Professional Documents

Culture Documents

X - Lubricación en Motores Pequeños

Uploaded by

Ray Cepeda MenaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X - Lubricación en Motores Pequeños

Uploaded by

Ray Cepeda MenaCopyright:

Available Formats

Small Engine Technical Review

Presentation Overview

General 2T lubrication overview

Applications of 2T engines

Lubrication of outboard versus non-outboard

Review of the market

Specifications

Air-cooled

Water-cooled

Challenges of small engine market

4T motorcycle update

2T Lubrication Overview

2T Lubrication Overview

Deposit Formation

Fuel and oil oxidation produces primary

contaminant particles (<0.03 )

As levels increase, particles interact to form

soluble agglomerates (0.03-0.05 )

Continued growth produces insolubles,

potential for deposits

Insolubles deposit on hot surfaces forming

resinous films that polymerize to lacquer and

carbonaceous deposits

0.5 to 1.5

Charge Repulsion

Dispersants suspend and isolate contaminants

in the oil, preventing deposits

Structure

Particle Size:

Mechanism:

Under 0.05

Barrier Film

2T Lubrication Overview

Dispersancy in Engine Oils

Dispersants can also displace

less polar contaminants and

protect engine surfaces

from deposits

2T Lubrication Overview

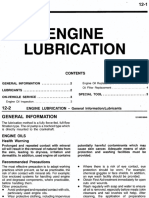

Components of 2T Engine Oil

Performance additive package

Keeps engine clean by preventing ring sticking, piston deposits, plug

fouling, and exhaust deposits

Prevents wear

Prevents corrosion

Base oils

Provide proper viscosity for hydrodynamic lubrication

Resists deposit formation during exposure to extreme heat

Maintain good flow properties

Diluent (solvent)

Provide good flow and mixing properties at low temperatures

Evaporate and burn cleanly with gasoline

Additives To Protect Against

Ashless Dispersant

Engine deposits at high and low

temperatures

Metallic Detergents

(Ash-Containing)

Engine deposits at high temperature

Corrosive wear

Oil oxidation

Auxiliary Oxidation and

Corrosion Inhibitors

Rust control

Oil oxidation

Bearing corrosion

2T Lubrication Overview

2T Engine Oil Additives

Typical

2-Stroke Cycle

Engine Oil

2T Lubrication Overview

Typical 2T Formulas

Air-Cooled Formula

1-7% Ash-Containing

~10% Bright Stock

~10% Solvent

~73-79% Mix Heavy

and Medium Neutral

Base Oil

Water-Cooled Formula

9-20% Ashless Additive

~10-15% Bright Stock

~15-20% Solvent

~45-66% Mix Heavy

and Medium Neutral

Base Oil

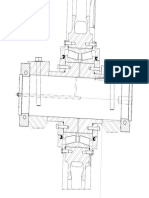

2-T Engine Classifications

Water/Liquid-Cooled or Air-Cooled

Water/Liquid-Cooled Engines Utilize a System of Channels in the

Engine Block to Circulate Coolant and Control Engine

Temperatures

Air-Cooled Engines Rely on Ambient for Cooling (Cylinder Head

Fins to Aid in Convective Heat Transfer)

Further Classification Involves More Detailed Engine

Design

Crankcase Versus Externally Scavenged (Blowers)

Loop, Cross-Flow, and Uniflow Scavenging

Premix (Petroil), Oil Injected, Electronic and More Recently Direct

Fuel Injection (EFI and DFI)

Outboard (TCW)

Water-cooled outboard engines

OEMs OMC, Mercury, Yamaha

and others

Non-outboard (non-TCW)

Air-cooled

Chainsaws, motorscooters, some motorcycles,

garden equipment, generators, snowmobiles

(can be liquid cooled)

OEMs Husqvarna, Stihl, Echo,

Shindaiwa, Poulan-Weedeater, Suzuki,

Yamaha, Kawasaki, Bombardier

Applications of 2T Engines

Two-Stroke Cycle Engine Oils (Also Known as: 2T, 2-Cycle)

Difference? TCW Versus Non-TCW (1)

Lubrication in Outboards Versus Non-Outboards

Outboards (TCW, water-cooled)

Outboard motor operation

Long operation periods

High loads

Constant throttle

ASHLESS additives are used to prevent accumulation of ash

deposits in crown of piston and combustion chamber

Ash-containing additives are NOT used so as to avoid:

