Professional Documents

Culture Documents

Man Lifts

Uploaded by

Vicente CondOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Man Lifts

Uploaded by

Vicente CondCopyright:

Available Formats

Man lifts

DMS Safety

MSHA LAWS

.14100 (a) Preshift Inspections

.14101 Breaking Systems .14205 Manufacturer design capacity

.14132 Horns & Backup alarms

.15005 Fall Protection .12071 Movement or operation of equipment near highvoltage power lines.

OSHA LAWS

29 CFR 1910.67 Vehicle-mounted elevating & rotating work platforms 29 CFR 1926.20 General Safety & Health 29 CFR 1926.21 Safety Training & Education 29 CFR 1926.28 PPE 29 CFR 1926.550 Cranes, Derricks, Hoists,

READ & HEED

1. Only trained & authorized operators shall be permitted to operate the aerial lift. 2. A malfunctioning lift shall be shut down until repaired 3. The controls shall be plainly marked as to their function. 4. The controls shall be tested each day prior to use to determine that they are in safe operating condition. 5. All personal in the platform shall at all times, wear approved fall protection devices and other safety gear as required.

READ & HEED

6. Load limits specified by the manufacturer shall not be exceeded. 7. Instruction & warning placards shall be legible. 8. Aerial lifts shall not be used near electric lines unless the lines have been de energized or adequate clearance is maintained. 9. Employees using aerial lift shall be instructed how to recognize & avoid unsafe conditions & hazards. 10. Regular inspection of the job site & aerial lift shall be performed by competent persons.

READ & HEED

11. Ground controls shall not be operated unless permission has been obtained from personnel in the platform, except in case of an emergency. 12. Personnel shall always stand on the floor of the platform, not on boxes, planks, railings or other devices for a work position. 13. Aerial lifts may be field modified for uses other than those intended by the manufacturer only if certified in writing by the manufacturer.

Manlift

This is a 135 foot JLG lift which drove one wheel into a 6 inch deep depression about 24 inches in diameter, this caused a catapult action at the basket. He had his fall protection on and hooked to the proper point in the basket. He was tossed clear (above) of the basket and landed back inside, he hit his shin on something and skinned it to the bone. It took 14 stitches to close the wound, no word on how long he will be out.

Does it take that much effort to raise the platform?

I just can't understand why someone who is working on a lift that has plenty of reach finds it necessary to stand on the guardrail.

Not Manufactures Recommendation

He stated to me the guy that does his aerial work quit and he hired a guy that was much shorter in height so he added these step rails so the new employee could reach farther.

#1 Sign

This is a rough terrain forklift with a man basket on it. The front of the man basket has been removed. I called the company about the safety of the site and they told me that I should mind my own business and not worry about their site. Notice the guy in the man basket is giving me the #1 sign.

Labels

METAL/NONMETAL MINE FATALITY

On August 10, 2000, a 49-yearold miner with 22 years mining experience was fatally injured at an underground limestone mine. The victim and a co-worker were scaling from the basket of a scaling rig, about 60 feet from the floor. The basked became wedged against a pillar and while attempting to free it, the basket suddenly broke free and threw the victim out of it.

Best Practices

Persons should always tie off when working in elevated work areas.

Man baskets should be kept a safe distance away from walls to avoid being snagged

MINE FATALITY

On Tuesday, February 3, 2004, a miner was fatally injured when he was thrown from the elevated bucket of a 42-foot aerial bucket truck. The victim and two other miners were dismantling a shop building at a surface area of an underground mine. To remove one of the building's wooden support posts from the ground, a chain was attached between the aerial lift bucket and the post. When the victim applied upward pressure on the chain with the aerial lift, the post released from the ground, causing the aerial bucket to shift suddenly, throwing the victim out of the bucket. The victim fell approximately 22 feet to the ground.

Best Practices

Use equipment only for its intended purpose. Manlifts are not cranes! Wear safety belts and lines where there is a danger of falling. All persons in man-lift type buckets should be tied off using a short lanyard regardless of the activity they are performing. Routinely monitor work habits and strictly enforce compliance with established safe work procedures to ensure that personal protective equipment is used. Ensure that equipment operators are properly trained and know the rated capacity, limitations, and appropriate use of the equipment.

