Professional Documents

Culture Documents

Safety Talk - Pinch Point

Uploaded by

Angel AngeleyeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Talk - Pinch Point

Uploaded by

Angel AngeleyeCopyright:

Available Formats

Safety Talk

Pinch Point

Procon Energie Limited

Safety Talk- Pinch Point

A pinch point is any point at which it is possible for a person or part of a persons body to be caught between moving parts of a machine, or between the moving and stationary parts of a machine, or between material and any part of the machine. A pinch point does not have to cause injury to a limb or body part, although it might cause injury it only has to trap or pinch the person to prevent them from escaping or removing the trapped part from the pinch point.

Safety Talk- Pinch Point

To most of us a pinch doesn't sound too serious. A pinch on the cheek or a friendly pinch for fun is one thing, but the pinches you get on the job are something else.

Safety Talk- Pinch Point

Recently, a worker was crushed to death against a wall by a huge truck that was backing up. That was a pinch point accident.

In another instance, a pair of pliers slipped and pinched a workers hand, which caused a blood blister

Between these two extremes lie hundreds of pinch point situations in industry. And there are just as many examples of injuries sustained because of these pinch points on record.

Safety Talk- Pinch Point

There are many commonplace items that are potential pinch points, like heavy steel doors or heavy covers for bins or hoppers, and often there is no way to guard against these hazards. Care is your only safeguard. Even extension ladders can create serious pinch points; the rungs sliding past each other can catch fingers, hands, and feet

Safety Talk- Pinch Point

Pinch point conditions are one of the most difficult hazards to guard against. For example, lets look at a set of two in-running calendar rolls used to finish cloth or manufacture paper or rubber. The material in the process must reach the in-running rolls to be carried through; no guard can be placed at the immediate point. There are some partial guards on such equipment, but operators must exercise extreme caution and alertness when these rolls are running, which are usually at a very high speed and under considerable pressure.

Safety Talk- Pinch Point

Closely stored 55-gallon steel drums, when moved or handled, create pinch points between each other or the dolly being used to move them. Because the drums are round, they are more difficult to handle and control in many cases.

Here the only protection is care and alertness

Safety Talk- Pinch Point

A little thought will bring to mind the many pinch points (sometimes called nip points) here in our own operation. Let's keep these in mind as we operate even the simplest of tools

You might also like

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Audit Checklist - Material ControlDocument4 pagesAudit Checklist - Material ControlAngel Angeleye100% (3)

- Lone Workers and The Risks of The Hidden WorkforceDocument2 pagesLone Workers and The Risks of The Hidden WorkforceGabriel BolatitoNo ratings yet

- InfoWorks ICM Overview 60 Mins PDFDocument31 pagesInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- JSA PresentationDocument17 pagesJSA Presentationdwivedi10100% (3)

- Slip Trip Fall PreventionDocument9 pagesSlip Trip Fall Preventionmuhammadarifh4486No ratings yet

- Hand Safety Training-FINALDocument37 pagesHand Safety Training-FINALAngel AngeleyeNo ratings yet

- Hand Safety Training-FINALDocument37 pagesHand Safety Training-FINALAngel AngeleyeNo ratings yet

- Audit Checklist - Blasting Painting1Document6 pagesAudit Checklist - Blasting Painting1Angel Angeleye100% (4)

- Mechanical Hazards and Machine SafeguardingDocument19 pagesMechanical Hazards and Machine Safeguardingm_alodat6144No ratings yet

- Examples of How Near Miss Reporting Can Stop AccidentsDocument4 pagesExamples of How Near Miss Reporting Can Stop AccidentsMikaelNo ratings yet

- A Complete Guide To Working at Height Regulations by At-HeightDocument6 pagesA Complete Guide To Working at Height Regulations by At-Heightat-height0% (1)

- Work at HightDocument32 pagesWork at HightMY TEC SUPPORTNo ratings yet

- Fall Protection HandoutDocument1 pageFall Protection HandoutRizki DarmawanNo ratings yet

- MCN 401 Ise Module 4-1Document97 pagesMCN 401 Ise Module 4-1taapseveniaavaniNo ratings yet