Deposit accumulation

Preignition

Plug fouling

Detonation

Difference? TCW Versus Non-TCW (2)

Lubrication in Outboards Versus Non-Outboards

Non-outboard (non-TCW, air-cooled)

Non-outboard motor operation

Transitional duty cycles

Fluctuating engine temperature

Higher temps at piston and piston/cylinder interface

ASH-CONTAINING additives use metallic detergents which

have higher thermal stabilities

Ash deposits left from combustion of ash-containing

additives:

Dislodge by thermal expansion/contraction of piston

Exit through exhaust gases

Global 2T Oil Volumes

Globally: ~122,000,000 gallons

North America: ~22,000,000 gallons

Europe: ~20,000,000 gallons

Latin America: ~15,000,000 gallons

Asia/Pacific: ~65,000,000 gallons

Specifications for

Two-Stroke Cycle Engine Oils

Specs for air-cooled 2T

Specs for water-cooled 2T

Air-Cooled Specifications and

Performance Levels

American Petroleum Institute (API): TC

Japanese Automotive Standards Organization

(JASO): FA, FB, FC, FD*

Thailand Industrial Standards Institute (TISI)

International Standards Organization (ISO):

EGB, EGC, EGD <EGE>

OEM levels: Piaggio, Husqvarna, Stihl

*Available by year-end 2001

API TC

Air-Cooled 2T Engine Oil Spec

API TC

Lubricity test: Yamaha CE50S

Detergency test: Yamaha Y350

Pre-ignition: Yamaha CE50S

A formal process for approvals was never adopted

Currently highly recognized performance level for oil marketers

worldwide

During 1998 ASTM meeting, an informal poll showed overwhelming

support for API TC category

Y350 detergency test is now officially available for testing

Severity shift since 1996, ring sticking problems

A new reference oil was adopted by ASTM

Long-term goal is to replace Y350 detergency test

JASO 2T Air-Cooled Specification

Universal acceptance of JASO standards

Chainsaw manufacturers require further

discrimination between good and poor oils

Chainsaw manufacturers modified detergency test of

JASO to run longer, with higher minimum passing

index

(JASO FC + 3 hour detergency test)

Lubricity, smoke and exhaust port blocking not changed

Led to global standard ISO/DIS 13738

specifications for two-stroke cycle gasoline engine

oils categories EGB, EGC and EGD

Tests Evaluation Test Method Measurement

Lubricity Seizure

Ring scuffing

Engine: HONDA DIO AF27

4000 rpm, WOT

Fuel/oil ratio = 50:1

Shut off cooling air at 160C

Initial torque

T plug = 200C

Torque drop from 200C to

300C of T plug

Detergency Ring sticking

Deposit formation in

combustion chamber and

on piston

Engine: HONDA DIO AF27

6000 rpm, WOT, T Plug = 235-245C

Fuel/oil ratio = 100:1

One hour

Weighted merit rating

(JPI-5S-34-91)

Smoke Exhaust smoke Engine: SUZUKI SX800R

Fuel/oil ratio = 10:1

Load 670W at 50 Hz after no load at

50 Hz for 20 minutes

Peak smoke level at 370W at

50 Hz by a smoke meter

Exhaust

System

Blocking

Carbon formation in

exhaust system

Engine: SUZUKI SX800R

3600 rpm

Fuel/oil ratio = 5:1

Cyclic load is applied

Load 750

15W at Texh = 370C

Off the load at Texh = 330C

One cycle: 1.5

0.75

minutes

Total running time (minutes)

until intake manifold pressure

reaches to 2.0 KPa

JASO M345-93

2T Engine Oil Tests

JASO 2T Air-Cooled Specification

JASO/ISO Specifications

Nomenclature

JASO FA, FB, FC, FD*

ISO-L-EGB, EGC, EGD

Approval system

JASO on-file registration administered and maintained by

the Petroleum Association of Japan (PAJ)

ISO self-certification

*Available by year-end 2001

JASO/ISO Test Method JASO FA FB / EGB FC / EGC FD / EGD ISO-L-EGE

Lubricity M340-92 90 minimum 95 minimum 95 minimum 95 minimum ???

Stihl test ???

Detergency M341-92 80 minimum 85 minimum 95 minimum

CEC L-79-T-97

1

125 minimum 125

CEC L-77-95

2

REF

Initial Torque M340-92 98 minimum 98 minimum 98 minimum 98 minimum ???

