Professional Documents

Culture Documents

Lecture14 True

Uploaded by

Satish KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture14 True

Uploaded by

Satish KumarCopyright:

Available Formats

Lecture 14 - Design

October 18, 2001

CVEN 444

Lecture Goals

Slab design reinforcement

Bar Development

Hook development

Flexural Reinforcement in Slabs

For a 1 ft strip of slab is designed like a beam

A

s(reqd)

is in units of (in

2

/ft)

(

=

inches in spacing bar

in 12

ft /

b s

A A

The table is A-9 from

MacGregors book.

Flexural Reinforcement in Slabs

The minimum spacing of the bars is given as:

Also, check crack control - important for exterior

exposure (large cover dimensions) - ACI Sec. 10.6.4

( )

( )

= 7.6.5 Sec. ACI

in. 18

thickness slab 3t

of smaller

max

S

Flexural Reinforcement in Slabs

Thin slabs shrink more rapidly than deeper beams.

Temperature & shrinkage (T&S) steel is provided

perpendicular to restrain cracks parallel to span.

(Flexural steel restrains cracks perpendicular to

span)

Maximum & Minimum reinforcement requirements

Flexural Reinforcement in Slabs

Maximum & Minimum reinforcement requirements

T&S Reinforcement (perpendicular to span) ACI Sec 7.12

( )

( )

( )

( )

( ) t

f t

f

f t

f t A

* " 12 * 0.0014

ksi 60 * " 12 *

60

* 0018 . 0

ksi 60 * " 12 * 0018 . 0

ksi 50 or 40 * " 12 * 0020 . 0

y

y

y

y min s

>

>

|

|

.

|

\

|

=

= =

= =

Flexural Reinforcement in Slabs

T&S Reinforcement (perpendicular to span) ACI Sec 7.12

Flexural Reinforcement (parallel to span) ACI Sec 10.54

S

max

from reinforced spacing

=

18"

5t

of smaller

max

S

( ) ( )

( ) ( ) bal s max s

& min s min s

75 . 0 A A

A A

S T

=

=

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

A. Concept of Bond Stress and Rebar Anchorage

Internal Forces in a beam

Forces in Rebar

Bond stresses provide mechanism

of force transfer between concrete

and reinforcement.

Forces developed in the beam

by loading.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

Equilibrium Condition for Rebar

= bond stress

(coefficient of

friction)

Note: Bond stress is zero at cracks

t

t

4

.

0

4

.

0 Force Bond . 0 F

b y

d

b b y

2

b

d f

l

l d f

d

T

=

=

= =

( ) bar

c

| f k

f k

=

~

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

Sources of Bond Transfer

(1) Adhesion between concrete & reinforcement.

(2) Friction

Note: These properties are quickly lost for tension.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

Sources of Bond Transfer

(3)Mechanical Interlock.

The edge stress concentration

causes cracking to occur.

Force interaction between the

steel and concrete.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

Splitting cracks result in loss of bond transfer.

Reinforcement can be used to restrain these cracks.

Splitting Load is Affected by:

Minimum edge distance and spacing of bars

(smaller distance= smaller load)

Tensile strength of concrete.

Average bond stress along bar.(Increase in bond

stress larger wedging forces)

1.

2.

3.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

Typical Splitting Failure

Surfaces.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

General splitting of

concrete along the

bars,either in vertical

planes as in figure (a) or

in horizontal plane as in

figure (b). Such splitting

comes largely from

wedging action when the

ribs of the deformed bar

bear against the concrete.

The horizontal type of splitting frequently begins at a diagonal crack.

The dowel action increases the tendency toward splitting. This

indicates that shear and bond failure are often intricately interrelated.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

ACI Code expression for development length for

bars in tension/in compression.

B.

Development Length, l

d

Shortest length of bar in which the

bar stress can increase from zero to

the yield strength, f

y

.

( l

d

used since bond stresses, ,

vary along a bar in a tension zone)

Development Length for Bars in Tension

Development length, l

d

12 ACI 12.2.1

f

c

10000 psi for Ch. 12 provisions for development length in ACI Codes.

Development length, l

d

(simplified expression from ACI

12.2.2)

Clear spacing of bars being developed or

spliced not less than d

b

, clear cover not less

than d

b

, and stirrups or ties throughout ld not

less than the code minimum

or

Clear spacing of bars being

developed or spliced not less than 2d

b

and

clear cover not less than d

b

.

