Professional Documents

Culture Documents

Coal

Uploaded by

Mumtaj Shah100%(2)100% found this document useful (2 votes)

119 views55 pagesIndian coal

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIndian coal

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

119 views55 pagesCoal

Uploaded by

Mumtaj ShahIndian coal

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 55

COAL

Coal is a stored fuel, occurring in layers

in the earths crust, which has been

formed by the partial decay of plant

materials accumulated millions of years

ago and further altered by the action of

heat and pressure.

COAL DEFINITION

IN SITU THEORY

DRIFT THEORY (Flood /Tsunami type wave velocity

800 km/h)

300 million of years/earth is 4.6 billion years old

15-20 m OF PLANT MATERIAL= 1 m OF COAL SEAM

In INDIA 30 m seam of coal has

been found

THEORIES OF COAL FORMATION

450-600 m of plant material might have

accumulated at that place.

(Taipei 101:509 m tallest building in world)

COAL FORMATION

COALIFICATION

COAL % C C H O Heating

value

(MJ/kg)

Cellulose

Wood

Peat

Lignite

Brown coal

Bituminous coal

Anthracite

Graphite

44.5

50.0

59.9

61.8

69.5

78.7

91.0

100

100

100

100

100

100

100

100

100

13.9

12.0

10.0

7.8

7.9

6.0

4.7

0.0

111

88

57

54

36

21

5.2

0.0

-

19.77

18.66

20-25

27.20

32.10

32.56

32.91

COAL RANKS

1. Peat: starting point of coal formation

does not come in the category of coal

Carbon: 62-64%; Oxygen:35-30%

2. Lignites: mark the transition of peat to coal

Carbon: 60-75% ; Oxygen: 30-20%

Colour: black, brown, earthy

Disintegrate very easily

Briquetting is done

Neyveli Lignite Corporation, Chennai

Tamilnadu possesses largest reserves in India

Electricity generation: 2490 MW

COAL RANKS contd

3. Bituminous coals

Sub-bituminous

Between lignites and bituminous

Carbon: 75-83% ; Oxygen: 20-10%

No caking power

Bituminous: black and banded

Industrial and domestic usage

Carbon: 75-90%: Oxygen:10-5%

Semi-bituminous

Between bituminous and anthracite

Metallurgical coke formation

Carbon: 90-93%; Oxygen:4-1%

COAL RANKS contd

4. Anthracites

Highest rank of coal

Extreme of metamorphosis from the original

plant material

Carbon: 93+%: Oxygen: 2-1%

Caking power zero

Unusual coals

Cannels: found rarely; high hydrogen content: burn

with smoke and bright flame; does not fall in any category.

Torbanites: fine grained coal, named after Torbane Hill

of Scotland, rich in paraffin oil.

Country Million tonnes

% of world production

China 2380

39.75

USA 1053.6

17.59

India 447.3

7.47

Australia 373.8

6.24

South Africa 256.9

4.29

Canada 62.9

1.05

United Kingdom 18.6

0.31

Pakistan 4.3

0.07

Japan 1.3

0.02

Total of the world 5,986.90 100

WORLD PRODUCTION OF COAL IN YEAR 2006

WORLD TOP TEN COAL PRODUCING AND

CONSUMING COUNTRIES

1 quadrillion=1000 trillion

1 Btu=1.055 kJ

Type of coal

TOTAL

RESERVE

PROVED

RESERVE

INDICATED

RESERVE

INFERRED

RESERVE

COKING 32 17 13 2

NON-

COKING

223 81 105 36

TOTAL 255 98 118 38

COAL RESERVES OF INDIA

Source: MoC

Years to consume this coal with present rate: 600

(As on 1.1.2007

in billion tonnes)