Smoke M342-92 40 minimum 45 minimum 85 minimum 85 minimum ???

Exhaust Blocking M343-92 30 minimum 45 minimum 90 minimum 90 minimum

CEC L-77-95

2

REF

Results are compared to JASOs reference oil, and an index is determined; reference oil is JATRE 1

1

ISO-L-EGD detergency test (CEC L-79-T-97) is 3 hour duration, 50:1 fuel:oil ratio; reference oil is JATRE 2

2

ISO-L-EGE requirements Piaggio proposal; reference oil is Piagio reference oil

JASO/ISO 2T Air-Cooled Specification

Comparison of ISO and JASO 2T Standards

Drivers for Future ISO Spec

Move away from motorcycle-based JASO

requirements

Focus on HIGHER PERFORMANCE

Chainsaws, snowmobiles, PWCs and highly

tuned motorcycles

Need for more severe, longer duration detergency

requirement beyond the JASO/ISO EGD level

STIHL keep low smoke attributes, but move away

from high-PIB formulations to avoid reduced lubricity

protection due to high temperature decomposition of

PIB

Future 2T Air-Cooled Engine Oil Specification

New Proposed ISO Category - ISO EGE

Chainsaws/snowmobiles/hp motorcycles need performance

beyond JASO and ISO EGD

Improvement beyond ISO EGD in detergency and lubricity

Proposed ISO EGE may include the following tests:

Detergency Piaggio hexagon test (CEC L-77-X-95)

Lubricity STIHl chainsaw (CEC PL-086 group formed

to investigate)

Test equipment is available to Chevron Oronite for product

development

JASO smoke requirement may be included

OEMs may drive this to be synthetic only via performance

targets

Test Performance Measured Pass/Fail Criteria

Yamaha CE-50S Preignition caused by

combustion chamber

deposits

No more major preignitions than last reference in same

test stand

Yamaha CE-50S Lubricity at ring and

cylinder/piston

Mean torque drop less than or equal to 3259 lubricant run

in same test

OMC 40 hp Deposit and wear control on

pistons, ring, and cylinders

Average piston deposits and ring sticking as good or

better than reference

Spark plug fouling: no more than reference oil + 1

Exhaust port blocking: not more than +10% than

reference oil

Preignition: No more than reference

OMC 70 hp Deposits and wear control

using fuel predisposed to

ring sticking

Regression line drawn through low and high reference

oils:

- Candidate ring sticking must equal or exceed line

- Candidate piston deposits must equal or exceed line

Mercury 15 hp Ring sticking

Piston and ring scuffing

Cold start spalling

No ring sticking failures in first 100 hours

Piston and ring scuffing within allowable limit

Piston pin bearing meet mercury requirements

NMMA TC-W3 Engine Tests

NMMA TC-W3 Additional Tests

Bench test requirements:

Rust

Fluidity/miscibility

Filterability

Compatibility

Future Outboard Engine Oils

Increasing demand for environmental friendliness:

Leaner oil: Fuel ratios

Oils with lower environmental impact

Direct fuel injection (DFI, Orbital, Ficht)

Catalytic converters

Four-stroke engines

NMMA has organized a subcommittee to investigate potential

specification requirements for 4T OBM oils

2-T Versus 4-T Engine Advantages

Lower Bulk Volume, Internal Size Lower Weight

Nearly 20% of 4-T Engine Weight is Due to the Valve Train, Which is

Absent in a Conventional 2-T Engine

Overall, a 2-T Engine May Be 40-50% Lighter Than a 4-T Engine of

Comparable Power

Lower Cost

Higher Reliability Less Components

(Valves, Camshaft, Drive Gears, Etc)

Greater Speed Potential No Inertia Derived Valve Float

Problems Breathing Limitations Cap Engine Speed Between

16-20,000 rpm

Improved Torque Response and Smoothness

Less Torque Fluctuations With 1 Power Stroke

Per Revolution

Combustion Instability Scavenging Changes Over

Powerband

High Exhaust Noise Exhaust Tuning Improves Charge

Delivery and Trapping Efficiency, But Increases Exhaust

Pressure Pulses

2-T Engine Disadvantages

High Hydrocarbon (HC) Emission

Due to Short Circuiting of

Fresh Charge (~30%) During

Scavenging Process

High Fuel Consumption

Overlapping Periods of Open

Inlet and Exhaust Ports

Eliminated With DFI Systems

2-T Engine Disadvantages

High Thermal Loading

Twice as Frequent Heat Release

Many Small 2-T Engines Are Air-Cooled

Engines Set to Run Under Fuel-Rich Conditions (30%

Excess Fuel) Use Fuel as Coolant

Reputation and Public Perception Noisy, Smelly,

Dirty, Fuel Starved, Cheap, Unreliable.

