Professional Documents

Culture Documents

Welding Metallurgy

Uploaded by

hemant1886Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Metallurgy

Uploaded by

hemant1886Copyright:

Available Formats

Welding Metallurgy 2

Welding Metallurgy 2

Lesson Objectives When you finish this lesson you will understand: The various region of the weld where liquid does not form Mechanisms of structure and property changes associated with these regions

Learning Activities 1. View Slides; 2. Read Notes, 3. Listen to lecture 4. Do on-line workbook 5. Do homework

Keywords: Heat affected zone, Base metal, Solutionizing treatment, Aging, welding procedure, heat input, Hydrogen cracking, Carbon equivalent, Lamellar Tearing, Reheat Cracking, Knife-line attack,

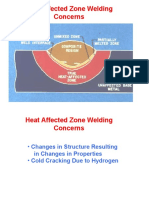

Heat Affected Zone Welding Concerns

Heat Affected Zone Welding Concerns

Changes in Structure Resulting in Changes in Properties Cold Cracking Due to Hydrogen

Look At Two Types of Alloy Systems

Cold Worked Alloy Without Allotropic Transformation

Introductory Welding Metallurgy, AWS, 1979

Welding Precipitation Hardened Alloys Without Allotropic Phase Changes Welded In: Full Hard Condition Solution Annealed Condition

Introductory Welding Metallurgy, AWS, 1979

Annealed upon Cooling

Precipitation Hardened Alloy Welded in Full Hard Condition

Introductory Welding Metallurgy, AWS, 1979

Precipitation Hardened Alloys Welded in Solutioned Condition

Introductory Welding Metallurgy, AWS, 1979

Turn to the person sitting next to you and discuss (1 min.): Precipitation hardened austenitic stainless steel is used for high strength applications like rocket components etc. Reviewing the various procedures for welding precipitation hardened steels, what procedure would you recommend? Does it make any difference that this is austenitic stainless steel and not just plain carbon steel?

Steel Alloys With Allotropic Transformation

Introductory Welding Metallurgy, AWS, 1979

Introductory Welding Metallurgy, AWS, 1979

Turn to the person sitting next to you and discuss (1 min.): As we saw, the cooling rate can depend upon the preheat and the heat input. Many codes actually specify the range of heat inputs that can be used to weld certain materials. We had an equation to determine the heat input before. What is it? What processes have the highest Heat Inputs? The lowest?

Cracking in Welds

Hydrogen Cracking

Hydrogen cracking, also called cold cracking, requires all three of these factors

Hydrogen Stress Susceptible microstructure (high hardness)

Occurs below 300C Prevention by

Preheat slows down the cooling rate; this can help avoid martensite formation and supplies heat to diffuse hydrogen out of the material Low-hydrogen welding procedure

0.1.1.5.2.T12.95.12

Dickinson

Carbon and Low-Alloy Steels

Why Preheat?

Preheat reduces the temperature differential between the weld region and the base metal

Reduces the cooling rate, which reduces the chance of forming martensite in steels Reduces distortion and shrinkage stress Reduces the danger of weld cracking Allows hydrogen to escape

0.1.1.5.1.T9.95.12

Using Preheat to Avoid Hydrogen Cracking

If the base material is preheated, heat flows more slowly out of the weld region

Slower cooling rates avoid martensite formation

Steel

Preheat allows hydrogen to diffuse from the metal

T base Cooling rate T - Tbase)3

Cooling rate T - Tbase)2

T base

Interaction of Preheat and Composition

Carbon equivalent (CE) measures ability to form martensite, which is necessary for hydrogen cracking

CE < 0.35 treatment 0.35 < CE < 0.55 0.55 < CE treatment no preheat or postweld heat

preheat preheat and postweld heat

Steel

CE = %C + %Mn/6 + %(Cr+Mo+V)/5 + %(Si+Ni+Cu)/15

Preheat temp. as CE and plate thickness

Carbon and Low-Alloy Steels

Why Post-Weld Heat Treat?

