Professional Documents

Culture Documents

Poros Edit

Uploaded by

Fahreza Masyudi0 ratings0% found this document useful (0 votes)

75 views31 pagesporos

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentporos

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

75 views31 pagesPoros Edit

Uploaded by

Fahreza Masyudiporos

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 31

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Shafting and Associated Parts

When a man has a vision, he cannot get the power from the vision until he has

performed it on the Earth for the people to see.

Black Elk, Oglala Sioux visionary, as told to John Niedhart.

Image: A crankshaft from an automotive diesel engine.

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Shaft Assembly

Figure 11.1 Shaft Assembly.

(a) Shaft with two bearings at

A and B and two gears with

resulting forces P

1

and P

2

;

(b) free-body diagram of

torque and forces resulting

from assembly drawing; (c)

moment diagram in x-z and

x-y planes; (d) torque

diagram.

Text Reference: Figure 11.1, page 425

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Example 11.1

Figure 11.2 Illustration used in Example

11.1. (a) Chain drive assembly; (b) free-

body diagram of forces; (c) bending

moment diagram.

Text Reference: Figure 11.2, page 427

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Example 11.2

Figure 11.3 Figures used in Example 11.2. (a) Assembly drawing; (b)

free-body diagram.

Text Reference: Figure 11.3, page 430

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Example 11.2 (cont.)

Figure 11.3 Figures used in

Example 11.2. (c) moment

diagram in x-y plane; (d)

moment diagram in x-z

plane; (e) torque diagram.

Text Reference: Figure 11.3, page 430

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Fluctuating Stresses on

Shaft

Figure 11.4 Fluctuating normal and

shear stresses acting on shaft. (a)

Stresses acting on rectangular

element; (b) stresses acting on

oblique plane at angle .

Text Reference: Figure 11.4, page 432

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Soderberg Line for Shear Stress

Figure 11.5 Soderberg line for shear stress.

Text Reference: Figure 11.5, page 433

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Illustration of Eq. (11.29)

Figure 11.6 Illustration of relationship given in Eq. (11.29).

Text Reference: Figure 11.6, page 434

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Example 11.4

Figure 11.7 Section of shaft used in Example 11.4.

Text Reference: Figure 11.7, page 438

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Single Spring-Mass System

Figure 11.8

Text Reference: Figure 11.8, page 440

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Example 11.5

Figure 11.9 Simply supported shaft arrangement used in

Example 11.5.

Text Reference: Figure 11.9, page 443

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Flat Key Assembly

Figure 11.10 Flat key assembly. (a) Cross-

sectional view of assembly of shaft, hub,

and key; (b) three-dimensional view of flat

key.

Text Reference: Figure 11.10, page 445

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Flywheel on Shaft

Figure 11.11 Flywheel with driving (mean) torque T

m

and load

torque T

l

.

Text Reference: Figure 11.11, page 448

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Coefficient of Fluctuation

Type of equipment C

f

Crushing machinery

Electrical machinery

Electrical machinery, direct driven

Engines with belt transmission

Flour milling machinery

Gear wheel transmission

Hammering machinery

Machine tools

Paper-making machinery

Pumping machinery

Shearing machinery

Spinning machinery

Textile machinery

0.200

0.003

0.002

0.030

0.020

0.020

0.200

0.030

0.025

0.030-0.050

0.030-0.050

0.010-0.020

0.025

Table 11.1 Coefficient of fluctuation for various types of equipment [Adapted from

Kents Mechanical Engineers Handbook (1969).]

Text Reference: Table 11.1, page 450

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Example 11.7

Figure 11.12 Load or output torque cariation for one cycle used

in Example 11.7.

Text Reference: Figure 11.12, page 451

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Materials for Flywheels

Material

Performance

index, M

f

,

kJ/kg Comment

Ceramics 200-2000

(compression only)

Brittle and weak in tension.

Eliminate.

Composites: CFRP

a

GFRP

b

200-500

100-400

The best performance. A good

choice

Almost as good as CFRP and

cheaper . Excellent choice.

Beryllium 300 Good but expensive, difficult

to work, and toxic.

High strength steel

High strength aluminum

High strength magnesium alloys

Titanium alloys

100-200

100-200

100-200

100-200

All about equal in

performance. Steal and AL-

alloys cheaper than Mg and Ti

alloys.

