Professional Documents

Culture Documents

5 Crystallization Mechanism

Uploaded by

Sarif NazarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 Crystallization Mechanism

Uploaded by

Sarif NazarCopyright:

Available Formats

SUPERSATURATION

NUCLEATION

CRYSTAL GROWTH

CRYSTAL

Non equilibrium

Equilibrium

NUCLEATION

SPONTANEOUS ARTIFICIAL

Agitation

Mechanical shock

Friction

Electric/magnetic field

Sonic/ultrasonic irradiation

Etc.

How dos nucleation occur?

Metastable zone width for KCl-water system

The classical theory of nucleation assumes that clusters are

formed in solution by an addition mechanism:

A + A A

2

A

2

+ A A

3

A

3

+ A A

4

. . . . . . . . . . .

A

n-1

+ A A

n

(critical cluster)

that continues until a critical size is reached

(n = tens to thousands)

CLASSICAL THEORY OF NECLEATION

The overall excess free energy, AG, between a small solid particle

of solute (assumed to be a sphere of radius r) and the solute in

the solution is defined as:

V S

G G G A + A = A (1)

AG

S

: surface excess free energy, i.e. the excess free

energy between the surface of the particles and

the bulk of the particle)

where

AG

V

: volume excess free energy, i.e. the excess free

energy between a very large particle, r = , and

the solute in solution.

AG

S

is a positive quantity and is proportional to r

2

. In a

supersaturated solution AG

V

is a negative quantity and is

proportional to r

3

.

v

G r r G A + = A

3 2

3

4

4 t t

(2)

AG

v

: free energy change of the transformation per

unit volume (a negative quantity)

where

: surface energy, i.e. interfacial tension between

the developing crystalline surface and the

supersaturated solution in which it is located

The two terms on the right-hand side of eq. (2) are of opposite

sign and depend differently on r, so AG passes through a

maximum.

This maximum value, AG

crit

, corresponds to the critical nucleus,

r

c

. For spherical cluster, it is obtained my maximizing eq. (2),

setting d(AG)/dr = 0:

( )

0 4 8

d

d

2

= A + =

A

v

G r r

r

G

t t

v

c

G

r

A

=

2

Where AG

v

is a negative quantity. From eqs. (2) and (3):

( )

3

4

3

16

2

2

3

crit

c

v

r

G

G

t t

=

A

= A

(3)

(4)

Particles smaller than r

c

will dissolve, or evaporate if the

particle is a liquid in a supersaturated vapor, because only in

this way can the particle achieve a reduction in its free energy.

Similarly, particles larger than r

c

will continue to grow.

Free energy diagram for nucleation

The rate of nucleation, B

0

, e.g. the number of nuclei formed

per unit time per unit volume, can be expressed in the form of

the Arrhenius type of expression:

|

.

|

\

|

A

=

kT

G

A B exp

0

(5)

where

k : Boltzmann constant = 1.3805 10

-23

J K

-1

A : pre-exponential factor

(theoretical value = 10

30

nuclei/cm

3

s)

The basic Gibbs-Thomson relationship for a non-electrolyte:

kTr

v

S

2

ln =

where

S : supersaturation ratio = c/c

*

v : molecular volume

(6)

v

S kT

v

S kT

r

G

c

v

ln

2

ln 2 2

= = = A

(7)

From eq. (6):

S kT

v

r

ln

2

=

Introducing the above equation into eq. (3) gives:

( ) ( )

2

2 3

2

3

crit

ln 3

16

3

16

S kT

v

G

G

v

t t

=

A

= A

(8)

Introducing eq. (7) into eq. (4) gives:

And from eq. (5) gives:

( )

(

=

2

3 3

2 3

0

ln 3

16

exp

S T k

v

A B

t

(9)

Induction Time for Nucleation of Water Vapor

S Induction time

1.0

2.0 10

62

years

3.0 10

3

years

4.0 0.1 seconds

5.0 10

-13

seconds

In the case of nucleation of water vapor, a critical super-

saturation could be said to exist in the region of S ~ 4.0, but it is

also clear that nucleation would have occurred at any value of S

> 1 if sufficient time had been allowed to elapse.

Effect of supersaturation on the nucleation rate

The rate equation predicts exponential growth once a critical

supersaturation is attained.

