Professional Documents

Culture Documents

Mat Piping Components

Uploaded by

Noor9911Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mat Piping Components

Uploaded by

Noor9911Copyright:

Available Formats

Piping

Components

Presented by Kundan Kumar (Piping Speciality)

An Overview Of

The term piping refers to the overall network of

various components used to measure, control,

condition, and convey fluids.

Piping components:

Pipe

Fittings

Flanges

Valves

Gaskets

Fasteners

Special Components

Piping Components

Piping Components

Codes and Standards

CODES

DESCRIPTION ASME SPEC NUMBER

Code for Power Piping. ASME B31.1

Process Piping ASME B31.3

Code for Liquid Transportation Systems ASME B31.4

Code for Gas Transmission and Distribution Systems ASME B31.8

Piping Components

Codes and Standards

STANDARDS

DESCRIPTION ASME SPEC NUMBER

Welded and seamless wrought Steel pipes. ASME B36.10M

Welded and seamless wrought Stainless Steel pipes. ASME B36.19M

Pipe Flanges and Flanged Fittings ASME B16.5

Factory made Wrought Steel Butt-Welding Fittings. ASME B16.9

Face-to-Face and End-to-End Dimensions of Valves ASME B16.10

Forged Steel Fittings, Socket Welding and Threaded. ASME B16.11

Metallic Gaskets for Pipe Flanges Ring-Joint, Spiral-Wound, and Jacketed ASME B16.20

Non-Metallic Flat Gaskets for Pipe Flanges ASME B16.21

Buttwelding Ends ASME B16.25

Valves Flanged, Threaded and Welding End ASME B16.34

Orifice Flanges. ASME B16.36

Large Diameter Steel Flanges ASME B16.47

Steel Line Blanks ASME B16.48

Square and Hex. Bolts and Screws (Inch Series). ASME B18.2.1

Square and Hex. Nuts (Inch Series). ASME B18.2.2

Piping Components

Concept of Schedule in Piping Components.

Schedule denotes the required Wall

thickness for any given Pipe, Fitting and

Flange. Please ref Table-I for Standard

Schedule.

Piping Components

Piping Components

Pipe

Elbows

Tees (Equal and Red.)

Lateral (Equal and Red.)

End Caps

Reducers

Stub end

Couplings

Flanges

Olet fittings

Nipple

Plugs

Swage nipples

Spectacle blinds and

spacers

Studs

Gaskets

Valves

Piping Specials

List Of Piping Components

Piping Components

Pipes

Closed annular circular cross sectional conduit used to convey fluid

is known as pipe.

The size of all pipe is identified by the nominal pipe size (NPS)

the outside diameters of tubes are numerically identical to the size

number for all sizes

Up to and including size 12 inch the outside diameter is more than the

size designator.

Outside diameter of NPS 14 and larger pipe is the same as the size

designator in inches

Prevalent Piping Specifications

Piping Components

Piping Components

Fittings Nipples

Basically these are straight pipe lengths cut in fixed lengths as specified

By purchaser (75mm, 100mm, 200mm Long) with different end connections

End Connections are:-

Plain Both Ends (PBE)

Both Threaded Ends (BTE)

One end Plain other end

Threaded (POExTOE)

Piping Components

Fittings - 90 Deg Elbow

Enables the pipe run to be turned through a Right Angle Radius of

1.5 times nominal pipe size.

Butt Welded Socket Welded Threaded

Piping Components

Fittings - 45 Deg Elbow

Enables the pipe run to be turned through 45 Deg, Radius of 1.5

times nominal pipe size.

Butt Welded Socket Welded Threaded

Piping Components

Fittings - Caps

Used to blank off at the END of Pipe Work.

Butt Welded Socket Welded Threaded

Piping Components

Fittings Concentric Reducer and Swage Nipple

Used to Connect Pipes with two different diameters. No change in

line Elevation.

Butt Welded

Reducer

Swage Nipple Threaded Swage

Nipple

Piping Components

Fittings Eccentric Reducer and Swage Nipple

Used to Connect Pipes with two different diameters. Has one side

straight allowing the pipe run to stay flat changing the elevation and

is preferred for some specific cases.

Butt Welded

Reducer

Swage Nipple Threaded Swage

Nipple

Piping Components

Fittings Stub End

Stub Ends are welded to Pipe with a CS backing Flange. Mainly used

for Cost Reduction.

Stub End

Piping Components

Fittings Full Coupling

It is used to connect two components which have plain or threaded

end connection. It is used as an inline fitting.

