Professional Documents

Culture Documents

Airlocks PPT 2005-02-18 DGL

Uploaded by

Andrey ScholdeaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Airlocks PPT 2005-02-18 DGL

Uploaded by

Andrey ScholdeaCopyright:

Available Formats

Airlocks

Field Operator Certification

Airlocks

Airlocks

Lesson Objectives

1. State the purpose of Airlocks

2. State the different types of Airlocks used in cement manufacturing

3. Explain the principle of operation for each type of Airlock

4. State the applications for Airlocks in cement manufacturing

5. Describe the running & static inspections for each type of Airlock 6. Describe the troubleshooting for common Airlock problems 7. Identify safety hazards associated with the operation of Airlocks 8. Perform running & static inspections on Airlocks (OJT)

Field Operator Certification 13/02/2014

Airlocks

Objective 1 - Purpose

To control the flow of solids & fluids from one process stream to another.

Field Operator Certification

13/02/2014

Airlocks

Objective 2 Types of Airlocks

Field Operator Certification

13/02/2014

Airlocks

Objective 2 Types of Airlocks

Rotary Valves Tipping / Gate Obturator Valves Pneumatic Pinch Valves

Field Operator Certification

13/02/2014

Airlocks

Principle of Operation Rotary Valve

Cast iron machined casing within which multi vane rotor revolves Tight tolerances between rotor & casing are critical in maintaining proper seal Material introduced into Rotary Valve through an inlet flange located on top

Field Operator Certification

13/02/2014

Airlocks

Principle of Operation Rotary Valve (contd)

As rotor vanes pass loading point, material falls by gravity into exposed rotor pockets

As rotor & material pass loading point, individual pockets become sealed against machined rotor casing

Field Operator Certification

13/02/2014

Airlocks

Principle of Operation Rotary Valve (contd)

Material evacuated from bottom of Rotary Valve once pockets pass into open discharge point Material falls by gravity through discharge flange into downstream equipment Rotary Valve can be driven at constant speed for continuous evacuation of material at controlled rate Can also be driven at variable speeds allowing Rotary Valve to be used as material feeder

Field Operator Certification

13/02/2014

Airlocks

Principle of Operation Rotary Valve (contd)

Visualize the operation of revolving doors commonly used in hotels & other building entrances Principle of operation is the same controlled flow of solids & fluids from one stream to another People enter or exit building while at the same time reduce energy losses associated with heating or air conditioning

Field Operator Certification

13/02/2014

Airlocks

Principle of Operation Tipping Valves

Fabricated or cast body with an inlet & outlet flange connected between two process streams

Between the two flanges, internal gate is used to control flow of material between two streams

Field Operator Certification

13/02/2014

10

Airlocks

Principle of Operation Tipping Valves (contd)

Material gate commonly fixed to pivoting shaft supported by bearing assembly at each end Material introduced into Tipping Valve through inlet flange Material accumulates above gate until either mechanical drive forces gate open, or mass of material above gate overcomes externally mounted counterweight which in turn forces gate to open

In both cases material is released through Tipping Valves

discharge flange into downstream equipment

Field Operator Certification

13/02/2014

11

Airlocks

Principle of Operation Tipping Valves (contd)

Those with mechanical drives are commonly open for predetermined period of time or until ideal material level is achieved Those using external counterweight open only long enough to release enough material to reset counterweight 2 commonly used in series to ensure proper Airlock

One of 2 gates remains

closed at all times ensuring positive seal between 2 streams

Field Operator Certification

13/02/2014

12

Airlocks

Principle of Operation Tipping Valves (contd)

Visualize the operation of double doors commonly used in shopping malls & other building entrances

Principle of operation is the same - controlled flow of solids & fluids from one stream to another People enter or exit building with doors closing behind them before doors are opened ahead

13/02/2014

Field Operator Certification

13

Airlocks

Principle of Operation Obturator Valve

Consists of 2 molded & prestressed elastomer diaphragms connected together at sides & inlet flange Open area at bottom adjusted by 2 positioning rods that ensure proper orientation of side diaphragms Absence of material, negative static pressure of upstream vessel forces 2 diaphragms together creating tight seal, isolating upper & lower streams

Field Operator Certification

13/02/2014

14

Airlocks

Principle of Operation Obturator Valve (contd)

Material introduced into closed valve & it accumulates until it creates material seal between upper & lower streams

pressure above

Diaphragm valve relaxes no longer exposed to negative static

Material evacuated until seal is lost & valve is forced closed Obturator Valve can only be used in applications where upper process stream is under negative pressure

Common applications are Dust Collectors & Cyclones

Field Operator Certification

13/02/2014

15

Airlocks

Principle of Operation Pneumatic Pinch Valves

2 piece cast iron body with integrated flanges on both ends Contained within 2 piece body is gum rubber tube insert with integrated flanges on both ends Insert flanges match casting flanges for an effective air seal within valve casing

Field Operator Certification

13/02/2014

16

Airlocks

Principle of Operation Pneumatic Pinch Valves (contd)

Commonly installed in round duct between 2 process streams to provide isolation & or flow control similar to installation of Tipping Valve or Rotary Valve

To provide isolation, compressed air is introduced into void between 2 piece assembled casting & gum rubber insert

Field Operator Certification

13/02/2014

17

Airlocks

Principle of Operation Pneumatic Pinch Valves (contd)

As pressure is increased from atmospheric to typically 50 psi, rubber tube insert is forced to collapse within casting

Collapsed insert creates a seal between upper & lower process streams isolating the two from one another

Field Operator Certification

13/02/2014

18

Airlocks

Principle of Operation Pneumatic Pinch Valves (contd)

Typical configuration - operation controlled by level detectors in process stream When target level is reached, compressed air vented from Pinch Valve & rubber tube opens (material flows) Once level detectors clear, Pinch Valve closes, isolating system Pinch Valve can be configured for flow control by applying variable pressure through controller to Pinch Valve

Field Operator Certification

13/02/2014

19

Airlocks

Objective 5 - Applications

Rotary Valves

Tipping / Gate Valves

Obturator Valves

Pneumatic Pinch Valves

Dust Collectors Cyclones Feeders Pneumatic Transport

Dust Collectors Cyclones Clinker Cooler Under Grate Compartments Gravel Bed Filters Vertical Roller Mill Feed & Rejects Chute HES Rejects Chutes

Dust Collectors Cyclones

Dust Collectors Cyclones Slurry Flow Control

Field Operator Certification

13/02/2014

20

Airlocks

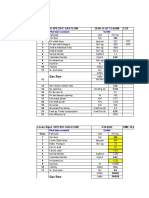

Objective 6 - Inspections

Running Inspection

Rotary Valves Tipping Valves Obturator Valves Pinch Valves

Static Inspection

Rotary Valves Tipping Valves Obturator Valves Pinch Valves

Field Operator Certification

13/02/2014

21

Airlocks

Objective 7 - Troubleshooting

Rotary Valves

Tipping / Gate Valves

Obturator Valves

Pneumatic Pinch Valves

Rotary Valve will not start Noisy drive Valve noisy Packing seals leaking Bearings noisy Product will not discharge

Valve will not operate Valve not sealing properly Noisy drive Valve operation is noisy Bearings noisy Valve will not discharge product

Valve will not seal Valve will not discharge product

Pinch Valve will not isolate material flow Material does not evacuate from Pinch Valve

Field Operator Certification

13/02/2014

22

Airlocks

Objective 8 - Safety

Mechanically driven Airlocks can start & stop automatically Casing & internal material temps can be extremely hot External Tipping Valve arms can be under extreme pressure from material above valve

Creates pinch point in many applications

Field Operator Certification

13/02/2014

23

Airlocks

Objective 8 Safety (contd)

Inspect all guards for damage & support integrity regularly Never attempt to remove build-up off components while in operation Keep clothing, fingers, hair, & other parts of body away from drive components Report all unsafe conditions or practices immediately

Field Operator Certification

13/02/2014

24

Airlocks

Lesson Review

What is the purpose of an Airlock?

To control the flow of solids & fluids from one process

stream to another

Field Operator Certification

13/02/2014

25

Airlocks

Lesson Review

List 4 types of Airlocks commonly found in cement manufacturing

1. Rotary Valves 2. Tipping Valves Gravity, Pneumatic, Hydraulic, Motor Driven 3. Pinch Valves 4. Obturator Valves

Field Operator Certification

13/02/2014

26

Airlocks

Lesson Review

Describe the unique limitation to the application of an Obturator Valve

Can only be used in applications where the upper

process stream is under negative pressure Common applications are Dust Collectors & Cyclones

Field Operator Certification

13/02/2014

27

Airlocks

Lesson Review

What real world application best illustrates the operation of a Rotary Valve, and why?

Rotary Valve concept can be visualized in the real world

through the operation of revolving doors commonly used in hotels & other building entrances Principle of operation is the same - the controlled flow of solids & fluids from one stream to another In this case people entering or exiting the building while at the same time reducing energy losses associated with heating or air conditioning

Field Operator Certification 13/02/2014

28

Airlocks

Lesson Review

What real world application best illustrates the operation of a Tipping Valve, and why?

Tipping Valve concept can be visualized in the real world

through the operation of double doors commonly used in shopping malls & other building entrances The principle of operation is the same - the controlled flow of solids & fluids from one stream to another In this case people entering or exiting the building with doors closing behind them before the doors are opened ahead

Field Operator Certification

13/02/2014

29

Airlocks

Lesson Review

How does a pinch valve control the flow of solids and fluids between two streams?

The pinch valve uses compressed air to collapse the

insert within the valve body isolating the two streams from one another.

Field Operator Certification

13/02/2014

30

Airlocks

Lesson Review

State 5 common applications for Airlocks in cement manufacturing.

1. 2. 3. 4. 5. 6. 7. 8. Pulse Jet Dust Collectors Cyclones Gravel Bed Filters Cooler Under Grate Compartments Pneumatic Transport Raw VRM Feed and Rejects Chutes Fuel Mill Feed Chute HES Separator Rejects

13/02/2014

Field Operator Certification

31

Airlocks

Lesson Review

Describe 5 inspection points for each of the 4 types of Airlocks described in this module

As per Inspection information

Field Operator Certification

13/02/2014

32

Airlocks

Lesson Review

Describe 3 conditions that could explain why product would not discharge from a Rotary Valve

As per Troubleshooting information

Field Operator Certification

13/02/2014

33

Airlocks

Lesson Review

Describe 3 conditions that could explain why a Pinch Valve would not isolate a material flow

As per Troubleshooting information

Field Operator Certification

13/02/2014

34

Airlocks

Lesson Review

Describe 3 safety hazards associated with any of the Airlocks described in this module

As per Safety information

Field Operator Certification

13/02/2014

35

You might also like

- Field Operator Certification: Air SlidesDocument27 pagesField Operator Certification: Air SlidesSatya Makhija100% (1)

- Air Slides PPT 2004-11-08 DGLDocument28 pagesAir Slides PPT 2004-11-08 DGLhgNo ratings yet

- How to perform refractory trialsDocument3 pagesHow to perform refractory trialsJuan Nacimba NacimbaNo ratings yet

- 10 Basic facts about cement productionDocument52 pages10 Basic facts about cement productionmahmoud13No ratings yet

- Atox 20 Coal Mill Critical Interlock SheetDocument6 pagesAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunNo ratings yet

- IPMEA Power Standard - Compress Air GuideDocument6 pagesIPMEA Power Standard - Compress Air GuideJunaid MazharNo ratings yet

- D1P3-Mill Feed CharacteristicsDocument23 pagesD1P3-Mill Feed CharacteristicsYhaneNo ratings yet

- PR RFR IS 08-01 v1.1 Refractory Management StandardDocument8 pagesPR RFR IS 08-01 v1.1 Refractory Management StandardJuan Nacimba NacimbaNo ratings yet

- PR GRI P07-08 How To Optimise A Ball ChargeDocument6 pagesPR GRI P07-08 How To Optimise A Ball ChargepawanroyalNo ratings yet

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcNo ratings yet

- Type of SurfaceDocument31 pagesType of SurfaceD N SHARMANo ratings yet

- How To Measure Gas Composition by Gas AnalyserDocument6 pagesHow To Measure Gas Composition by Gas AnalyserSalah RomdaniNo ratings yet

- Welcome To Grinding I Training SessionDocument5 pagesWelcome To Grinding I Training SessionabdulfetahNo ratings yet

- AUCBMPRESENTATIONMarrakish Nov 2014Document29 pagesAUCBMPRESENTATIONMarrakish Nov 2014sopian320100% (1)

- Field Operator Certification: BlowersDocument20 pagesField Operator Certification: BlowersSatya MakhijaNo ratings yet

- PR RFR P06-06 v1-1 How To Ensure Safety For Brick CuttingDocument6 pagesPR RFR P06-06 v1-1 How To Ensure Safety For Brick CuttingJuan Nacimba NacimbaNo ratings yet

- How To Conduct A Ball Mill AuditDocument7 pagesHow To Conduct A Ball Mill Auditsafwat hassan100% (1)

- 10-Breakdown Analysis, Key Indicators & Informatic SystemDocument26 pages10-Breakdown Analysis, Key Indicators & Informatic SystemElwathig BakhietNo ratings yet

- Field Operator Certification: Air BlastersDocument25 pagesField Operator Certification: Air BlastersSatya MakhijaNo ratings yet

- 042 Drying PDFDocument9 pages042 Drying PDFbkchoudhury1993No ratings yet

- Ventilacion Molienda de BolasDocument26 pagesVentilacion Molienda de BolasFran jimenezNo ratings yet

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099No ratings yet

- MHR21924 CMC Chapter CCDocument48 pagesMHR21924 CMC Chapter CCDede KaladriNo ratings yet

- Loesche Grinding Plants for Coal GasificationDocument45 pagesLoesche Grinding Plants for Coal GasificationMaxim Polevoy100% (1)

- Fan Flow - CementDocument5 pagesFan Flow - CementharikrushnaNo ratings yet

- Particle Size Distribution Analysis and Cyclone Testing ResultsDocument5 pagesParticle Size Distribution Analysis and Cyclone Testing ResultsThaigroup CementNo ratings yet

- PR RFR P10-25 v1-0 How To Ensure Safety Under Refractory RoofsDocument7 pagesPR RFR P10-25 v1-0 How To Ensure Safety Under Refractory RoofsJuan Nacimba NacimbaNo ratings yet

- Pozzolana Role PDFDocument36 pagesPozzolana Role PDFOsman QaasimNo ratings yet

- Performing A Cement Plant Operations AuditDocument6 pagesPerforming A Cement Plant Operations AuditJa Phe TiNo ratings yet

- 03 RP - Maintenance Practices For RPDocument50 pages03 RP - Maintenance Practices For RPaff bearNo ratings yet

- Dokumen - Tips - Atox Raw Mill 55844e0e63329Document13 pagesDokumen - Tips - Atox Raw Mill 55844e0e63329pipit agusNo ratings yet

- Fls Kiln Operation-Raw Material CharacteristicsDocument46 pagesFls Kiln Operation-Raw Material CharacteristicssadatjafariNo ratings yet

- How to remove scrap from ball millDocument5 pagesHow to remove scrap from ball millsafwat hassanNo ratings yet

- 2021 Pfisters Components Inspection ReportDocument12 pages2021 Pfisters Components Inspection ReportMohammed El rajyNo ratings yet

- EMR Standard #3 2017Document10 pagesEMR Standard #3 2017Hasnaoui SamirNo ratings yet

- Bogiflex KGD20 - For PlantDocument13 pagesBogiflex KGD20 - For PlantAnonymous PVXBGg9TNo ratings yet

- 04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemDocument16 pages04-03-PODFA-Function-Roller Mill QUADROPOL-Hydraulic SystemДен СтаднікNo ratings yet

- RCCPL Kundangunj Grinding with VRM systemDocument29 pagesRCCPL Kundangunj Grinding with VRM systemBir SinghNo ratings yet

- Greco - Flexiflame Burner Data Gathering Form: ObservationsDocument4 pagesGreco - Flexiflame Burner Data Gathering Form: ObservationsDilnesa EjiguNo ratings yet

- Building Foundation: Pyroprocessing 2a Kiln, Preheater & Cooler TechnologyDocument64 pagesBuilding Foundation: Pyroprocessing 2a Kiln, Preheater & Cooler TechnologySOFIA EL MENANI100% (1)

- Ceramic Ball in Cement IndustryDocument6 pagesCeramic Ball in Cement IndustryMauricio PortillaNo ratings yet

- Screw Conveyor: Lesson PlanDocument16 pagesScrew Conveyor: Lesson PlanafraNo ratings yet

- How to Ensure Cyclone SafetyDocument6 pagesHow to Ensure Cyclone SafetyJuan Nacimba NacimbaNo ratings yet

- Kiln Readings 23 06 17Document4 pagesKiln Readings 23 06 17zain140No ratings yet

- Course 3 – Clinker Production FuelsDocument26 pagesCourse 3 – Clinker Production FuelsAVcheerNo ratings yet

- (Ricardo Ponce) Preventive Maintenance, Trends, Indications, Wear Patterns and Their Evaluation R1.Document25 pages(Ricardo Ponce) Preventive Maintenance, Trends, Indications, Wear Patterns and Their Evaluation R1.Raúl Marcelo VelozNo ratings yet

- Training PODFA: Roller Mill Quadropol - Hydraulic System ComponentsDocument69 pagesTraining PODFA: Roller Mill Quadropol - Hydraulic System ComponentsДен Стаднік100% (1)

- Bag House Differential Pressure: Key Indicator of Operation and TroubleshootingDocument8 pagesBag House Differential Pressure: Key Indicator of Operation and TroubleshootingZegera Mgendi100% (2)

- NOx Reduction PDFDocument7 pagesNOx Reduction PDFfahimulehsanNo ratings yet

- enDocument22 pagesenAnonymous iI88LtNo ratings yet

- Weigh Feeder Training ModuleDocument89 pagesWeigh Feeder Training ModuleabdulfetahNo ratings yet

- HTML version of LURM mill process control documentDocument6 pagesHTML version of LURM mill process control documentkamjulajayNo ratings yet

- 03 Wear Phenomena Vietnam Seminar HK 2011Document51 pages03 Wear Phenomena Vietnam Seminar HK 2011quỳnh lêNo ratings yet

- Cpi CoolersDocument47 pagesCpi CoolersRobert BrownNo ratings yet

- Introduction of Bag Filters Constructional FeaturesDocument32 pagesIntroduction of Bag Filters Constructional FeaturesTin NguyenNo ratings yet

- Calciner Technology in AF Firing PDFDocument22 pagesCalciner Technology in AF Firing PDFJohn GiannakopoulosNo ratings yet

- Bab 2 Raw Mill System DG VRMDocument80 pagesBab 2 Raw Mill System DG VRMJoko DewotoNo ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- Manual - Dust Collector and Bin VentDocument13 pagesManual - Dust Collector and Bin Ventfrankz89No ratings yet

- Mini Plant Training Material: Air SlidesDocument28 pagesMini Plant Training Material: Air Slidesbulentbulut100% (2)

- Google Home: A Quick Start Guide: Step 1. Plug The Power Cable Into Google HomeDocument3 pagesGoogle Home: A Quick Start Guide: Step 1. Plug The Power Cable Into Google HomeAndrey ScholdeaNo ratings yet

- Google Home Mini and Max ManualDocument3 pagesGoogle Home Mini and Max ManualYogesh RathiNo ratings yet

- Magic Break OutDocument14 pagesMagic Break Outtshoe43No ratings yet

- NB 10-2 TMA Slope Indicator PDFDocument7 pagesNB 10-2 TMA Slope Indicator PDFAndrey ScholdeaNo ratings yet

- How To Count in German With Cardinal and Ordinal NumbersDocument2 pagesHow To Count in German With Cardinal and Ordinal NumbersAndrey ScholdeaNo ratings yet

- Trading Indicator BlueprintDocument55 pagesTrading Indicator BlueprintAndrey Scholdea100% (3)

- Pimsleur German IDocument29 pagesPimsleur German IHassan ElBanhawi100% (3)

- Human BodyDocument1 pageHuman BodyAndrey ScholdeaNo ratings yet

- S.C. "Rulmenti" S.A. Barlad - Romania: Tolerantele Si Tesiturile de MontajDocument2 pagesS.C. "Rulmenti" S.A. Barlad - Romania: Tolerantele Si Tesiturile de MontajAndrey ScholdeaNo ratings yet

- Carer Cookbook PDFDocument72 pagesCarer Cookbook PDFAndrey ScholdeaNo ratings yet

- Carer Cookbook PDFDocument72 pagesCarer Cookbook PDFAndrey ScholdeaNo ratings yet

- Short Stories in EnglishDocument7 pagesShort Stories in EnglishAnia KotarskaNo ratings yet

