Professional Documents

Culture Documents

AISC Seismic Design-Module4-Eccentrically Braced Frames

Uploaded by

yaramounaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC Seismic Design-Module4-Eccentrically Braced Frames

Uploaded by

yaramounaCopyright:

Available Formats

Design of Seismic-

Resistant Steel

Building Structures

Prepared by:

Michael D. Engelhardt

University of Texas at Austin

with the support of the

American Institute of Steel Construction.

Version 1 - March 2007

4. Eccentrically Braced

Frames

Design of Seismic-Resistant

Steel Building Structures

1 - Introduction and Basic Principles

2 - Moment Resisting Frames

3 - Concentrically Braced Frames

4 - Eccentrically Braced Frames

5 - Buckling Restrained Braced Frames

6 - Special Plate Shear Walls

4 - Eccentrically Braced Frames (EBFs)

Description of Eccentrically Braced Frames

Basic Behavior of Eccentrically Braced Frames

AISC Seismic Provisions for Eccentrically Braced

Frames

Eccentrically Braced Frames (EBFs)

Description of Eccentrically Braced Frames

Basic Behavior of Eccentrically Braced Frames

AISC Seismic Provisions for Eccentrically Braced

Frames

Eccentrically Braced Frames (EBFs)

Framing system with beam, columns and braces. At least one end of

every brace is connected to isolate a segment of the beam called a

link.

Resist lateral load through a combination of frame action and truss

action. EBFs can be viewed as a hybrid system between moment

frames and concentrically braced frames.

Develop ductility through inelastic action in the links.

EBFs can supply high levels of ductility (similar to MRFs), but can

also provide high levels of elastic stiffness (similar to CBFs)

e

e

Link

Link

e

e

Link

Link

Some possible bracing arrangement for EBFS

e e

e e

e

e

Eccentrically Braced Frames (EBFs)

Description of Eccentrically Braced Frames

Basic Behavior of Eccentrically Braced Frames

AISC Seismic Provisions for Eccentrically Braced

Frames

Inelastic Response of EBFs

Energy Dissipation Mechanisms

MRF CBF

EBF

Design of EBFs - General Approach

Design frame so that inelastic behavior is

restricted to links.

Links are "fuse" elements of frame.

Links are weakest element of frame. All

other frame elements (braces, columns,

beam segments outside of link,

connections) are stronger than links.

Detail links to provide high ductility

(stiffeners, lateral bracing).

EBFs - Link Behavior

Link plastic rotation angle

Forces in links

Shear vs flexural yielding links

Link nominal strength

Post-yield behavior of links

Examples of experimental

performance of links

p

= link plastic rotation angle (rad)

Link Plastic Rotation Angle

p

p

p

= link plastic rotation angle (rad)

Link Plastic Rotation Angle

M

V

P

Link Behavior: Forces in Links

e e

e

V V

M M

V

M

M

Will link plastic strength be

controlled by shear or flexure?

Link length "e" is key parameter

that controls inelastic behavior

Link Behavior: Shear vs Flexural Yielding Links

e

V V

M M

V

M

M

Shear yielding occurs when:

Shear yield

stress of steel

web area of link

V

p

= fully plastic shear

capacity of link section

V = V

p

= 0.6 F

y

(d - 2t

f

) t

w

e

V V

M M

V

M

M

Flexural yielding occurs when:

M = M

p

= Z F

y

M

p

= fully plastic moment of

link section

Static equilibrium of link: Ve = 2M or:

e

2M

V

=

e

V V

M M

Shear vs. Flexural Yielding Links:

Shear and flexural yielding occur simultaneously

when V=V

p

and M=M

p

or, when:

p

p

V

M 2

e =

e

V

p

V

p

M

p

M

p

Shear yielding will occur

when V=V

p

and M < M

p

or, when:

e

2M

V

p

p

s

e

V

p

V

p

M M

V =V

p

M < M

p

shear yielding of web along

entire length of link

Shear yielding will occur

when M = M

p

and V < V

p

or, when:

e

V V

M

p

M

p

V <V

p

M = M

p

e

2M

V

p

p

>

M = M

p

flexural yielding at link ends

Shear Vs. Flexural Yielding Links:

e

2M

V

p

p

s

Simple Plastic Theory (assumes no strain hardening and

no shear - flexure interaction)

SHEAR YIELDING LINK:

FLEXURAL YIELDING LINK:

e

2M

V

p

p

>

Link Nominal Shear Strength, V

n

:

Link Nominal Shear Strength:

Basis for sizing links

Based on link shear at first significant

yield if link (in shear or flexure)

Based on simple plastic theory

(neglects shear-flexure interaction)

Link Nominal Shear Strength, V

n

:

V

n

= lesser of

V

p

2M

p

/ e

controls for:

controls for:

e

2M

V

p

p

s

p

p

V

2M

e >

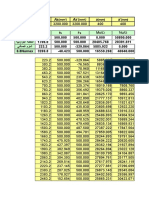

Example: W14x82 A992

kips in

ksi in

= = = 6950 50 139 ZF M

3

y p

( )

