Professional Documents

Culture Documents

2.2. Hydro 2 PT 1

Uploaded by

Arus EdoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.2. Hydro 2 PT 1

Uploaded by

Arus EdoCopyright:

Available Formats

1

Part B2: Hydropower

B2.2 Hydropower system design

2

B2.2 Hydropower system design

Topics: System design

Entry arrangements

Forbays, penstock inlets

Penstocks and surge control

Size of the penstock, pressure forces, anchoring

the penstock, water hammer and its control

Exit arrangements

draft tubes

Turbine selection

Force triangles, Turbine types, specific speed,

cavitation and its prevention

Electronics and control

Types of generator, Turbine control,

transmission

3

B2.2.1 Hydropower system design

Entry arrangements: Anatomy of a

forebay

4

B2.2.1 Hydropower system design

Entry arrangements: Anatomy of a

forebay

5

B2.2.1 Hydropower system design

Entry arrangements: Trash rack losses

4 3

2

sin

2

t t

t v

h K

b g

|

| |

=

|

\ .

Values for K

t

6

B2.2.1 Hydropower system design

Entry arrangements: trash racks

7

B2.2.1 Hydropower system design

Entry arrangements: Alternatives to trash

racks

8

B2.2.1 Hydropower system design

Entry arrangements: Velocity into the

penstock

v

1

v

3

p

1

p

3

Energy line

v

2

p

2

h

t

Typical values for penstock velocities 2-5 m/s

1 2

2

t

v v gh = =

9

B2.2.1 Hydropower system design

Entry arrangements: Entry losses into

the penstock

10

Type K

e

Hooded 1.0

Projecting 0.8

Sharp corner 0.5

Slightly rounded 0.2

Bell mouth (r>0.14D) 0

B2.2.1 Hydropower system design

Entry arrangements: Entry losses into

the penstock

2

2

e e

v

h K

g

=

11

B2.2.2 Hydropower system design

Penstocks: Comparison of penstock

materials

Material Friction

loss

Weight Corrosion

resistance

Cost Ease of

Jointing

Pressure

resist

Ductile iron

Asbestos cement

Concrete

Wood staves

GRP

uPVC

Mild steel

HDPE

MDPE

Poor Excellent

12

B2.2.2 Hydropower system design

Penstocks: Installation

13

B2.2.2 Hydropower system design

Penstocks: Friction losses in penstocks

7

B2.1.1 Fundamentals of Hydro power

The energy equation: Implications:

Flow in pipes: Friction: Moody diagram

9

B2.1.1 Fundamentals of Hydro power

The energy equation: Implications:

Flow in pipes: Friction: Equations

Blasius equation

For hydraulically smooth pipe

(Re 4,000 100,000)

0.25

0.3164

Re

f =

Swamee-Jain equation

10

-6

< k/D < 0.01

(5,000 3x10

8

)

2

10 0.9

0.25

5.74

log

3.7 Re

f

k

D

=

( | |

+

| (

\ .

8

B2.1.1 Fundamentals of Hydro power

The energy equation: Implications:

Flow in pipes: Friction: Nomogram

Darcys formula

See B2.1.1

2

2

f

L v

h f

D g

| |

=

|

\ .

Typical penstock losses are 5-10%

14

B2.2.2 Hydropower system design

Penstocks: Multiple penstocks

15

B2.2.2 Hydropower system design

Penstocks: Losses in bends

16

B2.2.2 Hydropower system design

Penstocks: Losses in bends

r/D

K

b

1 0.6

2 0.5

3 0.4

4 0.3

For 45 use K x 0.75

For 2 use K x 0.5

r

D

2

2

b b

v

h K

g

=

17

B2.2.2 Hydropower system design

Penstocks: Other Losses

Contractions

Valves

D

1

/d

2

K

c

1.5 0.25

2 0.35

2.5 0.40

5 0.50

Type K

v

Spherical 0

Gate 0.1

Butterfly 0.3

18

B2.2.2 Hydropower system design

Penstocks: Energy lines

19

B2.2.2 Hydropower system design

Penstocks: Anatomy of a penstock

20

B2.2.2 Hydropower system design

Penstocks: Slide blocks

21

F

e

= Force due to extension

C

e

= Coefficient of extension

AT = Change in temperature

E = Youngs modulus

D = Penstock diameter

t = Wall thickness

B2.2.2 Hydropower system design

Penstocks: Thermal expansion

F

e

F

e

e e

F C T E Dt t = A

22

B2.2.2 Hydropower system design

Penstocks: Expansion joints

23

B2.2.2 Hydropower system design

Penstocks: Forces on bends

2 sin

2

h

F gh A

| o

| |

=

|

\ .

