Professional Documents

Culture Documents

Slab Formworks Design

Uploaded by

evilmurdocOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slab Formworks Design

Uploaded by

evilmurdocCopyright:

Available Formats

Temporary Structures CM 420

Slab Form Design

Lecture 5

Temporary Structures CM 420

1

Slab formwork

Parts of typical slab formwork

Temporary Structures CM 420

2

Slab formwork

Design Steps:

Step 1: Estimate design loads

Step 2: Sheathing thickness and and

spacing of its supports (joist spacing)

Step 3: Joist size and spacing

of supports (stringer spacing)

Step 4: Stringer size and span (shore

spacing)

Step 5: Shore design to support stringers

Step 6: Check bearing stresses

Step 7: Design lateral bracing

Temporary Structures CM 420

3

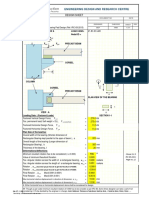

Slab form Example

Design forms to support a flat slab floor

8 in. thick of normal weight concrete,

using construction grade Douglas Fir-

Larch forming members and steel

shoring. Ceiling height is 8 ft. and bays

are 15x15 ft. Since forms will have

continuing reuse, do not adjust base

design values for short term load.

Temporary Structures CM 420

4

Slab form Design Example

STEP 1: ESTIMATE LOADS:

Dead load, concrete and rebar,

[8 in. / (12 in./ft.)]x 150 pcf = 100 psf

Minimum construction live load on forms

50 psf (refer to lecture #1)

Weight of forms, estimated

8 psf

Total form design load

100 + 50 + 8 = 158 psf

Temporary Structures CM 420

5

Slab form Design Example

STEP 2: SHEATHING DESIGN:

Assuming 3/4-in. form grade plywood

sheathing, from Tables 4-2 and 4-3:

F

b

= 1545 psi

F

S

= 57 psi

E = 1,500,000 psi

S = 0.412 in.

3

I = 0.197 in.

4

I b/Q = 6.762 in.

2

Temporary Structures CM 420

6

Slab form Design Example

STEP 2: SHEATHING DESIGN:

Tables 4-2 and 4-3, for plywood:

Temporary Structures CM 420

7

Slab form Design Example

CHECK BENDING

For design purposes, consider a 1-foot-wide

strip of plywood. Then:

lb/lf 158 ft. 1 psf 158 of load design = = w

in. 0 . 22

158

412 . 0 1545

95 . 10 =

= l

w

fS

l 95 . 10 =

Substituting in the equation:

Temporary Structures CM 420

8

Slab form Design Example

CHECK DEFLECTION

For A = l/360:

For A = 1/16:

in. 8 . 20 1870 69 . 1

158

197 . 0 1500000

69 . 1 69 . 1

3

3 3

= =

= =

w

EI

l

in. 2 . 21 1870 23 . 3

158

197 . 0 1500000

23 . 3 23 . 3

4

4 4

= =

= =

w

EI

l

Temporary Structures CM 420

9

Slab form Design Example

CHECK ROLLING SHEAR

For design purposes, consider a 1-foot-wide

strip of plywood. Then:

since V

max

= 0.6wL , so:

Ib

VQ

F

S

=

inches 48 or ft. 0 . 4 762 . 6

158 6 . 0

57

6 . 0

=

= =

Q

Ib

w

F

L

S

Ib

Q

wL

Ib

VQ

F

S

= = 6 . 0

Q

Ib

w

F

L

S

=

6 . 0

Substituting in above equation:

or:

Temporary Structures CM 420

10

Slab form Design Example

From the above calculations, l = 20.8 in.

governs.

Meaning that joist supports CANNOT

be more than 20.8 inches apart.

HOWEVER, in order to select the span,

we must consider the size of the

plywood sheets and equal spacing of

supports.

In this case, 5 equal spaces of 19.2

inches on an 8-ft. wide plywood sheet

will be appropriate.