- Pinch PointsREV3Document27 pagesPinch PointsREV3MasruriNo ratings yet

- Lathe Operation SafetyDocument1 pageLathe Operation Safetymustafa_staj8367No ratings yet

- Root Cause Analysis Example Near Miss Asphalt Drop FULLDocument9 pagesRoot Cause Analysis Example Near Miss Asphalt Drop FULLnayakya100% (1)

- Behavior Based SafetyDocument51 pagesBehavior Based SafetysixejoNo ratings yet

- Audit Checklist - Material ControlDocument4 pagesAudit Checklist - Material ControlAngel Angeleye100% (1)

- TBT 30 HousekeepingDocument2 pagesTBT 30 HousekeepingfrancisNo ratings yet

- Tables of Flange PDFDocument5 pagesTables of Flange PDFAngel AngeleyeNo ratings yet

- Behavior Safety (Perilaku Keselamatan) : By: Rosdja PurnamaDocument14 pagesBehavior Safety (Perilaku Keselamatan) : By: Rosdja PurnamaMerah PastelNo ratings yet

- 101 SafetyTalk Topics ZetekyDocument21 pages101 SafetyTalk Topics ZetekyMu'az ObadakiNo ratings yet

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Project Quality Plan.Document27 pagesProject Quality Plan.Adeel RazzaqNo ratings yet

- Lifting SafetyDocument1 pageLifting SafetyAaquil RaziNo ratings yet

- Causes & DefinitionsDocument11 pagesCauses & DefinitionsSayed DarwishNo ratings yet

- Lexus Brand BrochureDocument40 pagesLexus Brand Brochurejammypops100% (1)

- Jsa PDFDocument23 pagesJsa PDFIbnu MuariefNo ratings yet

- The Work at Height Regulations 2005: A Brief GuideDocument12 pagesThe Work at Height Regulations 2005: A Brief Guidesyed jeelani ahmedNo ratings yet

- Lifting Operations Risk Assessment Crane Risk AssessmentDocument13 pagesLifting Operations Risk Assessment Crane Risk Assessment9853318441No ratings yet

- Personal Protective Gear Pre-Operational Inspection Safety Device Checks DocumentationDocument2 pagesPersonal Protective Gear Pre-Operational Inspection Safety Device Checks DocumentationChris BonningtonNo ratings yet

- SWP Welder Gas Metal Arc AS560Document2 pagesSWP Welder Gas Metal Arc AS560Amirul Haris100% (1)

- Subject: Work at Height: Unit: Maihar Cement WorksDocument3 pagesSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Slinger Signaller BanksmanDocument88 pagesSlinger Signaller BanksmanAhmed GaballaNo ratings yet

- Respiratory Protective EquipmentDocument19 pagesRespiratory Protective EquipmentTan Khern WeeNo ratings yet

- 2.2industrail HousekeepingDocument16 pages2.2industrail HousekeepingAizm DinaniNo ratings yet

- British Glass - Incident and Near Miss Reporting Guidance (Jan 2015)Document14 pagesBritish Glass - Incident and Near Miss Reporting Guidance (Jan 2015)knabpshoNo ratings yet

- Lathe Machine Safety Operating ProcedureDocument2 pagesLathe Machine Safety Operating ProcedureDominic LibradillaNo ratings yet

- Mixing of Drilling MudsDocument4 pagesMixing of Drilling MudsYashwanth ReddyNo ratings yet

- Investigasi Kecelakaan Kerja - R1Document25 pagesInvestigasi Kecelakaan Kerja - R1manggungNo ratings yet

- The Importance of Near Miss Reporting - What You Need To KnowDocument6 pagesThe Importance of Near Miss Reporting - What You Need To KnowaneethavilsNo ratings yet

- Risk Assessment Procedure: By: Arañez, Raymond John VDocument12 pagesRisk Assessment Procedure: By: Arañez, Raymond John VLast UnknownNo ratings yet

- Working at Height Rescue PlanDocument1 pageWorking at Height Rescue PlanAbbas AsadNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarNo ratings yet