( )

kips

193

0 51 . 0 5 85 . 2 3 . 14 ksi 50 6 . 0

t t 2 d F 6 . 0 V

w f y p

=

' '

' '

' '

=

=

2 7 6 3 2

V

M 2

p

p

' '

=

' '

=

6 3

193

6950

V

M

p

p

' '

= =

kips

kips in

Example: W14x82 A992

V

n

= lesser of

V

p

2M

p

/ e

Link nominal shear strength:

= 193

kips

= 13,900

in-kips

/ e

Example: W14x82 A992

Link nominal shear strength:

0

50

100

150

200

250

0 36 72 108 144 180

Link Length e (inches)

L

i

n

k

N

o

m

i

n

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

i

p

s

)

0 1 2 3 4 5

e / (M

p

/V

p

)

V

n

=V

p

V

n

=2M

p

/e

-150

-100

-50

0

50

100

150

-0.15 -0.10 -0.05 0.00 0.05 0.10 0.15

Link Rotation, (rad)

L

i

n

k

S

h

e

a

r

F

o

r

c

e

(

k

i

p

s

)

Post-yield behavior of links: Strain hardening

V

n

V

ult

Post-yield behavior of links: Strain hardening

Effects of Strain Hardening:

At large inelastic deformations, link shear

resistance will significantly exceed V

n

V

ult

(1.25 to 1.5) V

n

Combined shear and flexural yielding will occur

over a range of link lengths.

e

1.6M

V

p

p

s

PREDOMINANTLY SHEAR YIELDING LINK:

PREDOMINANTLY FLEXURAL YIELDING LINK:

e

2.6 M

V

p

p

>

COMBINED SHEAR AND FLEXURAL YIELDING:

1.6M

V

e

2.6 M

V

p

p

p

p

s s

Post-yield behavior of links

Example: W14x82 A992

kips in

ksi in

= = = 6950 50 139 ZF M

3

y p

( )

( )

kips

193

0 51 . 0 5 85 . 2 3 . 14 ksi 50 6 . 0

t t 2 d F 6 . 0 V

w f y p

=

' '

' '

' '

=

=

6 3

193

6950

V

M

p

p

' '

= =

kips

kips in

Example: W14x82 A992 (cont)

6 3

V

M

p

p

' '

= 8 5

V

M

6 . 1

p

p

' '

= 4 9

V

M

6 . 2

p

p

' '

=

PREDOMINANTLY SHEAR YIELDING LINK: e s 58"

PREDOMINANTLY FLEXURAL YIELDING LINK: e > 94"

COMBINED SHEAR AND FLEXURAL YIELDING LINK: 58" < e < 94"

Link post-yield behavior:

Shear Yielding Links

p

p

V

M 1.6

e s

Provide best overall structural performance for:

strength

stiffness

ductility

V

A

e

=

A

e

Link Deformation:

(radian)

Experimental Performance of Shear Links

Experimental Performance of a Shear Link:

W10x33 (A992) e = 23" = 1.1 M

p

/V

p

Experimental Performance of a Shear Link:

W10x33 (A992) e = 23" = 1.1 M

p

/V

p

-150

-100

-50

0

50

100

150

-0.15 -0.10 -0.05 0.00 0.05 0.10 0.15

Link Rotation, (rad)

L

i

n

k

S

h

e

a

r

F

o

r

c

e

(

k

i

p

s

)

Experimental Performance of a Shear Link:

W10x33 (A992) e = 23" = 1.1 M

p

/V

p

Experimental Performance of a Shear Link:

W10x33 (A992) e = 23" = 1.1 M

p

/V

p

Experimental Performance of a Shear Link:

W10x33 (A992) e = 23" = 1.1 M

p

/V

p

-150

-100

-50

0

50

100

150

-0.15 -0.10 -0.05 0.00 0.05 0.10 0.15

Link Plastic Rotation,

p

(rad)

L

i

n

k

S

h

e

a

r

F

o

r

c

e

(

k

i

p

s

)

p

= 0.10 rad

Longer Links

p

p

V

M 1.6

e >

Longer links provide less strength, stiffness and

ductility

Use longer links only when needed for architectural

constraints

Experimental Performance of a Flexural Yielding Link:

W12x16 (A36) e = 44" = 3.4 M

p

/V

p

Experimental Performance of a Flexural Yielding Link:

W12x16 (A36) e = 44" = 3.4 M

p

/V

p

Experimental Performance of an Intermediate (Shear and Flexural Yielding) Link:

W16x36 (A992) e = 48" = 2 M

p

/V

p

Experimental Performance of an Intermediate (Shear and Flexural Yielding) Link:

W16x36 (A992) e = 48" = 2 M

p

/V

p

-200

-150

-100

-50

0

50

100

150

200

-0.15 -0.1 -0.05 0 0.05 0.1 0.15

Link Rotation, (rad)

L

i

n

k

S

h

e

a

r

F

o

r

c

e

(

k

i

p

s

)