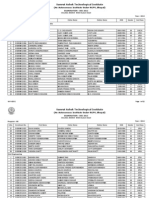

State Proved Indicated Inferred Total % of total

Jharkhand 36881 31094 6339 74314 29.11

Orissa 17464 30239 14296 61999 24.29

Chhattisgarh 10182 26826 4443 41451 16.24

West Bengal 11454 11810 5071 28335 11.10

Madhya Pradesh 7584 9259 2934 19777 7.75

Andhra Pradesh 8475 6328 2658 17461 6.84

Maharashtra 4856 2822 1992 9670 3.79

Uttar Pradesh 766 296 0 1062 0.42

Meghalaya 118 41 301 460 0.18

Assam 315 27 34 376 0.15

Bihar 0 0 160 160 0.06

Arunachal Pdesh 31 40 19 90 0.04

Sikkim 0 55 18 73 0.03

Nagaland 3 1 15 19 0.01

Total 98129 118838 38280 255247 100

COAL RESOURCES OF STATES

IN MILLION TONNES Jan 1, 2007

Coking coal (carbon: 81-91%)

Non-coking coal

GRADING OF INDIAN COAL

Grade Industry Ash %

I steel <15

II steel 15-18

I washery 18-21

II washery 21-24

III washery 24-28

IV washery 28-35

Grades of coking coal

High ash content (up to 50%)

Lower heating/calorific value

Inferior quality but suitable for power gen.

GRADING OF INDIAN COAL

Grade UHV, kcal/kg Ash %

A >6200 <13.56

B 5600-6200 13.56-17.91

C 4940-5600 17.91-22.69

D 4200-4940 22.69-28.06

E 3360-4200 28.06-34.14

F 2400-3360 34.14-41.10

G 1300-2400 41.10-49.07

Based on 6 % moisture content

Grades of non-coking coal

Nationalization in 1971

Coal companies are paying the

royalty to states

This varies from Rs 90-250/tonne

The rate is dependent of coal

grade

Rates are 16 August 2002 onwards

ROYALTY TO STATES

IMPORT OF COAL

Coking and non-coking coals being imported

Year Coking Non-coking Total

1991/92 5.27 0.66 5.93

1996/97 10.62 2.56 13.18

2000/01 11.06 9.87 19.70

2003/04 12.99 8.69 21.68

2005/06 16.89 21.70 38.59

2006/07 22.00 23.00 45.00

In million tonnes

Proximate analysis

Ultimate analysis

Heating/calorific value

ANALYSIS OF COAL

1. Moisture content: 105 -110

o

C

2. Volatiles: 92515

o

C for 7 min time (with lid)

3. Fixed carbon: by difference

4. Ash: 80015

o

C (without lid)

PROXIMATE ANALYSIS

IS:1350-I (1984)

REPORTING: AS RECEIVED BASIS, MOISTURE FREE

BASIS/DRY BASIS OR DRY ASH FREE BASIS

A sample of finely ground coal of mass 0.9945 g was placed

in a crucible of 8.5506 g in an oven, maintained at 105

o

C

for 4.0 ks. The sample was then removed, cooled in a

dessicator and reweighed; the procedure being repeated

until a constant total mass of 9.5340 g was attained. A second

sample, of mass 1.0120 g in a crucible of mass 8.5685 g was

heated with a lid in a furnace at 920

o

C for 420 s. On cooling

and reweighing, the total mass was 9.1921g. This sample was

then heated without a lid in the same furnace maintained at

725

o

C until a constant total mass of 8.6255 g was attained.

Calculate the proximate analysis of the sample and express

the results on as sampled and dry, ash-free basis.

EXAMPLE OF PA

MOISTURE

mass of sample = 0.9945 g

mass of dry coal = (9.5340-8.5506) = 0.9834 g

mass of moisture = (0.9945-0.9834) = 0.0111 g

% moisture = 0.0111 100/0.9945

= 1.11 %

EXAMPLE OF PA contd..

