Professional Documents

Culture Documents

ICAR Rheometer: Eric Koehler W.R. Grace & Co

Uploaded by

Hafiezul HassanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICAR Rheometer: Eric Koehler W.R. Grace & Co

Uploaded by

Hafiezul HassanCopyright:

Available Formats

ICAR Rheometer

Eric Koehler

W.R. Grace & Co.

eric.koehler@grace.com

2

Outline

What is Rheology?

Definition

Measurement

ICAR Rheometer

Description

Operation

Applications

Mixture proportioning

SCC

Production control

Formwork pressure

Segregation resistance

Pumpability

3

Concrete Rheology

Rheology is the scientific description of

flow.

The rheology of concrete is measured

with a concrete rheometer, which

determines the resistance of concrete

to shear flow at various shear rates.

Concrete rheology measurements are

typically expressed in terms of the

Bingham model, which is a function of:

Yield stress: the minimum stress to initiate

or maintain flow (related to slump)

Plastic viscosity: the resistance to flow once

yield stress is exceeded (related to

stickiness)

Concrete rheology provides many

insights into concrete workability.

Slump and slump flow are a function of

concrete rheology.

Shear Rate, (1/s)

S

h

e

a

r

S

t

r

e

s

s

,

(

P

a

)

q

t

=

q t =

Results

The Bingham Model

t t + =

0

slope = plastic viscosity ()

intercept = yield stress (t

0

)

Flow Curve

4

Workability and Rheology

Workability: The ease with which

[concrete] can be mixed, placed,

consolidated, and finished to a

homogenous condition. (ACI

Definition)

Workability tests are typically

empirical

Tests simulate placement condition and

measure value (such as distance or

time) that is specific to the test method

Difficult to compare results from one test

to another

Multiple tests needed to describe

different aspects of workability

Rheology provides a fundamental

measurement

Results from different rheometers have

been shown to be correlated

Results can be used to describe multiple

aspects or workability

ACI 238.1R-08 report describes 69

workability and rheology tests.

5

Concrete Flow Curves (Constitutive Models)

q t =

t t

+ =

0

b

a t t

+ =

0

b

a t t

+ =

0

b

a t t

+ =

0

b

a t t

+ =

0

b

a t t

+ =

0

Flow curves represent shear stress vs. shear rate

Bingham model is applicable to majority of concrete

Other models are available and can be useful for specific

applications (e.g. pumping)

Very stiff concrete behaves more as a solid than a liquid. Such

mixtures are not described by these models.

6

Concrete Rheology: Non-Steady State

Concrete exhibits different rheology when at rest than when flowing.

7

Concrete Rheology: Non-Steady State

Static Yield Stress

minimum shear stress to initiate flow from

rest

Dynamic Yield Stress

minimum shear stress to maintain flow after

breakdown of thixotropic structure

Plastic Viscosity

change in shear stress per change in shear

rate, above yield stress

Thixotropy

reversible, time-dependent reduction in

viscosity in material subject to shear

Shear Rate (1/s)

S

h

e

a

r

S

t

r

e

s

s

(

P

a

)

Time (s)

T

o

r

q

u

e

(

N

m

)

concrete sheared at constant, low rate

Flow Curve Test

Stress Growth Test

concrete sheared at various rates

maximum stress from rest

= static yield stress

area between up and down

curves due to thixotropy

slope = plastic viscosity

intercept =

dynamic

yield stress

Concrete exhibits different rheology

when at rest than when flowing.

Thixotropy is especially critical in highly flowable concretes.

8

Rheology Measurement: Typical Geometry

Rheometers continuously shear concrete through rotational

movement.

Rheometers must be uniquely designed for concrete (primarily

due to large aggregate size)

Results can be expressed in relative units (torque vs. speed) or

absolute units (shear stress vs. shear rate)

Coaxial Cylinders Parallel Plate Impeller

Typical Rheometer Geometry Configurations

9

Concrete Rheometers

Tattersall Two-Point Rheometer IBB Rheometer ICAR Rheometer

BML Viscometer BTRHEOM Rheometer

10

ICAR Rheometer

Portable concrete rheometer

Laboratory

Jobsite

Appropriate for moderately and

highly flowable concrete

Measures slumps greater than 75

mm

Especially well-suited for self-

consolidating concrete

Flexible interface allows

measurement of Bingham

parameters, thixotropy, and

other protocols set by user

11

ICAR Rheometer: Operation

Apply Rotation,

Measure Torque

Fluid

Outer

Cylinder

Inner Cylinder

Top View Side View

Based on wide-gap, coaxial

cylinders design

Vane acts as inner cylinder

Compact size

Prevents slip

Outer wall also has vertical

strips to prevent slip

Vane is immersed in concrete

and rotated at different speeds

Computer software operates

test and computes results

Single test complete in 60

seconds

Vane can be replaced with any

other type of impeller

H: 5 in (125 mm)

D: 5 in (125 mm)

12

ICAR Rheometer: Portability

Rheometer Weight: 13 lb (6 kg)

[with accessories: 40 lb (18 kg)]

16 (400 mm)

4.25

(110 mm)

Bucket size depends on aggregate size.