MINE FATALITY

On June 9, 2003, a 49-year old supervisor with 29 years mining experience was fatally injured when he was thrown from the elevated bucket of an aerial bucket truck. The victim and two other miners were dismantling a de-energized electrical substation on the surface area of an underground mine. To secure a steel "I-Beam" structure, a nylon rope was attached between the bucket of the aerial lift and the steel structure. After the steel structure was disconnected from the substation, the rope broke, causing the aerial bucket to shift suddenly, throwing the victim out of the bucket. The victim fell 28 feet 11 inches to the ground.

Best Practices

Use appropriate fall protection, including safety harnesses and safety lines, where there is a danger of falling. Use equipment for its intended purpose and within the design specifications of the manufacturer. Conduct pre-operational checks on equipment prior to operation and ensure that outriggers and equipment are ready for intended use. Size ropes/slings for maximum load applications and protect them from being cut when a load is applied. Ensure that all workers are properly trained in the task to be preformed, such as hoisting, rigging, equipment design capabilities, etc.

You might also like

- MS Erection of PH Activities 63mtr 25.12.21Document8 pagesMS Erection of PH Activities 63mtr 25.12.21AltafNo ratings yet

- Carrier Light Commercial Air Conditioner Split UnitDocument14 pagesCarrier Light Commercial Air Conditioner Split UnitABie ShallabyNo ratings yet

- Critical & General LiftingDocument9 pagesCritical & General LiftingVikash Kumar RayNo ratings yet

- Erection Methodology PresentationDocument34 pagesErection Methodology PresentationCyril BayugaNo ratings yet

- 2.LOAD CHART AT-22 T133750C (Color) PDFDocument21 pages2.LOAD CHART AT-22 T133750C (Color) PDFRoy Ferdy MassoloNo ratings yet

- Hoist Pre-Operational Inspection Check ListDocument1 pageHoist Pre-Operational Inspection Check ListMohd Shareen Ezzry Mohd SomNo ratings yet

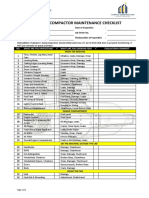

- Vibratory Compactor Maintenance Checklist: Carwill Construction IncDocument2 pagesVibratory Compactor Maintenance Checklist: Carwill Construction IncCarwill Tesda100% (1)

- JEI קטלוגDocument56 pagesJEI קטלוגחברת גוטמן ברזילי0% (1)

- Lift Classification Flow ChartDocument1 pageLift Classification Flow Chartcyno21100% (1)

- Swift TS06E Risk AssessmentDocument9 pagesSwift TS06E Risk AssessmentsouravrobinNo ratings yet

- SOP Endurequip HoistsDocument7 pagesSOP Endurequip HoistsMuhammad Zefrian SyahputraNo ratings yet

- JCB JS205LC Technical SpecsDocument2 pagesJCB JS205LC Technical SpecsMakNo ratings yet

- WMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1Document8 pagesWMS Infineon Project Tower ( Lightning Protection System Installation) - Rev-1tanaNo ratings yet

- Working at HeightDocument3 pagesWorking at HeightMelanie CortezNo ratings yet

- Catalogue For Self Loading Concrete MixerDocument11 pagesCatalogue For Self Loading Concrete Mixereduardofarfan30123265No ratings yet

- Man Basket Cert 7101Document1 pageMan Basket Cert 7101Mac-Ross Cordova100% (1)

- Machine Safety in ConstructionDocument27 pagesMachine Safety in ConstructionSawyu Nandar100% (1)

- 6 Safety Precautions When Moving Heavy Materials ManuallyDocument2 pages6 Safety Precautions When Moving Heavy Materials ManuallyMuhammad AmeenNo ratings yet

- Sany 60t Crane Loading ChartDocument11 pagesSany 60t Crane Loading Chartvivek pramod100% (1)

- Passenger HoistDocument10 pagesPassenger HoistParshant SainiNo ratings yet

- Lifting Fixing of GI SheetDocument1 pageLifting Fixing of GI SheetJack PNo ratings yet

- Contoh LIfting Plan #1Document5 pagesContoh LIfting Plan #1KevinNo ratings yet

- Complete ProjectDocument79 pagesComplete ProjectMithun RajNo ratings yet

- Topic For TBMDocument19 pagesTopic For TBMdauxomNo ratings yet

- Method Statement For CHP BracingDocument6 pagesMethod Statement For CHP BracingrajeshkunuNo ratings yet