ASH

mass of sample = 1.0120 g

mass of ash = (8.6255 - 8.5685) = 0.0560 g

% ash = 0.0560 100/1.0120

= 5.53 %

VOLATILE MATTER

mass of sample = 1.0120 g

mass of volatile matter + moisture = (9.1921-8.5685)

= 0.6236 g

% = 0.6236 x 100/1.0120

= 61.60

VOLATILE MATTER = 61.60-1.11

= 60.49%

EXAMPLE OF PA contd..

FIXED CARBON

% FC = 100 - % VM - % ash - % moisture

= 100 - 60.49 - 5.53 - 1.11

= 32.87%

Proximate analysis as received basis

Moisture : 1.11%

Ash : 5.53%

Fixed carbon :32.87%

Volatile matter :60.49%

Proximate analysis on dry, ash free basis

Moisture + ash= 5.53+1.11=6.64%

Fixed carbon :32.87x100/(100-6.64)=35.21%

Volatile matter :60.49x100/(100-6.64)=64.79%

EXAMPLE OF PA contd..

1. Carbon

2. Hydrogen

3. Oxygen

4. Sulfur :0.5-2.50 %

5. Nitrogen :1.0-2.25 %

6. Phosphorus :0.1%;Blast Furnace: <0.01 %

7. Chlorine

ULTIMATE ANALYSIS

IS:1350- IV (1974)

Mercury: A big problem from NTPC plants

(up to 0.3mg/kg)

1. Calculated from proximate analysis

2. Calculated from ultimate analysis

3. Experimental determination

HEATING VALUE

1. Gross/High heating value

2. Useful/low heating value

Hydrogen Water (gas/vapor or liquid phase)

Carbon Carbon Dioxide (gas phase)

Latent heat of vaporization of water: 2.26 MJ/kg

1. Calculated from proximate analysis

HEATING VALUE

TAYLOR AND PATTERSON RELATIONSHIP

HV=4.19 (82FC+ a VM) kJ/kg

Where FC and VM are on dry ash free basis and a is

an empirical constant which depends on the VM

content of coal.

VM 5 10 15 20 25 30 35 38 40

a 145 130 117 109 103 98 94 85 80

2. Calculated from ultimate analysis

HEATING VALUE

DULONG FORMULA

HV=338.2C+1442.8(H-O/8)+94.2S kJ/kg

Where C, H, O and S are the % of these elements on

dry ash free basis.

3. Experimental determination: Bomb calorimeter

HEATING VALUE

IS:1350-II (1970)

solid /liquid samples can be analyzed

1 g air dried sample is burnt in a bomb in oxygen

atmosphere

rise in temperature gives the heat liberated and

heating value is determined after doing the

corrections for resistance wire and thread.

microprocessor based bomb calorimeters are now

available

BOMB OF CALORIEMETER

VARIOUS COMPONENTS OF BOMB

CALORIMETERIC EQUIPMENT

ROUTES OF GENERATION OF HEAT AND

POWER FROM COAL

1. Direct use as thermal energy in heating processes,

furnaces and domestic heating by open fires

2. Transfer of the heat to a thermal fluid and application of

the latter for heating and power i.e., steam for heating in

process industry, central heating and electricity

generation by steam turbines

3. Gas turbine route to electricity generation

4. Conversion to gas/liquid fuels and subsequent usage in

IC engines/turbines (gas/steam)

ROUTE I

Domestic cooking/tea stalls/dhabas

Space heating

Lime and brick kilns

Ceramic industry

Generation of steam in a boiler

Space heating by transferring heat of steam to air

Process industry : Cogeneration is employed

Utility services : steam turbines used

ROUTE II

GOVERNMENT ALLOWED ELECTRICITY GENERATION

BY PRIVATE DEVELOPERS

Tariffing

Wheeling

Banking

SUPERCRITICAL BOILERS: A RECENT CONCEPT

Critical pressure: 218 bar; Critical temperature: 374

o

C

Mark Benson; in 1922 Patent was granted

22 MPa pressure ; = 1-T

1

/T

2

ROUTE II contd..