2 sin

2

v

F Q v

| o

| |

=

|

\ .

Hydrostatic

Velocity

F

= fluid density

g = gravity

h = total head

A = penstock area

Q = discharge

v = velocity

24

B2.2.2 Hydropower system design

Penstocks: Bends

25

B2.2.2 Hydropower system design

Penstocks: Forces on bends: Thrust

blocks

26

B2.2.2 Hydropower system design

Penstocks: Anatomy of a penstock

27

B2.2.2 Hydropower system design

Penstocks: Water hammer

28

T

c

= critical time (s)

L = pipe length (m)

C

p

= speed of sound in the pipe

C

w

= speed of sound in water

(1420m s

-1

)

G = bulk density of water

(2GPa)

E = Youngs modulus

D = diameter of the pipe (m)

t = wall thickness (m)

Ah = additional pressure due to water

hammer (m of water)

g = gravity

Av = Change in flow velocity (m s

-1

)

B2.2.3 Hydropower system design

Penstocks: Water hammer

2

c

p

L

T

c

=

1

w

p

c

c

G D

E t

=

+

p

c

h v

g

A = A

29

B2.2.2 Hydropower system design

Penstocks: Water hammer: Dealing with it

30

B2.2.2 Hydropower system design

Penstocks: Water hammer: Dealing with it:

Surge tanks

31

B2.2.2 Hydropower system design

Penstocks: Getting it wrong

32

B2.2.3 Hydropower system design

Draft tubes

Parallel sided Tapered

Allows turbine to be set

above water level but

uses vacuum pressure on

underside to increase

effective head

Recovers part of the

velocity head by

diffusion action

Limited by the vapour pressure of water

33

B2.2.3 Hydropower system design

Draft tubes: Exercise

Using Bernoulli's equation and mass

continuity, show how a tapered turbine

regains velocity head and converts it to

pressure reduction at the turbine

p

2

v

2

p

1

v

1

34

B2.2.3 Hydropower system design

Draft tubes: configurations

35

B2.2.3 Hydropower system design

Draft tubes

36

B2.2.3 Hydropower system design

Draft tubes

37

Nextturbines

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Indonesia East Kalimantan Kayan River Basin Hydropower and Aluminum Smelting ProjectDocument32 pagesIndonesia East Kalimantan Kayan River Basin Hydropower and Aluminum Smelting ProjectAkhid SidqiNo ratings yet

- Indonesia East Kalimantan Kayan River Basin Hydropower and Aluminum Smelting ProjectDocument32 pagesIndonesia East Kalimantan Kayan River Basin Hydropower and Aluminum Smelting ProjectAkhid SidqiNo ratings yet

- Media Systems Design: 4.1 General ConsiderationsDocument31 pagesMedia Systems Design: 4.1 General ConsiderationsAkhid SidqiNo ratings yet

- DSI-DYWIDAG Tie RoTie Rodsds 02 PDFDocument6 pagesDSI-DYWIDAG Tie RoTie Rodsds 02 PDFAnonymous 4ghB3BQNo ratings yet

- STP Design PDFDocument151 pagesSTP Design PDFMark Anthony AcangNo ratings yet

- Design of Rigid PavementDocument7 pagesDesign of Rigid PavementASHIK BELLARYNo ratings yet

- Infrastructure & Pathway Design: 3.1 General ConsiderationsDocument58 pagesInfrastructure & Pathway Design: 3.1 General ConsiderationsAkhid SidqiNo ratings yet