Temporary Structures CM 420

11

Slab form Design Example

STEP 3: JOIST SIZE AND SPACING OF

STRINGERS TO SUPPORT THE JOISTS:

Check 2x4 construction grade Douglas-Fir-

Larch as joist (forms are used repeatedly, so

there is no short-term load adjustment).

From Table 4-2: F

b

= 1000 psi and F

V

= 95 psi

and should be adjusted for horizontal shear

by a factor of 2. E = 1,500,000 psi.

psi 190 95 0 . 2 = =

'

V

F

Temporary Structures CM 420

12

Slab form Design Example

From Table 4-1B, for S4S 2x4s: bd = 5.25 in.

2

,

I = 5.36 in.

4

, and S = 3.06 in.

3

psf load, design

ft. in. 12

in. spacing, Joist

= w

lf lb 253 psf 158

ft. in. 12

in. 19.2

= = w

Temporary Structures CM 420

13

Slab Form Design Example

CHECK BENDING

in. 1 . 38

253

06 . 3 1000

95 . 10 95 . 10 =

=

'

=

w

S F

l

b

CHECK DEFLECTION

For A = l/360

in. 5 . 53 67 . 31 69 . 1 31778 69 . 1

253

36 . 5 1500000

69 . 1 69 . 1

3

3 3

= = =

= =

w

EI

l

Temporary Structures CM 420

14

Slab Form Design Example

CHECK SHEAR

Using the horizontal shear stress formula

for a uniformly loaded continuous beam

(similar to calculations on page 19):

|

.

|

\

|

=

12

2 9 . 0 d

L

bd

w

f

V

|

.

|

\

|

= =

12

5 . 3 2

25 . 5

253 9 . 0

190 L f

V

ft. 69 . 4 3 . 25 37 . 43 190 = = L L

Or L = 4.69x12 in./ft. = 59.5 inches

Temporary Structures CM 420

15

Slab Form Design Example

Comparing the three spans

calculated above, l = 38.1 inches

governs.

Considering 15x15 ft. bays and

desire for uniform spacing, 36 inch

spacing is a reasonable number.

This means that the spacing of

stringers will be at 5 equal spaces

per bay.

( ) feet 15 inches 180 6 3 5 = =

' '

Temporary Structures CM 420

16

Slab form Design Example

STEP 4: STRINGER SIZE AND SPAN:

Use 4x4 Construction grade Douglas-Fir-

Larch stringers. From Table 4-1B for S4S

4x4s: bd = 12.25 in.

2

, I = 12.50 in.

4

, S = 7.15

in.

3

; and d = 3.5 in.

lf lb 74 4 psf 158

ft. in. 12

in. 36

psf form, on load

ft. in. 12

in. spacing, Stinger

= = = w

CHECK BENDING

in. 5 . 42

474

15 . 7 1000

95 . 10 95 . 10 =

=

'

=

w

S F

l

V

Temporary Structures CM 420

17

Slab Form Design Example

CHECK DEFLECTION

For A = l/360

in. 6 . 57 07 . 34 69 . 1 39557 69 . 1

474

50 . 12 1500000

69 . 1 69 . 1

3

3 3

= = =

= =

w

EI

l

CHECK SHEAR

Use the horizontal shear stress formula for

a uniformly loaded continuous beam:

12

2

9 . 0

12

2 9 . 0 d

w

bd F

L

d

L

bd

w

F

V

V

+

'

=

|

.

|

\

|

=

'

in. 4 . 72 ft 03 . 6 58 . 0 45 . 5

12

5 . 3 2

474 9 . 0

25 . 12 190

= = + =

= L

Temporary Structures CM 420

18

Slab Form Design Example

From the above calculations, l = 42.5 in.

governs.

Meaning that stringers CANNOT be

more than 42.5 inches apart (span of

stringers).

HOWEVER, in order to select an

appropriate span, we must consider the

dimensions of the bay.

The 15-ft. bay could be divided into 5

equal spaces of 36 inches (180/5 = 36)

which is less than the maximum

allowable span of 42.5 inches.