The fast cooling rates associated with welding often produce martensite During postweld heat treatment, martensite is tempered (transforms to ferrite and carbides)

Reduces hardness Reduces strength Increases ductility Increases toughness

Residual stress is also reduced by the postweld heat treatment

0.1.1.5.1.T10.95.12

Postweld Heat Treatment and Hydrogen Cracking

Postweld heat treatment (~ 1200F) tempers any martensite that may have formed

Increase in ductility and toughness Reduction in strength and hardness

Steel

Residual stress is decreased by postweld heat treatment Rule of thumb: hold at temperature for 1 hour per inch of plate thickness; minimum hold of 30 minutes

Base Metal Welding Concerns

Cracking in Welds

Lamellar Tearing

Occurs in thick plate subjected to high transverse welding stress Related to elongated non-metallic inclusions, sulfides and silicates, lying parallel to plate surface and producing regions of reduced ductility Prevention by

Low sulfur steel Specify minimum ductility levels in transverse direction Avoid designs with heavy through-thickness direction stress

0.1.1.5.2.T14.95.12

Improve Cleanliness Improve through thickness properties Buttering

Carbon and Low-Alloy Steels

Multipass Welds

Heat from subsequent passes affects the structure and properties of previous passes

Tempering Reheating to form austenite Transformation from austenite upon cooling

Complex Microstructure

0.1.1.5.1.T11.95.12

Steel

Multipass Welds

Exhibit a range of microstructures Variation of mechanical properties across joint Postweld heat treatment tempers the structure

Reduces property variations across the joint

Cracking in Welds

Reheat Cracking

Mo-V and Mo-B steels susceptible Due to high temperature embrittlement of the heat-affected zone and the presence of residual stress Coarse-grained region near fusion line most susceptible Prevention by

Low heat input welding Intermediate stress relief of partially completed welds Design to avoid high restraint Restrict vanadium additions to 0.1% in steels

0.1.1.5.2.T15.95.12

Stainless Steel

Knife-Line Attack in the HAZ

HAZ

Cr23C6 precipitate in HAZ

Band where peak temperature is 8001600F

Weld

Knife-line attack

Can occur even in stabilized grades

Peak temperature dissolves titanium carbides Cooling rate doesnt allow them to form again

You might also like

- 01 - WELDING DEFECTS (Surface) - May 2021Document28 pages01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoNo ratings yet

- Visual Weld Inspection and Defect Identification GuideDocument46 pagesVisual Weld Inspection and Defect Identification GuideDương PhúcNo ratings yet

- Example Slide of User Functions: Time Guide The Slide Should Be Finished byDocument220 pagesExample Slide of User Functions: Time Guide The Slide Should Be Finished byScott K.L LeeNo ratings yet

- Welding Metallurgy - Detailed PDFDocument28 pagesWelding Metallurgy - Detailed PDFkarcoepm100% (1)

- Welding Metallurgy - Detailed PDFDocument28 pagesWelding Metallurgy - Detailed PDFkarcoepm100% (1)

- Distortion - Australian Welding InstituteDocument19 pagesDistortion - Australian Welding InstitutenellaiNo ratings yet

- 2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoDocument12 pages2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoJohn SmithNo ratings yet

- The Physics of Welding: International Institute of WeldingFrom EverandThe Physics of Welding: International Institute of WeldingRating: 1.5 out of 5 stars1.5/5 (2)

- WPE2 Course Notes PDFDocument356 pagesWPE2 Course Notes PDFQuoc Vinh100% (2)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- An Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandAn Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- Welding Processes and EquipmentDocument167 pagesWelding Processes and EquipmentTAF150850No ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Weld Imperfections and Preventive MeasuresDocument25 pagesWeld Imperfections and Preventive Measuresecaph244100% (1)

- Welding Defect TWI CSWIPDocument54 pagesWelding Defect TWI CSWIPMahdi Daly100% (4)