Socket welded

Threaded

Piping Components

Branch Fittings - Equal TEE

Allows connection of a branch at Right Angles from Main Pipe

Header. Branch size has same dimensions as Main Pipe Header.

Butt Welded Socket Welded Threaded

Piping Components

Branch Fittings - Reducing TEE

Allows connection of a branch at Right Angles from Main Pipe

Header. Branch size has same dimensions as Main Pipe Header.

Butt Welded Socket Welded Threaded

Piping Components

Branch Fittings Half Coupling

Allows to take a reducing branch connection from a Main Pipe

Header. The Connection of a branch is at Right Angles from Main

Pipe Header

Socket Welded Threaded

Piping Components

Branch Fittings Olets

Allows to take a self reinforced reducing branch connection from a

Main Header.

Various types of Olets available are listed below:-

SOCKOLET

WELDOLET

ENDDOLET

ELBOLET

THREADOLET

LATROLET

NIPPOLET

Piping Components

Branch Fittings Sockolet

Allows to take a self reinforced reducing branch

connection from a Main Header, the branch connection

will be of Socket welded type

Piping Components

Branch Fittings Weldolet

Allows to take a self reinforced reducing branch

connection from a Main Header, the branch connection

will be of Butt welded type

Piping Components

Branch Fittings Elbolet

Allows to take a self reinforced reducing branch

connection from a Elbow of Main Header, the branch connection

Can be Butt or Socket welded Or Threaded type.

Socket Welded Threaded Butt Welded

Piping Components

Branch Fittings Threadolet

Allows to take a self reinforced reducing branch

connection from a Main Header, the branch connection

will be of Threaded type

Piping Components

Branch Fittings Latrolet

Allows to take a self reinforced reducing branch

connection from a Main Header at a 45 deg angle, the branch connection

Can be Butt or Socket welded Or Threaded type.

Socket Welded Threaded Butt Welded

Piping Components

Flange

Flange J oints are used where joints need to be detached frequently

due to maintenance or any other means. Flange joints are to be used

always in pairs and are hold together by Bolts with proper Gaskets

installed between the two flange facing. Various types of flange are

being used in engineering.

Types of Flange used in Engineering:-

Weld neck Flanges

Socket Weld Flanges

Lap J oint Flanges

Ring J oint Flanges

Tongue and Groove J oint Flanges

Slip-On Flanges

Threaded Flanges

Blind Flanges

Piping Components

Flanges Weld Neck

Weld neck Flanges are drilled (machined) with the wall

thickness of the flange having the same dimensions of

the matching pipe. The lighter the pipe is, the larger the

bore, conversely, the heavier the pipe, the smaller the

bore. They are normally used for high-pressure, cold or

hot temperature. The Welding End of the flange is

j o i n ed t o t h e p i p i n g b y B u t t wel d i n g .

Piping Components

Flanges Slip-On

A Slip-on Flange is bored slightly larger than the outer Diameter of

the matching pipe. The pipe slips into the flange prior to welding,

Welding is done from both inside and outside to prevent leaks.

Piping Components

Flanges Socket Weld

This flange is similar to slip-on flange, except the bore and a

counter bore. The counter bore is slightly larger than the Outer

Diameter of the matching pipe, allowing the pipe to be inserted. A

restriction is built into the bottom of the bore, which acts as a

shoulder for the pipe to rest on, and has the same ID of matching

pipe. The flow is not restricted in any direction. The Welding End

of the flange is joined to the piping by Socket welding.

Piping Components

Flanges Lap J oint

Lap J oint Flanges are similar to slip-on flanges, the difference is it

has a curved radius at the bore and face to accommodate a lap

joint stub end. The lap joint flange and stub end assembly are

normally used for cost reduction.

Piping Components

Flanges Threaded

This flange is similar to Socket weld flange, except the bore is

threaded (Female threaded). Component joining this flange should

have a male thread for installation.

Piping Components

Flanges Blind

This is used to Close the End of a Flanged Piping or Nozzle

Piping Components

Flange Ring Type

This type of flanges will have a groove on both the matching

surface in which a ring gasket will be used for sealing. These

Flanges are normally used in High Pressure systems.

Piping Components

Flange Tongue and Groove Type

This type of flanges will have a groove on one flange surface and

on the Other flange it will have a projection on the surface to

match the groove and a proper Seal shall be installed for Bolting.

These Flanges are normally used in High Pressure systems.

Piping Components

Flanges Orifice

This is similar to the Weld Neck Flange with additional tapings on

the Flange thickness. These tapings are used for Instrument

connections. The number of taps (2 at 180 deg apart OR 4 at 90

deg apart) needs to be specified by purchaser depending on the

process requirement.