- SP-091-C CNC Router SOPDocument1 pageSP-091-C CNC Router SOPBorislav VulićNo ratings yet

- Safe Use of Oxy Acetylene-Code of PracticeDocument46 pagesSafe Use of Oxy Acetylene-Code of Practicescott2355No ratings yet

- Pocket PDFDocument437 pagesPocket PDFFranko MilovanNo ratings yet

- PC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFDocument363 pagesPC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFCarlos Israel Gomez100% (10)

- SafetyMgt Handouts Topic9Document7 pagesSafetyMgt Handouts Topic9ALyzha Mae LacuestaNo ratings yet

- Eis 28Document4 pagesEis 28Ab AUNo ratings yet

- Hazard IdentificationDocument4 pagesHazard IdentificationsuhailpmNo ratings yet

- Bow Tie Ebook PDFDocument23 pagesBow Tie Ebook PDFasuNo ratings yet

- WHS-42 Safe Operation of Overhead Cranes Procedure1 PDFDocument16 pagesWHS-42 Safe Operation of Overhead Cranes Procedure1 PDFviniciusgdelimaNo ratings yet

- Sample Detailed Estimates PDFDocument9 pagesSample Detailed Estimates PDFJj Salazar Dela CruzNo ratings yet

- Alimak Hek 65 - 32Document5 pagesAlimak Hek 65 - 32Zhoro Boyssan LestaluhuNo ratings yet

- STOP WORK AUTHORITY POLICY in Saudi ArabiaDocument1 pageSTOP WORK AUTHORITY POLICY in Saudi ArabiaaymenmoatazNo ratings yet

- Total Safety ManagementDocument18 pagesTotal Safety ManagementSidhant BudheNo ratings yet

- LOTOTODocument27 pagesLOTOTOKristine FontillasNo ratings yet

- Safety in Engineering IndustryDocument8 pagesSafety in Engineering IndustryzombieNo ratings yet

- Crane-Workclass Englis For EngineeringDocument3 pagesCrane-Workclass Englis For EngineeringDiego RobayoNo ratings yet

- Genie Superlift SOP 003Document27 pagesGenie Superlift SOP 003Mauricio SantanaNo ratings yet

- SOP Module Unloading & StorageDocument1 pageSOP Module Unloading & StorageRahul SahaNo ratings yet

- LOLER Indg290Document4 pagesLOLER Indg290Marky75No ratings yet

- Msds ChlorineDocument9 pagesMsds ChlorinesahilchemNo ratings yet

- Fatigue Risk Management Systems:: A Step-By-Step GuideDocument16 pagesFatigue Risk Management Systems:: A Step-By-Step GuideveeteeNo ratings yet

- Risk Assessment For Confined SpaceDocument5 pagesRisk Assessment For Confined Spaceappu pocom3No ratings yet

- Pinch PointsDocument2 pagesPinch PointsSantos RexNo ratings yet

- Lectura en Ingles Procesos IIDocument5 pagesLectura en Ingles Procesos IIleonardo eliasNo ratings yet

- Pinch PointsDocument1 pagePinch PointsnadhabindhuNo ratings yet

- Machine Shop SafetyDocument10 pagesMachine Shop SafetySreedhar Patnaik.MNo ratings yet

- Const221 Document caughtInHazardsAccessibleDocument22 pagesConst221 Document caughtInHazardsAccessiblelurawi2023No ratings yet

- Slinging Tubulars, Scaffold, BeamsDocument3 pagesSlinging Tubulars, Scaffold, BeamsAngel AngeleyeNo ratings yet

- Washing Machine ManualDocument44 pagesWashing Machine ManualAngel Angeleye100% (1)

- 03-01 Material TraceabilityDocument1 page03-01 Material TraceabilityAngel AngeleyeNo ratings yet

- Audit Checklist - Material ControlDocument4 pagesAudit Checklist - Material ControlAngel AngeleyeNo ratings yet

- The PID Control Algorithm How It Works, How To Tune It, and How To Use It. 2nd EdDocument68 pagesThe PID Control Algorithm How It Works, How To Tune It, and How To Use It. 2nd EdmiroperNo ratings yet