0

0.04

0.08

0.12

0 1 2 3 4 5

Link Length: e/ (M

p

/ V

p

)

L

i

n

k

P

l

a

s

t

i

c

R

o

t

a

t

i

o

n

C

a

p

a

c

i

t

y

:

p

(

r

a

d

)

Experimentally Determined Link Plastic Rotation Capacities

Shear Yielding Flexural Yielding

Shear +

Flexure

e

EBF Rigid-Plastic Kinematics

L

p p

e

L

u =

e

L

u

p

p

e

L

p p

e

L

u =

L

e

u

p

p

L

e e

e e

L

u

p

p

p p

e 2

L

u =

Design of EBFs

General Approach

1. Size links for code levels forces.

2. Size all other members and

connections for maximum forces that

can be generated by links.

3. Estimate ductility demand on links;

check that links can supply the

required ductility

4. Detail links to supply high ductility

(stiffeners and lateral bracing)

Eccentrically Braced Frames (EBFs)

Description of Eccentrically Braced Frames

Basic Behavior of Eccentrically Braced Frames

AISC Seismic Provisions for Eccentrically Braced

Frames

2005 AISC Seismic Provisions

Section 15 Eccentrically Braced Frames (EBF)

15.1 Scope

15.2 Links

15.3 Link Stiffeners

15.4 Link-to-Column Connections

15.5 Lateral Bracing of Links

15.6 Diagonal Brace and Beam Outside of Link

15.7 Beam-to-Column Connections

15.8 Requires Strength of Columns

15.9 Protected Zone

15.10 Demand Critical Welds

AISC Seismic Provisions - EBF

15.1 Scope

Eccentrically braced frames (EBF) are expected to

withstand significant inelastic deformations in the links

when subjected to the forces resulting from the motions

of the design earthquake.

The diagonal braces, columns and beam segments

outside of the links shall be designed to remain

essentially elastic under the maximum forces that can

be generated by the fully yielded and strain hardened

links.

AISC Seismic Provisions - EBF

15.2 Links

15.2a Limitations

Links shall meet the requirements of Section 8.2b

The web of the link shall be single thickness. Doubler-plate

reinforcement and web penetrations are not permitted.

15.2a Limitations

Links shall meet the requirements of Section 8.2b

Width-Thickness Limits for Link Flanges and Web:

b/t s

p

p

p

V

M

6 . 1 e for s

p

p

ps

V

M

6 . 1 e for >

AISC Seismic Provisions - EBF

15.2 Links

15.2b Shear Strength

Link design shear strength = | V

n

| = 0.9

V

n

= lesser of

V

p

2M

p

/ e

15.2b Link Shear Strength

Sizing Link:

V

u

s | V

n

V

u

= shear force in link under code

specified forces:

1.2D + 1.0E + 0.5L + 0.2S

0.9D + 1.0E

| V

n

= link design shear strength

15.2b Link Shear Strength

V

n

= lesser of

V

pa

2M

pa

/ e

If P

u

> 0.15 P

y

in link:

2

y

u

p pa

P

P

1 V V

|

|

.

|

\

|

=

where:

(

(

=

y

u

p pa

P

P

1 M M

P

y

= A F

y

and ....

15.2b Link Shear Strength

If P

u

> 0.15 P

y

in link:

e s

3 . 0

A

A

for

V

M

6 . 1

A

A

5 . 0 15 . 1

g

w

p

p

g

w

>

|

|

.

|

\

|

'

(

(

|

|

.

|

\

|

'

3 . 0

A

A

for

V

M

6 . 1

g

w

p

p

>

|

|

.

|

\

|

'

where:

u

u

V

P

=

'

( )

w f w

t t 2 d A =

AISC Seismic Provisions - EBF

15.2 Links

15.2c Link Rotation Angle

The link rotation angle is the inelastic angle between the link

and the beam outside of the link when the story drift is equal

to the design story drift, .

The link rotation angle shall not exceed the following values:

a) 0.08 radians for: e s 1.6 M

p

/ V

p

b) 0.02 radians for: e > 2.6 M

p

/ V

p

c) a value determined by linear interpolation between

the above values for: 1.6 M

p

/ V

p

< e < 2.6 M

p

/ V

p

15.2c Link Rotation Angle

Design Approach to Check Link Rotation Angle,

p

1. Compute elastic story drift under code specified

earthquake forces:

E

2. Compute Design Story Drift: = C

d

E

(C

d

= 4 for EBF)

3. Estimate Plastic Story Drift:

p

4. Compute plastic story drift angle u

p

u

p

p

/ h where h = story height

5. Compute link rotation angle

p

based on EBF

kinematics

p

= (L / e) u

p

for common EBFs

6. Check link rotation limit per Section 15.2c

15.2c Link Rotation Angle

p p

e

L

u =

e

L

u

p

p

L

e

u

p

p

p p

e

L

u =

e e

L

u

p

p

p p

e 2

L

u =

0

5

10

15

0 0.2 0.4 0.6 0.8 1

e/L

p

/

u

p

e

L

u

p

p

15.2c Link Rotation Angle

0

0.02

0.04

0.06

0.08

0.1

0 1 2 3 4 5

Non-dimensional Link Length: e/ (M

p

/V

p

)

M

a

x

i

m

u

m

P

e

r

m

i

s

s

i

b

l

e

p

1.6

2.6

Shear Yielding Flexural Yielding

Shear +

Flexure

15.2c Link Rotation Angle

AISC Seismic Provisions - EBF

15.3 Link Stiffeners

Full-depth web stiffeners shall be provided on both sides of the

link web at the diagonal brace ends of the link.