Other cases

No. 6 and smaller No. 7 and larger

bars and deformed bars

wires

>

s

c

y

b

d

25 f

f

d

l

o|

=

c

y

b

d

20 f

f

d

l

o|

=

c

y

b

d

50

3

f

f

d

l

o|

=

c

y

b

d

40

3

f

f

d

l

o|

=

Development Length for Bars in Tension

Development length, l

d

ACI 12.2.3

2.5 limit to safeguard against pullout type failure.

5 . 2 in which

40

3

b

ct

b

ct c

y

b

d

<

|

|

.

|

\

|

+

|

|

.

|

\

|

+

=

d

K c

d

K c f

f

d

l o|

Factors used in expressions for

Development Length (ACI 12.2.4)

o = reinforcement location factor

Horizontal reinforcement so placed that more than 12 in of fresh concrete

is cast in the member below the development length or splice

Other reinforcement

| = coating factor (epoxy prevents adhesion &

friction between bar and concrete.)

Epoxy-coated bars or wires with cover less than 3d

b

or clear spacing less

than 6d

b

All other epoxy-coated bars or wires

Uncoated reinforcement

1.3

1.0

1.5

1.2

1.0

where o| < 1.7

Factors used in expressions for

Development Length (ACI 12.2.4)

= reinforcement size factor (Reflects more favorable

performance of smaller | bars)

No.6 and smaller bars and deformed wire

No. 7 and larger bars

= lightweight aggregate concrete factor (Reflects lower

tensile strength of lightweight concrete, & resulting

reduction in splitting resistance.

When lightweight aggregate concrete is used.

However, when f

ct

is specified, shall be permitted to be taken as

but not less than

When normal weight concrete is used

0.8

1.0

1.3

1.0

1.0

ct c

7 . 6 f f

Factors used in expressions for

Development Length (ACI 12.2.4)

c = spacing or cover dimension, in.

Use the smaller of either

(a) the distance from the center of the bar or wire to

the nearest concrete surface.

or

(b) one-half the center-to-center spacing of the bar or

wires being developed.

Factors used in expressions for

Development Length (ACI 12.2.4)

K

ct

= transverse reinforcement index (Represents the contribution

of confining reinforcement across potential splitting planes.)

Total cross-section area of all transverse reinforcement within the spacing s,

which crosses the potential plane of splitting along the reinforcement being

developed with in the development length, in

2

.

Specified yield strength of transverse reinforcement, psi.

maximum center-to-center spacing of transverse reinforcement within l

d

in.

number of bars or wires being developed along the plane of splitting.

A

tr

=

f

yt

=

s =

n =

Note: It is permitted to use K

ct

=0 as a design simplification

even if transverse reinforcement is present.

n s

f A

K

* * 1500

yt tr

tr

=

Excess Flexural Reinforcement

Reduction (ACI 12.2.5)

Reduction = (A

s

reqd ) / (A

s

provided )

- Except as required for seismic design (see ACI 21.2.14)

- Good practice to ignore this provision, since use of

structure may change over time.

- final l

d

12 in.

( )

( ) ( ) provided n

u

provided n

d req' n

Reduction

M

M

M

M

|

= =

>

Development Length for Bars in

Compression (ACI 12.3)

Compression development length l

dc

= l

dbc

* applicable

reduction factors 8 in.

Basic Development Length for Compression, l

dbc

>

=

y b

c

y b

dbc

0003 . 0

0.02

of larger

f d

f

f d

l

Development Length for Bars in

Compression (ACI 12.3)

Reduction Factors (ACI 12.3.3)

- Excessive Reinforcement Factor = (A

s

reqd)/(A

s

provided)

- Spiral and Ties

If reinforcement is enclosed with spiral

reinforcement 0.25 in. diameter and 4 in. pitch or

within No. 4 ties according to 7.10.5 and spaced 4 in.

on center. Factor = 0.75

Note l

dc

< l

d

(typically) because

- Beneficial of end bearing is considered

- weakening effect of flexural tension cracks is not

present for bars in compression.

> s

s

Hooked Bar at Discontinuous

Ends (ACI 12.5.4)

If side cover and top (or bottom cover) 2.5 in.

Enclose hooked bar w/ ties or stirrup-ties:

s

Spacing 3d

b

d

b

=| of hooked bar

s

Note: Multiplier for ties or

stirrups (ACI 12.5.3.3)

is not applicable for

this case.