- Pid ControllerDocument27 pagesPid ControllerAngel AngeleyeNo ratings yet

- Global Deduplication Array Administration Guide: DD OS 5.0Document70 pagesGlobal Deduplication Array Administration Guide: DD OS 5.0Rajesh KumarNo ratings yet

- ResumeDocument3 pagesResumeabreddy2003No ratings yet

- Original Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwDocument32 pagesOriginal Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwnikosvitalNo ratings yet

- Set 2 Unit 2 PDF FreeDocument13 pagesSet 2 Unit 2 PDF FreeASHWATH G (RA2111018010045)No ratings yet

- About Some Important Items of Composite Insulators Design: February 1999Document6 pagesAbout Some Important Items of Composite Insulators Design: February 1999ipraoNo ratings yet

- Report For Neha Lem ArchitectureDocument17 pagesReport For Neha Lem ArchitecturewafasaNo ratings yet

- 2012-13 Waste CalendarDocument2 pages2012-13 Waste CalendarOmar9998No ratings yet

- Electra BrochureDocument10 pagesElectra BrochureVërshim KastratiNo ratings yet

- DBMS-LM Kavi With MinipjtDocument56 pagesDBMS-LM Kavi With Minipjtkavi_mithuNo ratings yet

- Physics 23 Fall 1993 Lab 2 - Adiabatic Processes: PV NRTDocument13 pagesPhysics 23 Fall 1993 Lab 2 - Adiabatic Processes: PV NRTvipul ch v v n s sNo ratings yet

- MARTA: 2012 KPMG Phase II Final DraftDocument114 pagesMARTA: 2012 KPMG Phase II Final DraftthomaswheatleyNo ratings yet

- All The Wrong MovesDocument13 pagesAll The Wrong Movesabhishek2006100% (1)

- 08L76 HR3 A21Document6 pages08L76 HR3 A21liebofreakNo ratings yet

- Confined Spaces: Avoiding Common Mistakes in Gas DetectionDocument1 pageConfined Spaces: Avoiding Common Mistakes in Gas Detectiontrravi1983No ratings yet

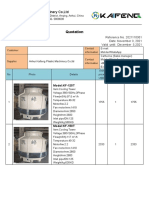

- KAIFENG Quotation For 150T Cooling TowerDocument13 pagesKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyNo ratings yet

- Principles of Management 07Document8 pagesPrinciples of Management 07knockdwnNo ratings yet

- Blue Solar Charge Controller MPPT: NOT AcceptedDocument12 pagesBlue Solar Charge Controller MPPT: NOT Accepted1382aceNo ratings yet

- NFC Reader LibrarayDocument63 pagesNFC Reader Libraraysekhar479No ratings yet

- Mercedes Benz RangeDocument37 pagesMercedes Benz RangeUZNAPMNo ratings yet

- Drive List BoxDocument3 pagesDrive List BoxLuis Carlos VillegasNo ratings yet

- Molded Case Circuit Breakers Section 6: Spectra RMSDocument1 pageMolded Case Circuit Breakers Section 6: Spectra RMSArslan LashariNo ratings yet

- Catalogo de Oleohidraulica AGVDocument73 pagesCatalogo de Oleohidraulica AGVadjime3No ratings yet

- List of International and National Professional Bodies - PECDocument4 pagesList of International and National Professional Bodies - PECerumerNo ratings yet

- Tutorial Joint Push Pull - English - V1.1 - 20 Feb 08Document31 pagesTutorial Joint Push Pull - English - V1.1 - 20 Feb 08shadownrunNo ratings yet

- Teoh Zi Wei 0323372 Vivian Tay 0323869 Vinnie Tan 0323706 Yeoh Sin Yuen 0323737 Tey Cheng Fern 0323912Document22 pagesTeoh Zi Wei 0323372 Vivian Tay 0323869 Vinnie Tan 0323706 Yeoh Sin Yuen 0323737 Tey Cheng Fern 0323912api-292027950No ratings yet