Temporary Structures CM 420

19

Slab Form Design Example

Alternatively, we can check the possibility

of using a deeper stringer, i.e. 3x6, in

order to increase the shore spacing.

Since bending is dominant here, we will

check bending for a 3x6 member.

For S4S 3x6s from Table 4-2: F

b

= 1000 psf,

and from Table 4-1B, S = 12.60 in.

3

in. 4 . 56 16 . 5 95 . 10

474

60 . 12 1000

95 . 10 95 . 10 = =

=

'

=

w

S F

l

b

Now we can use 45-in. support spacing for

the 3x6 stringers, which will divide the bay

into 5 equal spaces.

Temporary Structures CM 420

20

Slab form Design Example

STEP 5: SHORE DESIGN:

Stringers are placed 36-inches apart,

supported by shores spaced 45 inches

apart. The area of support for each shore

is:

( ) ( )

2

ft. 25 . 11 12 / 45 12 / 36 Area = =

lb. 1778 psf 158 ft. 25 . 11

2

=

Then the total load per shore is:

Temporary Structures CM 420

21

Slab form Design Example

Schematic design:

Temporary Structures CM 420

22

Slab form Design Example

Refer to Table 7-11 for wood shoring

material. Both 3x4 and 4x4 are more

than adequate to carry 1778 lbs for an

effective length of 8 ft.

Temporary Structures CM 420

23

Slab form Design Example

Step 6: Check Bearing Stresses:

Bearing should be checked where

stringers bear on shores and where

joists bear on stringers.

Stringers bearing on shore:

Assume the head piece of the adjustable

steel shore is 11x3 5/8". The 3x6 stringer

is actually 2 in. thick.

Temporary Structures CM 420

24

Slab form Design Example

If the headpiece is placed parallel to

the stringer, bearing area is 2x11 0r

28.75 in.

2

. Bearing stress will be:

This is well below the base F

c

, which

is obtained from Table 4-2 (the value of

compression to grain, F

c

, for No. 2

24 Douglas Fir-Larch is 625 psi).

psi 62

75 . 28

1778

area bearing

load shore total

~ =

Temporary Structures CM 420

25

Joist bearing on Stringers:

The two members are 1 and 2 in. wide.

Contact bearing area = 2x1 = 3.75 in.

2

Average load transmitted by joist to stringer is:

Joist spacing x joist span x form load

Slab form Design Example

lb. 758 158

12

36

12

2 . 19

=

psi 202

in. 75 . 3

lb 758

2

=

Bearing at this point is also low relative

to the 625 psi base value for F

c

.

You might also like

- 345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Document1 page345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Satya kaliprasad vangaraNo ratings yet

- Precast Concrete SlabDocument17 pagesPrecast Concrete Slabprajakta vaidyaNo ratings yet

- Introduction To Bridge DesignDocument67 pagesIntroduction To Bridge DesignSukrit GhoraiNo ratings yet

- Analysis of Slab Culvert Bridges Using ConventionaDocument7 pagesAnalysis of Slab Culvert Bridges Using Conventionajeeva anandNo ratings yet

- Formwork/Shuttering: CMR College of Engineering and TechnologyDocument47 pagesFormwork/Shuttering: CMR College of Engineering and TechnologyGlistering DharNo ratings yet

- Bridge Deck FormworkDocument8 pagesBridge Deck Formworkedgarabraham100% (1)

- RCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Document13 pagesRCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Shivendra KumarNo ratings yet

- Grade Slab DetailsDocument1 pageGrade Slab DetailsVarun Kumar MunjalNo ratings yet

- Formwork SeminarDocument19 pagesFormwork Seminarfaisal0% (1)

- Detailed Longitudinal Section Through RCC Deep BeamDocument1 pageDetailed Longitudinal Section Through RCC Deep BeamShaikh ImranNo ratings yet