In practice, an optimal temperature exists below which the

liquid is too viscous to nucleate and above which molecular

motions prevent crystal formation.

The viscous effects can be incorporated into the rate

equation by taking into account the viscous free energy

( )

(

A

+

=

kT

G

S T k

v

A B

visc

2

3 3

2 3

0

ln 3

16

exp

t

(10)

This was observed by Tamman (1925) for several organic

salts, and Mullin and Leci (1969) for the spontaneous

nucleation of citric acid solutions and is shown in the

following figure.

Spontaneous nucleation in supercooled citric acid solution:

(A) 4.6 kg of citric acid monohydrate/kg of "free" water (T= 62 C)

and (B) 7.0 kg/kg (T= 85 C).

An empirical approach to the nucleation process is described by

Nielsen (1964), expressing a relationship between the induction

period, t

ind

(the time interval between mixing two reacting

solutions and the appearance of crystals) and the initial

concentration, c, of the supersaturation solution:

p

c k t

=

1

ind

(11)

where k : constant

p : number of molecules in a critical nucleus

A foreign substance present in a supersaturated solution is

generally known to reduce the energy required for nucleation.

Nucleation in a heterogeneous system generally occurs at a

lower supersaturation than a homogeneous system.

Partial attraction is possible in a case where the foreign

substance and the crystal have almost identical atomic

arrangement.

It was shown (Preckshot and Brown 1952) that the energy for

nucleus formation was reduced only if the difference in iso-

morphism between the crystal and the foreign particle was

<15%.

For differences >15%, the energy requirements were similar to

that for a homogeneous system.

Secondary nucleation results from the presence of crystals in

the supersaturated solution.

These parent crystals have a catalyzing effect on the

nucleation phenomena, and thus, nucleation occurs at a

lower supersaturation than needed for spontaneous

nucleation.

Although several investigations of secondary nucleation exist,

the mechanisms and kinetics are poorly understood.

Strickland-Constable (1968) described several

possible mechanisms of secondary nucleation:

Initial breeding (crystalline dust swept off a newly

introduced seed crystal)

Needle breeding (the detachment of weak out-growths)

Polycrystalline breeding (the fragmentation of weak

polycrystalline mass)

Collision attrition breeding (a complex process resulting

from the interaction of crystals with one another or with

parts of the crystalline vessel)

FACTORS AFFECTING SECONDARY NUCLEATION

Several factors influence these processes:

(1) the supersaturation,

(2) the rate of cooling,

(3) the degree of agitation, and

(4) the presence of impurities.

The degree of supersaturation is the critical parameter

controlling the rate of nucleation.

The size of the critical nucleus decreases with increasing

supersaturation, thus, the probability of the nuclei surviving

to form crystals is higher.

In general, nucleation rates are enhanced with increasing

supersaturation. However, the nucleation exponent is found

to be lower than that for primary nucleation

Supersaturation

Temperature

The role of temperature in the production of secondary

nuclei is not fully understood.

For several systems, the nucleation rate declined with

increasing temperature for a given supersaturation.

A few contradictory results exist - Genck and Larson (1972)

found a decrease in nucleation rate with increasing

temperature for a potassium nitrate system and increasing

rates with increasing temperature for a potassium chloride

system.

It was shown by Nyvlt (1981) and others that the nucleation

order is not sensitive to temperature variations.

Stirring the solution leads to lower nucleation rates.

However, Sikdar and Randolph (1976) found that the

nucleation rate increased with the degree of agitation for

smaller crystals of magnesium sulfate (8-10 m) the

nucleation rates were independent of the degree of agitation

for larger crystals.

The results of Melia and Moffit (1964a, 1964b) on the

secondary nucleation of potassium chloride are shown in the

following figure; they found that the nucleation rate increases

with supersaturation, and the degree of supercooling and

agitation

Stirring

Dependence of number of secondary nuclei produced on stirrer speed

and supercooling in secondary nucleation of potassium chloride

In general, it was found that a harder material is more

effective in enhancing the nucleation rates.

For example, it was found that a polyethylene stirrer reduced

the nucleation rates by a factor of 4-10, depending on the

agitation

Crystal hardness also affects nucleation behavior a hard,

smooth crystal is less effective.

Irregular crystals with some roughness are generally more

active.