Lead alloys

Cast Iron

3

8-10

High density makes these a

good (and traditional) selection

when performance is velocity

limites, not strength limited.

a

Ceramic-fiber reinforced polymer

b

Graphite-fiber reinforced polymer

Table 11.2 Materials for flywheels. [Adapted from Ashby (1992).]

Text Reference: Table 11.2, page 455

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Punch Press

Figure 11.13 Punch Press

Text Reference: Figure 11.13, page 457

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Torque Requirements of Press

Figure 11.14 Torque requirements of mechanical power press. (TDC=top

dead center, BDC=bottom dead center.)

Text Reference: Figure 11.14, page 457

Hamrock, J acobson and Schmid 1998 McGraw-Hill

JENIS POROS

POROS BEBAN :

Beban Tetap dan Beban Berputar

Jenis Pembebanan : lenturan dan geseran

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Hamrock, J acobson and Schmid 1998 McGraw-Hill

POROS TRANSMISI

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Perhitungan Kekuatan poros :

Perhitungan kekuatan terhadap lenturan

Perhitungan kekuatan terhadap tekanan

bidang antara tap dan bantalan

Perhitungan kekuatan terhadap penyaluran

panas

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Perhitungan terhadap lenturan :

Hamrock, J acobson and Schmid 1998 McGraw-Hill

MOMEN INERTIA (I) dan

MOMEN TAHANAN BENDING (Wb)

Hamrock, J acobson and Schmid 1998 McGraw-Hill

MOMEN TAHANAN POLAR

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Hamrock, J acobson and Schmid 1998 McGraw-Hill

Hamrock, J acobson and Schmid 1998 McGraw-Hill

You might also like

- CE ENG HL660,660L, HL665,665L AUG2018 Rev.0 WebDocument4 pagesCE ENG HL660,660L, HL665,665L AUG2018 Rev.0 WebJohn LeonneNo ratings yet

- F3 Maths 2012 1stexam Paper1Document3 pagesF3 Maths 2012 1stexam Paper1YiuhangLeung100% (2)

- IP BookDocument96 pagesIP Booknew mediaNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Northern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderDocument8 pagesNorthern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderSean DolanNo ratings yet

- Design of Transmission ShaftsDocument5 pagesDesign of Transmission ShaftsHadidNo ratings yet

- Shaft Design ProjectDocument14 pagesShaft Design Projectjwm6085% (13)

- Campbell PDFDocument25 pagesCampbell PDFAnonymous d23gWCRQNo ratings yet

- Engineering Vibroacoustic Analysis: Methods and ApplicationsFrom EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Paper Rotor DynamicsDocument12 pagesPaper Rotor DynamicsTony HeNo ratings yet

- Experience With Torsional Vibration at Reciprocating CompressorsDocument14 pagesExperience With Torsional Vibration at Reciprocating CompressorsÏmŗäņPŗïņċëNo ratings yet

- Shaft DesignDocument7 pagesShaft DesignRafael ReyesNo ratings yet

- Dictionary of Oil Industry TerminologyDocument79 pagesDictionary of Oil Industry Terminologyniksharris100% (22)

- Hydrodynamic and Hydrostatic BearingsDocument31 pagesHydrodynamic and Hydrostatic BearingsCharles_DNo ratings yet

- Design of Shaft PDFDocument5 pagesDesign of Shaft PDFAnonymous oTrMzaNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- OHS Policies and Guidelines (TESDA CSS NC2 COC1)Document1 pageOHS Policies and Guidelines (TESDA CSS NC2 COC1)Anonymous fvY2BzPQVx100% (2)

- 12 New Trends in ManagementDocument18 pages12 New Trends in ManagementSaqib IqbalNo ratings yet

- Campbell Diagram: in RotordynamicsDocument2 pagesCampbell Diagram: in RotordynamicslauracarrionNo ratings yet

- Bulk Deformation Processes - ManufacturingDocument107 pagesBulk Deformation Processes - ManufacturingsengcanNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Report U Ditch RMIDocument25 pagesReport U Ditch RMIDevy ApriyaniNo ratings yet

- Implementing Product ManagementDocument156 pagesImplementing Product ManagementJyoti MohantyNo ratings yet

- Design Concepts For Jib Cranes 1Document12 pagesDesign Concepts For Jib Cranes 1sankalpNo ratings yet

- Classic Text Messages Morning GreetingsDocument2 pagesClassic Text Messages Morning GreetingsDhamukarthikeyanNo ratings yet