- DSI-DYWIDAG Tie RoTie Rodsds 02 PDFDocument6 pagesDSI-DYWIDAG Tie RoTie Rodsds 02 PDFAnonymous 4ghB3BQNo ratings yet

- Media Systems Design: 4.1 General ConsiderationsDocument31 pagesMedia Systems Design: 4.1 General ConsiderationsAkhid SidqiNo ratings yet

- Appendix A Reference Materials: California State UniversityDocument3 pagesAppendix A Reference Materials: California State UniversityAkhid SidqiNo ratings yet

- Facilities Planning and Programming: 2.1 General Goals and ObjectivesDocument48 pagesFacilities Planning and Programming: 2.1 General Goals and ObjectivesAkhid SidqiNo ratings yet

- Introduction and General Requirements: 1.1 The TIP Standards ConceptDocument11 pagesIntroduction and General Requirements: 1.1 The TIP Standards ConceptAkhid SidqiNo ratings yet

- Infrastructure & Pathway Design: 3.1 General ConsiderationsDocument58 pagesInfrastructure & Pathway Design: 3.1 General ConsiderationsAkhid SidqiNo ratings yet

- Design Standards For Urban Infrastructure - StormwaterDocument130 pagesDesign Standards For Urban Infrastructure - StormwaterbraackwNo ratings yet

- Introduction and General Requirements: 1.1 The TIP Standards ConceptDocument11 pagesIntroduction and General Requirements: 1.1 The TIP Standards ConceptAkhid SidqiNo ratings yet

- Facilities Planning and Programming: 2.1 General Goals and ObjectivesDocument48 pagesFacilities Planning and Programming: 2.1 General Goals and ObjectivesAkhid SidqiNo ratings yet

- Wollongong DCP 2009 Chapter E15 - Water Sensitive Urban Design PDFDocument28 pagesWollongong DCP 2009 Chapter E15 - Water Sensitive Urban Design PDFPaulo PangilinanNo ratings yet

- Appendix A Reference Materials: California State UniversityDocument3 pagesAppendix A Reference Materials: California State UniversityAkhid SidqiNo ratings yet

- Concrete Pipe-Cat - Concrete - Pipes - 1170714 PDFDocument40 pagesConcrete Pipe-Cat - Concrete - Pipes - 1170714 PDFAnonymous lM2VHSMs7uNo ratings yet

- WBD StormwaterHarvestingGuidelines Draft02 PDFDocument130 pagesWBD StormwaterHarvestingGuidelines Draft02 PDFAkhid SidqiNo ratings yet

- EiaDocument76 pagesEiaAkhid SidqiNo ratings yet

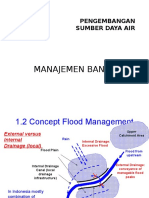

- Managemnet BanjirDocument18 pagesManagemnet BanjirAkhid SidqiNo ratings yet

- Design Standards For Urban Infrastructure - StormwaterDocument130 pagesDesign Standards For Urban Infrastructure - StormwaterbraackwNo ratings yet

- ETABS Examples ManualDocument50 pagesETABS Examples ManualSaikat Kabiraj90% (30)

- Tank ModelDocument26 pagesTank Modelnippo123No ratings yet

- 2013editionhandbookonclimatechangeadaptedurbanplanninganddesigneng 130716042218 Phpapp01Document120 pages2013editionhandbookonclimatechangeadaptedurbanplanninganddesigneng 130716042218 Phpapp01Akhid SidqiNo ratings yet

- Conceptual & Detail Engineering Design Macro Stormwater & Drainage System 9/6/16Document8 pagesConceptual & Detail Engineering Design Macro Stormwater & Drainage System 9/6/16Akhid SidqiNo ratings yet

- Rainwater Harvesting Design MethodsDocument35 pagesRainwater Harvesting Design MethodsAkhid SidqiNo ratings yet

- 2015 Construction StandardsDocument64 pages2015 Construction StandardsAkhid SidqiNo ratings yet

- 2015 Construction StandardsDocument64 pages2015 Construction StandardsAkhid SidqiNo ratings yet