Hardness of the contact material

Effect of agitator speed on secondary nucleation rate

for steel and plastic impellers.

It is well known that a small amount of impurity can

profoundly affect the nucleation rate, however, it is

impossible to predict the effect prior.

The presence of additives can either enhance or inhibit the

solubility of a substance.

Enhanced solubilities would lead to lower supersaturations

and lower growth rates.

The effect of impurities is complex and unpredictable.

Impurity

A general theory for the prediction of nucleation rates does not

exist.

Several correlations based on the power law model have been

found to explain most of the experimental data satisfactorily.

The power law is given by:

n

N

C k B A =

This form is valid if the adsorption layer mechanism is the

source of nuclei.

The nucleation rate in this case is independent of the

suspension concentration.

(no/m

3

.s) (12)

In the industrial crystallizer, most of the nuclei are generated

by contact with the crystallizer environment.

The nucleation rate in this case is a function of the degree of

agitation, the suspension density, and the supersaturation.

( )

n j

T

i

N

C M W k B A =

'

(13)

where W : agitation rate (rpm)

M

T

: suspension density (mass of crystals per volume

of solution).

In some situations an equation that does not include the effect

of agitation is used

( )

n j

T N

C M k B A =

"

In this case may vary with the agitation rate.

"

N

k

(14)

The kinetics for secondary nucleation can be measured either

by measuring the width of the metastable zone, the induction

time, or by counting the number of nuclei formed.

One of the methods for the determination of nucleation rates is

by measuring the maximum possible supercooling that can be

obtained in a saturated solution when it is cooled at different

rates (metastable zone width measurement).

The polythermal experiment (proposed by Nyvlt 1968) is

carried out in a jacketed crystallizer cooled by a circulating

water/ethylene-glycol bath accurate to 0.1 C.

The temperature can be increased or decreased at a constant

rate by a programmed controller.

The crystallizer is fitted with an accurate thermometer 0.1 C

to read the solution temperatures.

A schematic of the apparatus is shown in the following figure.

Schematic diagram of apparatus for

measurement of nucleation rates.

Approximately 200 ml of saturated solution is placed in a

crystallizer and allowed to equilibrate thermally.

The solution is stirred at a constant rate and cooled slowly

until a number of small crystals are formed.

The temperature of the solution is then raised at a very slow

rate until the last crystal disappears.

This temperature is denoted as the saturation temperature, T

s

.

The solution is then heated to a temperature 1 above T

s

and

maintained for 30 min.

The solution is now cooled at a constant rate (r

1

) and the

temperature at which the first crystal appears is noted (T

1

).

The difference between this temperature and the saturation

temperature is denoted as AT

1max

for the cooling rate r

1

.

The experiment is repeated for two different cooling rates.

The growth of a crystal is often described by the change in

some dimension of the crystal with time linear growth rate .

However, crystals are made up of a number of faces that can

grow at different rates.

Therefore, a fundamental expression of the growth rate is the

linear growth rate of a particular face.

This refers to the rate of growth of the face in the direction

normal to the face.

When a linear growth rate is used to describe the growth of an

entire crystal it is describing the increase in some characteristic

dimension of the crystal.

If the crystal was a sphere, the characteristic dimension would

be the diameter and we would express the crystal growth rate

by the increase of the diameter with time.

If the crystal is of another shape, the characteristic dimension

used is usually the second longest dimension.

This can be understood by thinking of what happens when you

pass crystals through screens or sieves. The dimension of the

crystal, which determines if it will pass through a sieve of a

given size, is the second largest dimension rather than the

largest dimension.

This characteristic dimension can be related to the volume and

surface area of the crystal through the shape factor.

Another way of measuring crystal growth rates is through the

measurement of the mass change of the crystal.

The increase in mass with time is often used and can be

directly related to the overall linear growth velocity through

the relation

t

L

G

t

m

A

R

G

d

d

3 3

d

d 1

|

o

|

o

= = =

(1)

where R

G

: increase of mass per unit time per unit

surface area

A : surface area of the crystal

o, | : volume and area shape factors, respectively

: crystal density

L : characteristic dimension

Surface structure of a growing crystal

From an energetic point of view, C is more favorable than B,

and B more favorable than A.