- Failure Prediction For Loading StaticDocument31 pagesFailure Prediction For Loading StaticAlexDiazNo ratings yet

- Bridge Abutment Design ExampleDocument10 pagesBridge Abutment Design Exampleloyalmate100% (3)

- Week 5 - Creativity in ResearchDocument4 pagesWeek 5 - Creativity in ResearchD Barik100% (1)

- Metal-Forming Machines PDFDocument31 pagesMetal-Forming Machines PDFdaha333No ratings yet

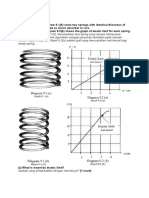

- EM1 631 1998 Resortes Materia HamrockDocument20 pagesEM1 631 1998 Resortes Materia HamrockCIM VLPSONo ratings yet

- HamrockDocument497 pagesHamrockrevandifitroNo ratings yet

- Hydrostatic Bearing SystemsDocument71 pagesHydrostatic Bearing Systems1mmahoneyNo ratings yet

- 2023 - Paku Keling - KuliahDocument68 pages2023 - Paku Keling - KuliahHusni FadilNo ratings yet

- Group 4 Project ReportDocument8 pagesGroup 4 Project ReportFurqan AhmadNo ratings yet

- Failure Prediction For Static LoadingDocument22 pagesFailure Prediction For Static LoadingthirumalaikumaranNo ratings yet

- FME Ch11Document21 pagesFME Ch11Ahmad O KhasawnehNo ratings yet

- Optimum Strength Ratio of Hysteretic DamperDocument12 pagesOptimum Strength Ratio of Hysteretic DamperÁngelDeJesúsLópezPérezNo ratings yet

- Main ShaftDocument7 pagesMain Shaftcosta59dac9242No ratings yet

- Design of ShaftDocument5 pagesDesign of ShaftAnonymous oTrMzaNo ratings yet

- Basic MechanicalDocument18 pagesBasic MechanicalSundar SivamNo ratings yet

- Chapter 19-23 EHL Elliptical Conjunctions - ThermoHDL & ThermoEHLDocument86 pagesChapter 19-23 EHL Elliptical Conjunctions - ThermoHDL & ThermoEHLsatoNo ratings yet

- Chapter 5 - Friction Devices - Theory of Machines - Part 1Document17 pagesChapter 5 - Friction Devices - Theory of Machines - Part 1Sandip GhoshNo ratings yet

- CE297 Ch7Document8 pagesCE297 Ch7madhes4everNo ratings yet

- Aerodynamic Analysis of Morphing Blade For Horizontal Axis Wind TurbineDocument8 pagesAerodynamic Analysis of Morphing Blade For Horizontal Axis Wind TurbineIAEME PublicationNo ratings yet

- FME Ch12Document31 pagesFME Ch12raumil123No ratings yet

- DC Machine Power StagesDocument20 pagesDC Machine Power StagesNoel Joseph TobsNo ratings yet

- Linear Aerodynamic Wing DesignDocument18 pagesLinear Aerodynamic Wing DesignAshutosh VermaNo ratings yet

- Linear Aerodynamics VLM Wing DesignDocument22 pagesLinear Aerodynamics VLM Wing DesignAshutosh VermaNo ratings yet

- Calculate Shear Forces and Bending MomentsDocument2 pagesCalculate Shear Forces and Bending MomentsAhmad RidzuwanNo ratings yet

- Surface Durability of Spur and Helical Gears - KHK GearsDocument12 pagesSurface Durability of Spur and Helical Gears - KHK GearsKalipse FerreiraNo ratings yet

- Sheet Metalworking: ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/eDocument38 pagesSheet Metalworking: ©2007 John Wiley & Sons, Inc. M P Groover, Fundamentals of Modern Manufacturing 3/eadvancetenNo ratings yet

- Section: R Assignment No. Date of Assignment - /9/2015 Date of Submission - /9/2015Document3 pagesSection: R Assignment No. Date of Assignment - /9/2015 Date of Submission - /9/2015Bharat SharmaNo ratings yet

- Experimental Thermal and Fluid Science: Kazumasa Ameku, Baku M. Nagai, Jitendro Nath RoyDocument8 pagesExperimental Thermal and Fluid Science: Kazumasa Ameku, Baku M. Nagai, Jitendro Nath RoyBhagyashree KadaleNo ratings yet

- Helical Pipe Heat Exchanger Modeling FEADocument15 pagesHelical Pipe Heat Exchanger Modeling FEAUsama ArifNo ratings yet