Coal

Boiler

Steam turbine

Heat exchanger

Condensate

Coal

Hot air

for

space

heating

Alternator Electricity

to process

plant/grid

Process plant

Steam

Steam

Cogeneration

Steam

turbine

Alternator

Electricity to grid

Condensate

Steam

Steam

Air

ROUTE III

Pulverizer

Gas turbine

Heat

exchanger

Coal

Compressor

Electricity

to grid

Alternator

Preheated air

Combustion

chamber

Air

Vent

Turbine

exhaust

ROUTE III (cleaner option)

Gasifier and gas

cleaning unit

Gas turbine

Heat

exchanger

Coal

Compressor

Electricity

to grid

Alternator

Preheated air

Combustion

chamber

Air

Vent

Turbine

exhaust

ROUTE IV (Pyrolysis / Gasification)

1. Partial Gasification or Pyrolysis /coking

/carbonization / destructive distillation

(heating in the absence of air)

Solid

Liquid

Gas

2. Complete gasification with air/oxygen

Gas

PYROLYSIS

Coke (solid fuel) maximum; classical domestic smokeless fuel

production

Gas and liquid fractions low

Liquid fraction for chemicals recovery/liquid fuel

Coke for metallurgical furnaces; gas yield high; liquid low

Low temperature carbonization 500-700

o

C

High temperature carbonization >900

o

C

Medium temperature carbonization 700-900

o

C

PYROLYSIS

Pyrolyser

Coal

Condenser

Water in

Water out

Gas

for IC engines/

Gas turbines/

thermal

applications

Coke

Liquid

fraction

Gas for heating of pyrolyser

Flue gas

Pretreatment unit

Coal tar

Liquid fuels

Chemicals

GASIFICATION

ROUTE IV BERGIUS PROCESS

1. Bergius process

Friedrich Karl Rudolf Bergius in 1913, Germany

Nobel Prize in 1931

Worked with Haber

World war II 56,000 bbl per day production

Hydrogenation of vegetable oils

2. Fischer-Tropsch process

Franz Fischer and Hans Tropsch in 1926, Germany

Coal is hydrogen starved/hydrogen needs to be added to make it

liquid (directly or indirectly)

BERGIUS PROCESS

Pulverizer

Coal pasting

unit

Hydrogen Coal

Fractionating

column

Bergius

Reactor

Heavy fraction

HCs

T=400-500

o

C

P= 20 -70 MPa

Catalyst=Tin

Conver.=97%

F-T PROCESS

Gasification

unit

Syn gas

Cleaning

Coal

Fractionating

column

F-T

Reactor

HCs

T=150-250

o

C

P= 1 -25 MPa

Syn gas

Catalysts : Iron or cobalt based

Large number of patents worldwide

F-T PROCESS (COMMERCIAL PLANTS)

South Africa Oil and Gas

Company

1950 established

Oldest plant proving the F-T

process viability

Presently engaged in Qatar,

Iran and Nigeria in similar

projects

F-T PROCESS (COMMERCIAL PLANTS)

F-T PROCESS(COMMERCIAL PLANTS)

F-T PROCESS

Players in this area of Gas To Liquid (GTL)

1. GE

2. Exxon

3. Shell

4. BP

5. Chevron

6. Sasol

With crude touching the $145+ these two

technologies would be economically viable now

UNDERGROUND/ IN SITU COAL

GASIFICATION

A process applied to the non-mined coal seams

Injection and production wells are drilled

End gas mix depends on type of coal seam

Air/ oxygen can be used for gasification

Syn gas can be used for power generation in combined cycle

Syn gas can be converted to chemicals/fuel by F-T process

UNDERGROUND/ IN SITU COAL

GASIFICATION

Source: World Coal Institute

COAL COMBUSTION AND ENVIORNMENT

Global warming

Green house gases: water vapor, carbon dioxide,

methane, nitrous oxide, CFCs, SF

6

(circuit breakers,

high DE constant)