This can be generalized by saying that molecules tend to bond

at locations where they have the maximum number of nearest

neighbors. These are the most energetically favorable sites.

The general mechanism for incorporation of a molecule into a

crystal face is its adsorption onto the surface followed by its

diffusion along the surface to a step (B-type) or kink (C-type)

site for incorporation.

From this explanation you can see why crystals grow in a

layer-by-layer fashion since it is easier for molecules to bond

to an existing step that is spreading over a surface than to

form a new one.

Two-Dimensional Growth Theories

Formation of two-dimensional critical

nucleus on a crystal surface

Molecules will be

continually

absorbing on the surface

diffusing and desorbing.

They also will collide

with each other and

form two-dimensional

aggregates

Burton-Cabrera-Frank (BCF) Model

Development of a growth spiral from a screw dislocation

The relationship between supersaturation and crystal growth:

g

g

C k G A =

g

g g

C K R A =

(length/time) (1)

(mass/time) (2)

and

The power g in the growth equations does not depend on the

form of the equation used and is normally a number between 1

and 2

The constants k

g

and K

g

are temperature-dependent and are

usually fit to the Arrhenius equation to obtain a general

expression for growth rate as a function of temperature.

( ) RT E A k

G g

= exp

(4)

where

A : pre-exponential factor

E

G

: activation energy

The constants in eqs. (1) and (2) can be related to each other

through the expression:

g g

k K

|

o

3 =

(3)

Recirculation apparatus for single crystal growth

500 1000 cm

3

2.5 cm diameter

crystal

Flow apparatus for single crystal growth

Effect of flow rate on the growth rate of single crystal of

potassium aluminum sulfate to dodecahydrate

The methods for measurement of crystal growth kinetics

discussed to this point all involve the growth of a single seed

crystal.

This is clearly different from the environment in an industrial

crystallizer where many crystals are growing in a suspension.

A laboratory method known as a fluidized bed crystallizer,

which attempts to measure the growth rates of a number of

crystals, is shown in the following figure.

Fluidized bed crystallizer; glass tube (1), stock vessel (2), cooler (3),

thermostat (4), centrifugal pump (5), infrared lamp (6), power source

(7), contact thermometer (8), mercury thermometer (9), and stirrer (10)

In this method, solution is circulated through a crystallizer in

which seed crystals are suspended by the flowing fluid.

The flow is such that the crystal will not settle and will not

flow out of the crystallization vessel.

As in single crystal growth experiments, the mass of solute

depositing on the growing crystals must be small enough so

that the system is considered to be at constant supersaturation.

By using seed crystals of the same initial size, the final size and

mass of the crystals can be used to obtain an average growth

rate.

The most common method for obtaining crystal growth

kinetics involving suspensions involves the use of a mixed

suspension, mixed product removal (MSMPR) continuous

crystallizer operating at steady state.

You might also like

- Bub GB YcjFAV4WZ9MC PDFDocument634 pagesBub GB YcjFAV4WZ9MC PDFMax Powel100% (1)

- TalismansDocument5 pagesTalismansMike Cedersköld100% (1)

- The Development of CalculusDocument8 pagesThe Development of CalculusDayse CleodetNo ratings yet

- The Arabic Theory of Astral Influences in Early Modern MedicineDocument19 pagesThe Arabic Theory of Astral Influences in Early Modern MedicineSettemontiErma1No ratings yet

- Elementary Reactor Physics: The Commonwealth and International Library: Nuclear Engineering DivisionFrom EverandElementary Reactor Physics: The Commonwealth and International Library: Nuclear Engineering DivisionNo ratings yet

- Chem Lab Report - Electronic Absorption Spectra of Some Cu ComplexesDocument6 pagesChem Lab Report - Electronic Absorption Spectra of Some Cu ComplexesMiguel Ackah-Yensu93% (14)

- The Golden Age of ScienceDocument17 pagesThe Golden Age of SciencePaulNo ratings yet

- (THBN 19) (Barthel, Van Kooten, Eds.) The Star of Bethlem and The Magi - Interdiscliplinary Perspectives PDFDocument718 pages(THBN 19) (Barthel, Van Kooten, Eds.) The Star of Bethlem and The Magi - Interdiscliplinary Perspectives PDFCvrator MaiorNo ratings yet

