Professional Documents

Culture Documents

Strengthing of Building

Uploaded by

subathraponniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthing of Building

Uploaded by

subathraponniCopyright:

Available Formats

By

D.SHANKAR

1

STRENGTHENING

Strengthening is the process of improving the original

strength to the structure.

Strengthening of member is done by providing poor

quality or defective material by better quality material.

Strengthening is the most common seismic improvement

strategy for buildings with inadequate lateral force resisting

systems

2

NEED FOR STRENGTHENING

Damages to structural parts due to aging of construction

materials or fire damages, corrosion of reinforcement.

Errors in construction due to insufficient design dimension

and insufficient reinforcing steel.

Load increases due to higher live loads, increase wheel

loads, installation of heavy machinery.

3

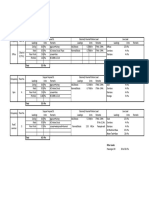

Assessment procedure for evaluating the damaged structure

4

Physical Inspection

Study of documents

Estimate of load activity

Estimate of environmental effect

Diagnosis

Retrospective analysis

Diagnosis conformed

Assessing of Structural adequacy

Choice of course of action

Load test

Estimate of

future use

yes

No

Material tests

CORROSION

5

CORROSION

The corrosion of reinforcing steel in concrete is a major

problem faced by the civil engineers and surveyors. Today as

they maintain an ageing infrastructure.

Corrosion is the gradual distraction of material (usually

metals),by chemical reaction with its environment.

Rust staining, corrosion cracks and cover spalling are also

occurred

6

RUSTING OF BARS

7

CORROSION OF STEEL

Difference in electrical potential occur

+ve ferrous ions (fe++) at anode pass into solution

-ve free ions (e) combines with water and oxygen to form

hydroxyl ion

These combine with ferrous ions to form ferric hydroxide

which is converted to rust.

8

DAMAGES DUE TO CORROSION

Loss of strength in the reinforcement.

Formation of brown patches on the concrete surface.

Formation of multiple wide cracks.

Spalling of cover concrete.

Buckling of bars.

Bulging of concrete.

9

PROTECTIVE COATING FOR

REINFORCEMENT

Methods of coating

Cement slurry coating.

Phospatic jelly coating.

Epoxy coating.

Plastic coating.

Galvanizing.

10

CEMENT SLURRY COATING

Cement slurry coating provides short-term protection until

placement of concrete.

Coating is the mixture of cement, silica and polymer.

It is found to be impermeable to water, chlorides and CO

2

.

EPOXY COATING

Epoxy coating is formed by the application of an Epoxy resing

with curing agent,catalysts,pigments and flow control agents.

Epoxy coating provides long term protection against corrosion.

Cost of implementing this method is significantly high

compare to other method of coating.

PLASTIC COATING

Plastic coating is very similar to epoxy coating, the Plastic

coating is very effective in the preventing corrosion of

reinforcement even in high alkaline or chloride contaminated

environment

The reduction in bond between plastic coated bars and the

concrete is quite substaintial.

GALVANIZING

Galvanizing gives the protection to the reinforcement

against corrosion by means of metallic coating( ZINC).

This method reduces the effects of chlorides, but it is not

advisable to use in the highly chloride contaminated

environment.

STRENGTHENING OF BUILDING

16

Strengthing techniques

Strengthing can be done by following techniques

Jacketing

Underpinning

Shoring

Resin injection

Epoxy resin

17

JACKETING CONCRETE COLUMN

18

JACKETING

Jacketing is the process of fastening a durable material

over the concrete and filling the gaps with grout.

The material used for jacketing are metal,rubber

ferrocement, plastic .

when jacket is provided around the periphery of the

column is called collar.

The main function the collar is to transfer the vertical load

to the column

19

DISADVANTAGE OF JACKETING

It can damage the existing column

It takes More time consumption.

It is more expansive.

20

21

UNDERPINNING

What is Underpinning?

In construction, underpinning is the process of

strengthening and stabilizing the foundation of an

existing building or other structure.