- 06 - Weld Ability and Defects in WeldmentsDocument50 pages06 - Weld Ability and Defects in Weldmentsamitjee138463No ratings yet

- WIS5 Mechanical Testing - 03Document57 pagesWIS5 Mechanical Testing - 03Sầu ĐờiNo ratings yet

- TWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyDocument53 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyOnur Altuntaş100% (1)

- 15.welding Engineering PDFDocument15 pages15.welding Engineering PDFEmad A.Ahmad100% (2)

- Good Welding Practice Stainless Steels-PresentaciónDocument30 pagesGood Welding Practice Stainless Steels-PresentaciónSaúl L Hdez TNo ratings yet

- Iiw Welding GuidelinesDocument95 pagesIiw Welding Guidelinestomychalil100% (2)

- CSWIP-WI-6-92 14th Edition April 2017Document17 pagesCSWIP-WI-6-92 14th Edition April 2017mullanjiNo ratings yet

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- Defects and Discontinuities GuideDocument68 pagesDefects and Discontinuities GuideRahulKumarNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- 01 Wis5 Defect NewDocument55 pages01 Wis5 Defect NewHai Vuu100% (2)

- WIS5 Imperfections 2006Document78 pagesWIS5 Imperfections 2006hemant1886No ratings yet

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- Documents Governing Welding Inspection and QualificationDocument56 pagesDocuments Governing Welding Inspection and Qualificationtuvu100% (4)

- Lecture 1-Fundamentals of Welding MetallurgyDocument46 pagesLecture 1-Fundamentals of Welding MetallurgyHamiduNo ratings yet

- Welding MetallurgyDocument30 pagesWelding MetallurgySamanthaPereraNo ratings yet

- Iwt Book PDFDocument1,196 pagesIwt Book PDFsree100% (1)

- Iws Materials and Their Behaviour PDFDocument282 pagesIws Materials and Their Behaviour PDFkatfy1No ratings yet

- Introduction to the Physical Metallurgy of WeldingFrom EverandIntroduction to the Physical Metallurgy of WeldingRating: 3 out of 5 stars3/5 (2)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Welding MetallurgyDocument37 pagesWelding Metallurgyhemant1886100% (4)

- Weld TestingDocument51 pagesWeld TestingYuki FongNo ratings yet

- Weldability of Aluminium Alloys GuideDocument3 pagesWeldability of Aluminium Alloys Guidebrijesh kinkhabNo ratings yet

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDocument29 pagesMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- TWI CSWIP 3.1 Wis 5 Welding Inspection NDT: World Centre For Materials Joining TechnologyDocument91 pagesTWI CSWIP 3.1 Wis 5 Welding Inspection NDT: World Centre For Materials Joining TechnologyOnur AltuntaşNo ratings yet

- API Safety and Fire Protection STANDARDSDocument3 pagesAPI Safety and Fire Protection STANDARDShemant1886No ratings yet

- Quality STANDARDDocument3 pagesQuality STANDARDhemant1886100% (1)

- ISO 9692 joint preparation guideDocument46 pagesISO 9692 joint preparation guidebiancogallazziNo ratings yet

- Weldability of Steels: CSWIP 3.1 Welding InspectionDocument105 pagesWeldability of Steels: CSWIP 3.1 Welding InspectionLương Hồ VũNo ratings yet

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFvijay rajputNo ratings yet

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsFrom EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsRating: 5 out of 5 stars5/5 (1)

- UW Computational-Finance & Risk Management Brochure Final 080613Document2 pagesUW Computational-Finance & Risk Management Brochure Final 080613Rajel MokNo ratings yet

- Gas Cutting WLDNG Process - 06 - Module 6Document100 pagesGas Cutting WLDNG Process - 06 - Module 6sskiitb100% (1)

- Prestressing ProductsDocument40 pagesPrestressing ProductsSakshi Sana100% (1)

- DAC3 March 2012Document319 pagesDAC3 March 2012John Boran100% (1)