- Vemuri Sastri The Doyen in Jaimini ColorDocument5 pagesVemuri Sastri The Doyen in Jaimini ColorSubbuNo ratings yet

- Logic and Set Theory ExamDocument4 pagesLogic and Set Theory ExamskleklNo ratings yet

- Crystallization Crystallization: Prof. V V Basava RaoDocument56 pagesCrystallization Crystallization: Prof. V V Basava RaoIlyas PashaNo ratings yet

- RRRRRR Chido ReactHetExamenOrdinarioJunio2020aDocument4 pagesRRRRRR Chido ReactHetExamenOrdinarioJunio2020aDaniel Moreno CabreraNo ratings yet

- Particle Processing Research: Terry A. Ring Chemical Engineering University of UtahDocument58 pagesParticle Processing Research: Terry A. Ring Chemical Engineering University of UtahOmar Abd ElsalamNo ratings yet

- Paper Nature GosiaDocument4 pagesPaper Nature GosiaAna Paula da LuzNo ratings yet

- CY2301Document11 pagesCY2301Prarabdha SharmaNo ratings yet

- ChE426 Final Exam 2005Document2 pagesChE426 Final Exam 2005احمد الدلالNo ratings yet

- Potenciales de Interacción ElectroquimicoDocument21 pagesPotenciales de Interacción ElectroquimicofadarkNo ratings yet

- Assignment 1Document6 pagesAssignment 1Yi Hong LowNo ratings yet

- Surface Tension Effects on Bubble CoalescenceDocument5 pagesSurface Tension Effects on Bubble CoalescenceCassiana BatistaNo ratings yet

- Reaction Path Bifurcation in An Electrocyclic Reaction Ring Opening of The Cyclopropyl RadicalDocument20 pagesReaction Path Bifurcation in An Electrocyclic Reaction Ring Opening of The Cyclopropyl RadicalAnonymous UYDJtUnNo ratings yet

- Chalker FinalDocument44 pagesChalker FinalMuhammad Shifan JayadiNo ratings yet

- Neutron Log: GS, Sudan Oct. 2005Document24 pagesNeutron Log: GS, Sudan Oct. 2005Awad AlmalkiNo ratings yet

- Solitary Waves and Supersonic Reaction Front in Metastable SolidsDocument30 pagesSolitary Waves and Supersonic Reaction Front in Metastable Solidstestonly261No ratings yet

- Section 6 - General Physics 2 With SolutionsDocument15 pagesSection 6 - General Physics 2 With SolutionspaimoNo ratings yet

- Chap03 5esolns TemplateDocument12 pagesChap03 5esolns TemplateHangyuNo ratings yet

- Makoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesDocument49 pagesMakoto Tsubota - Quantum Turbulence: From Superfluid Helium To Atomic Bose-Einstein CondensatesQMDhidnwNo ratings yet

- Cool FlamesDocument12 pagesCool FlamesQasim IsmailNo ratings yet

- Heterogeneous Nucleation Wetting AngleDocument7 pagesHeterogeneous Nucleation Wetting Anglemarthin_nielsenNo ratings yet

- 2016 Sample Paper 12 Chemistry 02 AnsDocument7 pages2016 Sample Paper 12 Chemistry 02 AnsjrajaNo ratings yet

- Chemical Dynamics of The Formation of The 1,3-Butadiynyl Radical (C H (X) ) and Its IsotopomersDocument14 pagesChemical Dynamics of The Formation of The 1,3-Butadiynyl Radical (C H (X) ) and Its IsotopomersRaj KumarNo ratings yet

- The Kinetics of Silica-Water ReationsDocument17 pagesThe Kinetics of Silica-Water ReationsIbrahim SouleimanNo ratings yet

- Chemistry Matriculation Note SK025 by Vinarti MahmudDocument47 pagesChemistry Matriculation Note SK025 by Vinarti MahmudNurun NajwaNo ratings yet

- 22.01 Fall 2015, Problem Set 7 (Normal Version) : 1 Conceptual/Analytical QuestionsDocument8 pages22.01 Fall 2015, Problem Set 7 (Normal Version) : 1 Conceptual/Analytical QuestionsDANIELA FORERO RAMÍREZNo ratings yet