Challenges of Small Engine Market

Emissions

Emissions/Government mandates

New U.S. regulations reduction of hydrocarbon emissions from

outboards by 25% of current levels

by 2006

California lawn and garden equipment emission reductions

tightening every couple of years

Regulations in Europe and Asia are dictating changes in 2T

hardware

Governments in Asian countries have pushed to reduce smoke

emissions from 2T engines (JASO, TISI)

Challenges of Small Engine Market

OEM efforts to meet these challenges:

Direct Fuel Injection (DFI)

Mercury marine (Orbital) and OMC (Ficht)

Polaris introduced Ficht DFI for PWC (Genesis)

Bombardier to introduce orbital system

Honda (Japan) introduced DFI motorcycle in 1998

Yamaha introducing their HPDI system for outboards

4-Stroke Engines

Mercury marine to increase presence of 4T outboards (API SH)

Yamaha outboards to dramatically increase 4T usage

Honda to switch motorcycles from 2T to 4T by 2002

Catalytic Converters

Mandatory in some Asian markets

Husqvarna E-tech engine/other lawn and garden OEMs to

follow suit

Honda to commercialize 2T motorcycle with exhaust emission control system

Chevron Oronite 2T Air Cooled

Products

OLOA 9362

A low-ash performance additive package that demonstrates superior detergency and

dispersancy in both low-smoke and traditional air-cooled two-stroke cycle engine

applications.

OLOA 9362 was developed to exceed the high performance demands of ISO-L-EGD as

well as the proposed ISO-L-EGE category, TISI, API TC, and is fully cascadable down to

JASO FB.

Extensively tested in various severe OEM tests, such as the Piaggio Hexagon

detergency test as well as the Husqvarna 242 detergency test.

OLOA 9357

A low-ash performance additive package that demonstrates superior detergency and

dispersancy in both low-smoke and traditional air-cooled two-stroke cycle engine

applications.

OLOA 9357 provides high performance demands of ISO-L-EGD as well as the proposed

ISO-L-EGE category, TISI, API TC, and is fully cascadable for all ISO and JASO 2T

categories.

Used as the additive package in various OEM oils.

Extensively field tested in various applications

Chevron Oronite 2T Water Cooled

Products

OLOA 9335

Incorporates new technology for deposit control performance.

Low color, no molybdenum

Better low temperature detergency

Lower additive viscosity for ease of handling.

OLOA 9333

Unique molybdenum based technology

Better high temperature detergency

Based on OR 71591, TC-W3 detergency reference oil technology.

OLOA 340R

Historically, strongest player as NMMA TC-WII @ 9.35 vol.%

Fighting grade TC-W3 @ 11.3 vol.%

ISO is considering a proposal based on JASO

specification to be incorporated in ISO system

Japanese OEMs report no problems with JASO

specification

4T Motorcycle Update

4T Motorcycle JASO Activities

Background 4T Versus PCMO

Scooters

Oil primarily for crankcase lubrication

Motorcycles

Integrated transmission, uses

engine oil as a transmission fluid

Engine oil interacts with the wet

clutch in addition to lubricating

the gears

Clutch must provide adequate

friction to maintain proper driveability

4T Motorcycle JASO Activities

Background 4T Versus PCMO

Volatility more critical due to

Higher operating temperatures

Higher oil consumption

Need for improved oxidation performance

Temperatures may exceed 150C

Shear stability critical for gear durability

Proper VII selection

Oil shear down in transmission

SAE 10W-30 minimum viscosity grade

Low friction (fuel efficient) oils may hinder wet clutch performance

Clutch slipping may cause poor driveability

Power loss and starting problems

High fuel dilution increased wear severity

Test Item Performance Criteria Test Procedure

Sulfated Ash (Mass %) 1.2 Maximum JIS K 2278-85

Evaporation Loss (Mass %) 20 Maximum JPI-5S-41-93

Foaming Tendency

Seq. I

Seq. II

Seq. III

10/0

50/0

10/0

JIS K 2518

Shear Stability

Kv (100

o

C) After Test (cSt)