1 (25 mm) aggregate shown

13

Software Interface

All operations managed through single screen.

Flow Curve

Stress Growth

settings

start

real time

data

calculated

results

settings

start

real time

data

calculated

results

All data

automatically

written to text

and Excel file

14

Aggregate Size

Vane is constant size for

all aggregate sizes

Height: 5 in. (125 mm)

Diameter: 5 in. (125 mm)

Outer container is

selected based on

aggregate size

Horizontal and vertical

gaps should be at least 4x

the maximum aggregate

size

Larger container can be

always be used, but

smaller container should

never be used.

15

Stress Growth Test

Stress growth test consists

of the following:

Rotate vane at low, constant

speed

Measure gradual increase in

torque

Identify maximum torque and

convert to stress, which is

equal to static yield stress

Note: reduction in torque after

peak value is associated with

further yielding of material and

is not typically analyzed further

Material is previously at rest

for pre-determined period to

detect effect of thixotropy

Vane speed is typically 0.01

to 0.05 rps

16

Flow Curve Test

Flow curve test measures

shear stress at different

shear rates

Raw torque vs. rotation

speed data are converted to

fundamental units of shear

stress and shear rate

Can also be used to measure

thixotropy

Software Inputs

Test Units

17

Rheometer Test File

All settings and results are

written automatically to a

summary text file.

Raw data (instantaneous

torque and rotation speed) can

optionally be written to a file

for Excel

18

Thixotropy Testing: Flow Curve or Stress Growth

Flow Curve Test

Place concrete in container and allow to rest

for pre-determined time (to allow thixotropic

build-up)

Run flow curve with speeds in ascending

order (low to high), exclude breakdown

period

Immediately run second curve with speeds in

descending order (high to low), include

breakdown period at high speed to assure

full breakdown of thixotropy

Area between up and down curves is

indicative of thixotropy

Stress Growth Test

Place concrete in container and allow to rest

for pre-determined time (to allow thixotropic

build-up)

Run stress growth test, which measures the

static yield stress

The difference between the static yield stress

and dynamic yield stress (flow flow curve) is

indicative of thixotropy

Shear Rate (1/s)

S

h

e

a

r

S

t

r

e

s

s

(

P

a

)

Time (s)

T

o

r

q

u

e

(

N

m

)

concrete sheared at constant, low rate

Flow Curve Test

Stress Growth Test

concrete sheared at various rates

maximum stress from rest

= static yield stress

area between up and down

curves due to thixotropy

slope = plastic viscosity

intercept =

dynamic

yield stress

19

Applications: Mixture Proportioning

Both the mixture proportions and the admixture can adjusted to

tailor the rheology to the application.

Precast vs. ready mix

SCC vs. conventional concrete

Formwork pressure

Pumpability

Segregation resistance

Mixing

Stickiness and Cohesion

Form surface finish

Finishability

20

Applications: Mixture Proportioning

Reference: Koehler, E.P., Fowler, D.W. (2007). ICAR Mixture Proportioning

Procedure for SCC International Center for Aggregates Research, Austin, TX.

Yield

Stress

Plastic

Viscosity

Aggregate max. size (increase)

Aggregate grading (optimize)

Aggregate angularity

Aggregate shape (equidimensional)

Paste volume (increase)

Water/powder (increase)

Fly ash

Slag

Silica fume (low %)

Silica fume (high %)

VMA

HRWR

AEA

Yield Stress (Pa)

P

l

a

s

t

i

c

V

i

s

c

o

s

i

t

y

(

P

a

.

s

)

AEA

Silica Fume

HRWR

Water

Effects of Materials and Mixture Proportions on Rheology

21

Applications: SCC Rheology

SCC is designed to flow under its own

mass, resist segregation, and meet

other requirements (e.g. mechanical

properties, durability, formwork

pressure, pump pressure)

Compared to conventional concrete,

SCC exhibits:

Significantly lower yield stress (near zero):

allows concrete to flow under its own mass

Similar plastic viscosity: ensures

segregation resistance

Plastic viscosity must not be too high

or too low

Too high: concrete is sticky and difficult to

pump and place

Too low: concrete is susceptible to

segregation

Thixotropy is more critical for SCC due

to low yield stress

Shear Rate, (1/s)

S

h

e

a

r

S

t

r

e

s

s

,

(

P

a

)

q

t

=

q t =

t

0

t

0

Similar plastic

viscosity

Near zero

yield stress

Conventional

Concrete

SCC

Yield stress is the main difference between SCC and conventional concrete.