These stiffeners shall have a combined width not less than

(b

f

-2t

w

) and a thickness not less than 0.75 t

w

or 3/8-inch,

whichever is larger.

Link Length = e

Full depth stiffeners

on both sides

15.3 Link Stiffeners

15.3 Link Stiffeners (cont)

Links shall be provided with intermediate web stiffeners as

follows:

a) Links of length e s 1.6 M

p

/ V

p

Provide equally spaced stiffeners as follows:

spacing s 30 t

w

- d /5 for

p

= 0.08 radian

spacing s 52 t

w

- d /5 for

p

= 0.02 radian

interpolate for 0.02 <

p

< 0.08 radian

e s 1.6 M

p

/ V

p

(Shear Yielding Links)

s s s s s

Link Length = e

s s

30 t

w

- d /5 for

p

= 0.08 radian

52 t

w

- d /5 for

p

= 0.02 radian

interpolate for 0.02 <

p

< 0.08 radian

15.3 Link Stiffeners

t

w

= link web thickness d = link depth

15.3 Link Stiffeners (cont)

Links shall be provided with intermediate web stiffeners as

follows:

b) Links of length 2.6 M

p

/ V

p

< e < 5 M

p

/ V

p

Provide stiffener at a distance of 1.5 b

f

from each end of link

15.3 Link Stiffeners

Link Length = e

1.5 b

f

1.5 b

f

b

f

= link flange width

2.6 M

p

/ V

p

< e < 5 M

p

/ V

p

(Flexural Yielding Links)

15.3 Link Stiffeners (cont)

Links shall be provided with intermediate web stiffeners as

follows:

c) Links of length 1.6 M

p

/ V

p

< e < 2.6 M

p

/ V

p

Provide stiffeners meeting the

requirements of both (a) and (b)

d) Links of length e > 5 M

p

/ V

p

No stiffeners are required

15.3 Link Stiffeners

Link Length = e

1.5 b

f

1.5 b

f

s s s s

s s

30 t

w

- d /5 for

p

= 0.08 radian

52 t

w

- d /5 for

p

= 0.02 radian

interpolate for 0.02 <

p

< 0.08 radian

1.6 M

p

/ V

p

< e < 2.6 M

p

/ V

p

(Shear and Flexural Yielding Links)

AISC Seismic Provisions - EBF

15.4 Link-to-Column Connections

Link-to-column connections must be capable of sustaining the

maximum link rotation angle based on the length of the link, as

specified in Section 15.2c

The strength of the connection measured at the column face

shall equal at least the nominal shear strength of the link, V

n

,

as specified in Section 15.2b, at the maximum link rotation

angle

15.4 Link-to-Column Connections

e

e

Link-to-column connections

Must be capable of sustaining:

interpolate for

1.6 M

p

/ V

p

< e < 2.6 M

p

/ V

p

p

> 0.08 rad. for e s 1.6 M

p

/ V

p

p

> 0.02 rad. for e > 2.6 M

p

/ V

p

15.4 Link-to-Column Connections (cont)

To demonstrate conformance with link-to-column connection

performance requirements:

a) Use a Prequalified link-to-column connection in

accordance with Appendix P

or

b) Provide qualifying cyclic test results in

accordance with Appendix S

Comments:

Currently no prequalified link-to-column connections

FEMA 350 or AISC 358 prequalified SMF moment

connections not necessarily suitable for link-to-

column connections

Suggest avoiding EBF configurations with links

attached to columns until further research available on

link-to-column connections

15.4 Link-to-Column Connections (cont)

15.4 Link-to-Column Connections (cont)

Exception:

The link-to-column connection need not be Prequalified or

be qualified by testing if:

the connection is reinforced to preclude yielding within

the reinforced section of the link, and

link length e s 1.6 M

p

/ V

p

full depth stiffeners are provided at interface of link and

reinforced section

e

15.4 Link-to-Column Connections

Reinforced Link-to-Column Connection

AISC Seismic Provisions - EBF

15.5 Lateral Bracing of Link

Lateral bracing shall be provided at both the top and

bottom link flanges at the ends of the link.

The required strength of each lateral brace at the link

ends shall be:

| |

o

Link y y

b

h

Z F R

06 . 0 P =

h

o

= distance between link flange centroids

Link Length = e

Lateral bracing required at top

and bottom link flanges at link

ends

15.5 Lateral Bracing of Link

AISC Seismic Provisions - EBF

15.6 Diagonal Brace and Beam Outside of Link

The required strength of the diagonal brace and the

beam outside of the link is based on the maximum

forces that can be generated by the fully yielded and

strain hardened link.