Piping Components

Spectacle Blind

This is also know as FIG 8. These are used for Positive Isolation.

For Larger size depending on pressure Rating the spectacle

blinds are made in to two different components SPACER and

BLIND.

FIG 8

BLIND

SPACER

Piping Components

Typical J oints Used for inter connecting piping

components

Bell And Spigot J oint

Butt Welded J oint Socket Welded J oint

Threaded J oint Flanged J oint

SAMSUNG ENGINEERING INDIA P LTD.

An Overview of Piping Material Specification

Valves:

Type Purpose

Gate On / Off

Globe Throttle / Regulation

Check Restrict flow in one

direction

Butterfly On / Off / Regulation

Ball On / Off

Standard Gate Valve Part List: API

600

SAMSUNG ENGINEERING INDIA P LTD.

An Overview of Piping Material Specification

SAMSUNG ENGINEERING INDIA P LTD.

An Overview of Piping Material Specification

Valve Trim Material, Temperature Limits (Fahrenheit, Only for guidance)

SAMSUNG ENGINEERING INDIA P LTD.

An Overview of Piping Material Specification

Trim Material Characteristics (Only for guidance)

Gate Valve Ball Valve

SAMSUNG ENGINEERING INDIA P LTD.

An Overview of Piping Material Specification

Butterfly Valve

Swing Check

Valve

Dual Plate

Check Valve

Piping Specials

These are used to accomplish specialized functions in piping systems:

Item Purpose

Strainers to control solid particle size in the media

Steam Traps to remove condensate from steam lines

Air Traps to remove moisture from air lines

Flame Arrestors to prevent propagation of fire into equipments

Sight Glasses to provide visibility to flow

Vent Silencers to reduce noise level

Hoses to provide flexible connections in piping system

Sample Coolers to facilitate sample collection

Valve Interlocks to ensure operating sequence of valve systems

Piping Components

Piping Components

Flame Arrestor Sight Glass Sample Cooler

Piping Components

Thermodynamic Ball Float Bimetallic Inverted

Bucket

some of the common types of steam traps

Piping Components

You might also like

- PipeDocument47 pagesPipemohanNo ratings yet

- Fittings TrainingDocument61 pagesFittings TrainingsbmmlaNo ratings yet

- Piping ComponentsDocument39 pagesPiping Componentsbvenky991100% (1)

- Fundamentals of Piping Design & MaterialDocument57 pagesFundamentals of Piping Design & MaterialGunturMudaAliAkbarNo ratings yet

- Piping Fittings: Elbows or EllsDocument17 pagesPiping Fittings: Elbows or Ellsleading_aliNo ratings yet

- Piping PresentationDocument144 pagesPiping PresentationSUNIL TVNo ratings yet

- Piping Presentation L & TDocument61 pagesPiping Presentation L & TBukti SiahaanNo ratings yet

- Piping & Piping ComponentsDocument37 pagesPiping & Piping ComponentsRavindra S. JivaniNo ratings yet

- Basics of Pipe For Oil & Gas EngineerDocument12 pagesBasics of Pipe For Oil & Gas EngineerMannuddin KhanNo ratings yet

- Piping Presentation MasterDocument61 pagesPiping Presentation MasterQC NGUYEN100% (2)

- Piping Engineering Course OverviewDocument2 pagesPiping Engineering Course Overviewmayur_lanjewar0% (1)

- Implementation of Expansion LoopsDocument13 pagesImplementation of Expansion LoopsSSSNo ratings yet

- Codes Pipe LeDocument197 pagesCodes Pipe Levermaakash22No ratings yet

- PIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesDocument21 pagesPIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesAdil KhawajaNo ratings yet

- Pipe Fittings PDFDocument164 pagesPipe Fittings PDFjlvega18No ratings yet

- Expansion Loop DesignDocument61 pagesExpansion Loop DesignTauqueerAhmadNo ratings yet

- PTI Piping Training Day 1 Rev.0Document84 pagesPTI Piping Training Day 1 Rev.0Karl Caudal100% (1)

- Piping Engineering Certification CourseDocument22 pagesPiping Engineering Certification Courseshiraz ahmedNo ratings yet

- Basics of Piping Scribd PDFDocument60 pagesBasics of Piping Scribd PDFmohamed sheerazNo ratings yet

- 1722 Piping Drafting Instruc GuideDocument26 pages1722 Piping Drafting Instruc GuideRizwan Ashraf100% (2)

- Piping Interview QuestionnaireDocument9 pagesPiping Interview QuestionnaireRakesh RanjanNo ratings yet