22

Applications: SCC Rheology

Slump flow vs. yield stress for single

mixture proportion, variable HRWR

R

2

= 0.90

0

1

2

3

4

5

6

7

8

9

10

0 30 60 90 120

Plastic Viscosity (Pa.s)

T

2

0

(

s

)

T

20

vs. plastic viscosity

Reference: Koehler, E.P., Fowler, D.W. (2008). Comparison of Workability Test

Methods for Self-Consolidating Concrete Submitted to Journal of ASTM International.

Empirical workability tests are a function of rheology.

Rheology provides greater insight into workability.

23

Applications: SCC Rheology

0

5

10

15

20

25

30

0 30 60 90 120

Elapsed Time (Minutes)

S

l

u

m

p

F

l

o

w

(

i

n

c

h

e

s

)

PC 068

PC 059

PC 915

w/c = 0.35

0

50

100

150

200

250

0 30 60 90 120

Elapsed Time (Minutes)

D

y

n

a

m

i

c

Y

i

e

l

d

S

t

r

e

s

s

(

P

a

)

PC 068

PC 059

PC 915

w/c = 0.35

0

20

40

60

80

100

120

0 30 60 90 120

Elapsed Time (Minutes)

P

l

a

s

t

i

c

V

i

s

c

o

s

i

t

y

(

P

a

.

s

)

PC 068

PC 059

PC 915

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0 30 60 90 120

Elapsed Time (Minutes)

T

h

i

x

o

t

r

o

p

y

(

N

m

/

s

)

PC 068

PC 059

PC 915

w/c = 0.35

3 Different HRWRs | Same Slump Flow | Same Mix Design | Different Rheology

R

e

f

e

r

e

n

c

e

:

J

e

k

n

a

v

o

r

i

a

n

,

A

.

,

K

o

e

h

l

e

r

,

E

.

P

.

,

G

e

a

r

y

,

D

.

,

M

a

l

o

n

e

,

J

.

(

2

0

0

8

)

.

C

o

n

c

r

e

t

e

R

h

e

o

l

o

g

y

w

i

t

h

H

i

g

h

-

R

a

n

g

e

W

a

t

e

r

-

R

e

d

u

c

e

r

s

w

i

t

h

E

x

t

e

n

d

e

d

S

l

u

m

p

F

l

o

w

R

e

t

e

n

t

i

o

n

P

r

o

c

e

e

d

i

n

g

s

o

f

S

C

C

2

0

0

8

,

C

h

i

c

a

g

o

,

I

l

l

i

n

o

i

s

.

24

Applications: Production Control

The workability box is an effective

way to ensure production

consistency

Definition: Zone of rheology

associated with acceptable workability

(self-flow and segregation resistance)

Mixture proportions affect

rheology; therefore, controlling

rheology is an effective way to

control mixture proportions

Workability boxes are mixture-

specific

SCC encompasses a wide range of

materials and rheology

Rheology appropriate for one set of

materials may be inappropriate for

another set of materials

Larger workability box corresponds to

greater robustness

0

5

10

15

20

25

30

35

40

45

50

0 50 100 150

Yield Stress (Pa)

P

l

a

s

t

i

c

V

i

s

c

o

s

i

t

y

(

P

a

.

s

)

Low Flow

Good

Segregation

Example

Requires Vibration

Segregation

Good

25

Applications: Formwork Pressure

Formwork pressure is related to

concrete rheology

Pressure is known to increase with slump

SCC often exhibits high formwork

pressure due to its high fluidity

Concrete is at rest in forms, therefore,

static yield stress is relevant

Static yield stress is affected by dynamic

yield stress and thixotropy

SCC is placed in lifts, which takes

advantage of thixotropy

SCC must be designed to flow under

its own mass and exert low formwork

pressure

Low dynamic yield stress (self flow)

Fast increase in static yield stress

(reduced formwork pressure)

26

Applications: Formwork Pressure Case Study

Reference: Koehler, E.P., Keller, L., and Gardner, N.J. (2007). Field Measurements of

SCC Rheology and Formwork Pressure Proceedings of SCC 2007, Ghent, Belgium

0

100

200

300

400

500

600

0 20 40 60 80 100 120

Time from Placement, Minutes

D

y

n

a

m

i

c

Y

i

e

l

d

S

t

r

e

s

s

(

P

a

)

Mix 1 (Base)

Mix 2 (Increased

CA)