XW-30

XW-40

XW-50

9.0 Minimum

12.0 Minimum

15.0 Minimum

JPI-5S-29-88

High Temperature High Shear Viscosity

(mPas) 2.9 Minimum

JPI-5S-36-91

JASO T 903-98

Physiochemical Properties of JASO 4T MC Oils:

4T Motorcycle JASO Activities

Specifications Categories

API SE, SF, SG, SH, SJ, and Future Categories

ILSAC GF-1, GF-2 and Future Categories

ACEA A1, A2, A3, and Future Categories

CCMC G-4 and G-5

JASO T 903-98

Performance Classification Standards Required

for JASO 4T MC Oils:

4T Motorcycle JASO Activities

Classification

Rated Parameter MA MB Test Procedure

Dynamic Friction Index = 1.45 <1.45

Static Friction Index = 1.15 <1.15 JASO T 904-98

Stop Time Index = 1.55 <1.55

A candidate oil that does not meet even one of the

three indexes of MA shall be classified as MB

JASO T 903-98

Performance Classification of JASO 4T MC Oils:

4T Motorcycle JASO Activities

Chevron Oronite 4T MCO Products

OLOA 9364 and OLOA 9364A are Chevron Oronite new additive

technology developed specifically for 4T motorcycle gasoline

engines providing step out performance compared to PCMO

technology.

OLOA 9364 was developed as a cascadable additive system which

can be applied to the wide range of 4T MC performance criteria's.

OLOA 9364A was developed for premium 4T motorcycle applications.

OLOA 9364 and 9364A technology has demonstrated excellent field

performance in small engine 4T applications.

You might also like

- The Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?From EverandThe Death of Reliability: Is it Too Late to Resurrect the Last, True Competitive Advantage?No ratings yet

- Lagermeister XXL GBDocument2 pagesLagermeister XXL GBsureshNo ratings yet

- Pall Influence of Water On BearingDocument6 pagesPall Influence of Water On BearingJon CarbonNo ratings yet

- 2935 0412 10 - Rotoglide - ENDocument1 page2935 0412 10 - Rotoglide - ENNicholas Muronda100% (1)

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Document4 pagesPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbNo ratings yet

- ANALEX PQL Datasheet PDFDocument2 pagesANALEX PQL Datasheet PDFmaye palominoNo ratings yet

- Mobil Serv Lubricants Analysis Guide 2 PDFDocument20 pagesMobil Serv Lubricants Analysis Guide 2 PDFFajar EkoNo ratings yet

- Crushing - GrindingDocument118 pagesCrushing - GrindingHarrison Antonio Mira NiloNo ratings yet

- Presentation On Dragline NEWDocument17 pagesPresentation On Dragline NEWVivek Raj0% (1)

- R9800Document12 pagesR9800tugu_tgNo ratings yet

- LSG007 - Automated System DesignDocument6 pagesLSG007 - Automated System DesignwilmerNo ratings yet

- Investmech (Oil Analysis For PMM) TN R0.0Document49 pagesInvestmech (Oil Analysis For PMM) TN R0.0Santiago Solorzano ValenciaNo ratings yet

- PC 3000-6 PDFDocument8 pagesPC 3000-6 PDFDashzeveg BayrsaikhanNo ratings yet

- Nuevos Productos ShellDocument1 pageNuevos Productos ShellCara GutierrezNo ratings yet

- Iso 3448Document1 pageIso 3448Corina StanculescuNo ratings yet

- Shell Albida EMS2Document1 pageShell Albida EMS2Muhammad Haris BaigNo ratings yet

- 01.03.01 Coolant TR0199991209109 - enDocument18 pages01.03.01 Coolant TR0199991209109 - enEbied Yousif AlyNo ratings yet

- Drive Coupling SKFDocument19 pagesDrive Coupling SKFFrank MwafulirwaNo ratings yet

- Minimac - ProfileDocument40 pagesMinimac - ProfileAnshuman AgrawalNo ratings yet

- CAT Reference Materials (Oil, Fuel, Coolant, Etc)Document1 pageCAT Reference Materials (Oil, Fuel, Coolant, Etc)victor.ciprianiNo ratings yet