- Piping QA Quiz Answers for Fluor Daniel ProjectsDocument13 pagesPiping QA Quiz Answers for Fluor Daniel Projectssairam2234100% (1)

- Basic PipingDocument80 pagesBasic PipingarunkumarNo ratings yet

- PipingDocument11 pagesPipingAshley JacksonNo ratings yet

- Oil & Gas Piping Fundamentals Knowledge PlatformDocument153 pagesOil & Gas Piping Fundamentals Knowledge PlatformKalaiYarasanNo ratings yet

- Typical Questions For Piping EngineerDocument6 pagesTypical Questions For Piping EngineerVenkataratnam Gollapalli100% (1)

- Piping 5.0 - Introduction to Piping EngineeringDocument32 pagesPiping 5.0 - Introduction to Piping EngineeringSteve WanNo ratings yet

- Pipe Fitting Symbols ChartDocument0 pagesPipe Fitting Symbols ChartMPCReaderNo ratings yet

- PIPING SYSTEM R1 (13-07-2010) Part-1 PDFDocument78 pagesPIPING SYSTEM R1 (13-07-2010) Part-1 PDFyogNo ratings yet

- Buttweld Fittings Accesorios SoldadosDocument5 pagesButtweld Fittings Accesorios SoldadosJuan CadenaNo ratings yet

- Piping Codes & Standards - Piping GuideDocument8 pagesPiping Codes & Standards - Piping Guideabhilibra14No ratings yet

- Piping IsometricsDocument18 pagesPiping Isometricsharold_bhieNo ratings yet

- Piping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDocument5 pagesPiping Material Take Off-MTO, BOM, BOQ & MTO Stages (With PDFDhiren PatelNo ratings yet

- Piping NotesDocument33 pagesPiping NotesSyed FarhanNo ratings yet

- 5.piping SeminarDocument85 pages5.piping Seminarvg100% (2)

- Piping GuideDocument13 pagesPiping GuidemuraliNo ratings yet

- 1Document156 pages1Abhijeet DarvekarNo ratings yet

- PIPING INSPECTION GUIDEDocument17 pagesPIPING INSPECTION GUIDEravindra_jivaniNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Piping Design (Revised)Document22 pagesPiping Design (Revised)Yash PatelNo ratings yet

- Distillation Column Nozzle Location Guidelines PDFDocument21 pagesDistillation Column Nozzle Location Guidelines PDFShyam MurugesanNo ratings yet

- 4) Piping Interview QuestionnaireDocument2 pages4) Piping Interview QuestionnaireAjaz Malik33% (3)

- C1 The Basic of Plant Layout Design - Process Plant Layout and Piping DesignDocument81 pagesC1 The Basic of Plant Layout Design - Process Plant Layout and Piping Designdung100% (1)

- Standards in The Valve IndustryDocument2 pagesStandards in The Valve IndustryessnelsonNo ratings yet

- Piping Interview Questions and Answers - Part 01 - Engineering, Competitive Exams and Jobs PDFDocument9 pagesPiping Interview Questions and Answers - Part 01 - Engineering, Competitive Exams and Jobs PDFAnonymous PMSDqHNo ratings yet

- P&ID drawing symbology guideDocument36 pagesP&ID drawing symbology guideSterling GordianNo ratings yet

- Material Selection and SpecificationDocument50 pagesMaterial Selection and SpecificationbashirNo ratings yet

- Mat Piping ComponentsDocument49 pagesMat Piping Componentsnsr2tNo ratings yet

- Piping Presentation L & TDocument61 pagesPiping Presentation L & TJitendra SurveNo ratings yet

- Pipe FlangesDocument7 pagesPipe FlangesAli SafdarNo ratings yet

- Piping Presentation L & TDocument61 pagesPiping Presentation L & TDidi MercadoNo ratings yet

- Flat Face Vs Raised FaceDocument6 pagesFlat Face Vs Raised Facedidlakiran100% (4)

- Olet - Complete GuideDocument8 pagesOlet - Complete GuideSanjeev KumarNo ratings yet

- Everything about Pipe FittingsDocument11 pagesEverything about Pipe FittingsFaysal Qadeer KhanNo ratings yet

- Pipe ComponentDocument28 pagesPipe Componentarifinzaky27No ratings yet

- PRESENTATION Flanges Andd CouplingsDocument39 pagesPRESENTATION Flanges Andd Couplingsashishntpc1309100% (1)

- Piping Material Specification GuideDocument60 pagesPiping Material Specification GuideNeeraj Bora100% (10)

- Piping Presentation Components and DesignDocument52 pagesPiping Presentation Components and Designmayank pandya100% (2)