Mix 3 (Lower w/cm,

Different Admix)

-0.1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0 20 40 60 80 100 120

Time from Placement, Minutes

T

h

i

x

o

t

r

o

p

i

c

B

r

e

a

k

d

o

w

n

A

r

e

a

(

N

m

/

s

)

Mix 1 (Base)

Mix 2 (Increased

CA)

Mix 3 (Lower w/cm,

Different Admix)

Peterborough Trial 2 - July 12, 2006

Concrete temperature 20C

-10

-5

0

5

10

15

20

25

30

35

40

11.0 11.5 12.0 12.5 13.0

Time (Hour + Decimal)

L

a

t

e

r

a

l

P

r

e

s

s

u

r

e

(

k

P

a

)

Cell 13 (Hyd.Pres. 36.1 kPa)

Cell 14 (Hyd.Pres. 63.5 kPa)

Cell 15 (Hyd.Pres. 91.1 kPa)

Cell 16 (Hyd.Pres. 98.7 kPa)

Peterborough Trial 3 - Sept 20, 2006,

Concrete temperature 21C

-20

0

20

40

60

80

100

10.0 10.5 11.0 11.5 12.0 12.5 13.0

Time (Hour + Decimal)

L

a

t

e

r

a

l

P

r

e

s

s

u

r

e

(

k

P

a

)

Cell 13 (Hyd.Pres. 36.1 kPa)

Cell 14 (Hyd.Pres. 63.5 kPa)

Cell 15 (Hyd.Pres. 91.1 kPa)

Cell 16 (Hyd.Pres. 98.7 kPa)

Mix 1 and 2: Fast increase in yield stress and thixotropy low

formwork pressure

Mix 3: Slow increase in yield stress and thixotropy high formwork

pressure

Results confirm that high static yield stress

reduces formwork pressure.

27

Applications: Segregation Resistance

SCC consists of aggregates suspended in a thixotropic, Bingham

paste

Paste must exhibit proper rheology to suspend a particular set of

aggregates

Static yield stress > minimum static yield stress: no segregation

Static yield stress < minimum static yield stress: rate of descent of aggregate

depends on paste yield stress and viscosity

Reference Equation

Beris, A. N., Tsamopoulos, J.A., Armstrong,

R.C., and Brown, R.A. (1985). Creeping motion

of a sphere through a Bingham plastic, J ournal

of Fluid Mech., 158, 219-244.

Jossic, L., and Magnin, A. (2001). Drag and

Stability of Objects in a Yield Stress Fluid,

AIChE J ournal, 47(12). 2666-2672.

Saak, A.W., Jennings, H.M., and Shah, S.P.

(2001). New Methodology for Designing Self-

Compacting Concrete, ACI Materials J ournal,

98(6), 429-439.

( )R g

fluid sphere

t > ) 09533 . 0 (

0

( )R g

fluid sphere

t > ) 124 . 0 (

0

( )R g

fluid sphere

t >

3

4

0

Buoyancy + Resisting Force

-Paste rheology

-Paste density

-Aggregate morphology

-Neighboring aggregates (lattice

effect)

Gravitational Force

-Aggregate density

-Aggregate size

Equations relating descent of sphere to rheology

Reference: Koehler, E.P., and Fowler, D.W. (2008). Static and Dynamic

Yield Stress Measurements of SCC Proceedings of SCC 2008, Chicago, IL.

28

Applications: Segregation Resistance

0

5

10

15

20

25

30

35

40

45

50

0 20 40 60 80 100

Dynamic Yield Stress, 0 min. (Pa)

P

l

a

s

t

i

c

V

i

s

c

o

s

i

t

y

,

0

m

i

n

.

(

P

a

.

s

)

Column Seg<10%

Column Seg>10%

-0.05

0.00

0.05

0.10

0.15

0.20

0 20 40 60 80 100

Dynamic Yield Stress, 0 min. (Pa)

T

h

i

x

o

t

r

o

p

y

y

,

0

m

i

n

.

(

N

m

/

s

)

Column Seg<10%

Column Seg>10%

Segregation resistance increased with:

Higher yield stress (static and dynamic yield stress assumed equal initially)

Higher plastic viscosity

Higher thixotropy

Reference: Koehler, E.P., and Fowler, D.W. (2008). Static and Dynamic

Yield Stress Measurements of SCC Proceedings of SCC 2008, Chicago, IL.

29

Applications: Pumpability

Concrete moves through a

pump line as a plug

surrounded by a sheared

region at the walls.