15.6 Diagonal Brace and Beam Outside of Link

Beam outside of link

Diagonal Brace

M

ult

M

ult

V

ult

V

ult

V

ult

M

ult

V

ult

M

ult

Diagonal Brace and Beam Outside of Link

M

ult

M

ult

V

ult

V

ult

15.6 Diagonal Brace and Beam Outside of Link

Determining Link Ultimate Shear and End Moment for design

of diagonal brace and beam outside of link

Link Length = e

15.6a: For design of diagonal brace: Take V

ult

= 1.25 R

y

V

n

15.6b: For design of beam outside of link: Take V

ult

= 1.1 R

y

V

n

V

n

= link nominal shear strength = lesser of V

p

or 2 M

p

/ e

M

ult

M

ult

V

ult

V

ult

15.6 Diagonal Brace and Beam Outside of Link

Determining Link Ultimate Shear and End Moment for design

of diagonal brace and beam outside of link

Link Length = e

Given V

ult

, determine M

ult

from link equilibrium:

2

V e

M

ult

ult

=

(assumes link end moment equalize)

M

V

P

15.6 Diagonal Brace and Beam Outside of Link

AISC Seismic Provisions - EBF

15.6c Bracing Connections

The required strength of brace connections, at both ends of

the brace, shall be at least equal to the required strength of

diagonal the brace.

Brace connections shall also satisfy Section13.3c.

13.3c: The required axial compressive strength of the brace

connections shall be at least 1.1 R

y

P

n

of the brace,

where: P

n

= nominal compressive strength of brace

V

ult

M

ult

15.6c Bracing Connections

Bracing Connections

Design for forces (P and M)

generated in brace by V

ult

and

M

ult

of link

Also check for axial

compression force of 1.1 R

y

P

n

of brace

No need to provide "fold line,"

since braces are not designed

to buckle, as in SCBF

Bracing Connections - Typical Details

AISC Seismic Provisions - EBF

15.7 Beam-to-Column Connections

Beam-to-column connections away from links:

Provide simple framing ("pinned" connection)............. R=7 per ASCE-7

Provide moment resisting connection............................R=8 per ASCE-7

Moment resisting beam-to-column connections

must satisfy requirements for OMF (Section 11)

15.7 Beam-to-Column Connections

Beam-to-column connections

away from links:

Simple Framing: R=7

Moment Resisting

Connections (design per

OMF requirements): R=8

AISC Seismic Provisions - EBF

15.8 Required Strength of Columns

The required strength of columns in EBF is based on the

maximum forces generated by the fully yielded and strain

hardened links.

V

ult

M

ult

V

ult

M

ult

V

ult

M

ult

V

ult

M

ult

V

ult

M

ult

V

ult

M

ult

15.8 Required Strength of Columns

Column Required Strength =

forces generated in column when all

links above level under

consideration have developed their

ultimate shear resistance (V

ult

) and

their ultimate flexural resistance

(M

ult

).

Take V

ult

= 1.1 R

y

V

n

for each link.

AISC Seismic Provisions - EBF

15.9 Protected Zone

Links in EBF are protected zones, and shall satisfy

requirements of Section 7.4:

no shear studs

no deck attachments that penetrate beam flange

(screws, shot pins)

no welded, bolted, screwed or shot in attachments for

perimeter edge angles, exterior facades, partitions,

duct work, piping, etc.

Welding is permitted in link for stiffeners

15.9 Protected Zone

Protected Zones

AISC Seismic Provisions - EBF

15.10 Demand Critical Welds

CJP Groove welds attaching the link flanges and the

link web to the column are demand critical welds, and

shall satisfy the requirements of Section 7.3b.

CVN Requirements:

20 ft-lbs at - 20

0

F and

40 ft-lbs at 70

0

F

Section 15 Eccentrically Braced Frames (EBF)

15.1 Scope

15.2 Links

15.3 Link Stiffeners

15.4 Link-to-Column Connections

15.5 Lateral Bracing of Links

15.6 Diagonal Brace and Beam Outside of Link

15.7 Beam-to-Column Connections

15.8 Requires Strength of Columns

15.9 Protected Zone

15.10 Demand Critical Welds

You might also like

- AISC Seismic Design-Module5-Buckling Restrained Braced FramesDocument59 pagesAISC Seismic Design-Module5-Buckling Restrained Braced FramesBracilides Mamani ArizaNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Concentrically Braced FramesDocument121 pagesConcentrically Braced FramesAkshay Reddy100% (1)

- AISC Seismic Design-Module4-Eccentrically Braced FramesDocument134 pagesAISC Seismic Design-Module4-Eccentrically Braced FramesMiguel A Zuñiga100% (2)