- Lubricant Properties CalculatorDocument10 pagesLubricant Properties CalculatorAlberico Muratori0% (1)

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- 3 - Pertaabi, 29 November 2021Document28 pages3 - Pertaabi, 29 November 2021Noviandra SallasaNo ratings yet

- Catalina Punta Pluma 7495 HRDocument1 pageCatalina Punta Pluma 7495 HRmilenko CortesNo ratings yet

- General Discussions On Lubricating OilsDocument59 pagesGeneral Discussions On Lubricating OilsHari PurwadiNo ratings yet

- Presentation STLE 2015 v4Document25 pagesPresentation STLE 2015 v4Carlos ZapataNo ratings yet

- SKF TKGR Shaft Grounding Ring Kit: Installation InstructionsDocument2 pagesSKF TKGR Shaft Grounding Ring Kit: Installation InstructionsRoque Huaraya EdwinNo ratings yet

- SEBD0640 OIL and Your EngineDocument50 pagesSEBD0640 OIL and Your EngineariwibowoNo ratings yet

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Document42 pagesTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiNo ratings yet

- Engine Oil MythsDocument2 pagesEngine Oil Mythshpss77No ratings yet

- Planned Maintenance Manual: GEK-75889J SUP. 2, REV. 1Document2 pagesPlanned Maintenance Manual: GEK-75889J SUP. 2, REV. 1ait mimouneNo ratings yet

- Ficha Técnica Cat DEO - 15W40 & 10W30Document2 pagesFicha Técnica Cat DEO - 15W40 & 10W30RhuanNo ratings yet

- Engine LubricationDocument4 pagesEngine LubricationmkNo ratings yet

- KOMATSU Service News FN17006 KOWADocument9 pagesKOMATSU Service News FN17006 KOWAgilar herliana putraNo ratings yet

- Overview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil AnalysisDocument6 pagesOverview of Rotating Disc Electrode (RDE) Optical Emission Spectroscopy For In-Service Oil AnalysisenioleaoNo ratings yet

- LK Series Metering Pump Instruction Manual: Five Boynton Road Hopping Brook Park Holliston, MA 01746 USADocument34 pagesLK Series Metering Pump Instruction Manual: Five Boynton Road Hopping Brook Park Holliston, MA 01746 USAEdgar NercarNo ratings yet

- Consistency Training: Contamination ControlDocument67 pagesConsistency Training: Contamination ControlMaerks KevinNo ratings yet

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoNo ratings yet

- OEM Approval GuideDocument8 pagesOEM Approval GuideEsteban Fernando Meza IbacetaNo ratings yet

- SKF Multilube - Operation Manual PDFDocument32 pagesSKF Multilube - Operation Manual PDFCeliocp PinheiroNo ratings yet

- Shell Rimula R4X BrochureDocument4 pagesShell Rimula R4X BrochureAdiWijayaNo ratings yet

- Cat ElcDocument4 pagesCat ElcDoru IonNo ratings yet

- SOS Kit PDFDocument22 pagesSOS Kit PDFHectorDeJesusNo ratings yet

- Every Ton.: For Mining ApplicationsDocument4 pagesEvery Ton.: For Mining ApplicationsRafaelNo ratings yet

- Recuperacion de CarrierDocument57 pagesRecuperacion de Carrierariel avalosNo ratings yet

- Oil Analysis User GuideDocument20 pagesOil Analysis User GuideHidayatullahNo ratings yet

- Fluid Analysis For Bearing Reliability 1684619066Document30 pagesFluid Analysis For Bearing Reliability 1684619066Alvaro Javier Reyes ParraNo ratings yet

- Test Method Units of Measure Sample Reqd Rush Availability NotesDocument5 pagesTest Method Units of Measure Sample Reqd Rush Availability Notesjuanmanuel_4615958No ratings yet

- Caterpillar - Tablas de Desgaste de Todos Los EquiposDocument1,808 pagesCaterpillar - Tablas de Desgaste de Todos Los EquiposMarcelo RiverosNo ratings yet

- Sis 2.0 PDFDocument4 pagesSis 2.0 PDFDahi Med100% (1)

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- Astm d7720 PDFDocument14 pagesAstm d7720 PDFRodrigo Andres Vallejo Castro100% (1)

- PC5500 SN 15032 Operation and Maintenance ManualDocument527 pagesPC5500 SN 15032 Operation and Maintenance ManualFernando Pérez Sarria100% (1)