Hooked Bar at Discontinuous

Ends (ACI 12.5.4)

Table A-11, A-12, A-13 (Back of textbook) - Basic

Development lengths

Others Mechanical Anchorage ACI (12.6)

Welded Wire Fabric ACI (12.7)

Bundled Bars ACI (12.4)

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

C. Use of Standard Hooks for Tension Anchorage

Hooks provide additional anchorage when

there is insufficient length available to

develop a bar.

Note: Hooks are not allowed to developed

compression reinforcement.

Reinforcement Development Lengths, Bar

Cutoffs, and Continuity Requirements

C. Use of Standard Hooks for Tension Anchorage

Standard Hooks are

defined in ACI 7.1.

Hooks resists tension by

bond stresses on bar

surface and bearing on on

concrete inside the hook.

Design of Standard Hooks for

Tension Anchorage (ACI 12.5)

Development Length for Hooked Bar, l

db

.

. in 6 and 8 where s multiplier *

db b db hd dh

> > = l d l l l

Basic Development Length for Hooked Bar = l

hb

when f

y

= 60,000 psi

c

b

hd

1200

f

d

l =

Design of Standard Hooks for

Tension Anchorage (ACI 12.5)

Conditions

Bar Yield Strength

Bars with f

y

other than 60,000 psi

Concrete Cover for 180 Degree Hooks

For No. 11 bars and smaller.

Side cover (normal to plane of hook) 2.5 in.

Concrete Cover for 90 Degree Hooks

For No. 11 bars and smaller.

Side cover (normal to plane of hook) 2.5 in.

Cover on bar extension beyond hook tail 2 in.

Multiplier

f

y

/60,000

0.7

0.7

>

>

>

Design of Standard Hooks for

Tension Anchorage (ACI 12.5)

Conditions

Excessive Reinforcement

Where anchorage or development for fy is not

specified required.

Lightweight Aggregate Concrete

Ties or Stirrups

For No. 11 bar and smaller.

Hook enclosed vertically or horizontally within ties

or stirrup-ties spaced along full l

dh

no farther apart

than 3d

b

, where d

b

is diameter of hooked bar.

Multiplier

A

s

(reqd) /

A

s

(provided)

1.3

0.8

Design of Standard Hooks for

Tension Anchorage (ACI 12.5)

Conditions

Epoxy-coated Reinforcement

Hooked bars with epoxy coating

Multiplier

1.2

Example

Determine the

anchorage of 4 #8 top

bars in column. The

transverse steel is 4#11.

f

y

= 60000 psi

f

c

= 3000 psi

You might also like

- 425-Chp7-Bond Development Length SplicesDocument41 pages425-Chp7-Bond Development Length SplicesJorge SerranoNo ratings yet

- 425-Chp7-Bond Development Length SplicesDocument41 pages425-Chp7-Bond Development Length SplicesAhsan BuriroNo ratings yet

- Reinforcement Development LengthsDocument41 pagesReinforcement Development LengthsOsthePrakashNo ratings yet

- CLASS NOTES Chap 10 1 Bond & AnchorageDocument13 pagesCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105No ratings yet

- Development Length - Part 1Document39 pagesDevelopment Length - Part 1Tawfeeq AbusaifNo ratings yet

- Rebar Development Length CalculatorDocument29 pagesRebar Development Length CalculatorSebastian TobonNo ratings yet

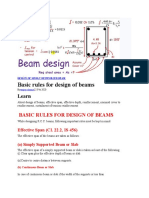

- Basic Rules For Design of BeamsDocument8 pagesBasic Rules For Design of BeamsJaswanth JNo ratings yet

- Longitud de Desarrollo Aci-318-11Document4 pagesLongitud de Desarrollo Aci-318-11Gabriel EspinalNo ratings yet

- ACI-318-11 Development Lengths for Deformed BarsDocument4 pagesACI-318-11 Development Lengths for Deformed BarsAgustin CahuanaNo ratings yet

- Bond, Development Lengths and SplicesDocument11 pagesBond, Development Lengths and SplicesDong DimalantaNo ratings yet

- Flexural Design Procedure For Singly Reinforced Rectangular BeamsDocument3 pagesFlexural Design Procedure For Singly Reinforced Rectangular BeamstvelasquezNo ratings yet

- Ces 3 Reinforced Concrete Design Bond, Development Lengths, and SplicesDocument10 pagesCes 3 Reinforced Concrete Design Bond, Development Lengths, and SplicesInglis, Carell Erica P.No ratings yet