22

Underpinning may be necessary for a variety

of reasons

The original foundation is simply not strong or stable

enough.

The usage of the structure has changed.

The properties of the soil supporting the foundation may

have changed .

23

STRENGTHENING OF FOUNDATION

24

Common methods in underpinning

i)Micropiles ii)Jetgrouting

25

SHORING

Shoring is the temporary structure for providing support

and stability during repair and alteration.

Shoring can be used for various circumstance, they are

Alteration are carried out in adjacent building for

remodelling , strengthening of foundation etc..

The stability of structure is endangered due to unequal

settlement during construction

26

Types of shoring

Raking or inclined shores

Flying shores

Dead or vertical shores

27

SOME OTHER METHODS

This an be achieved

(a) By grouting

(b) By providing wire mesh

(c) By connection between existing stone walls.

28

GROUTING

Grouting is a process of group improvement

attained by injecting fluid like material into

subsurface soil or rock.

A number of holes are drilled in the wall,

(2 to 4 m

2

).

First water is injected in order to wash the wall

inside and to improve the cohesion between the

grouted mixture and the wall elements.

29

Conti..

Secondly a cement water mixture (1:1) is grouted at low

pressure (0.1 to 0.25 MPa) in the holes starting from the lower

holes and going up.

Alternatively, polymeric mortars may be used for

grouting. The increase of shear strength can be achieved.

30

STRENGTHENING WITH WIRE MESH

Two steel meshes (welded wire fabric with an elementary

mesh of approximately 50 x 50 mm) are placed on the two

sides of the wall, they are connected by passing steel each 500

to 750 mm apart.

A 20 to 40 mm thick cement mortar or microconcrete

layer is then applied on the two networks thus giving rise to

two interconnected vertical plates. This system can also be

used to improve connection of orthogonal walls.

31

32

STRENGTHENING OF STONE WALLS

In stone buildings of historic importance consisting of

fully dressed stone masonry in good mortar effective

sewing of perpendicular walls can be done by drilling

inclined holes through them, inserting steel rods and

injecting cement grout.

33

34

STIFFENING OF WOODEN FLOOR BY

WOODEN PLANKS

35

36

You might also like

- CrossingsDocument34 pagesCrossingssubathraponniNo ratings yet

- Formulas and ConversionsDocument6 pagesFormulas and ConversionssubathraponniNo ratings yet

- FiberDocument12 pagesFibersubathraponniNo ratings yet

- Self Curng FRCDocument75 pagesSelf Curng FRCsubathraponniNo ratings yet

- Natural Wood Fibres For Self Healing ConcreteDocument6 pagesNatural Wood Fibres For Self Healing ConcretesubathraponniNo ratings yet

- Indonesian Earthquake Resistant DesignDocument34 pagesIndonesian Earthquake Resistant DesignsubathraponniNo ratings yet

- Shear ConnectorsDocument11 pagesShear ConnectorssubathraponniNo ratings yet

- IS 432 (Part 1) 1982 R 1995Document11 pagesIS 432 (Part 1) 1982 R 1995Ciddarthn100% (1)

- Composite BeamDocument10 pagesComposite BeamsubathraponniNo ratings yet

- Civil - Bureau of Indian StandardsDocument168 pagesCivil - Bureau of Indian StandardsH.V. PatilNo ratings yet

- A Seismic Design of Elevated Water TanksDocument16 pagesA Seismic Design of Elevated Water Tankssatoni12100% (4)

- Compact SubathraDocument3 pagesCompact SubathrasubathraponniNo ratings yet

- Earthquake Resistant StructuresDocument15 pagesEarthquake Resistant Structuressubathraponni0% (1)

- Cities PlanningDocument98 pagesCities PlanningsubathraponniNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DSR 07-LatestDocument165 pagesDSR 07-LatestRamakrishna MahantiNo ratings yet