Higher viscosity increases

pumping pressure, reduces flow

rate

Unstable mixes may cause

blocking

Pumping concrete in high-rise

buildings presents unique

challenges

High strength mixes often have

low w/cm, resulting in high

concrete viscosity

Blockage can result in significant

jobsite delays

(

(

|

|

.

|

\

|

+

|

|

.

|

\

|

=

4

0 0

4

3

1

3

4

1

8

w w

L

PR

Q

t

t

t

t

t

Buckingham-Reiner Equation

sheared

region

plug flow

region

flow

shear stress = yield stress

wall at stress shear

radius tube

rate flow

=

=

=

w

R

Q

t

length tube

pressure

=

=

L

P

30

Applications: Pumpability Case Study

Duke Energy Building, Charlotte, NC

52 Story Office Tower (764 ft) with 9 story building

annex

8 Story Parking Structure 95 ft below street level

Concrete Mixture Requirements

Compressive Strength

5,000 psi to 18,000 psi (35 to 124 MPa)

Modulus of Elasticity

4.6 to 8.0 x 10

6

psi (32 to 55 GPa)

Workability

27 +/- 2 inch spread (690 +/- 50 mm)

To meet compressive strength and elastic

modulus requirements, the high strength

concrete mixtures were proportioned with:

Low w/c

Silica fume

High-modulus crushed coarse aggregate

The resulting mixture exhibited:

High viscosity

High pump pressure

Reference: Koehler, E.P., and Brooks, W., Neuwald, A., and

Mogan, E.. (2009). Applications of Rheology Measurements to

Enable and Ensure Concrete Performance NRMCA Concrete

Technology Forum, Cincinnati, OH.

31

Applications: Pumpability Case Study

Duke Energy Building, Charlotte, NC

32

Applications: Pumpability Case Study

VMA and/or other changes in

mixture proportions were shown to

increase pumpability by reducing

concrete viscosity.

Role of VMA in reducing viscosity:

VMA results in shear-thinning behavior

Increased viscosity (thickens) concrete at rest

and at low shear rates: beneficial for reduced

formwork pressure and increased segregation

resistance

Decreased viscosity (thins) at high shear rates:

beneficial for improved pumpability

Reduced pump stroke time confirmed

in field mix with VMA

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

0.00 0.10 0.20 0.30

Rotation Speed (rps)

T

o

r

q

u

e

(

N

m

)

#1: baseline

#4: Increase paste vol

#4: +VMA

#5: Increase w/cm

#5: +VMA

#6: Change agg

#6: +VMA

Duke Energy Building, Charlotte, NC

33

Conclusions

Rheology is the scientific description of workability.

The ICAR rheometer enables portable rheology measurements in

the lab and field.

Measures concrete greater than 75 mm slump

Measures yield stress, plastic viscosity, and thixotropy

Rheology was shown to provide insights into the following

applications:

Mixture proportioning

SCC

Production control

Formwork pressure

Segregation resistance

Pumpability

34

Thank You.

Questions?

You might also like

- ICAR Rheometer Users ManualDocument24 pagesICAR Rheometer Users ManualJAVIER ANDRADE MARTINEZNo ratings yet

- Le ' Mac Apartments: Floor Plan Sectional PlanDocument2 pagesLe ' Mac Apartments: Floor Plan Sectional PlanAdnan KhanNo ratings yet

- The Remarkable Effect of Sugar in ConcreteDocument4 pagesThe Remarkable Effect of Sugar in ConcretepixeldirigbleNo ratings yet

- Building Management System (BMS) OR Building Automation System (BAS)Document23 pagesBuilding Management System (BMS) OR Building Automation System (BAS)NIRU CHAUDHARYNo ratings yet

- Case Study - 2Document93 pagesCase Study - 2Amanpreet Singh100% (1)

- Computer Aided Civil Engineering Lab Semester: 02 Duration: 3 Hrs. Branch: Civil Engineering Max. Marks: 100Document4 pagesComputer Aided Civil Engineering Lab Semester: 02 Duration: 3 Hrs. Branch: Civil Engineering Max. Marks: 100Anonymous SEDun6PW100% (2)

- Air Content Test ApparatusDocument10 pagesAir Content Test ApparatusGolam MasudNo ratings yet

- Heat of HydrationDocument3 pagesHeat of HydrationvigneshwarimahamuniNo ratings yet

- Concrete Technology Mini Project Group:8Document22 pagesConcrete Technology Mini Project Group:8Mashal Shah JehanNo ratings yet

- Sikadur 31 CF Normal: 2-Part Thixotropic Epoxy AdhesiveDocument4 pagesSikadur 31 CF Normal: 2-Part Thixotropic Epoxy Adhesiverahayu59No ratings yet

- Report 2 Water Absorption of BlockDocument8 pagesReport 2 Water Absorption of BlockZhiwar oramariNo ratings yet