- Design of Singly Reinforced BeamDocument7 pagesDesign of Singly Reinforced BeamfelipeNo ratings yet

- Lecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Document35 pagesLecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Ram RamisettiNo ratings yet

- Splitting Design For Anchorages and Splices With Post-Installed ReinforcementDocument6 pagesSplitting Design For Anchorages and Splices With Post-Installed ReinforcementpicottNo ratings yet

- Bond, Anchor and ShearDocument15 pagesBond, Anchor and ShearBatepola BacNo ratings yet

- Longitud de Desarrollo Aci-318-11Document10 pagesLongitud de Desarrollo Aci-318-11salgatranNo ratings yet

- 107 ConcreteDocument44 pages107 Concretenoadspls2029No ratings yet

- Development LengthDocument22 pagesDevelopment LengthAlok MamNo ratings yet

- Anclaje y Longitud de Desarrollo 1Document64 pagesAnclaje y Longitud de Desarrollo 1Anonymous YH4jBAiDOqNo ratings yet

- Rreinforced Concrete-Beam DesignDocument38 pagesRreinforced Concrete-Beam DesignMohamed AbdNo ratings yet

- LBC201 - Chapter 8Document49 pagesLBC201 - Chapter 8stephanieelhachemNo ratings yet

- Chapter 6 Ribbed Slab and Waffle SlabDocument15 pagesChapter 6 Ribbed Slab and Waffle Slaba20082909No ratings yet

- Rcc-Lec-07-Bond and Dev LengthDocument83 pagesRcc-Lec-07-Bond and Dev LengthMarvinEboraNo ratings yet

- 7 Bond and Development Length-SlightDocument47 pages7 Bond and Development Length-Slightريام الموسويNo ratings yet

- Design of Anchor Bolts in PedestalsDocument10 pagesDesign of Anchor Bolts in PedestalsVertical Starter100% (5)

- Dev and Lap Splice Lengths - ETN-D-1-15Document9 pagesDev and Lap Splice Lengths - ETN-D-1-15erleosNo ratings yet

- Development Length: CE A433 - RC Design T. Bart Quimby, P.E., PH.DDocument22 pagesDevelopment Length: CE A433 - RC Design T. Bart Quimby, P.E., PH.DJatinder SinghNo ratings yet

- Design of Anchorage Length EC2Document4 pagesDesign of Anchorage Length EC2ECC100% (2)

- Development Length Development LengthDocument4 pagesDevelopment Length Development LengthSeifeldin Ali MarzoukNo ratings yet

- Effect of Shear Reinforcement On Punching Shear CaDocument11 pagesEffect of Shear Reinforcement On Punching Shear CaFelipeMatiasCardosoNo ratings yet

- Anclaje y Longitud de DesarrolloDocument43 pagesAnclaje y Longitud de DesarrolloAnonymous YH4jBAiDOqNo ratings yet

- Ce4014 - 1 Bond Anchorage & Development LengthDocument31 pagesCe4014 - 1 Bond Anchorage & Development Lengthprakashcg123100% (1)

- Lec 5 CE 806 RCM Development, Anchorage and Splicing of ReinforcementDocument69 pagesLec 5 CE 806 RCM Development, Anchorage and Splicing of ReinforcementwasimkhaliqNo ratings yet

- Rule of Thumb For RC DesignDocument12 pagesRule of Thumb For RC DesignJeefry Arranguez50% (2)

- CE 419 Lec 1 Bond and Developement LengthDocument55 pagesCE 419 Lec 1 Bond and Developement LengthwasimkhaliqNo ratings yet

- Anchor Bolts Design of Headed Anchor BoltsDocument12 pagesAnchor Bolts Design of Headed Anchor BoltsDoug LambNo ratings yet

- Programa Logitud de Desarrollo en ColumnasDocument6 pagesPrograma Logitud de Desarrollo en ColumnasLeonardo PimentelNo ratings yet

- ACI Detailing ManualDocument9 pagesACI Detailing Manualwinard21No ratings yet

- 03 Section 2 Example Bridge (E)Document11 pages03 Section 2 Example Bridge (E)Diego Benavides KNo ratings yet

- Chapter 4 Ribbed Slabs and Waffle SlabsDocument11 pagesChapter 4 Ribbed Slabs and Waffle SlabsSharan Bvp75% (4)