- Welding Process and ConsumableDocument64 pagesWelding Process and Consumablenizar_ikmps100% (1)

- Label-Welding Defects PDFDocument1 pageLabel-Welding Defects PDFMuthuKumarNo ratings yet

- ME 328.3 E5 - Welding MetallurgyDocument41 pagesME 328.3 E5 - Welding Metallurgytbmari100% (1)

- 2004A Rev.4Document83 pages2004A Rev.4Ridwan Baharum100% (2)

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- Course Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)Document8 pagesCourse Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)SanthaKumar Muthu ThankaveluNo ratings yet

- WC514Document1 pageWC51455312714No ratings yet

- Welding Inspection Guide for SteelsDocument132 pagesWelding Inspection Guide for SteelsfahreezNo ratings yet

- METALURGI LAS (Welding Metallurgy) : Kristiana Pasau, ST., MT Teknik Mesin UkipDocument36 pagesMETALURGI LAS (Welding Metallurgy) : Kristiana Pasau, ST., MT Teknik Mesin UkipRobinson PasaribuNo ratings yet

- Welding MetallurgyDocument37 pagesWelding MetallurgyHary adiNo ratings yet

- Welding Metallurgy and Heat Affected Zone PropertiesDocument198 pagesWelding Metallurgy and Heat Affected Zone PropertiesAgil SetyawanNo ratings yet

- Heat Affected Zone Welding ConcernsDocument10 pagesHeat Affected Zone Welding ConcernsKirandeep GandhamNo ratings yet

- Welding MetallurgyDocument30 pagesWelding MetallurgySenakeNo ratings yet

- Heat Treatment and The Effect of Welding: Week 2Document44 pagesHeat Treatment and The Effect of Welding: Week 2Arun SundarNo ratings yet

- GOST Regulations GuideDocument10 pagesGOST Regulations Guidehemant1886No ratings yet

- Steel Heat Treatment Metallurgy and TechnologiesDocument832 pagesSteel Heat Treatment Metallurgy and TechnologiesSUNDRAMNAGANo ratings yet

- GATE Mechanical Engineering 2002Document12 pagesGATE Mechanical Engineering 2002hemant1886No ratings yet

- BSIDocument163 pagesBSIhemant1886100% (1)

- Welding CODESDocument4 pagesWelding CODEShemant1886No ratings yet

- International Standards OrganizationsDocument5 pagesInternational Standards Organizationshemant1886No ratings yet

- Most Popular Titles From APIDocument2 pagesMost Popular Titles From APIhemant1886No ratings yet

- Gate 2014 1 PDFDocument25 pagesGate 2014 1 PDFhemant1886No ratings yet

- Health & SAFETY STANDARDDocument2 pagesHealth & SAFETY STANDARDhemant1886No ratings yet

- GATE 2013: Answer Keys For ME - Mechanical EngineeringDocument2 pagesGATE 2013: Answer Keys For ME - Mechanical Engineeringhemant1886No ratings yet

- Aws Welding ShowDocument21 pagesAws Welding Showhemant1886No ratings yet

- RC2 30 07008 WRR 000 0001 B CDocument5 pagesRC2 30 07008 WRR 000 0001 B CRene D. ArrietaNo ratings yet

- Linings Vs CoatingsDocument2 pagesLinings Vs Coatingshemant1886No ratings yet

- Basic Weld JointsDocument14 pagesBasic Weld Jointshemant1886No ratings yet

- Arc Welding and Cutting NoiseDocument45 pagesArc Welding and Cutting Noisehemant1886No ratings yet

- Offshore EngineeringDocument392 pagesOffshore Engineeringriz2010No ratings yet

- Offshore Engineering - An IntroductionDocument273 pagesOffshore Engineering - An Introductionloveforyou_erNo ratings yet

- Microsoft PowerPoint - Austenitic Manganese Steel Compatibility Mode 2Document81 pagesMicrosoft PowerPoint - Austenitic Manganese Steel Compatibility Mode 2Damla Kaymakçı100% (1)