- SEEP-W PowerPointDocument43 pagesSEEP-W PowerPointketema DNo ratings yet

- Coating - PaintsDocument76 pagesCoating - Paintsjeo TinioNo ratings yet

- Basf Masterflow 950 TdsDocument3 pagesBasf Masterflow 950 TdsplmoNo ratings yet

- Ferrocement C-Beams/Rafters: Submitted By: Pratyush 12617Document6 pagesFerrocement C-Beams/Rafters: Submitted By: Pratyush 12617AnjalySinhaNo ratings yet

- Project For Using Different Sizes of Coarse Aggregate For Concrete StrengthDocument18 pagesProject For Using Different Sizes of Coarse Aggregate For Concrete StrengthZohaib Siapad100% (7)

- Eaab BomceDocument22 pagesEaab BomceBert EngNo ratings yet

- Mebs6000 1011 01 Cold & Flush WaterDocument70 pagesMebs6000 1011 01 Cold & Flush Waterstaryklt100% (1)

- Department of Civil Engineering: Reticulation DesignDocument30 pagesDepartment of Civil Engineering: Reticulation Designanon_307271108100% (1)

- Grouts Standards and TestingDocument12 pagesGrouts Standards and TestingmithileshNo ratings yet

- Complex Engineering Problem Fall 2019 HE, CE-432Document1 pageComplex Engineering Problem Fall 2019 HE, CE-432Muhammad AdilNo ratings yet

- ACI (Absolute Volume) MethodDocument5 pagesACI (Absolute Volume) Methodjyothis_joy77No ratings yet

- Design # 1: TitleDocument11 pagesDesign # 1: TitleFarah Mujahid0% (1)

- Low Density Concretes: For Insulation and FillDocument3 pagesLow Density Concretes: For Insulation and FillAnonymous EIjnKecu0JNo ratings yet

- Test 1 - Concrete Mix Design DishanDocument20 pagesTest 1 - Concrete Mix Design DishanYasndra AbeygunewardhaneNo ratings yet

- Co 34Document10 pagesCo 34Baskar Srinivas SNo ratings yet

- AJEL2013 Notes (202201)Document109 pagesAJEL2013 Notes (202201)JckyNo ratings yet

- Structural Engineering Presentation - GeneDocument51 pagesStructural Engineering Presentation - Genepm1802No ratings yet

- StudentDocument7 pagesStudentKartik AryanNo ratings yet

- Major and Minor LossesDocument8 pagesMajor and Minor Lossesapi-376123036No ratings yet

- Design and Analysis of Flat Slab Floor SDocument93 pagesDesign and Analysis of Flat Slab Floor SKousalya MkNo ratings yet

- Final ProjectDocument26 pagesFinal Projecteidalin100% (1)

- Structural Steel Reuse in ConstructionDocument12 pagesStructural Steel Reuse in ConstructionMuhammad MurtazaNo ratings yet

- TP Water RetainingDocument22 pagesTP Water RetainingChinthaka SomaratnaNo ratings yet

- Quantity of CementDocument19 pagesQuantity of CementAl Patrick Dela CalzadaNo ratings yet

- Standard Room Sizes and Room Area - Detailed InformationDocument9 pagesStandard Room Sizes and Room Area - Detailed InformationTATA STEELNo ratings yet

- Curved BeamsDocument2 pagesCurved Beamsivan bolañosNo ratings yet

- (IOE) MSc. Old Questions of Transportation Engg. I/IDocument23 pages(IOE) MSc. Old Questions of Transportation Engg. I/ISwopnil KalikaNo ratings yet

- Ethiopian ES 4050 ES 1176-3:2005: First Edition 2005-03-12Document12 pagesEthiopian ES 4050 ES 1176-3:2005: First Edition 2005-03-12Dilnesa EjiguNo ratings yet

- Material Particulars Unit Quantity Rate AmountDocument4 pagesMaterial Particulars Unit Quantity Rate Amountsam_bhopNo ratings yet

- Government Gazette Staatskoerant: Republic of South Africa Republiek Van Suid AfrikaDocument16 pagesGovernment Gazette Staatskoerant: Republic of South Africa Republiek Van Suid AfrikaDocumentsZANo ratings yet

- Waffle SlabDocument23 pagesWaffle SlabAmgad TalalNo ratings yet

- Concrete Slab CheckDocument2 pagesConcrete Slab CheckdennyherdanathaNo ratings yet

- Manual SewercadDocument8 pagesManual SewercadDianna VillavicencioNo ratings yet

- Total 17,800 6.33 3,015 62 10,400 262 7.82: BrickworkDocument2 pagesTotal 17,800 6.33 3,015 62 10,400 262 7.82: BrickworkFireSwarmNo ratings yet