- Lifting MethodologyDocument5 pagesLifting MethodologyRajveer SinghNo ratings yet

- 2021 JLG Training Catalog FinalDocument21 pages2021 JLG Training Catalog FinalYesica RamirezNo ratings yet

- Work Method Statement: Wms Rev. NoDocument5 pagesWork Method Statement: Wms Rev. NoKarthik babu100% (1)

- S-Aerial Lift SafetyDocument10 pagesS-Aerial Lift SafetyKostan AbdillahNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranNo ratings yet

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtNo ratings yet

- Power AscenderDocument6 pagesPower AscenderApriliando KurniawanNo ratings yet

- Crane Lift PlanDocument3 pagesCrane Lift PlandammyNo ratings yet

- Lift Installation Sequence of WorkDocument2 pagesLift Installation Sequence of Workaugus1982No ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

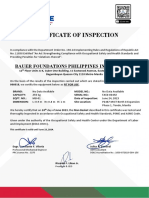

- Concrete Pump TPIDocument1 pageConcrete Pump TPIWakil AhmadNo ratings yet

- Genie Superlift SOP 003Document27 pagesGenie Superlift SOP 003Mauricio SantanaNo ratings yet

- JSA For HOT JobDocument1 pageJSA For HOT JobEquipment MaterialsNo ratings yet

- DAR Vol1-2013Document744 pagesDAR Vol1-2013chitransh2002No ratings yet

- Caretaker Risk Assessment - Working at HeightDocument8 pagesCaretaker Risk Assessment - Working at HeightLina MarcelaNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Manual LiftingDocument1 pageManual Liftingusama666100% (1)

- Injection Brochure MC-BauchemieDocument28 pagesInjection Brochure MC-BauchemieAlinMariciucNo ratings yet

- Weekly Monthly Inspection-Pdf-En PDFDocument1 pageWeekly Monthly Inspection-Pdf-En PDFMohamed Moustafa ElashwahNo ratings yet

- Belt Conveyor Troubleshooting: HGRS MASTER - MaintenanceDocument7 pagesBelt Conveyor Troubleshooting: HGRS MASTER - MaintenanceJerry HukyNo ratings yet

- Method Statement For Lifting Operations - Builders SafetyDocument2 pagesMethod Statement For Lifting Operations - Builders SafetyMuhammad Sami Parvez100% (1)

- Genie Scissor Lift GS 2632 - SWP Nov 12 2013Document5 pagesGenie Scissor Lift GS 2632 - SWP Nov 12 2013Cvijic DejanNo ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- Transport SpesificationDocument10 pagesTransport SpesificationJohn NainggolanNo ratings yet

- Cmci Cmci: Cemtec 200Document2 pagesCmci Cmci: Cemtec 200pravi3434No ratings yet

- APPENDIX 1 Issues For Method Statements in Industrial Roof WorkDocument3 pagesAPPENDIX 1 Issues For Method Statements in Industrial Roof WorkJulianna BakerNo ratings yet

- Drilling Process PDFDocument2 pagesDrilling Process PDFmool rajNo ratings yet

- Uta Ast RiggingDocument34 pagesUta Ast RiggingfawnNo ratings yet

- 2002 MNM FataliltiesDocument25 pages2002 MNM Fataliltiescurrent007No ratings yet

- Safety at Construction SiteDocument18 pagesSafety at Construction SiteShikhin GargNo ratings yet

- Safety and Health Checklist For Monitoring Transmission Line Construction WorksDocument6 pagesSafety and Health Checklist For Monitoring Transmission Line Construction WorksWinstone Audi100% (3)

- OSH5002 AssessmentDocument21 pagesOSH5002 AssessmentWan Ching WongNo ratings yet

- Enlightenment and The French RevolutionDocument20 pagesEnlightenment and The French RevolutionBKumrNo ratings yet

- Circular No. 38 /2016-Customs: - (1) Notwithstanding Anything Contained in This Act ButDocument18 pagesCircular No. 38 /2016-Customs: - (1) Notwithstanding Anything Contained in This Act ButAnshNo ratings yet

- BOQ-Lighting Control System-Swiss PharmaDocument1 pageBOQ-Lighting Control System-Swiss PharmaTalha FarooqNo ratings yet

- Eastern Shipping Lines v. POEA, G.R. No. 76633Document5 pagesEastern Shipping Lines v. POEA, G.R. No. 76633Daryl CruzNo ratings yet

