Professional Documents

Culture Documents

Instrumentation & Control

Uploaded by

Muhammad Farhan SabirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instrumentation & Control

Uploaded by

Muhammad Farhan SabirCopyright:

Available Formats

Presented

to: Dr.Ing Naveed Ramzan by: Shahbaz Ali

Presented

07-chem-02

Sequence of design steps Block flow diagram Process flow diagram Piping and instrument diagram Instrument identification by P $ ID Standard symbols for instruments Standard symbols for equipments Standard symbols for fluid motive machinery Standard symbols for vessels Standard symbols for valves Standard symbols for lines

Stoichiometry

Input - Output Diagram

Preliminary Process Conditions

Generic Block Flow Diagram

Preliminary Material Balance

Block Flow Diagram (BFD)

Material, Energy Balances + Equipment Specifications

Process Flow Diagram (PFD)

Mechanical &Instrumentation Information

Piping and Instrument Diagram (PID)

It consists of simple block elements that are connected with an arrow. It describes following informations, Each block represents a process function which in reality may consist of several pieces of equipment. Gives a clear overview uncluttered by details. Effective for conceptualizing a new process or a PFD. Major flow lines shown with arrows giving direction of flow. Flow goes from left to right whenever possible. Light streams (gases, vapors) towards top and heavy streams (solid, liquid) go toward bottom. Critical information unique to the process supplied. If lines cross each other then, horizontal line is continuous and vertical line is broken. Provides preliminary material balance.

Ammonia Air

Ammonia Unit

Carbon Dioxide

Urea Unit

Urea Prills

Bagging & Shipping

Fuel Gas

Utility Utility Unit Unit

It is a diagram of fluid flow system showing the equipment items connected by major process pipes and containing data on essential process control circuits or major process requirements. It would include following details. Process piping Major equipment names Major equipment numbers Major equipment identification numbers Control valves Interconnection with other system Major bypass and circulation lines System rating and operational values as maximum, minimum and normal flow

Process parameters i.e. temperature and pressure Composition of fluids A process flow diagram does not following details, Pipe class Pipe line number Isolation and shutoff valves Maintenance vents and drains Relief and safety valves Code class information Seismic class information Instruments

It is a schematic representation of functional relationship of piping, instrumentation and system equipment components. It is termed as final step of process design. It includes following informations, Instrumentation and their designation along with indicators, recorders and controllers All equipments with their names and particular numbers All valves and their corresponding numbers Piping related to its size, schedule, material of construction and insulation Miscellaneous - vents, drains, special fittings, sampling lines, reducers, increasers and swaggers Permanent start-up and flush lines Directions of flow Interlinked references Control inputs and outputs, interlocks Quality standard

Computer control system input Vendor and contractor interfaces Identification of components and subsystems delivered by others Intended physical sequence of the equipment All utilities with identification related to inputs and outputs It doesnt include following parameters, Route valves for instruments Control relays Manful switches Equipment rating or capacity Pressure, temperature and flow data Elbows, tees and its related standard fitting Extensive explanatory notes

Instruments are identified by a tag number in P $ ID. For example, - TIC 103 shows instrument identification or tag number - T 103 shows loop identification 103 shows loop number - TIC shows functional identification - T shows first letter - IC shows second letter. The first letter dictates the control device involved in a process. And second letter dictates the parameter the device is intended to control.

Any Question?

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mercedes 722.9 Transmission GuideDocument56 pagesMercedes 722.9 Transmission GuideAlex Maceira Graterol100% (13)

- Pakistan - A Personal HistoryDocument257 pagesPakistan - A Personal Historypakzeeshan1100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- G 32 - 16Document20 pagesG 32 - 16juan fNo ratings yet

- Formulas For Structural Dynamics Tables, Graphs and SolutionsDocument492 pagesFormulas For Structural Dynamics Tables, Graphs and SolutionsErshad Ahmed100% (1)

- ISO Tank ProcedureDocument25 pagesISO Tank ProcedureRodrigo NunesNo ratings yet

- Shop Safety Inspection Checklist ReviewDocument4 pagesShop Safety Inspection Checklist ReviewMuhammad Farhan SabirNo ratings yet

- Hydraulic Thrust DeviceDocument2 pagesHydraulic Thrust DeviceGuilherme Augusto100% (1)