- Chapter 1B Mat FoundationsDocument17 pagesChapter 1B Mat Foundationsmohamed hassan adenNo ratings yet

- The Effect of Excess Water in ConcreteDocument2 pagesThe Effect of Excess Water in ConcreteKevin NacalabanNo ratings yet

- Water RecDocument2 pagesWater RecMatthew WeeNo ratings yet

- Chapter 8Document12 pagesChapter 8gilbert850507No ratings yet

- Sieve Analysis IntroductionDocument2 pagesSieve Analysis IntroductionJacky TanNo ratings yet

- Environmental Exposure Conditions of StructuresDocument2 pagesEnvironmental Exposure Conditions of StructuresDeep DebnathNo ratings yet

- (Invalid) PDFDocument69 pages(Invalid) PDFshubham goelNo ratings yet

- External MoistureDocument198 pagesExternal MoistureVasant SunerkarNo ratings yet

- Impact of JetDocument13 pagesImpact of JetUmmi SurayaNo ratings yet

- Koehler Rheology v1Document32 pagesKoehler Rheology v1Narasimham GuggillaNo ratings yet

- RheologyDocument37 pagesRheologyVassilios Kelessidis0% (1)

- Portable Rheometer For SCCDocument6 pagesPortable Rheometer For SCCSanjay MokalNo ratings yet

- Hydraulic FracturingDocument8 pagesHydraulic FracturingSikander Mushtaq100% (1)

- DRILLING HYDRAULICS (Introduction)Document27 pagesDRILLING HYDRAULICS (Introduction)Yusuf Maringga100% (1)

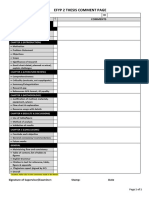

- Efyp 2 Thesis Comment Page: Area CommentsDocument1 pageEfyp 2 Thesis Comment Page: Area CommentsHafiezul HassanNo ratings yet

- Circuit DesignDocument15 pagesCircuit DesignHafiezul HassanNo ratings yet

- Eçon C ' G:: Ahier D Accompagnement Rammaire Notes ET Exercices SupplémentairesDocument13 pagesEçon C ' G:: Ahier D Accompagnement Rammaire Notes ET Exercices SupplémentairesHafiezul HassanNo ratings yet

- Fatigue FailureDocument5 pagesFatigue FailureHafiezul HassanNo ratings yet

- Numerical MethodDocument46 pagesNumerical MethodHafiezul HassanNo ratings yet

- Titanium Green MaterialDocument1 pageTitanium Green MaterialHafiezul HassanNo ratings yet

- Press Release: "Trupunch 5000" Increases Sheet Metal Forming CapacityDocument2 pagesPress Release: "Trupunch 5000" Increases Sheet Metal Forming CapacityHafiezul HassanNo ratings yet

- Ethics Practice ProblemsDocument5 pagesEthics Practice ProblemsHafiezul HassanNo ratings yet

- Titanium: The Green Metal For The 21st Century: George - Chen@nottingham - Ac.ukDocument1 pageTitanium: The Green Metal For The 21st Century: George - Chen@nottingham - Ac.ukHafiezul HassanNo ratings yet

- Memorial Go-Kart Inc.: 5308 Hwy 175 Hartford, WI 53027 262-644-8375Document5 pagesMemorial Go-Kart Inc.: 5308 Hwy 175 Hartford, WI 53027 262-644-8375Hafiezul HassanNo ratings yet

- Experiment 5: Impact of Water JetDocument8 pagesExperiment 5: Impact of Water JetHafiezul HassanNo ratings yet

- Small Business Innovation Research (SBIR)Document132 pagesSmall Business Innovation Research (SBIR)Hafiezul HassanNo ratings yet

- Small Business Innovation Research (SBIR)Document132 pagesSmall Business Innovation Research (SBIR)Hafiezul HassanNo ratings yet

- HijabDocument18 pagesHijabHafiezul HassanNo ratings yet

- Power Curve PerformanceDocument7 pagesPower Curve PerformanceHafiezul HassanNo ratings yet

- Sunmotor Solar Power SystemsDocument10 pagesSunmotor Solar Power SystemsHafiezul HassanNo ratings yet

- Bending Stress Formula Shear Stress FormulaDocument2 pagesBending Stress Formula Shear Stress FormulaHafiezul HassanNo ratings yet

- Approaching Free Electricity: How The Real-World Differs From Thermodynamic ModelsDocument12 pagesApproaching Free Electricity: How The Real-World Differs From Thermodynamic ModelsHafiezul HassanNo ratings yet

- Risk AssessmentDocument7 pagesRisk AssessmentHafiezul HassanNo ratings yet

- Research Center For Modeling & Simulation (RCMS) National University of Sciences & TechnologyDocument2 pagesResearch Center For Modeling & Simulation (RCMS) National University of Sciences & TechnologyHafiezul HassanNo ratings yet

- Applied Physics (BCS-1) : Assignment#2Document2 pagesApplied Physics (BCS-1) : Assignment#2Muhammad Hammad MustafaNo ratings yet

- Dog Leg SeverityDocument7 pagesDog Leg Severitymadonnite3781No ratings yet

- (10-4-3) NPTEL - Gas Liquefaction and Refrigeration SystemsDocument46 pages(10-4-3) NPTEL - Gas Liquefaction and Refrigeration SystemsThermal_EngineerNo ratings yet

- Measurement of Ground Vibrations and Airblast: Technical Note 03Document8 pagesMeasurement of Ground Vibrations and Airblast: Technical Note 03Abdul jNo ratings yet

- 10 Book PDFDocument226 pages10 Book PDFayesh aldiriNo ratings yet

- Bigbang TheoryDocument13 pagesBigbang TheoryRen-ren MacanNo ratings yet

- Artikel Fisika Bahasa Inggris Tentang Waves-2Document4 pagesArtikel Fisika Bahasa Inggris Tentang Waves-2Xerxes Xanthe XyzaNo ratings yet

- AA02Phys132 Course Guide Midyear Term 2020-2021Document4 pagesAA02Phys132 Course Guide Midyear Term 2020-2021Music LastNo ratings yet

- Rheology: Essential Elements ..How Materials Flow 4 Essential Elements of Rheology AreDocument17 pagesRheology: Essential Elements ..How Materials Flow 4 Essential Elements of Rheology Arefakemoney makeNo ratings yet

- Problems s4Document4 pagesProblems s4zangue billy jamesNo ratings yet

- J. Dario Aristizabal-Ochoa: Ph.D. School of Mines, National University, Medellin, Colombia, Jdaristi@unal - Edu.coDocument11 pagesJ. Dario Aristizabal-Ochoa: Ph.D. School of Mines, National University, Medellin, Colombia, Jdaristi@unal - Edu.cokarrakukafeoNo ratings yet

- 2018 Theme 4c Kinematics Thrust BlocksDocument47 pages2018 Theme 4c Kinematics Thrust BlocksAclaire ChamussaNo ratings yet

- List of Definition For SPM PhysicsDocument11 pagesList of Definition For SPM PhysicsRyan KerkNo ratings yet

- Figure 1. Drag Coefficient As A Function of SphericityDocument9 pagesFigure 1. Drag Coefficient As A Function of SphericityPAULA ANDREA CARO BAEZNo ratings yet

- 2 ManometersDocument18 pages2 Manometersatb160No ratings yet

- Fde312 Part IDocument39 pagesFde312 Part ISrijan GuptaNo ratings yet

- Aerodynamically Induced Resonance in Rectangular Cavities: Sound VibDocument11 pagesAerodynamically Induced Resonance in Rectangular Cavities: Sound VibRehan NaseerNo ratings yet

- GEASDocument5 pagesGEASEdward Roy “Ying” AyingNo ratings yet

- Drag DerivationDocument3 pagesDrag DerivationMani VannanNo ratings yet

- Open Ended Structure LabDocument24 pagesOpen Ended Structure LabIzzatul Syahira Binti ZakariaNo ratings yet

- SDOF PlasticDocument19 pagesSDOF Plasticvaram1No ratings yet

- Friction Notes - Iit-Jee - Bitsat - Neet - AiimsDocument32 pagesFriction Notes - Iit-Jee - Bitsat - Neet - Aiims145Ducks50% (10)

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3Hunnymijie NorNo ratings yet

- IFEM Solution Ch15Document3 pagesIFEM Solution Ch15Sajjad AhmadNo ratings yet

- Astm D 2170 - 07Document10 pagesAstm D 2170 - 07m_seyedNo ratings yet

- 1 Background - The 2D Distinct Element MethodDocument36 pages1 Background - The 2D Distinct Element MethodRakshit MishraNo ratings yet

- Simple MachinesDocument16 pagesSimple Machinesapi-176501107No ratings yet

- Lifting Analysis - TrunnionDocument3 pagesLifting Analysis - TrunnionMudasir MughalNo ratings yet

- Machine Design SpringsDocument4 pagesMachine Design Springscoc boyNo ratings yet

- Weight of Block + Weight Added vs. Weight of Pan + Weight AddedDocument1 pageWeight of Block + Weight Added vs. Weight of Pan + Weight AddedJohnoricks Ace Camarillo CatlingNo ratings yet