- Chem Trend Thermoplastics-Product-Selector-Guide PDFDocument5 pagesChem Trend Thermoplastics-Product-Selector-Guide PDFbap06No ratings yet

- Radial Shaft SealDocument4 pagesRadial Shaft SealPieter van der WaltNo ratings yet

- Clean Oil GuideDocument28 pagesClean Oil GuideAlex VulpeNo ratings yet

- The Premium Industrial Tyre RangeDocument6 pagesThe Premium Industrial Tyre RangewillupowersNo ratings yet

- Kosher Certificate - Mobilgrease FM - Mobil SHC Polyrex 2014 PDFDocument1 pageKosher Certificate - Mobilgrease FM - Mobil SHC Polyrex 2014 PDFangel017No ratings yet

- Engine Oil 15W 40 PDFDocument2 pagesEngine Oil 15W 40 PDFAngela Jackson100% (1)

- Catterpillar LubricantsDocument74 pagesCatterpillar Lubricantsmnowaq100% (1)

- Mobil Planned Engineering Service: This Is Your Legacy This Is Your BrandDocument19 pagesMobil Planned Engineering Service: This Is Your Legacy This Is Your BrandRay Cepeda MenaNo ratings yet

- Waxrex 2405 - Msds - EnglishDocument8 pagesWaxrex 2405 - Msds - EnglishRay Cepeda MenaNo ratings yet

- 3 - Syntetic Pocket GuideDocument9 pages3 - Syntetic Pocket GuideRay Cepeda MenaNo ratings yet

- X - Hydraulic Fluids Electronic HandoutDocument41 pagesX - Hydraulic Fluids Electronic HandoutRay Cepeda Mena100% (1)

- 2 - SyntheticsDocument57 pages2 - SyntheticsRay Cepeda Mena100% (1)

- Atlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDDocument36 pagesAtlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDRay Cepeda Mena100% (5)

- Marcol 82 MSDSDocument7 pagesMarcol 82 MSDSRay Cepeda MenaNo ratings yet

- L200aetx 2007Document75 pagesL200aetx 2007Ray Cepeda MenaNo ratings yet

- Mobilgear 600 XP SeriesDocument3 pagesMobilgear 600 XP SeriesRay Cepeda MenaNo ratings yet

- 2806C-E18+workshop+manual pdf+CATERPILLAR+C18Document192 pages2806C-E18+workshop+manual pdf+CATERPILLAR+C18Jhon Hever Benitez100% (27)

- F200aet 2006Document88 pagesF200aet 2006Ray Cepeda MenaNo ratings yet

- Motor de Moto PDFDocument38 pagesMotor de Moto PDFAnninha Sud AlvesNo ratings yet

- Yamaha Ft50cehdx 2008Document72 pagesYamaha Ft50cehdx 2008Ray Cepeda MenaNo ratings yet

- Yamaha Ft50cehdx 2007Document80 pagesYamaha Ft50cehdx 2007Ray Cepeda MenaNo ratings yet

- F100betl 2004Document78 pagesF100betl 2004Ray Cepeda MenaNo ratings yet

- F100bet 2008Document77 pagesF100bet 2008Ray Cepeda MenaNo ratings yet

- F100betl 2005Document78 pagesF100betl 2005Ray Cepeda MenaNo ratings yet

- 30HMHL 2008Document60 pages30HMHL 2008Ray Cepeda MenaNo ratings yet

- 200aetl 2000Document0 pages200aetl 2000Ray Cepeda MenaNo ratings yet

- Ft50cehdl 2006Document86 pagesFt50cehdl 2006Ray Cepeda MenaNo ratings yet

- Fx1100b-E Fx1100b-E MJ-FX1100B'06Document0 pagesFx1100b-E Fx1100b-E MJ-FX1100B'06Ray Cepeda MenaNo ratings yet

- Fx1100-G Fx1100-G Fx1100-G Fx1100-G: Waverunner FX High OutputDocument0 pagesFx1100-G Fx1100-G Fx1100-G Fx1100-G: Waverunner FX High OutputRay Cepeda MenaNo ratings yet

- F1X1 2006Document0 pagesF1X1 2006Ray Cepeda MenaNo ratings yet

- 200aetl 2003Document0 pages200aetl 2003Ray Cepeda MenaNo ratings yet

- Isuzu Axiom 2002 ManualDocument2,100 pagesIsuzu Axiom 2002 Manualgasman11195% (19)