SF

6

is 22, 200 more potential than CO

2

Carbon dioxide gas: main culprit from fossil fuels; not

from biomass

Intergovernmental Panel on Climate Change (IPCC)

Nobel Peace Prize 2007 : R. K. Pauchari and Al Gore

Reduction in Carbon Dioxide emissions

G8 meeting in Japan in July 2008

COAL COMBUSTION AND ENVIORNMENT

Carbon Dioxide Emissions and Carbon Dioxide Concentrations (1751-2004)

Present CO

2

level:483 PPM

COAL COMBUSTION AND ENVIORNMENT

Global Carbon Cycle (Billion Metric Tons Carbon)

COAL COMBUSTION AND ENVIORNMENT

U.S. Anthropogenic Greenhouse Gas Emissions by Gas,

2006 (Million Metric Tons of Carbon Dioxide Equivalent)

CARBON DIOXIDE CAPTURE AND SEQUESTRATION

Sequestration

1. Gaseous storage in various deep geological formations (including

saline formations and exhausted gas fields)

2. Liquid storage in the ocean

3. Solid storage by reaction of carbon dioxide with metal oxides

to produce stable carbonates

Capture

Proven technology being used in process industries and power plants

BUT THE COST IS DECIDING FACTOR

ULTIMATE SOLUTIONS

Fuel cells: Chemical to electrical conversion

Solar: photovoltaic

Hybrid vehicles: Honda introduced in India

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Ebooks Chemical EngineeringDocument1 pageEbooks Chemical EngineeringMumtaj ShahNo ratings yet

- C PH Z3 GN JQre Os 2 SDDocument6 pagesC PH Z3 GN JQre Os 2 SDMumtaj ShahNo ratings yet

- PUBMLDocument10 pagesPUBMLMumtaj ShahNo ratings yet

- 2012AEST-ethicsformDocument1 page2012AEST-ethicsformMumtaj ShahNo ratings yet

- TVNI Awards 2015Document3 pagesTVNI Awards 2015Mumtaj ShahNo ratings yet

- Nirma University, Ahmedabad1Document1 pageNirma University, Ahmedabad1Mumtaj ShahNo ratings yet

- DesignDocument32 pagesDesignMumtaj ShahNo ratings yet

- Absolute Relative ErrorDocument1 pageAbsolute Relative ErrorSamuel Flexor GyasiNo ratings yet

- RegistrationForm SERB School at UPES 2013Document1 pageRegistrationForm SERB School at UPES 2013Mumtaj ShahNo ratings yet

- Format of SC STDocument3 pagesFormat of SC STMumtaj ShahNo ratings yet

- BE (All)Document22 pagesBE (All)Mumtaj ShahNo ratings yet

- CalenderDocument1 pageCalenderhajikaderNo ratings yet

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Case Study Bicine Formation Amine UnitDocument14 pagesCase Study Bicine Formation Amine Unitmahesh070No ratings yet

- Chapter2 Lab WorksheetDocument3 pagesChapter2 Lab WorksheetKunakorn KunthamasNo ratings yet

- Air Pollution Management (2 Marks QA)Document16 pagesAir Pollution Management (2 Marks QA)rssdpm100% (4)

- ARUP Embodied Carbon Timber 1Document22 pagesARUP Embodied Carbon Timber 1Gabriel MacaulayNo ratings yet

- TERM 2 Chapter 7 Topical Revision Bio STPMDocument59 pagesTERM 2 Chapter 7 Topical Revision Bio STPMKeertana SubramaniamNo ratings yet

- 7theories of Climate ChangeDocument32 pages7theories of Climate ChangeAnonymous OYHdrCjNo ratings yet

- Carbon Sequestration by Rocks and MineralsDocument22 pagesCarbon Sequestration by Rocks and MineralsNikhil SirdesaiNo ratings yet