- Clad Vessle InfoDocument81 pagesClad Vessle Infohemant1886No ratings yet

- Abs GuidlineDocument340 pagesAbs Guidlinehemant1886No ratings yet

- MSS SP-75 2004Document31 pagesMSS SP-75 2004Argenis Daniel Nieves BerroetaNo ratings yet

- Pig PDFDocument74 pagesPig PDFNasron NasirNo ratings yet

- E-TON - Vector ST 250Document87 pagesE-TON - Vector ST 250mariusgrosyNo ratings yet

- Conplast SP430 0407Document4 pagesConplast SP430 0407Harz IndNo ratings yet

- AnkitDocument24 pagesAnkitAnkit MalhotraNo ratings yet

- FEM Lecture Notes-2Document18 pagesFEM Lecture Notes-2macynthia26No ratings yet

- Teleprotection Terminal InterfaceDocument6 pagesTeleprotection Terminal InterfaceHemanth Kumar MahadevaNo ratings yet

- APM Terminals Safety Policy SummaryDocument1 pageAPM Terminals Safety Policy SummaryVaviNo ratings yet

- Janapriya Journal of Interdisciplinary Studies - Vol - 6Document186 pagesJanapriya Journal of Interdisciplinary Studies - Vol - 6abiskarNo ratings yet

- Fujitsu Spoljni Multi Inverter Aoyg45lbt8 Za 8 Unutrasnjih Jedinica KatalogDocument4 pagesFujitsu Spoljni Multi Inverter Aoyg45lbt8 Za 8 Unutrasnjih Jedinica KatalogSasa021gNo ratings yet

- Make a Battery Level Indicator using LM339 ICDocument13 pagesMake a Battery Level Indicator using LM339 ICnelson100% (1)

- Planning For Network Deployment in Oracle Solaris 11.4: Part No: E60987Document30 pagesPlanning For Network Deployment in Oracle Solaris 11.4: Part No: E60987errr33No ratings yet

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDocument217 pages13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNo ratings yet

- Palmetto Bay's Ordinance On Bird RefugeDocument4 pagesPalmetto Bay's Ordinance On Bird RefugeAndreaTorresNo ratings yet

- Information Pack For Indonesian Candidate 23.06.2023Document6 pagesInformation Pack For Indonesian Candidate 23.06.2023Serevinna DewitaNo ratings yet

- WitepsolDocument21 pagesWitepsolAnastasius HendrianNo ratings yet

- OBHR Case StudyDocument8 pagesOBHR Case StudyYvonne TanNo ratings yet

- Ralf Behrens: About The ArtistDocument3 pagesRalf Behrens: About The ArtistStavros DemosthenousNo ratings yet

- Database Chapter 11 MCQs and True/FalseDocument2 pagesDatabase Chapter 11 MCQs and True/FalseGauravNo ratings yet

- TX Set 1 Income TaxDocument6 pagesTX Set 1 Income TaxMarielle CastañedaNo ratings yet

- 5.PassLeader 210-260 Exam Dumps (121-150)Document9 pages5.PassLeader 210-260 Exam Dumps (121-150)Shaleh SenNo ratings yet

- An Overview of National Ai Strategies and Policies © Oecd 2021Document26 pagesAn Overview of National Ai Strategies and Policies © Oecd 2021wanyama DenisNo ratings yet

- KDL 23S2000Document82 pagesKDL 23S2000Carlos SeguraNo ratings yet

- Lister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal WorldDocument4 pagesLister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal Worldcountry boyNo ratings yet

- Mini Ice Plant Design GuideDocument4 pagesMini Ice Plant Design GuideDidy RobotIncorporatedNo ratings yet

- Discursive Closure and Discursive Openings in SustainabilityDocument10 pagesDiscursive Closure and Discursive Openings in SustainabilityRenn MNo ratings yet

- Backup and Recovery ScenariosDocument8 pagesBackup and Recovery ScenariosAmit JhaNo ratings yet