- F.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentDocument13 pagesF.sq-p-009 Rev. 0 Procedure For Inspection of Rotating EquipmentIksan Adityo Mulyo100% (1)

- 10speed EatonDocument2 pages10speed EatonChristopherNo ratings yet

- Wood Composite DeckingDocument1 pageWood Composite DeckingMuhammad Farhan SabirNo ratings yet

- Big Flat Community Connects To The World: Info@turnermontana - UsDocument1 pageBig Flat Community Connects To The World: Info@turnermontana - UsMuhammad Farhan SabirNo ratings yet

- Student WorkbookDocument49 pagesStudent WorkbookMuhammad Farhan SabirNo ratings yet

- CRM: An Introduction To Customer Relationship Management: How You Will BenefitDocument2 pagesCRM: An Introduction To Customer Relationship Management: How You Will BenefitMuhammad Farhan SabirNo ratings yet

- 20 Chemical Engineering QuestionsDocument5 pages20 Chemical Engineering QuestionsMuhammad Farhan SabirNo ratings yet

- Final Ppta ReportDocument41 pagesFinal Ppta ReportMuhammad Farhan SabirNo ratings yet

- AMSOIL MCF - Synthetic 10W-40 Motorcycle OilDocument2 pagesAMSOIL MCF - Synthetic 10W-40 Motorcycle OilamsoildealerNo ratings yet

- AC motor torque and train questionsDocument6 pagesAC motor torque and train questionssaravanababu jayapalNo ratings yet

- SENR5672Document2 pagesSENR5672Gilvan JuniorNo ratings yet

- C4000 Om en 17Document91 pagesC4000 Om en 17David Craig100% (1)

- High Head Drainage PumpsDocument9 pagesHigh Head Drainage PumpsEnrique MurgiaNo ratings yet

- Super King Air 300Document11 pagesSuper King Air 300aeroengineer1100% (1)

- Selection of Materials For Roller Chains From The Perspective of Manufacturing ProcessDocument7 pagesSelection of Materials For Roller Chains From The Perspective of Manufacturing Processhijzain0% (1)

- DX520LC Dx520lcaDocument8 pagesDX520LC Dx520lcaJohny Mazer IchsanNo ratings yet

- VENTURIMETERDocument10 pagesVENTURIMETERKrishan PrajapatiNo ratings yet

- Calculation Salim 1Document9 pagesCalculation Salim 1Abdullahi AwwalNo ratings yet

- Air cleaner system V2403M-T engine parts listDocument3 pagesAir cleaner system V2403M-T engine parts listSergeyNo ratings yet

- Vibration Study - Electromontaj - 400kV Tantareni-Kozlodui - ACSR 160 - 95-Rev. ADocument14 pagesVibration Study - Electromontaj - 400kV Tantareni-Kozlodui - ACSR 160 - 95-Rev. ALiciu CiprianNo ratings yet

- Lec02 ManipulatorsDocument7 pagesLec02 ManipulatorsMohamad YazidNo ratings yet

- Strain Modeling of Transpressional and Transtensional DeformationDocument12 pagesStrain Modeling of Transpressional and Transtensional Deformationmehenna ouidjaNo ratings yet

- Gad 20406510 10 En-00 PDFDocument1 pageGad 20406510 10 En-00 PDFErikikoNo ratings yet

- Studies On Shock Waves Produced by Reddy TubeDocument7 pagesStudies On Shock Waves Produced by Reddy TubeSai DhruvNo ratings yet

- Article 162Document10 pagesArticle 162Zoran PanicNo ratings yet

- 2-Vle Part 2Document22 pages2-Vle Part 2Arfa Zulkifli01No ratings yet

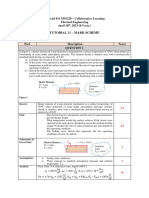

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Document6 pagesTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsNo ratings yet

- Bladedesign CalcDocument55 pagesBladedesign CalcMeiring PretoriusNo ratings yet

- Sumitomo HSMDocument68 pagesSumitomo HSMEdisson Yanqui VivancoNo ratings yet

- Baja Saeindia 2018 RulebookDocument73 pagesBaja Saeindia 2018 RulebookSrijan VermaNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet