Professional Documents

Culture Documents

08-Sundyne Presentation - Fs Installation1

Uploaded by

joseellargoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08-Sundyne Presentation - Fs Installation1

Uploaded by

joseellargoCopyright:

Available Formats

INSTALLATION AND START-UP

PREPARATION FOR SHIPMENT

SHIPPING COVERS ON SUCTION AND DISCHARGE FLANGES BULL PLUGS IN SEAL HOUSING, PORTS AND FLANGE PRESSURE TAPS DRIVER SHIPPED SEPARATELY FROM PUMP AND GEARBOX COUPLING AND OTHER SHIP LOOSE ITEMS SUCH AS SPECIAL TOOLS ARE ATTACHED TO THE SKID CHECK FOR SHIPPING DAMAGE

STORAGE

STORE IN CLEAN DRY AREA, IF NOT IMMEDIATELY INSTALLED

LEAVE SHIPPING COVERS, BULL PLUGS & ETC IN PLACE

OBSERVE DRIVER MANUFACTURE'S STORAGE INSTRUCTIONS

SEE LONG TERM STORAGE INSTRUCTIONS IN THE MANUAL

INSPECTION

SUCTION AND DISCHARGE PIPING

PROVIDE 10 DIAMETERS OF STRAIGHT PIPE ON SUCTION PROVIDE 5 DIAMETERS ON DISCHARGE ALWAYS INSTALL CHECK VALVE IN DISCHARGE PIPING NEVER USE CONCENTRIC OR ECCENTRIC REDUCERS CLOSE TO SUCTION SUCTION AND DISCHARGE PIPES TO BE SUPPORTED INDEPENDENTLY FROM PUMP FLANGES CONTROL VALVE (FCV or manual) SHOULD BE INSTALLED CLOSE TO THE PUMP

STRAINERS TO BE SET AND CHECKED FOR CLEANLINESS

PIPING CONNECTIONS

Align process piping to pump Constrain piping to maintain allowable forces and moments (See Outline drawing for allowables) Torque piping connections Verify alignment after all piping connections have been made

MOUNTING

LMV/LMC VERTICAL WITOUT MOTOR STANDS:

MOTOR MUST BE REMOVED FOR MOST MAINTENANCE LEAVE HEAD ROOM FOR MOTOR REMOVAL PROVIDE SIDE ROOM FOR NORMAL MAINTENANCE

BMP/BMC HORIZONTAL:

MOTOR REMOVAL NOT REQUIRED FOR MAINTENANCE PROVIDE SIDE ROOM FOR MAINTENANCE

LMV/LMC VERTICAL STAND MOUNTED:

MOTOR REMOVAL NOT REQUIRED NEED ROOM TO REMOVE GEARBOX AND SEAL HOUSING ASSEMBLY

MOUNTING

<100HP DRIVE UNITS - IN-LINE NO BASE REQUIRED

ADEQUATE PIPE SUPPORT BOTH SIDES

18X18 BASE RECOMMENDED

CONCRETE FOUNDATION/GROUT REQUIRED FOR ALL OTHERS

MOUNTING

Vertical stand? Level top- shim and grout.

Horizontal? Level base- shim and grout.

Always let grout cure before tightening bolts.

MOTOR INSTALLATION

COUPLING ALIGNEMENT

Ensure shaft hubs are undamaged If pump casing removed for maintenance, re-install shims before alignment process Align motor to the pump Alignment tolerances to achieve (Record actual values)

Axial Coupling DBSE should be established from the coupling drawing Parallel +/- .002 (0.05mm) Angular +/- .002 (0.05mm)

PREPARATION FOR START-UP

DRAIN STORAGE OIL

FILL WITH CORRECT LUBRICATING OIL (ISO VG 32 OR 46):

ADJUST LEVEL ACCORDING TO THE MIN/MAX MARKS ON THE SIGHT GLASS

FILL FILTER AND HEAT EXCHANGER WITH OIL:

RUN AUXILIARY LUBE OIL PUMP IF AVAILABLE FILL MANUALLY IF NOT

PERFORM UNCOUPLED RUN OF THE MOTOR:

CHECK ROTATION (CW ON LMV-322, CCW ON OTHERS) CHECK AMPERAGE

PREPARATION FOR START-UP

OPEN PORT 1 CONNECTION

CHECK PRESENCE OF THE FILL AND VENT CAP OF THE GEARBOX

PRESSURIZE BUFFER IF REQUIRED

PRESSURIZE CASING

VENT CASING IF POSSIBLE (Through port 5 or 6)

IF NO AUXILIARY LUBE OIL PUMP:

JOG START (2-3 SEC.) UNTIL THE OIL PRESSURE RISE

START-UP

OPEN THE SUCTION VALVE AT 100% OPEN DISCHARGE VALVE PARTIALLY (depending on valve size and piping section) NEVER START AGAINST CLOSED DISCHARGE VALVE START CONTROL CRITICAL PARAMETERS (Oil pressure, minimum flow) BRING THE PUMP TO THE DESIRED FLOW BY THROTTLING DISCHARGE VALVE ADJUST THE COOLING WATER FLOW THROUGH THE HEAT EXCHANGER:

REQUIRED TEMPERATURE OF OIL IN THE GEARBOX SUMP: 60 TO 80C

START-UP

CHECK FOR ANY LEAKAGE ON PORT 1 CHECK THE LEVEL OF OIL CHECK THE LEVEL IN SEAL BUFFER POT (IF APPLICABLE) CHECK ALL PARAMETERS ACCORDING TO THE DESIGN:

FLOW, DIFFERENTIAL PRESSURE ( HEAD), AMPERAGE, BUFFER PRESSURE

You might also like

- Gearbox Improved Oil Pump Sundyne 40-20-27 Field Engineering BulletinDocument1 pageGearbox Improved Oil Pump Sundyne 40-20-27 Field Engineering BulletinSuresh Kumar MittapalliNo ratings yet

- Start Up and Operation: Presented by Fs Engineer SundyneDocument36 pagesStart Up and Operation: Presented by Fs Engineer SundyneNaveedullah AwanNo ratings yet

- 04-Gearbox 311 - OkDocument61 pages04-Gearbox 311 - OkNaveedullah Awan100% (1)

- 04 Sundyne Presentation Fscontrol SystemDocument27 pages04 Sundyne Presentation Fscontrol SystemjoseellargoNo ratings yet

- Diagnostic Reference ChartDocument4 pagesDiagnostic Reference ChartRao ShahbazNo ratings yet

- 07-Sundyne Presentation Fs OringsDocument26 pages07-Sundyne Presentation Fs Oringsjoseellargo0% (1)

- 05-Sundyne Presentation Fs NPSHDocument35 pages05-Sundyne Presentation Fs NPSHjoseellargoNo ratings yet

- 10 MonitoringDocument75 pages10 MonitoringNaveedullah Awan100% (1)

- Laser AlignmentDocument187 pagesLaser AlignmentEhsanNo ratings yet

- Vertical PumpsDocument27 pagesVertical PumpsmersiumNo ratings yet

- Sundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)Document3 pagesSundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)önder KarakayaNo ratings yet

- s33x UpgradeDocument15 pagess33x UpgradeAlexandre Borges BorgesNo ratings yet

- Shaft Alignment & CouplingsDocument30 pagesShaft Alignment & CouplingsInaam Ur RehmanNo ratings yet

- Coupling - John Crane PDFDocument133 pagesCoupling - John Crane PDFsurawutwijarn100% (1)

- Root Cause Analysis: HPDGA 1000 KW Centrifugal Pump High Vibration ResolvedDocument8 pagesRoot Cause Analysis: HPDGA 1000 KW Centrifugal Pump High Vibration ResolvedAbdulrahman AlkhowaiterNo ratings yet

- LMV 322 Iom - 0603Document53 pagesLMV 322 Iom - 0603hacenescribdNo ratings yet

- Sundyne Pump Iso13709 API617 OH6 LMV 313 Maintenance Manual SpanishDocument82 pagesSundyne Pump Iso13709 API617 OH6 LMV 313 Maintenance Manual SpanishGanesh UpadhyayaNo ratings yet

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Sunflo Pumps SundyneDocument30 pagesSunflo Pumps Sundynemasoud67aNo ratings yet

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementmohammadNo ratings yet

- Full Load Test ExpanderDocument8 pagesFull Load Test Expanderdhanu_aquaNo ratings yet

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- 03 Product OverviewDocument44 pages03 Product OverviewMamdouh ElhanafyNo ratings yet

- Iom TSKSDocument12 pagesIom TSKSTakbir2011No ratings yet

- Centrifugal Pump Troubleshooting GuideDocument2 pagesCentrifugal Pump Troubleshooting GuideFahad MaqsoodNo ratings yet

- Rod DropDocument22 pagesRod DropSomen Mukherjee100% (3)

- Mechanical Seal ReplacementDocument21 pagesMechanical Seal ReplacementshahjahanhashimaliNo ratings yet

- TilTing Pad Radial BeaRings PDFDocument28 pagesTilTing Pad Radial BeaRings PDFmrbookaniNo ratings yet

- Gates Belt For Fin FanDocument131 pagesGates Belt For Fin FanJeffry KarundengNo ratings yet

- SealsDocument118 pagesSealsBalachandar Sathananthan0% (1)

- Centrifugal Pump Axial ThrustDocument4 pagesCentrifugal Pump Axial Thrustfawmer61100% (1)

- Pressure Pulsation in Reciprocating Pump - Part 1Document9 pagesPressure Pulsation in Reciprocating Pump - Part 1Jose PradoNo ratings yet

- CMVA2010 Pump Cavitation PresentationDocument30 pagesCMVA2010 Pump Cavitation PresentationHéctor RiveraNo ratings yet

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreFrom EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo ratings yet

- Balancing Axial Force in Centrifugal Pumps With Pump Out VanesDocument5 pagesBalancing Axial Force in Centrifugal Pumps With Pump Out VanesGunjanNo ratings yet

- Listing of Installation (Gas Compressor Facilities)Document36 pagesListing of Installation (Gas Compressor Facilities)AyaanNo ratings yet

- Maintenance Elliott TurbinesDocument8 pagesMaintenance Elliott TurbinesVILLANUEVA_DANIEL2064No ratings yet

- Reciprocating CompressorsDocument4 pagesReciprocating CompressorsRoyalAryans100% (1)

- 6 Centrifugal Compressor IDocument40 pages6 Centrifugal Compressor IBassam AmirNo ratings yet

- Maintenance of BCHDocument44 pagesMaintenance of BCHdoanducbaoNo ratings yet

- Hoer Questions and AnswersDocument4 pagesHoer Questions and AnswersAnonymous LfeGI2hMNo ratings yet

- Vibration in Pumps PDFDocument5 pagesVibration in Pumps PDFonspsnonsNo ratings yet

- Guide To Measure Rotating EquipmentDocument18 pagesGuide To Measure Rotating EquipmentMDRNo ratings yet

- 06-Sundyne Presentation Fs SealsDocument74 pages06-Sundyne Presentation Fs Sealsjoseellargo88% (8)

- SCHROEDER Automatic Recirculation Check ValveDocument14 pagesSCHROEDER Automatic Recirculation Check ValveAli Bari100% (1)

- Pumps CentrifugalDocument44 pagesPumps CentrifugalEhab Abowarda100% (1)

- 2007 C 1 Mechanical Seal System Reliability Through SpecificationDocument36 pages2007 C 1 Mechanical Seal System Reliability Through SpecificationReyes SanchezNo ratings yet

- 5 Reciprocating Compressor SelectionDocument27 pages5 Reciprocating Compressor SelectionHazem RamdanNo ratings yet

- The Relatioship of Vibration To Problems in Centrifugal Pumps - CheDocument7 pagesThe Relatioship of Vibration To Problems in Centrifugal Pumps - Chehtaboada2008100% (1)

- Boiler Feed Pump New 1Document39 pagesBoiler Feed Pump New 1789krishnaNo ratings yet

- Seal Reliability and Failure AnalysisDocument41 pagesSeal Reliability and Failure Analysiskarioke mohaNo ratings yet

- Turbo ExpanderDocument17 pagesTurbo ExpanderFathy CaceresNo ratings yet

- Reciprocating Compressor Condition MonitoringDocument7 pagesReciprocating Compressor Condition MonitoringSantos Arauz Menacho100% (1)

- 3-Day Gen Open 112003 5a (Compatibility Mode)Document111 pages3-Day Gen Open 112003 5a (Compatibility Mode)api-3703348100% (1)

- John Crane Power TransmissionDocument98 pagesJohn Crane Power TransmissionJavier García100% (1)

- Alignment Procedure PDocument8 pagesAlignment Procedure PvinothenergyNo ratings yet

- Factor of Alignment-PDocument12 pagesFactor of Alignment-Pvinothenergy100% (1)

- Centrifugal Compressor HorsepowerDocument9 pagesCentrifugal Compressor HorsepowerCurtis DookieNo ratings yet

- I and O-1012 - 1014 - 1015 - and 1017 Pumps 1-1Document9 pagesI and O-1012 - 1014 - 1015 - and 1017 Pumps 1-1Mo'men AdelNo ratings yet

- Autodesk Navisworks Simulate 2012 - Manual Del UsuarioDocument834 pagesAutodesk Navisworks Simulate 2012 - Manual Del UsuarioLeon HernandezNo ratings yet

- PRN0124 - A DCTools 1-12-14Document3 pagesPRN0124 - A DCTools 1-12-14joseellargoNo ratings yet

- Manual EB 2512 de SAMSON PDFDocument2 pagesManual EB 2512 de SAMSON PDFjoseellargoNo ratings yet

- Gasket Design Criteria PDFDocument58 pagesGasket Design Criteria PDFjoseellargoNo ratings yet

- Ed M 01.00 I 05Document18 pagesEd M 01.00 I 05joseellargo100% (1)

- Design Data General Data Nozzles List: (Dimensions in MM)Document1 pageDesign Data General Data Nozzles List: (Dimensions in MM)joseellargoNo ratings yet

- Ed G 01.03 I 01Document13 pagesEd G 01.03 I 01joseellargoNo ratings yet

- Ed D 02.00 I 01Document25 pagesEd D 02.00 I 01joseellargoNo ratings yet

- 07-Sundyne Presentation Fs OringsDocument26 pages07-Sundyne Presentation Fs Oringsjoseellargo0% (1)

- Ed Q 01.00 I 02Document22 pagesEd Q 01.00 I 02joseellargoNo ratings yet

- 05-Sundyne Presentation Fs NPSHDocument35 pages05-Sundyne Presentation Fs NPSHjoseellargoNo ratings yet

- DeltaValve 2010 Customer VersionDocument97 pagesDeltaValve 2010 Customer VersionjoseellargoNo ratings yet

- 06-Sundyne Presentation Fs SealsDocument74 pages06-Sundyne Presentation Fs Sealsjoseellargo88% (8)

- 09-Sundyne Presentation Fs ImprovementDocument39 pages09-Sundyne Presentation Fs Improvementjoseellargo100% (2)

- CAESAR II Manual PDFDocument708 pagesCAESAR II Manual PDFPhung Ha Long83% (6)

- 150 FX 4 ElectriDocument646 pages150 FX 4 ElectrilefontNo ratings yet

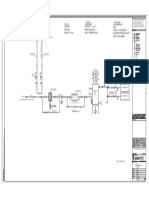

- 10815-PID-01 Sht. 1 of 2 - REV. 3Document1 page10815-PID-01 Sht. 1 of 2 - REV. 3R.P.PATELNo ratings yet

- KS-SE3 SEL 80 (950rpm, 320mm) Data Sheet-Treated EffluentDocument1 pageKS-SE3 SEL 80 (950rpm, 320mm) Data Sheet-Treated EffluentJaeni GilangNo ratings yet

- Content - Fisher RegulatorsDocument44 pagesContent - Fisher Regulatorsbcjal100% (1)

- BOG For Receiving TerminalsDocument16 pagesBOG For Receiving TerminalsmishraenggNo ratings yet

- Training Guide Chapter 5 Spray Methods 2Document10 pagesTraining Guide Chapter 5 Spray Methods 2Derviş Mehmet BaşakNo ratings yet

- Problems and Solutions Physical Chemistry by LAIDLERDocument1,919 pagesProblems and Solutions Physical Chemistry by LAIDLERMohammad Khaled75% (4)

- Problem Set #2 WPS 760Document15 pagesProblem Set #2 WPS 760weilong9183% (12)

- Case Studies For Fluid FlowDocument30 pagesCase Studies For Fluid FlowimranunarNo ratings yet

- Agam Sastrowibowo-Tugas Analisa Pencemaran Lingkungan PDFDocument12 pagesAgam Sastrowibowo-Tugas Analisa Pencemaran Lingkungan PDFagam sastrowibowoNo ratings yet

- Cartoon DivingDocument7 pagesCartoon Divingapi-321333695No ratings yet

- NFPA 25 Training Notes - Module 2 - ITM of Wet and Dry Sprinkler SystemsDocument8 pagesNFPA 25 Training Notes - Module 2 - ITM of Wet and Dry Sprinkler SystemsAlejo SztybelNo ratings yet

- 2020 Sept14 ME004ADocument11 pages2020 Sept14 ME004ADaniel ManivoughNo ratings yet

- Distillation ColumnDocument23 pagesDistillation ColumnRanjani J DeepakNo ratings yet

- PRY 20 00026 MC EAL 4 A1 - Sala EProveedores y SeguridadDocument9 pagesPRY 20 00026 MC EAL 4 A1 - Sala EProveedores y SeguridadJose Esthith BohorquezNo ratings yet

- LPRVP - Admissible Load On BranchesDocument2 pagesLPRVP - Admissible Load On Branchesrebelde1986No ratings yet

- PFI ES-4-1985 (R1997) Hydrostatic Testing of Fabricated PipingDocument4 pagesPFI ES-4-1985 (R1997) Hydrostatic Testing of Fabricated PipingRodrigo Chambilla VernazaNo ratings yet

- GasesDocument14 pagesGasesArdee MendozaNo ratings yet

- Crowngas Detection System Profile - Doha, QatarDocument8 pagesCrowngas Detection System Profile - Doha, QatarCrowngas Detection System - Doha, QatarNo ratings yet

- Task 2 Overview and Instructions 2021Document3 pagesTask 2 Overview and Instructions 2021alindafitrotNo ratings yet

- 07a40302 Fluid Mechanics & Heat TransferDocument8 pages07a40302 Fluid Mechanics & Heat TransferSRINIVASA RAO GANTANo ratings yet

- Catalogue Oilfree Screw CompressorsDocument4 pagesCatalogue Oilfree Screw Compressorsramachandran_chemNo ratings yet

- Hydraulis All BVKDocument149 pagesHydraulis All BVKgotu123No ratings yet

- A Project Report On: TMT Bar Bending MachineDocument46 pagesA Project Report On: TMT Bar Bending MachinePrajay BhavsarNo ratings yet

- SsovgasvalvesDocument12 pagesSsovgasvalvesTin Aung KyiNo ratings yet

- Effect Injection On Air Lift PumpDocument6 pagesEffect Injection On Air Lift PumpDavid Fransiskus SimarmataNo ratings yet

- Ammonia PDFDocument49 pagesAmmonia PDFmfruge7No ratings yet

- Excellent Thesis DesignDocument117 pagesExcellent Thesis DesignHemanth Peddavenkatappa GariNo ratings yet

- Surface Condenser Eng2Document5 pagesSurface Condenser Eng2MuhammadFikriNo ratings yet