- 88-02 KA ATV Bayou 220 Manual-SDocument225 pages88-02 KA ATV Bayou 220 Manual-Sjames walker80% (5)

- Telephone: Fax: VAT Registration No.Document4 pagesTelephone: Fax: VAT Registration No.Miguel GutierrezNo ratings yet

- Operational Manual For Mechanical Transplanting of Rice PDFDocument28 pagesOperational Manual For Mechanical Transplanting of Rice PDFDeepali KaduNo ratings yet

- F200F FL200F F200F1 FL200F1: Owner'S ManualDocument104 pagesF200F FL200F F200F1 FL200F1: Owner'S Manualalawnehsaed18No ratings yet

- CâmbioDocument21 pagesCâmbiopaulojfeitoza100% (1)

- MANUAL DE SERVICIO Motor UD CWB459Document319 pagesMANUAL DE SERVICIO Motor UD CWB459bambinounos93% (15)

- Operationmaintenance ManualDocument26 pagesOperationmaintenance ManualRicardo Burgos0% (1)

- 2015 Filtration Catalog - CompressedDocument985 pages2015 Filtration Catalog - Compressedcesarsegura57100% (2)

- Listofproprietar1419unit 7Document44 pagesListofproprietar1419unit 7beta2009No ratings yet

- SsangYong Actyon Service Manual PDFDocument2,172 pagesSsangYong Actyon Service Manual PDFVictor Abel Ovalle Retamal94% (36)

- Yamaha Neo's 50-Service ManualDocument161 pagesYamaha Neo's 50-Service ManualbcnscribdNo ratings yet

- BYD - 473qb 1.5 PDFDocument119 pagesBYD - 473qb 1.5 PDFAnderson Moribe100% (3)

- Maintenance Manuals - New Wheels - HA - 231013 - 121559Document213 pagesMaintenance Manuals - New Wheels - HA - 231013 - 121559Produção PelotasNo ratings yet

- Manual de Mantenimiento D637Document1,025 pagesManual de Mantenimiento D637Augusto Menendez Buitron100% (2)

- HRC - 2008 Cbr1000rr Kit Set-Up ManualDocument85 pagesHRC - 2008 Cbr1000rr Kit Set-Up Manualcicciolaminchia80% (5)

- Dexos1™ Gen 2 Brands - Lista CompletaDocument20 pagesDexos1™ Gen 2 Brands - Lista CompletaRoger ObregonNo ratings yet

- Service Manual US-S 40-3... S 150-3Document100 pagesService Manual US-S 40-3... S 150-3Anonymous 6oskJgq100% (1)

- Pulsar 150 User ManualDocument33 pagesPulsar 150 User ManualEdgar Carreira0% (1)

- Warning: Complete Gearbox With MotorDocument35 pagesWarning: Complete Gearbox With MotorSinaNo ratings yet

- Spec 223 2Document2 pagesSpec 223 2Larry DeemNo ratings yet

- Yamaha 115b 115ADocument261 pagesYamaha 115b 115AAlexandre Oliveira100% (2)

- Compressor Catalogue 2014Document729 pagesCompressor Catalogue 2014volpromtradeNo ratings yet

- Hydraulic Fluids and Lubricants - DanfossDocument48 pagesHydraulic Fluids and Lubricants - DanfossmanjunathNo ratings yet

- Lubricants Comparision Between BrandsDocument6 pagesLubricants Comparision Between BrandsJen Ekx80% (5)

- Pumps Concrete Mayco LS 40 40TD 50TD Manual DataId 18861 Version 2Document140 pagesPumps Concrete Mayco LS 40 40TD 50TD Manual DataId 18861 Version 2fernandojimenezde100% (1)

- Chico Malo PDFDocument242 pagesChico Malo PDFJuan ContrerasNo ratings yet

- Shell Turbo S4 GX 46: Performance, Features & BenefitsDocument3 pagesShell Turbo S4 GX 46: Performance, Features & BenefitsHEENA SHAIKHNo ratings yet

- Service and Maintenance Manual AFPX 513 PDFDocument146 pagesService and Maintenance Manual AFPX 513 PDFManuel Amado Montoya AgudeloNo ratings yet

- Hino J08Document171 pagesHino J08thomascaru94% (31)