- AISC Seismic Design-Module3-Concentrically Braced FramesDocument129 pagesAISC Seismic Design-Module3-Concentrically Braced FramesRobert Andy WoodNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- A Model Specification For Stability Design by Direct AnalysisDocument10 pagesA Model Specification For Stability Design by Direct Analysisalexmolina3No ratings yet

- AISC Seismic Design-Module3-Concentrically Braced FramesDocument129 pagesAISC Seismic Design-Module3-Concentrically Braced Framesantonio100% (4)

- Direct Analysis and Design Using Amplified First Order Analysis2part PDFDocument27 pagesDirect Analysis and Design Using Amplified First Order Analysis2part PDFPauloAndresSepulvedaNo ratings yet

- 1002 Aisc d1w Shape Tension MemberDocument6 pages1002 Aisc d1w Shape Tension MemberFWICIPNo ratings yet

- Chapter 8 - Building Types S1/S1A: Steel Moment Frames: 8.1 Description of The Model Building TypeDocument295 pagesChapter 8 - Building Types S1/S1A: Steel Moment Frames: 8.1 Description of The Model Building Typefasih_baqai4252No ratings yet

- Night School 23 Session 3Document50 pagesNight School 23 Session 3Luis CortesNo ratings yet

- Vicwest DiaphragmsDocument62 pagesVicwest Diaphragmsrmsa17No ratings yet

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 2Document80 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 2Percy Romero Murillo100% (1)

- AISI S912-13 - SDocument11 pagesAISI S912-13 - SEdison BecerraNo ratings yet

- Direct Analysis Method - Part IIDocument6 pagesDirect Analysis Method - Part IISamKtkNo ratings yet

- Advanced Design Examples of Seismic Retrofit of StructuresFrom EverandAdvanced Design Examples of Seismic Retrofit of StructuresRating: 1 out of 5 stars1/5 (1)

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 1Document76 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 1Percy Romero MurilloNo ratings yet

- Aisc Seismic Design Module1 IntroductionDocument107 pagesAisc Seismic Design Module1 IntroductionFreddy Mauricio LucayNo ratings yet

- Composite Floor Deck Design PDFDocument4 pagesComposite Floor Deck Design PDFsaipodinNo ratings yet

- Night School 15 Session 2Document59 pagesNight School 15 Session 2LCSNo ratings yet

- Design of Seismic-Resistant Steel Building Structures: 3. Concentrically Braced FramesDocument123 pagesDesign of Seismic-Resistant Steel Building Structures: 3. Concentrically Braced FramesMarvin MessiNo ratings yet

- The Evolution of Stability Provisions in The AISC SpecificationDocument30 pagesThe Evolution of Stability Provisions in The AISC SpecificationapirakqNo ratings yet

- Designing Compact Gussets With The Uniform Force MethodDocument8 pagesDesigning Compact Gussets With The Uniform Force MethodJonathan Schauder100% (1)

- Simpson Strong-Tie CFS Designer ManualDocument26 pagesSimpson Strong-Tie CFS Designer Manualdnl_vicarsNo ratings yet

- Steel Design Guide 14 - Staggered Truss Framing Systems PDFDocument45 pagesSteel Design Guide 14 - Staggered Truss Framing Systems PDFAndré Luiz Nogueira100% (1)

- 2-Steel Seismic Design-Moment Resisting FramesDocument115 pages2-Steel Seismic Design-Moment Resisting FramesNiyat PatelNo ratings yet

- Seaoc Bluebook PDFDocument472 pagesSeaoc Bluebook PDFErland Ramírez SalazarNo ratings yet

- ASCE 7-16 Practical Seismic DesignDocument21 pagesASCE 7-16 Practical Seismic Designcloudbooks007No ratings yet

- Guide To The Design of Diaphragms, Chords and Collectors Based On The 2006 IBC and ASCE/SEI 7-05Document22 pagesGuide To The Design of Diaphragms, Chords and Collectors Based On The 2006 IBC and ASCE/SEI 7-05Daniel SilvaNo ratings yet

- Seismic Design of Concentrically Braced FramesDocument127 pagesSeismic Design of Concentrically Braced Framesrmm99rmm9950% (2)

- 2003 NEHRP Seismic Regulation For New BuildingsDocument804 pages2003 NEHRP Seismic Regulation For New BuildingsNazri Mokhdar100% (1)

- Tips - For - Designers AISC Design Guide VibrationDocument5 pagesTips - For - Designers AISC Design Guide VibrationRicardo Argentton FicanhaNo ratings yet

- AISC Seismic Design - Module1 - IntroductionDocument107 pagesAISC Seismic Design - Module1 - IntroductionCristhian Solano BazalarNo ratings yet

- AISC Uniform Force Method Handouts 4 Per - REV 1Document32 pagesAISC Uniform Force Method Handouts 4 Per - REV 1Ken SuNo ratings yet

- Shear Transfer at Top Plate, Drag Strut DesignDocument4 pagesShear Transfer at Top Plate, Drag Strut DesignVarga Zoran100% (1)

- Seismic Design Manual - Google SearchDocument3 pagesSeismic Design Manual - Google Searchchondroc110% (1)

