yet

- Excavations QuizDocument12 pagesExcavations QuizMax McguireNo ratings yet

- LTE Handover OptimizationDocument33 pagesLTE Handover Optimizationthang_1986dh100% (2)

- Data Assest Management System (DAMS)Document32 pagesData Assest Management System (DAMS)Greg WiedemanNo ratings yet

- Questionnaire PMDocument97 pagesQuestionnaire PMapi-3781101100% (7)

- JVC KD-SD631 Manuel D'utilisationDocument42 pagesJVC KD-SD631 Manuel D'utilisationteuiragNo ratings yet

- Bugs 6 EjerciciosDocument33 pagesBugs 6 EjerciciosmoncaciNo ratings yet

- PCRFDocument9 pagesPCRFDebasish RautNo ratings yet

- Is 650Document11 pagesIs 650Sougata DasNo ratings yet

- BA121576-121579 NPK09-en006 0314Document24 pagesBA121576-121579 NPK09-en006 0314Yew LimNo ratings yet

- Connection Examples g1501sDocument15 pagesConnection Examples g1501sandy131078No ratings yet

- Remedy API call log analysisDocument2 pagesRemedy API call log analysisLuis A. VarelaNo ratings yet

- IqaDocument3 pagesIqaPamela ColemanNo ratings yet

- Catalogo Técnico KaiserDocument2 pagesCatalogo Técnico KaiserEmerson GrandaNo ratings yet