- Presentation 1Document25 pagesPresentation 1vanithaethirajNo ratings yet

- GR XI Term 2 CHEMISTRY Ans KeyDocument10 pagesGR XI Term 2 CHEMISTRY Ans Keyrohan fernandesNo ratings yet

- Bulk Property EntanglementDocument4 pagesBulk Property EntanglementgejikeijiNo ratings yet

- Chap 03Document33 pagesChap 03echelon12No ratings yet

- Francesca Maggioni and Renzo L. Ricca - Writhing and Coiling of Closed FilamentsDocument16 pagesFrancesca Maggioni and Renzo L. Ricca - Writhing and Coiling of Closed FilamentsVortices3443No ratings yet

- Dekruif Colloidal DispersionsDocument10 pagesDekruif Colloidal Dispersionsparis.hiltonNo ratings yet

- Fly High Group Tuitions Chemistry Test 2Document3 pagesFly High Group Tuitions Chemistry Test 2Manthan RathodNo ratings yet

- TGA Limestone DegradationDocument18 pagesTGA Limestone DegradationTammie HendersonNo ratings yet

- Standard Model Electroweak Theory Lecture Pylos 2002Document158 pagesStandard Model Electroweak Theory Lecture Pylos 2002George PadurariuNo ratings yet

- B.sc. (Hons) Chemistry, Part III Physical Chemistry-IV - CHHT-513 SEM-V (6017)Document6 pagesB.sc. (Hons) Chemistry, Part III Physical Chemistry-IV - CHHT-513 SEM-V (6017)GaichuingamPanmeiNo ratings yet

- Calculating conductivity of natural watersDocument40 pagesCalculating conductivity of natural watersWajid NizamiNo ratings yet

- Transferencia de MasaDocument11 pagesTransferencia de MasaAndrea GomezNo ratings yet

- K /K Against I Is Linear. Figure 8.5 Shows This PlotDocument6 pagesK /K Against I Is Linear. Figure 8.5 Shows This PlotDyah SukmaNo ratings yet

- So = -139.7 J/KT = 298 K∆Go = ∆Ho - T∆So = -18 kJ/mol - (298 K)(-139.7 J/K/mol) = -18 kJ/mol + 41.7 kJ/mol = 23.7 kJ/molSince ∆Go is positive, the reaction is non-spontaneousDocument46 pagesSo = -139.7 J/KT = 298 K∆Go = ∆Ho - T∆So = -18 kJ/mol - (298 K)(-139.7 J/K/mol) = -18 kJ/mol + 41.7 kJ/mol = 23.7 kJ/molSince ∆Go is positive, the reaction is non-spontaneousStephanie MejiaNo ratings yet

- Review of Measuring Methods and Results in Nonviscous Gas-Liquid Mass Transfer in Stirred VesselsDocument8 pagesReview of Measuring Methods and Results in Nonviscous Gas-Liquid Mass Transfer in Stirred VesselsAntonela PortaNo ratings yet

- Simulation of The e Ect of Froth Washing On !otation PerformanceDocument9 pagesSimulation of The e Ect of Froth Washing On !otation PerformanceWilliam AndreasNo ratings yet

- Federal Board HSSC-I Examination Chemistry Model Question Paper (2006Document20 pagesFederal Board HSSC-I Examination Chemistry Model Question Paper (2006Alina Syedd32No ratings yet

- Fluid Dynamics & Thermal Performance of NanofluidsDocument73 pagesFluid Dynamics & Thermal Performance of Nanofluidsmind2008No ratings yet

- ), of A Radioactive Sample Is The Change in Number of Nuclei (N) Divided by TheDocument7 pages), of A Radioactive Sample Is The Change in Number of Nuclei (N) Divided by TheMilescent Rose Juguilon PadillaNo ratings yet

- Magnetoplastic Effect in Nonmagnetic MaterialsDocument8 pagesMagnetoplastic Effect in Nonmagnetic MaterialsSeindahNyaNo ratings yet

- Advanced Extension Award in PhysicsDocument16 pagesAdvanced Extension Award in PhysicsRowena Fletcher-WoodNo ratings yet

- Numerical Model For The Nucleation Growth and Removal of Deoxidation InclusionsDocument8 pagesNumerical Model For The Nucleation Growth and Removal of Deoxidation InclusionsEstéfano Aparecido VieiraNo ratings yet