- Design LoadingsDocument1 pageDesign LoadingsKrisnel RavalNo ratings yet

- V061E12 NT Support Tool V4.6 Operation ManualDocument565 pagesV061E12 NT Support Tool V4.6 Operation ManualRashid BasironNo ratings yet

- LogDocument7 pagesLoglialove085No ratings yet

- GV-N98TZL-512H GV-N98TZL-1GH: Sales KitDocument8 pagesGV-N98TZL-512H GV-N98TZL-1GH: Sales Kitchristophe_GIGABYTENo ratings yet

- Overview of Bridge Design and ConstructionDocument81 pagesOverview of Bridge Design and ConstructionrajfabNo ratings yet

- DataSheet ESP 07 WIFI Module enDocument18 pagesDataSheet ESP 07 WIFI Module enTresna WidiyamanNo ratings yet

- Robots, Mazes, and Subsumption ArchitectureDocument13 pagesRobots, Mazes, and Subsumption ArchitectureeBeliBalaNo ratings yet

- R-12 Iexpenses SetupDocument101 pagesR-12 Iexpenses Setupfunctional_alwalaNo ratings yet

- (1931) Year Book of The Archite - Architectural League of New Yor PDFDocument718 pages(1931) Year Book of The Archite - Architectural League of New Yor PDFCHNo ratings yet

- SAP Fiori ArchitectureDocument4 pagesSAP Fiori ArchitectureaunhavcNo ratings yet

- ARCHIGRAMDocument9 pagesARCHIGRAMIndraja RmNo ratings yet

- Picturesque and Neo-Classical Architecture: TimelineDocument20 pagesPicturesque and Neo-Classical Architecture: TimelineAkanksha VermaNo ratings yet

- Autodesk Design Review Getting Started GuideDocument56 pagesAutodesk Design Review Getting Started GuideKamal SekarNo ratings yet

- Routing Concept: Sirak KaewjamnongDocument45 pagesRouting Concept: Sirak KaewjamnongAjay BarwalNo ratings yet

- ASEM2M Iridium SBD Developers GuideDocument59 pagesASEM2M Iridium SBD Developers Guidekira019No ratings yet

- LOad On Bridge 2Document140 pagesLOad On Bridge 2shamsukarim2009No ratings yet

- Total Control STG Data SheetDocument2 pagesTotal Control STG Data Sheetrebin1988No ratings yet

- PH Installation PDFDocument180 pagesPH Installation PDFpatytigreraNo ratings yet

- SimCity Exception Report 2011.03.27 16.59.58Document4 pagesSimCity Exception Report 2011.03.27 16.59.58pmears_2No ratings yet

- ARTS9 NCRomantic ARTDocument60 pagesARTS9 NCRomantic ARTAngela Joy AmparadoNo ratings yet

- ZXUR 9000 GSM (V6.50.10) Base Station Controller Radio Parameter ReferenceDocument1,981 pagesZXUR 9000 GSM (V6.50.10) Base Station Controller Radio Parameter ReferenceRaven Zaven100% (4)

- Kitchen Sinks PDFDocument7 pagesKitchen Sinks PDFAshokanand NeelambaranNo ratings yet

- Report of Monument and PatternsDocument23 pagesReport of Monument and PatternsMAHEEN FATIMANo ratings yet

- PCI MNL-116-99 Structural QC Manual PDFDocument332 pagesPCI MNL-116-99 Structural QC Manual PDFJason Powell100% (1)

- Specs PyrostopDocument7 pagesSpecs PyrostopfakemasterkgpNo ratings yet

- Request For Quotation (RFQ) Amendment 1: Mechanical Design"Document47 pagesRequest For Quotation (RFQ) Amendment 1: Mechanical Design"Saptarshi RoyNo ratings yet

- D8 Catalog Digital Update 20190521Document80 pagesD8 Catalog Digital Update 20190521Tuan QuangNo ratings yet

- The Principles of DesignDocument44 pagesThe Principles of Designyashusoni100% (1)

- IS3000 and SIP@NetDocument12 pagesIS3000 and SIP@NetAdli Yaumil HakimNo ratings yet