- Troubleshooting Pneumatic Circuits: Fluid PowerDocument34 pagesTroubleshooting Pneumatic Circuits: Fluid PowerMi LuanaNo ratings yet

- Williams 'V' Series Pneumatic Plunger PumpsDocument6 pagesWilliams 'V' Series Pneumatic Plunger PumpsDayo IdowuNo ratings yet

- CPE 75 150 CPVS 100 150 Instruction Manual 6230579365Document24 pagesCPE 75 150 CPVS 100 150 Instruction Manual 6230579365CPP EI DSpNo ratings yet

- REMF-1 Fist Clutch For Physically Challenged HumansDocument3 pagesREMF-1 Fist Clutch For Physically Challenged HumansretechNo ratings yet

- PN 2200Document92 pagesPN 2200cresjohnNo ratings yet

- Chapter 1 Part ADocument26 pagesChapter 1 Part AYip Tuck WaiNo ratings yet

- FPC Question BankDocument6 pagesFPC Question Bankaskjdbq2eNo ratings yet

- Manage Your Steam With Greater Safety, Reliability and EfficiencyDocument28 pagesManage Your Steam With Greater Safety, Reliability and EfficiencyMohammad FouladiNo ratings yet

- Basic Pneumatics System GuideDocument36 pagesBasic Pneumatics System Guidesaid ismailNo ratings yet

- Jackhammer Safety Training: DANGER Whipping Air HoseDocument6 pagesJackhammer Safety Training: DANGER Whipping Air HoseUhiro PongkiNo ratings yet

- HPC PPC SeriesDocument2 pagesHPC PPC SeriesDina LydaNo ratings yet

- Catalogo Pneumatica Damecomm MinDocument106 pagesCatalogo Pneumatica Damecomm MinCarlo SoloNo ratings yet

- Report: Pneumatic UTMDocument14 pagesReport: Pneumatic UTMadibah ismail50% (2)

- Pneumatics Practical GuideDocument62 pagesPneumatics Practical GuideSuper WingNo ratings yet

- Air Starting Systems For Marine Gas Turbine Engines: $1.50 Per Copy To Asme MembersDocument11 pagesAir Starting Systems For Marine Gas Turbine Engines: $1.50 Per Copy To Asme MembersFikadie AregaNo ratings yet

- Rotary Kiln Inlet With Pneumatic SealDocument38 pagesRotary Kiln Inlet With Pneumatic SealRahmat Hidayat100% (1)

- Exp. 2 Pneumatic Control of A Double-Acting CylinderDocument10 pagesExp. 2 Pneumatic Control of A Double-Acting CylinderLuke-man Akim0% (1)

- Design Experiment 1: Pneumatic ControlDocument5 pagesDesign Experiment 1: Pneumatic ControlKim Angelo GonzalesNo ratings yet

- Parker HydDocument460 pagesParker HydKhang TrangNo ratings yet

- Fluid Power Coarse OutlineDocument1 pageFluid Power Coarse OutlineMikias BelaynehNo ratings yet

- (##) Anti Theft Steering SystemDocument85 pages(##) Anti Theft Steering SystemstarNo ratings yet

- Danais 150 ActuadoresDocument28 pagesDanais 150 Actuadoresedark2009No ratings yet

- Presentation on Low Cost Automation Strategies and Case StudiesDocument16 pagesPresentation on Low Cost Automation Strategies and Case StudiesDeekshu 4141likilNo ratings yet

- 22.service Machines For Flat CardsDocument24 pages22.service Machines For Flat CardsCraig MartinNo ratings yet

- Compressed Air - ENDocument11 pagesCompressed Air - ENMike MichaelidesNo ratings yet

- Automatic Pneumatic Vice and JackDocument33 pagesAutomatic Pneumatic Vice and JackTechnico Technocrats100% (2)

- ESA Instruction Manual English 1.01Document18 pagesESA Instruction Manual English 1.01Stephany Sucerquia100% (1)

- DP Parker-Praedifa GBDocument2 pagesDP Parker-Praedifa GBElvio MNo ratings yet

- Pneumatics vs Hydraulics: A ComparisonDocument19 pagesPneumatics vs Hydraulics: A ComparisonGebBerheNo ratings yet

- Trojan Type A - 3Document2 pagesTrojan Type A - 3Cairo Oil Refining Co.No ratings yet