- Chemical Kinetics and Reaction DynamicsDocument3 pagesChemical Kinetics and Reaction DynamicsShri VidhatriNo ratings yet

- Solid-Gas SeparationDocument13 pagesSolid-Gas SeparationMark LoraNo ratings yet

- Quantum Confinement Controls Photocatalytic Water SplittingDocument3 pagesQuantum Confinement Controls Photocatalytic Water Splittingm_holmes9990No ratings yet

- Modeling and Simulation of Nano-Aluminum Synthesis in A Plasma ReactorDocument15 pagesModeling and Simulation of Nano-Aluminum Synthesis in A Plasma ReactorMuraleetharan_BNo ratings yet

- XI Chemistry Target Paper 2023 (Sir Nasim Zulfiqar)Document5 pagesXI Chemistry Target Paper 2023 (Sir Nasim Zulfiqar)adeel mehmoodNo ratings yet

- Kinetics: Graduate Institute of Ferrous Technology, POSTECH Rongshan Qin (R. S. Qin)Document9 pagesKinetics: Graduate Institute of Ferrous Technology, POSTECH Rongshan Qin (R. S. Qin)Anonymous T02GVGzBNo ratings yet

- Slides - 3Document51 pagesSlides - 3Rahul Pandey100% (1)

- CHE 323 Electrochemisty Problem Set 3-16-17Document2 pagesCHE 323 Electrochemisty Problem Set 3-16-17Zhu Chen ChuanNo ratings yet

- Aguado 2001Document9 pagesAguado 2001Luis M. MolinaNo ratings yet

- Chemical Kinetics 119 Ques!!!Document27 pagesChemical Kinetics 119 Ques!!!elifnazNo ratings yet

- Nuclear, Particle and Many Body PhysicsFrom EverandNuclear, Particle and Many Body PhysicsPhilip MorseNo ratings yet

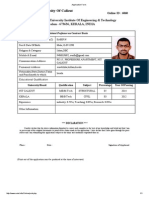

- Item' 2011-2012 (LYG) UG Electri Onics UG Mechani CAL: Year Number of New Titles AddedDocument3 pagesItem' 2011-2012 (LYG) UG Electri Onics UG Mechani CAL: Year Number of New Titles AddedSarif NazarNo ratings yet

- 1Document1 page1Sarif NazarNo ratings yet

- TKM College of Engineering, Kollam-5 Internal Assessment (Series Test) (2016)Document1 pageTKM College of Engineering, Kollam-5 Internal Assessment (Series Test) (2016)Sarif NazarNo ratings yet

- Workshop AttendanceDocument1 pageWorkshop AttendanceSarif NazarNo ratings yet

- SARIF N'S CV FOR ASSISTANT PROFESSOR POSITIONDocument3 pagesSARIF N'S CV FOR ASSISTANT PROFESSOR POSITIONSarif NazarNo ratings yet

- Resched LeDocument2 pagesResched LeSarif NazarNo ratings yet

- Uribapplicationform 22627439Document1 pageUribapplicationform 22627439Sarif NazarNo ratings yet

- Links and ReferencesDocument1 pageLinks and ReferencesSarif NazarNo ratings yet

- Attendance MechaDocument3 pagesAttendance MechaSarif NazarNo ratings yet

- Suhaib Salawdeh ThesisDocument424 pagesSuhaib Salawdeh ThesisSarif NazarNo ratings yet

- Leaflet StabilizationDocument20 pagesLeaflet StabilizationAsmir SofticNo ratings yet

- Curriculum Vitae: Pin:673 601 Kerala IndiaDocument3 pagesCurriculum Vitae: Pin:673 601 Kerala IndiaSarif NazarNo ratings yet

- Ar5 Second Series Question Nov 2016Document1 pageAr5 Second Series Question Nov 2016Sarif NazarNo ratings yet

- New Text DojjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjcumentDocument1 pageNew Text DojjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjjcumentSarif NazarNo ratings yet

- Application For StipendjumDocument2 pagesApplication For StipendjumSarif NazarNo ratings yet

- 1Document1 page1Sarif NazarNo ratings yet

- EulaDocument3 pagesEulaSarif NazarNo ratings yet

- Curriculum Vitae: Pin:673 601 KeralaDocument3 pagesCurriculum Vitae: Pin:673 601 KeralaSarif NazarNo ratings yet