- Optimize Positioning of Relief Shelf in Cantilever Retaining WallDocument3 pagesOptimize Positioning of Relief Shelf in Cantilever Retaining WallGRD Journals100% (1)

- JK Prestressing CatalougeDocument60 pagesJK Prestressing Catalougeravi aroraNo ratings yet

- Design A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchDocument1 pageDesign A RCC T Beam Girder Bridge To Suit The Following Data - Google SearchamitNo ratings yet

- Dome Structures. Saldome 2Document6 pagesDome Structures. Saldome 2Lidhia Fairuz HarlyNo ratings yet

- Lap LengthDocument10 pagesLap LengthSohagNo ratings yet

- Tutorial SheetsDocument5 pagesTutorial SheetsMr.A.R. VimalNo ratings yet

- 08-2011 Friction Slab Crash Barrier PDFDocument9 pages08-2011 Friction Slab Crash Barrier PDFraviNo ratings yet

- BRIDGES - PPT by VASUMATHIDocument48 pagesBRIDGES - PPT by VASUMATHIVASUMATHINo ratings yet

- Girder ErrectionDocument16 pagesGirder ErrectionSujeet DubeyNo ratings yet

- Design of Composite Steel Tub Girder - JLDelaCruzDocument72 pagesDesign of Composite Steel Tub Girder - JLDelaCruzChristine LaurdenNo ratings yet

- Input Data: Smaller Projection Greater Projection Thickness of Base PlateDocument4 pagesInput Data: Smaller Projection Greater Projection Thickness of Base PlateSUDHIR GAYAKENo ratings yet

- Bridge CantileverDocument9 pagesBridge CantileverPriyal vasaiwalaNo ratings yet

- Chapter 10 Design of Prestressed 761661594169023Document15 pagesChapter 10 Design of Prestressed 761661594169023Puzzle ArtsNo ratings yet

- BEAMDocument7 pagesBEAMAnonymous sfkedkym100% (1)

- Girder Stressing CalculationsDocument11 pagesGirder Stressing CalculationsSarmad WaqasNo ratings yet

- Precast RCC Girder MethodologyDocument6 pagesPrecast RCC Girder Methodologygaurav kumarNo ratings yet

- Super Elevation Wizard MXRoadV8iSS2Document15 pagesSuper Elevation Wizard MXRoadV8iSS232agukNo ratings yet

- Brdige Engineering Presentation Final1 2 1Document49 pagesBrdige Engineering Presentation Final1 2 1Nhorwin Jay TadeoNo ratings yet

- MAURER Spherical BearingsDocument9 pagesMAURER Spherical BearingsTiago Carvalho100% (1)

- RCC Slab BridgeDocument12 pagesRCC Slab BridgeSanjay GargNo ratings yet

- Presentation On Formwork 2 by Neeraj Jha DelhiDocument12 pagesPresentation On Formwork 2 by Neeraj Jha DelhidudynaynNo ratings yet

- Design Pmgsy WideningDocument5 pagesDesign Pmgsy WideningDaljeet SidhuNo ratings yet

- Temporary Box Culvert-ModelDocument1 pageTemporary Box Culvert-ModelDian RoesmanaNo ratings yet

- HMM Infra LTD, Anbala: Design of Trestle (Cribs)Document10 pagesHMM Infra LTD, Anbala: Design of Trestle (Cribs)Anonymous sfkedkymNo ratings yet

- What Is The Ratio of Grades M10, M15, M20, M25, M30, M35, M40Document6 pagesWhat Is The Ratio of Grades M10, M15, M20, M25, M30, M35, M40Varma ChintamaneniNo ratings yet

- Pre Stressing GirderDocument5 pagesPre Stressing GirderRapolu VyshnaviNo ratings yet

- Openwell StaircaseDocument8 pagesOpenwell StaircaseAbdul AzeemNo ratings yet

- SDPL CH 148-160 Shuttering Design For Girder-Layout-23Document1 pageSDPL CH 148-160 Shuttering Design For Girder-Layout-23Sudeep JoshiNo ratings yet

- Culverts and Low Level CrossingsDocument3 pagesCulverts and Low Level CrossingsAbdykafy ShibruNo ratings yet

- Design of Deck Slab 3Document35 pagesDesign of Deck Slab 3Allan MarbaniangNo ratings yet

- Irc SP 105 2015 Explanatory Handbook To Irc 112 2011Document36 pagesIrc SP 105 2015 Explanatory Handbook To Irc 112 2011vivekNo ratings yet

- Design Sheet: View A Load Case= Nodal ID = α F F F Precast BeamDocument5 pagesDesign Sheet: View A Load Case= Nodal ID = α F F F Precast BeamGanesh PrabuNo ratings yet

- Image PDFDocument44 pagesImage PDFAkshay Kumar SahooNo ratings yet

- Loads For Design of Sub-Structure 28.12.20Document72 pagesLoads For Design of Sub-Structure 28.12.20mayank007aggarwalNo ratings yet

- Guideline Notes For RCC WorkDocument10 pagesGuideline Notes For RCC Workvikas WaghmareNo ratings yet

- CribDocument1 pageCribskumarsrNo ratings yet

- A Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodDocument4 pagesA Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodEditor IJTSRDNo ratings yet

- Nandyal SSE Office: Load Calculations Details of Loads 1 Floor LoadDocument1 pageNandyal SSE Office: Load Calculations Details of Loads 1 Floor Loadravi4paperNo ratings yet

- Erection of Steel BridgesDocument15 pagesErection of Steel BridgesTfk BajaNo ratings yet

- Sunita BhusalDocument35 pagesSunita BhusalAbhay SuwalNo ratings yet

- Bridge DesignDocument12 pagesBridge DesignpdhurveyNo ratings yet

- Structure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Document37 pagesStructure Details FOR Foundation: Practical Architectural Training-Fun Begins (For Interns and Freshers)Divya Varshney100% (1)

- A Comparative Study On T-Beam Girder and Box Girder Bridges For Different Skew AnglesDocument6 pagesA Comparative Study On T-Beam Girder and Box Girder Bridges For Different Skew AnglesVikramNo ratings yet

- 03 Section 2 Example Bridge (E)Document11 pages03 Section 2 Example Bridge (E)Diego Benavides KNo ratings yet

- Irjet V5i4994Document4 pagesIrjet V5i4994Namrata ThapaNo ratings yet

- Technical Specification For Crash Barrier For Traffic Signal PolesDocument2 pagesTechnical Specification For Crash Barrier For Traffic Signal PolesHariHaranNo ratings yet

- Design of Slab FormsDocument27 pagesDesign of Slab FormsZevanyaRolandTualaka100% (1)

- Formwork DesignDocument17 pagesFormwork DesignEajaz Buzruk100% (3)

- Concrete Formwork DesignDocument17 pagesConcrete Formwork DesignRsjBugtongNo ratings yet

- Philippines Folk MusicDocument8 pagesPhilippines Folk MusicevilmurdocNo ratings yet

- Yamaha THR10/5 Owner's ManualDocument21 pagesYamaha THR10/5 Owner's ManualevilmurdocNo ratings yet

- IBz JEM BluePrintDocument1 pageIBz JEM BluePrintKYO_78% (9)

- Sample Letters of Corrective Action StepsDocument9 pagesSample Letters of Corrective Action StepsevilmurdocNo ratings yet

- Construction Scheduling SeminarDocument24 pagesConstruction Scheduling SeminarevilmurdocNo ratings yet

- January 2013: Brain Sync AttendanceDocument12 pagesJanuary 2013: Brain Sync AttendanceevilmurdocNo ratings yet

- Guitar - Tab Book - Steve Vai - Fire Garden PDFDocument232 pagesGuitar - Tab Book - Steve Vai - Fire Garden PDFleandronegrinNo ratings yet