- Dev LengthDocument5 pagesDev LengthdghtghfgjhhjjhnNo ratings yet

- Importance of Detailing Transverse Reinforcement for Beams, Columns and WallsDocument3 pagesImportance of Detailing Transverse Reinforcement for Beams, Columns and WallssudarsancivilNo ratings yet

- Masonry Design - FINAL - PPTX (Read-Only)Document77 pagesMasonry Design - FINAL - PPTX (Read-Only)haixdpro100% (1)

- Design For Shear: Slabs Without Shear ReinforcementDocument12 pagesDesign For Shear: Slabs Without Shear ReinforcementEmad KhanNo ratings yet

- ACI Concrete Beam DetailingDocument12 pagesACI Concrete Beam DetailingShaik Eliyas BashaNo ratings yet

- Slabs: Serviceability and Shear: WWW - Eurocode2.infoDocument56 pagesSlabs: Serviceability and Shear: WWW - Eurocode2.infoKai Lin TayNo ratings yet

- Bar CutooffDocument8 pagesBar CutooffdependNo ratings yet

- Design of Short Axially Loaded ColumnsDocument38 pagesDesign of Short Axially Loaded ColumnsMohamed Nk100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- SSC Je Practice BookDocument1,008 pagesSSC Je Practice BookSatish Kumar0% (1)

- Feat of Civil EngineeringDocument15 pagesFeat of Civil EngineeringSatish KumarNo ratings yet

- 05 01 Limit Equilibrium Slope StabilityDocument14 pages05 01 Limit Equilibrium Slope StabilityDani Darma Putra100% (1)

- Sbi ADocument5 pagesSbi AJeshiNo ratings yet

- Strength of Materials Lab JWFILESDocument14 pagesStrength of Materials Lab JWFILESSatish KumarNo ratings yet

- DrdaDocument5 pagesDrdaSatish KumarNo ratings yet

- Fluid MachinesDocument29 pagesFluid MachinesmetheoneandoneNo ratings yet

- IGBC Green Factory Building Rating SystemDocument82 pagesIGBC Green Factory Building Rating SystemRavish PatidarNo ratings yet

- GreenDocument15 pagesGreenSatish KumarNo ratings yet

- Engg - Colleges BTECHDocument50 pagesEngg - Colleges BTECHsarita571990281No ratings yet

- Pavement Design SeminarDocument12 pagesPavement Design SeminarWayaya2009100% (3)

- Advanced Sentence Correction 1 - Answers PDFDocument1 pageAdvanced Sentence Correction 1 - Answers PDFHari Harul VullangiNo ratings yet

- DrdaDocument5 pagesDrdaSatish KumarNo ratings yet

- 01 CPT DOT PresentationDocument30 pages01 CPT DOT PresentationJamie MooreNo ratings yet

- 07a80106 Pavement Analysis and DesignDocument8 pages07a80106 Pavement Analysis and DesignSharanya ThirichinapalliNo ratings yet

- Dedicated Freight Corridor Corporation of India Limited: 1004310442 Suman TDocument1 pageDedicated Freight Corridor Corporation of India Limited: 1004310442 Suman TSatish KumarNo ratings yet

- Pavement DesignDocument2 pagesPavement DesignvanamgouthamNo ratings yet

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDocument7 pagesEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestJorge Vanegas100% (1)

- Structural Analysis and Design of An Industrial BuildingDocument54 pagesStructural Analysis and Design of An Industrial BuildingChandra Shekar85% (39)

- Engg - Colleges BTECHDocument50 pagesEngg - Colleges BTECHsarita571990281No ratings yet

- Construction Management and AccountsDocument134 pagesConstruction Management and AccountsRajanbabu50% (2)

- Thin Concrete Shell Structures GuideDocument5 pagesThin Concrete Shell Structures GuideSatish Kumar100% (1)

- Post Tensioning ManualDocument11 pagesPost Tensioning ManualSatish KumarNo ratings yet

- Best Civil Engineering Books for GATE ExamDocument1 pageBest Civil Engineering Books for GATE ExamSatish KumarNo ratings yet

- EstimationandQuantitySurveying 2MARKSDocument25 pagesEstimationandQuantitySurveying 2MARKSSatish KumarNo ratings yet

- Lecture 16 - Bar DevelopmentDocument11 pagesLecture 16 - Bar DevelopmentSatish KumarNo ratings yet