- AreadadffdDocument1 pageAreadadffdSarif NazarNo ratings yet

- Matched ChiChi.Document89 pagesMatched ChiChi.Sarif NazarNo ratings yet

- Layout DrawingDocument18 pagesLayout DrawingSandesh Kumar100% (1)

- Calicut University Institute of Engineering & Technology Thenhipalam - 673636, KERALA, INDIADocument1 pageCalicut University Institute of Engineering & Technology Thenhipalam - 673636, KERALA, INDIASarif NazarNo ratings yet

- Daemon ProcessDocument1 pageDaemon ProcessSarif NazarNo ratings yet

- Matched ChiChi.Document89 pagesMatched ChiChi.Sarif NazarNo ratings yet

- Displacement LRDocument4 pagesDisplacement LRSarif NazarNo ratings yet

- Tutorial 4 ModelDocument1 pageTutorial 4 ModelSarif NazarNo ratings yet

- Review of Literature: 2.1 GeneralDocument4 pagesReview of Literature: 2.1 GeneralSarif NazarNo ratings yet

- AreadadffdDocument1 pageAreadadffdSarif NazarNo ratings yet

- Basasm Mahmoud Blal - RezumatDocument36 pagesBasasm Mahmoud Blal - Rezumatpradeepjoshi007No ratings yet

- Determine Metacentric Height of a Ship ModelDocument2 pagesDetermine Metacentric Height of a Ship ModelsuryavigneNo ratings yet

- String Theory PaperDocument3 pagesString Theory PaperRiad RifaiNo ratings yet

- WW3 World War 3 Predictions and WarningsDocument3 pagesWW3 World War 3 Predictions and WarningsChad BrotzNo ratings yet

- Indian Intellectual HistoryDocument10 pagesIndian Intellectual Historyysaeed7No ratings yet

- MIT8 09F14 Chapter 1Document29 pagesMIT8 09F14 Chapter 1pestaNo ratings yet

- QuizDocument2 pagesQuizshivi08No ratings yet

- Atomic Theory and Periodicity FR Worksheet KEYDocument12 pagesAtomic Theory and Periodicity FR Worksheet KEYsmartohiogirl3No ratings yet

- MKA Physics - 1Document52 pagesMKA Physics - 1vallabhaneni sivasankar80% (5)

- Moon Inharmonious SaturnDocument2 pagesMoon Inharmonious SaturnPhalgun BalaajiNo ratings yet

- 07hydrostatic Forces On Curved SurfacesDocument6 pages07hydrostatic Forces On Curved SurfacesjrklingNo ratings yet

- Science, Technology and Society (Reviewer)Document8 pagesScience, Technology and Society (Reviewer)Irish CostalesNo ratings yet

- Inspirations For Oculus Sword & Backpack RPG Microscope Risus: The Anything RPGDocument2 pagesInspirations For Oculus Sword & Backpack RPG Microscope Risus: The Anything RPGblah234mNo ratings yet

- Aliester Crowley Moon Phase For 1875-10-12 PDFDocument4 pagesAliester Crowley Moon Phase For 1875-10-12 PDFMarcus MacdonaldNo ratings yet

- Introduction to Dimensional Analysis: Part 1Document7 pagesIntroduction to Dimensional Analysis: Part 1tahadostmushtaqNo ratings yet

- Cosmic RaysDocument92 pagesCosmic RaysJTKirk61No ratings yet

- Categorical PropositionDocument19 pagesCategorical PropositionBary PatwalNo ratings yet

- Bennett Explores Object-Oriented Ontology of Harman and MortonDocument10 pagesBennett Explores Object-Oriented Ontology of Harman and Mortontigubarcelos2427No ratings yet

- Motion Along A Straight LineDocument16 pagesMotion Along A Straight LineNorhapidah Mohd SaadNo ratings yet

- The Greatest Mathematicians by Group 2Document7 pagesThe Greatest Mathematicians by Group 2Jaymar JaminNo ratings yet

- Casio W-753-1avDocument4 pagesCasio W-753-1avoksjaerNo ratings yet

- 1306 6352Document204 pages1306 6352unicornmfkNo ratings yet