- IAS Prelims General Studies Paper 1993 Part 1 PDFDocument4 pagesIAS Prelims General Studies Paper 1993 Part 1 PDFAntara Ramesh NairNo ratings yet

- Respiratory and Circulatory Systems Module Pre-AssessmentDocument152 pagesRespiratory and Circulatory Systems Module Pre-Assessmentmarvin agubanNo ratings yet

- Gaseous FuelsDocument5 pagesGaseous FuelsEmmanuel Jimenez-Bacud, CSE-Professional,BA-MA Pol Sci100% (1)

- A Technical and Economic Assessment of Ammonia-Based Post-Combustion CO2 Capture at Coal-Fired Power PlantsDocument10 pagesA Technical and Economic Assessment of Ammonia-Based Post-Combustion CO2 Capture at Coal-Fired Power PlantsBánh Cuốn Tôm ThịtNo ratings yet

- Rotary Kiln Cement 1Document13 pagesRotary Kiln Cement 1iimcaemdwNo ratings yet

- Iron and Steel ReportDocument31 pagesIron and Steel ReportDinesh Kumar KarurNo ratings yet

- NCERT Class 8 Pollution SolutionsDocument4 pagesNCERT Class 8 Pollution SolutionsdeenaNo ratings yet

- Underground Coal Gasification (UCG)Document10 pagesUnderground Coal Gasification (UCG)partha das sharmaNo ratings yet

- Tank CleaningDocument19 pagesTank CleaningWiwatthana Kumpim100% (4)

- Power Plants: Continuous Emissions Monitoring and Process ControlDocument4 pagesPower Plants: Continuous Emissions Monitoring and Process ControlHoang Chau TrungNo ratings yet

- "Plop, Plop, Fizz, Fizz, Oh What A Reaction Is ": Effect of Temperature On Rate of ReactionDocument4 pages"Plop, Plop, Fizz, Fizz, Oh What A Reaction Is ": Effect of Temperature On Rate of Reactioniloveit52252No ratings yet

- Graduation Project Final DraftDocument11 pagesGraduation Project Final Draftapi-281576265No ratings yet

- Agri and Food e Newsletter PDFDocument422 pagesAgri and Food e Newsletter PDFtanujaNo ratings yet

- Perrut, 2019. Supercritical Fluids in The Food Industry PDFDocument27 pagesPerrut, 2019. Supercritical Fluids in The Food Industry PDFFabian MendozaNo ratings yet

- Determination of The Concentration of Atmospheric Carbon DioxideDocument7 pagesDetermination of The Concentration of Atmospheric Carbon DioxideIbrahim AliNo ratings yet

- PPL MSDS Material Data Safety SheetDocument6 pagesPPL MSDS Material Data Safety SheetvyompvNo ratings yet

- Part 4 in Situ CombustionDocument33 pagesPart 4 in Situ CombustionFlorian Ananias ByarugabaNo ratings yet

- DNV GL Complete-Alt-Fuels Guidance Paper 2018-04 WebDocument44 pagesDNV GL Complete-Alt-Fuels Guidance Paper 2018-04 WebGeorge KanellakisNo ratings yet

- Persuasive Strategy Definitions: Claim Logos Pathos Ethos Kairos ResearchDocument4 pagesPersuasive Strategy Definitions: Claim Logos Pathos Ethos Kairos ResearchLouie Jay SilangNo ratings yet

- Uredba o Razvrstavanju Objekta Delatnosti I Zemljista U Kategorije Ugrozenosti Od PozaraDocument16 pagesUredba o Razvrstavanju Objekta Delatnosti I Zemljista U Kategorije Ugrozenosti Od PozaraIvana VujčićNo ratings yet

- Advantages and Disadvantages of Global WarmingDocument11 pagesAdvantages and Disadvantages of Global WarmingA Aldika Farlis50% (2)

- IGCSE Biology Paper 6 CardsDocument21 pagesIGCSE Biology Paper 6 CardsSara EmadNo ratings yet