- Diaphragm Presentation3Document78 pagesDiaphragm Presentation3Iho1100% (3)

- Bellos, 2017, Coomplete Solution For Soil Pressure of Rigid FoundationsDocument26 pagesBellos, 2017, Coomplete Solution For Soil Pressure of Rigid Foundationsprisciliano1No ratings yet

- An Overview of Changes in The ACI 318-19 Building Code, and Looking Ahead To ACI 318-25 - Andrew W. TaylorDocument72 pagesAn Overview of Changes in The ACI 318-19 Building Code, and Looking Ahead To ACI 318-25 - Andrew W. TaylorAjong DdpNo ratings yet

- Night School 23 Session 1Document54 pagesNight School 23 Session 1Luis CortesNo ratings yet

- Behavior and Design of Single AngleDocument18 pagesBehavior and Design of Single AngleandyhrNo ratings yet

- Direct Analysis and Design Using Amplified First-Order AnalysisDocument18 pagesDirect Analysis and Design Using Amplified First-Order Analysisอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- SteelDeckDesignManualThirdEdition PDFDocument294 pagesSteelDeckDesignManualThirdEdition PDFAugusto MendozaNo ratings yet

- Night School 23 Session 4Document79 pagesNight School 23 Session 4Luis CortesNo ratings yet

- CompositeMegaColumns Full ReportDocument275 pagesCompositeMegaColumns Full ReportRonakShah100% (1)

- Wrap Around Gusset PDFDocument25 pagesWrap Around Gusset PDFmuralihare100% (1)

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 3Document75 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 3Percy Romero Murillo100% (1)

- Aisc Bracing Connections 01 PDFDocument69 pagesAisc Bracing Connections 01 PDFPatrick PolujanNo ratings yet

- 2018 Sei Advocating For Performance Based Design ReportDocument20 pages2018 Sei Advocating For Performance Based Design ReportPraveen GavadNo ratings yet

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 1Document13 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 1Luís Macedo100% (2)

- C StrucAnalysis Wong Jan17 1Document4 pagesC StrucAnalysis Wong Jan17 1Hattori HanzoNo ratings yet

- CH4 - Construction LoadsDocument14 pagesCH4 - Construction LoadsRodelNo ratings yet

- AISC Design Guide 10 Revisions-And-Errata-List PDFDocument2 pagesAISC Design Guide 10 Revisions-And-Errata-List PDFCarlo DizonNo ratings yet

- Unit - II Tension Members: Two Mark Question and AnswersDocument7 pagesUnit - II Tension Members: Two Mark Question and AnswersSourabh SrivastavaNo ratings yet

- Case Studies in Structural Engineering: Jack Bouwkamp, Mohamad Ghasem Vetr, Ali GhamariDocument14 pagesCase Studies in Structural Engineering: Jack Bouwkamp, Mohamad Ghasem Vetr, Ali GhamariJhon Smit Gonzales UscataNo ratings yet

- Example 3.2 - Continuous Beam-Updated 010812Document15 pagesExample 3.2 - Continuous Beam-Updated 010812Muhammad Farhan Gul100% (2)

- L01 03Document85 pagesL01 03eadaladarenuNo ratings yet

- Example of Simply Supported Two Way Slab PDFDocument4 pagesExample of Simply Supported Two Way Slab PDFyaramounaNo ratings yet

- Installing AbaqusDocument17 pagesInstalling AbaqusyaramounaNo ratings yet

- Wind DesignDocument11 pagesWind DesignyaramounaNo ratings yet

- B L As As' A A': (MM) (MM) (MM) (MM) (MM) (MM)Document8 pagesB L As As' A A': (MM) (MM) (MM) (MM) (MM) (MM)yaramounaNo ratings yet

- Design To Plan or To Make Drawings Which Is Not Yet StructuredDocument9 pagesDesign To Plan or To Make Drawings Which Is Not Yet StructuredyaramounaNo ratings yet

- الكود العربي السوري لتصميم وتنفيذ المنشآت بالخرسانة المسلحةDocument333 pagesالكود العربي السوري لتصميم وتنفيذ المنشآت بالخرسانة المسلحةMkh EngcivilNo ratings yet

- Civl101 - Introduction To Tall Building StructuresDocument13 pagesCivl101 - Introduction To Tall Building StructuresAravind BhashyamNo ratings yet

- Ccip Concise Ec2Document118 pagesCcip Concise Ec2Sanka Seneviratne100% (9)

- الكود العربي السوري لتصميم وتنفيذ المنشآت بالخرسانة المسلحةDocument333 pagesالكود العربي السوري لتصميم وتنفيذ المنشآت بالخرسانة المسلحةMkh EngcivilNo ratings yet

- الكود العربي السور ي الملحق3Document42 pagesالكود العربي السور ي الملحق3AbdoNo ratings yet

- Models For Flexural Cracking in Concrete (The State of The Art)Document10 pagesModels For Flexural Cracking in Concrete (The State of The Art)bogrumNo ratings yet