- Elasticity QuizDocument5 pagesElasticity QuizTuck Diery0% (1)

- CH 9 WeldingDocument18 pagesCH 9 WeldingHazim KhalilNo ratings yet

- Practice Problems 14: Influence LineDocument8 pagesPractice Problems 14: Influence LineMikhael Wakin RodriguezNo ratings yet

- Fatigue analysis and endurance limit determinationDocument12 pagesFatigue analysis and endurance limit determinationSon TranNo ratings yet

- 11.a.ii - ME03031 QA 1Document22 pages11.a.ii - ME03031 QA 1Bakkiya Raj100% (1)

- Ch16 Sheet Metal Forming HODocument12 pagesCh16 Sheet Metal Forming HOChristianSchenkelNo ratings yet

- Design of Elements Machine, Bearing, Shaft, Spur Gear and Others, Superficie Profile, Lubrication, FrictionDocument31 pagesDesign of Elements Machine, Bearing, Shaft, Spur Gear and Others, Superficie Profile, Lubrication, FrictionIván DasimuNo ratings yet

- Sliding Contact Bearings - DmeDocument47 pagesSliding Contact Bearings - DmeSumitNo ratings yet

- FME3 Ch18Document25 pagesFME3 Ch18Iván DasimuNo ratings yet

- Structural Analysis of NAB Propeller Replaced With Composite MaterialDocument5 pagesStructural Analysis of NAB Propeller Replaced With Composite MaterialIJMERNo ratings yet

- UN 9252-06 Part 1-UD-AU-000-EB-00020 PDFDocument7 pagesUN 9252-06 Part 1-UD-AU-000-EB-00020 PDFManjeet SainiNo ratings yet

- Manifest Merger Debug ReportDocument14 pagesManifest Merger Debug ReportRam PankhaniyaNo ratings yet

- 7 Robert Boyle and Experimental Methods: © 2004 Fiona KisbyDocument8 pages7 Robert Boyle and Experimental Methods: © 2004 Fiona Kisbydaveseram1018No ratings yet

- Update CV KhanDocument2 pagesUpdate CV KhanqayyukhanNo ratings yet

- Final AnswersDocument4 pagesFinal AnswersAnshul SinghNo ratings yet

- Unsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan PielichowskiDocument2 pagesUnsaturated Polyester Resins: Chemistry and Technology: Piotr Penczek (U) Piotr Czub Jan Pielichowskiae0011979No ratings yet

- AN-029Wired Locker Access Control ENDocument13 pagesAN-029Wired Locker Access Control ENpetar petrovicNo ratings yet

- Academic SummaryDocument4 pagesAcademic SummaryJacqui PendergastNo ratings yet

- ARHITECTURA Si FOCULDocument282 pagesARHITECTURA Si FOCULTheodor DinuNo ratings yet

- 2d3d Opal Card Vending Machine ManualDocument40 pages2d3d Opal Card Vending Machine ManualbsimonopalNo ratings yet

- Openroads Designer User ManualDocument112 pagesOpenroads Designer User ManualNilay BhavsarNo ratings yet

- Cooperating Sequential Processes (Dijkstra) - PaperDocument74 pagesCooperating Sequential Processes (Dijkstra) - PaperCole AroraNo ratings yet

- Order Details for Order #10105Document2 pagesOrder Details for Order #10105Mohamed HarbNo ratings yet

- Present Environment and Sustainable Development - Annual Review Report 2015Document7 pagesPresent Environment and Sustainable Development - Annual Review Report 2015catalinlungeanu758No ratings yet

- Personal Data Form: World English Placement Test Package Photocopiable © 2011 Heinle, Cengage LearningDocument2 pagesPersonal Data Form: World English Placement Test Package Photocopiable © 2011 Heinle, Cengage Learningadri shimizuNo ratings yet

- NASA: 2202main COL Debris Boeing 030121Document9 pagesNASA: 2202main COL Debris Boeing 030121NASAdocumentsNo ratings yet

- Adolescent InterviewDocument9 pagesAdolescent Interviewapi-532448305No ratings yet

- Business Conclave - Concept DesignDocument3 pagesBusiness Conclave - Concept DesignSajal GuptaNo ratings yet

- Economics and Its NatureDocument4 pagesEconomics and Its NatureElrey IncisoNo ratings yet

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocument8 pagesPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniNo ratings yet