- Chapter 0Document0 pagesChapter 0Christian ReyesNo ratings yet

- Chapter 0 ADocument0 pagesChapter 0 ASatish KumarNo ratings yet

- Lecture 21 - Reinforced Columns: November 15, 2001 CVEN 444Document19 pagesLecture 21 - Reinforced Columns: November 15, 2001 CVEN 444Satish KumarNo ratings yet

- Lecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Document35 pagesLecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Ram RamisettiNo ratings yet

- Nano CompositeDocument26 pagesNano Compositenandan akNo ratings yet

- Numerical Study of Stretch-Blow Molding of PET Bottles: January 2010Document7 pagesNumerical Study of Stretch-Blow Molding of PET Bottles: January 2010Anas AlbasarhNo ratings yet

- مقاومه مواد محاضرات د.فراتDocument121 pagesمقاومه مواد محاضرات د.فراتlana_salahadinNo ratings yet

- Division 16 - Electrical Section 16720 - Fire Alarm SystemsDocument3 pagesDivision 16 - Electrical Section 16720 - Fire Alarm SystemsMd. Mominul IslamNo ratings yet

- CEOR REVIEWER MIDTERMS 1ST QUIZ WordDocument5 pagesCEOR REVIEWER MIDTERMS 1ST QUIZ WordAngelica Ulpindo BalubarNo ratings yet

- Plate Type Heat ExchangerDocument6 pagesPlate Type Heat ExchangerarjmandquestNo ratings yet

- VCCT For Abaqus PDFDocument14 pagesVCCT For Abaqus PDFFelipe Dornellas SilvaNo ratings yet

- Thermo Analytical AnalysisDocument149 pagesThermo Analytical AnalysisHarold MangaNo ratings yet

- Bernt - EC3 1 5Document44 pagesBernt - EC3 1 5Rosario BlancaNo ratings yet

- ACM Hydro Fact SheetDocument2 pagesACM Hydro Fact SheetPetarNo ratings yet

- GTX BeamDocument6 pagesGTX BeamSanjay SudhakaranNo ratings yet

- Is.8042.1989 White Cement SpecificationsDocument18 pagesIs.8042.1989 White Cement SpecificationsLucky KhanNo ratings yet

- Secondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsDocument12 pagesSecondary Seal For Sealed Insulating Glass Units For Structural Sealant Glazing ApplicationsAbdullah NajjarNo ratings yet

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- Trestles Design 1Document10 pagesTrestles Design 1Anonymous sfkedkymNo ratings yet

- Revised Malaysian Code of Timber StructuresDocument6 pagesRevised Malaysian Code of Timber Structuresmcwong_98No ratings yet

- Design Basis Memorandum - Mechanical Equipment and SystemsDocument26 pagesDesign Basis Memorandum - Mechanical Equipment and SystemsLuojisi Cil50% (2)

- Offer Legrand SandwichBBT BMTC EV 02.04.2022Document1 pageOffer Legrand SandwichBBT BMTC EV 02.04.2022Darshit VyasNo ratings yet

- Tabla 310.15 (B) (16) - Ampacidades PDFDocument1 pageTabla 310.15 (B) (16) - Ampacidades PDFDettagli GuateNo ratings yet

- HVAC Systems Duct DesignDocument39 pagesHVAC Systems Duct Designsardarmkhan100% (2)

- Bostik Low Voc Catalogue-A4-Nov20Document24 pagesBostik Low Voc Catalogue-A4-Nov20Stefano CamillucciNo ratings yet

- Advanced Fluid MechanicsDocument154 pagesAdvanced Fluid MechanicsMohammad irfanNo ratings yet

- BS 5839-6 2004 Fire DetectionDocument29 pagesBS 5839-6 2004 Fire Detectionamhosny64No ratings yet

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- Structural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersDocument3 pagesStructural Calculation of Box Culvert Type: B2.00m X H0.50m Class I Road Soil Cover Depth: 1.0 M 1 Dimensions and ParametersBoby CuliusNo ratings yet

- Design of Steel StructuresDocument2 pagesDesign of Steel Structuressou_kgec100% (3)

- Design of Syphon AqueductDocument118 pagesDesign of Syphon AqueductGuru MurthyNo ratings yet

- Principles of RCCDocument28 pagesPrinciples of RCCprashmce100% (1)

- Installation Manual: R410A Split SeriesDocument14 pagesInstallation Manual: R410A Split Serieswarick mNo ratings yet

- 15 ACE Congress Program - Version 1Document31 pages15 ACE Congress Program - Version 1Shahab AhmadNo ratings yet