- Bryan Stafford Smith Alex Coull Tall Building Structures Analysis and Design Wiley Interscience 1991Document289 pagesBryan Stafford Smith Alex Coull Tall Building Structures Analysis and Design Wiley Interscience 1991yaramouna100% (3)

- 2010 StructuralDesignConcrete SherifDocument8 pages2010 StructuralDesignConcrete SherifVenkata Raju KalidindiNo ratings yet

- Energy Dissipated DispDocument4,985 pagesEnergy Dissipated DispyaramounaNo ratings yet

- 440r - 96 State-Of-The-Art Report On Fiber Reinforced Plastic Reinforcement For Concrete StructuresDocument68 pages440r - 96 State-Of-The-Art Report On Fiber Reinforced Plastic Reinforcement For Concrete StructuresSwathi SvNo ratings yet

- Seismic Design of Reinforced Concrete Special Moment FramesDocument31 pagesSeismic Design of Reinforced Concrete Special Moment FrameswilfredNo ratings yet

- Wormholes and Non-Simply Connected Manifolds (1991)Document26 pagesWormholes and Non-Simply Connected Manifolds (1991)oldmanbearsNo ratings yet

- Sommerfeld Arnold PDFDocument211 pagesSommerfeld Arnold PDFfahrul3xNo ratings yet

- Review Notes For RT10Document16 pagesReview Notes For RT10Daniel MontesNo ratings yet

- 9 Momentum Principle Tutorial SolutionDocument24 pages9 Momentum Principle Tutorial SolutionMfundo100% (1)

- Work Power Energy: Etoos Academy Pvt. LTDDocument28 pagesWork Power Energy: Etoos Academy Pvt. LTDNavin RaiNo ratings yet

- Shaping MachineDocument14 pagesShaping MachineMohammad Javed IqbalNo ratings yet

- Chapter 30 PhysicsDocument29 pagesChapter 30 Physicseg40340% (1)

- Symmetrical Components 2Document15 pagesSymmetrical Components 2CaribNo ratings yet

- Magnetic Fields: Right Hand RulesDocument14 pagesMagnetic Fields: Right Hand RulesFeolo Riel TarayNo ratings yet

- Bölüm 4 TümüDocument32 pagesBölüm 4 Tümüramazanvank40No ratings yet

- POLEDocument18 pagesPOLEJosue HasbunNo ratings yet

- Textbook of ElectrotherapyDocument345 pagesTextbook of ElectrotherapyAlice Teodorescu100% (19)

- Department of Chemistry SUNY/Oneonta Chem 221 - Organic Chemistry I Examination #4 - December 9, 2002Document9 pagesDepartment of Chemistry SUNY/Oneonta Chem 221 - Organic Chemistry I Examination #4 - December 9, 2002alkanzyNo ratings yet

- Design A Model For Human Body To Determine The Center of GravityDocument15 pagesDesign A Model For Human Body To Determine The Center of GravityCinthya Acevedo JiménezNo ratings yet

- Module Exercise 2Document30 pagesModule Exercise 2Andrea MagtutoNo ratings yet

- Interview QuestionsDocument13 pagesInterview QuestionsJoseph George100% (1)

- Lesson Plan in PBL & Ibl#1Document7 pagesLesson Plan in PBL & Ibl#1Jackylou SaludesNo ratings yet

- NaK DeterminationDocument5 pagesNaK DeterminationIflakhatul UlfaNo ratings yet

- GDT-Related Actual Mating EnvelopeDocument10 pagesGDT-Related Actual Mating EnvelopeManoj Kumar MurmuNo ratings yet

- Gearsand GearingDocument57 pagesGearsand Gearingcamohunter71No ratings yet

- 73 1st Long Problem SetDocument11 pages73 1st Long Problem SetLemuelClementCastroNo ratings yet

- Chapter 4 Reviewing Content Questions 4.1 Defining The AtomDocument7 pagesChapter 4 Reviewing Content Questions 4.1 Defining The AtomTouheed RamzaniNo ratings yet

- Electromagnetic Interference (EMI)Document17 pagesElectromagnetic Interference (EMI)Anonymous eWMnRr70qNo ratings yet

- Aircraft Performance AnalysisDocument4 pagesAircraft Performance AnalysisdanielNo ratings yet

- Comment On "A Generalized Helmholtz Theorem For Time-Varying Vector Fields," by Artice M. DavisDocument3 pagesComment On "A Generalized Helmholtz Theorem For Time-Varying Vector Fields," by Artice M. Davisfersoto07No ratings yet

- Serway 6 e Problems 27Document12 pagesSerway 6 e Problems 27David SaucedoNo ratings yet

- Static Equilibrium and ElasticityDocument43 pagesStatic Equilibrium and ElasticitysssNo ratings yet

- Phy 2 Mtwara and Lindi 2023Document19 pagesPhy 2 Mtwara and Lindi 2023sam2jbegNo ratings yet

- First Order de Problem Set 2010 Math 208Document3 pagesFirst Order de Problem Set 2010 Math 208Jen ChavezNo ratings yet