- 5101 - ITS Chapter 2 Two PDFDocument41 pages5101 - ITS Chapter 2 Two PDFAkshay SinghNo ratings yet

- Tale of ZesteriaDocument74 pagesTale of ZesteriaWWW.SCRIBD.L0GIN.PWNo ratings yet

- Purpose:: Configuring The DASABCIP IO Server (V 4.x)Document8 pagesPurpose:: Configuring The DASABCIP IO Server (V 4.x)Charoon SuriyawichitwongNo ratings yet

- Code 239Document3 pagesCode 239subhrajitm47No ratings yet

- The Answer Is:: D. All of The AboveDocument7 pagesThe Answer Is:: D. All of The AboveShalabhNo ratings yet

- Seed Savers Food Gardens in Schools HandbookDocument88 pagesSeed Savers Food Gardens in Schools HandbookBotanical Garden University of California Berkeley100% (1)

- Archigram, Kenzo TangeDocument29 pagesArchigram, Kenzo TangeŇıthîšh ĐānīēĺNo ratings yet

- White Paper Application Performance Management (APM)Document26 pagesWhite Paper Application Performance Management (APM)solo_gauravNo ratings yet

- FivecornerDocument4 pagesFivecornerPebrian SyahNo ratings yet

- PaintingDocument137 pagesPaintingLin Xian XingNo ratings yet

- Signaling Telecommunication Networks: John G. BosseDocument1 pageSignaling Telecommunication Networks: John G. BosseRajeev KumarNo ratings yet

- TDDDocument34 pagesTDDKaylen WheelerNo ratings yet

- Data Sheet: Fike Engineered Nozzles For Dupont™ Fm-200® or Hfc-227Ea Clean Agent SystemsDocument2 pagesData Sheet: Fike Engineered Nozzles For Dupont™ Fm-200® or Hfc-227Ea Clean Agent SystemsTiago Levi CardosoNo ratings yet

- XMS Administration Guide Xmsadm - v21-410Document136 pagesXMS Administration Guide Xmsadm - v21-410NugrohoNo ratings yet

- BP090&120 50 HZ TechDocument24 pagesBP090&120 50 HZ Techmauricio.vidalyork6735No ratings yet

- Verizon SD NN F V Reference ArchitectureDocument220 pagesVerizon SD NN F V Reference ArchitectureShashank S. Prasad100% (2)

- PPTDocument23 pagesPPTVishnu Vardhan MekalaNo ratings yet

- Gis Mgnrega 27062016Document32 pagesGis Mgnrega 27062016Lakhvir Singh100% (1)

- Concrete Rate Analysis: Grade of Concrete (N/MM )Document2 pagesConcrete Rate Analysis: Grade of Concrete (N/MM )Debarshi SahooNo ratings yet

- The Chow CollectionDocument51 pagesThe Chow CollectionStephen ChowNo ratings yet

- Vendors in Pan IndiaDocument132 pagesVendors in Pan IndiaVivekanand SinghNo ratings yet

- Royal Quay BrochureDocument8 pagesRoyal Quay Brochureapi-26419872No ratings yet

- Alstom Stress 3Document36 pagesAlstom Stress 3sivaguruswamy thangaraj100% (1)

- TFL Bus Spider Map For Burgess ParkDocument1 pageTFL Bus Spider Map For Burgess Parkhrpwmv83No ratings yet

- 04Document13 pages04kyjwowNo ratings yet

- Etsi Eg 202 057-1Document34 pagesEtsi Eg 202 057-1Dusan JokanovicNo ratings yet

- InformaCastBasicPaging 1202Document344 pagesInformaCastBasicPaging 1202gabeNo ratings yet

- Nagpal 7 Num Rep OrgDocument67 pagesNagpal 7 Num Rep OrgntnitinNo ratings yet

- Lost TriptychDocument196 pagesLost Triptychartlabor1001No ratings yet

- 10W InstructionsDocument22 pages10W InstructionsJesúsM.OrtizNo ratings yet