- Imex CaseDocument17 pagesImex Caseipsita pandaNo ratings yet

- NET MAUI For C# Developers Jesse Liberty, Rodrigo Juarez, 2023 PacktDocument296 pagesNET MAUI For C# Developers Jesse Liberty, Rodrigo Juarez, 2023 PacktsvwerwolfNo ratings yet

- Ateneo de Manila University Philippine StudiesDocument34 pagesAteneo de Manila University Philippine Studiessamon sumulongNo ratings yet

- BSA1-5 PascualRaymond FinalExDocument5 pagesBSA1-5 PascualRaymond FinalExRaymond Pascual100% (1)

- LECTURE NOTES-Translation of Foreign FSDocument4 pagesLECTURE NOTES-Translation of Foreign FSGenesis CervantesNo ratings yet

- Laborlaw Orient Hope Agencies V Jara KeeDocument2 pagesLaborlaw Orient Hope Agencies V Jara KeeApple Ke-eNo ratings yet

- Pains of Imprisonment: University of Oslo, NorwayDocument5 pagesPains of Imprisonment: University of Oslo, NorwayFady SamyNo ratings yet

- Module 5 Ipr RMDocument48 pagesModule 5 Ipr RMravirayappaNo ratings yet

- ORIX PresentationDocument15 pagesORIX PresentationManish MishraNo ratings yet

- Roman Vs HerridgeDocument8 pagesRoman Vs HerridgeJanice PolinarNo ratings yet

- Case DigestDocument14 pagesCase DigestMerxeilles Santos100% (5)

- Subhash Chandra Bose The Untold StoryDocument9 pagesSubhash Chandra Bose The Untold StoryMrudula BandreNo ratings yet

- Declaration Form: District Police Station Mouza With J. L. No. Khatian No. Plot No. Total Area Area OwnedDocument1 pageDeclaration Form: District Police Station Mouza With J. L. No. Khatian No. Plot No. Total Area Area Ownedalok dasNo ratings yet

- Introduction of Corporate Governance: Unit-1Document20 pagesIntroduction of Corporate Governance: Unit-1Kusum LataNo ratings yet

- UP BOR vs. CA Case Digest - Richelle SendinDocument3 pagesUP BOR vs. CA Case Digest - Richelle SendinAlexis CatuNo ratings yet

- (DAILY CALLER OBTAINED) - Doe V San Diego Unified SCH Dist Doc. 5 1 Urgent Motion For IPADocument53 pages(DAILY CALLER OBTAINED) - Doe V San Diego Unified SCH Dist Doc. 5 1 Urgent Motion For IPAHenry Rodgers100% (1)

- Federal Lawsuit 5 16 CV 00184 RevisedDocument38 pagesFederal Lawsuit 5 16 CV 00184 RevisedPINAC NewsNo ratings yet

- Punong Himpilan Hukbong Dagat NG PilipinasDocument9 pagesPunong Himpilan Hukbong Dagat NG PilipinasSheryl Sofia GanuayNo ratings yet

- 2020 Contract Negotiations - Official ATU Proposal 6-25-21Document5 pages2020 Contract Negotiations - Official ATU Proposal 6-25-21Chicago Transit Justice CoalitionNo ratings yet

- Gender and Human Rights-5Document18 pagesGender and Human Rights-5Fahad AmeerNo ratings yet

- Ma2-2019 - Phan Gia BaoDocument8 pagesMa2-2019 - Phan Gia BaoBao PNo ratings yet

- CHAP03Document28 pagesCHAP03Dheeraj ShuklaNo ratings yet

- Five Ws Internal Audit36700Document13 pagesFive Ws Internal Audit36700Shah Maqsumul Masrur TanviNo ratings yet

- Gerund or Infinitive Worksheet Like Love Dislike Enjoy Hate Would Like Would Rather Want Interested in Good at Bad at PDFDocument2 pagesGerund or Infinitive Worksheet Like Love Dislike Enjoy Hate Would Like Would Rather Want Interested in Good at Bad at PDFKeyEliiz OrdoñezNo ratings yet

- EXTFILE134991159Document24 pagesEXTFILE134991159Narciso JuniorNo ratings yet

- J.K Shah Full Course Practice Question PaperDocument16 pagesJ.K Shah Full Course Practice Question PapermridulNo ratings yet