- Piping Olets: Branching Fittings GuideDocument3 pagesPiping Olets: Branching Fittings Guiderenger20150303100% (1)

- Company Profile of DAEJU CONTROL CO., LTD.Document17 pagesCompany Profile of DAEJU CONTROL CO., LTD.Ki Ho ChungNo ratings yet

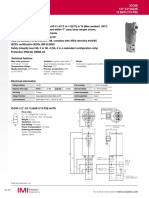

- IMI Maxseal ICO3S 1-2, 3-Way, 174 PdiDocument2 pagesIMI Maxseal ICO3S 1-2, 3-Way, 174 PdiHamed YadegariNo ratings yet

- Parts Manual k21-k25 Non-Epa Gas EngineDocument48 pagesParts Manual k21-k25 Non-Epa Gas EngineCoque de LunaNo ratings yet

- General-Service Packaged Air Compressors and ReceiversDocument11 pagesGeneral-Service Packaged Air Compressors and ReceiversElie HajjNo ratings yet

- 950H - Sebp3866-24 - K5K - Vol 2Document735 pages950H - Sebp3866-24 - K5K - Vol 2Nilder Rojas100% (4)

- 90-mm Gun Tank T48 TM 9-718B 1952Document583 pages90-mm Gun Tank T48 TM 9-718B 1952Thomas Conroy-RunyonNo ratings yet

- CLS CLH BassaDocument342 pagesCLS CLH Bassaapi-3769211100% (1)

- Tobee® TSH Horizontal Split Case Water PumpDocument24 pagesTobee® TSH Horizontal Split Case Water PumpDonna ZhangNo ratings yet

- INVENTORY REPORTDocument29 pagesINVENTORY REPORTBujang SuksesNo ratings yet

- Catalog 14 en 1630606Document552 pagesCatalog 14 en 1630606tanhieungoNo ratings yet

- Installation Manual: System Air ConditionerDocument27 pagesInstallation Manual: System Air ConditionerJavierJMNo ratings yet

- Eliminador Aire - 22AV ArmstrongDocument2 pagesEliminador Aire - 22AV ArmstrongVictor Enrique Rosales ParadaNo ratings yet

- Flowmeter Measurement ApparatusDocument29 pagesFlowmeter Measurement ApparatusSyafiq Izzuddin100% (2)

- ASCO Solenoid Valve Troubleshooting GuideDocument2 pagesASCO Solenoid Valve Troubleshooting GuideNeeraj JangidNo ratings yet

- UniSim Flare Getting Started GuideDocument62 pagesUniSim Flare Getting Started GuideSaputra100% (1)

- Manual MK6Document572 pagesManual MK6David A. López100% (1)

- Piping Design GuideDocument65 pagesPiping Design GuideShrey PatelNo ratings yet

- Central Cooling System On ShipsDocument7 pagesCentral Cooling System On Shipsmister_no34No ratings yet

- Technische Unterlagen PVG 32 EnglischDocument76 pagesTechnische Unterlagen PVG 32 EnglischDarNo ratings yet

- PRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Document10 pagesPRE - Delivery Inspection OF EX200 Super: /TTC-KGP/SOP/2)Habibur RahamanNo ratings yet

- WOM Subsea Brochure 8Document40 pagesWOM Subsea Brochure 8arietilangNo ratings yet

- T 44Document4 pagesT 44Tony_Black99No ratings yet

- Nibe VPA 300 Manual PDFDocument24 pagesNibe VPA 300 Manual PDFTom MurphyNo ratings yet

- Conversion ContiMaster PowerMaster IIIDocument26 pagesConversion ContiMaster PowerMaster IIIVictor Edy Facundo DelzoNo ratings yet

- DOOSAN DX140LC Plano Hidraulico PDFDocument1 pageDOOSAN DX140LC Plano Hidraulico PDFJorge Luis BahamondeAzcarateNo ratings yet

- Machine Design Final Coaching Shuffled PDFDocument385 pagesMachine Design Final Coaching Shuffled PDFJaypes ManzanoNo ratings yet

- ECU Diagnostic Codes & Recommended TestsDocument15 pagesECU Diagnostic Codes & Recommended Testspankituna5487No ratings yet

- Combustion Control by Pulse Firing: SP-456 February, 2007Document8 pagesCombustion Control by Pulse Firing: SP-456 February, 2007Thaiminh VoNo ratings yet

- ReportDocument272 pagesReportPrathmesh GhiyaNo ratings yet

- VARCO September 2013Document48 pagesVARCO September 2013Pumper MagazineNo ratings yet