Professional Documents

Culture Documents

Chapter4-Allowable Stresse

Uploaded by

yhproOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter4-Allowable Stresse

Uploaded by

yhproCopyright:

Available Formats

Chapter 5

Fatigue

FATIGUE STRESSES

1- General 2- Definitions 3- Fatigue Loads

1. General

This chapter presents a general method for the fatigue of structural elements that are subjected to repeated fluctuations of stresses. Members subjected to stresses resulting from fatigue load shall be designed so that the maximum stress do not exceed the allowable stress given in chapter (2) of the Egyptian steel code of practice and that the stress range does not exceed the allowable fatigue stress range given in chapter (3) of this code. Wind bracing does not consider subjected to fatigue load.

2. Definitions

Fatigue: damage in member (gradual crack propagation) caused by repeated live load (stress fluctuations). Design Life: the period which the structure will not fail or require repair. Stress Range: the algebric difference between two extreme values of stress due to fatigue load.

3. Fatigue Loads

1. Crane: Full traveling crane load + impact. 2. Roadway Bridge: 60 % of live load + impact. 3. Railway Bridge: Full standard live load + impact.

For Roadway Bridge with design lives > 50 years, the fatigue loads should be increased by factors M.

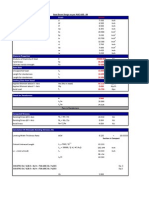

No of year M

50 1.0

80 1.10

100 1.15

120 1.20

For Roadway Bridges

Depending on the average daily truck traffic (ADTT) for 50 years design life, the number of constant stress cycles (N) is given in table 3.1a for long members and transverse members.

For Railway Bridges

Divided the bridge to 3 classes; Class 1 for chords and main girder (plate girder)

Class 2 for web of truss bridge

Class 3 for transverse floor beams, vertical of truss and sub-diagonal. For crane Depending on the average daily application (ADA) for 50 years design life, the number of constant stress cycles (N) is given in table 3.1C for different operation.

High strength Bolts Friction type

For H.S.B friction type and according to (N), the allowable stress ranges (Fsr) are given in table page 39 for bolts of grade 8.8 & 10.9. Each structural element has a particular detail category as shown in table 3.3 (page 43). The classification is divided into four parts which correspond to the following groups:

Group 1 non-welded details, plain materials, and bolted plates. Group 2 welded element. Group 3 welds and bolts. Group 4 orthotropic deck bridge details.

Depending on the details, member (rolled or built up), connection shape, type of weld, etc., the code divided the details to eight categories (A, B, B, C, D, E, E, F). Depending on these categories and on (N), the allowable stress range (Fsr) is given in table 3.2 (p. 41) and in Fig. 3.1 (p42). For fatigue consider the number of constant stress cycles (N) > 2,000,000 and the detail category class (A) for rolled section, class (B) for built up section, class (C) for high strength bolts in shear, class (D) for ordinary bolts and class (F) for bolts in tension.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 150 KV Substation Cost EstimationDocument21 pages150 KV Substation Cost EstimationMuhammadFajar100% (1)

- How To Design Concrete Structures Using Eurocode 2Document104 pagesHow To Design Concrete Structures Using Eurocode 2Adil Javed Chaudhary97% (36)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- D 1652 - 04Document4 pagesD 1652 - 04yhpro100% (1)

- Standard AASHTO 2002 17th Edition 740 Pages FullDocument740 pagesStandard AASHTO 2002 17th Edition 740 Pages Fullyhpro85% (54)

- Dynamic Foundation DesignDocument2 pagesDynamic Foundation DesignyhproNo ratings yet

- Shear Modulus at Room Temperature: Standard Test Method ForDocument5 pagesShear Modulus at Room Temperature: Standard Test Method ForROHITNo ratings yet

- Code of Pactice For Dead and Imposed Loads 2011Document30 pagesCode of Pactice For Dead and Imposed Loads 2011iyhkNo ratings yet

- 038 02-659-02 WB References-IraqDocument13 pages038 02-659-02 WB References-IraqyhproNo ratings yet

- Bailey Bridges Fm5 277Document373 pagesBailey Bridges Fm5 277jmcc2No ratings yet

- 2010 Bridges EN1993 GSedlacek PDFDocument148 pages2010 Bridges EN1993 GSedlacek PDFyhproNo ratings yet

- tc9 PDFDocument2 pagestc9 PDFyhpro100% (1)

- SSPC - Paint 22Document5 pagesSSPC - Paint 22yhpro100% (1)

- Chapter43 PDFDocument20 pagesChapter43 PDFyhproNo ratings yet

- Bollhoff The Manual of Fastening en 8100 PDFDocument106 pagesBollhoff The Manual of Fastening en 8100 PDFOliver KrausNo ratings yet

- Design of Reinforced Concrete Structure - Volume 1 - DR. Mashhour A. Ghoneim PDFDocument11 pagesDesign of Reinforced Concrete Structure - Volume 1 - DR. Mashhour A. Ghoneim PDFyhproNo ratings yet

- Welding of BridgeDocument18 pagesWelding of BridgeVimalan KannanNo ratings yet

- Steel Bridges Types History ConstructionDocument113 pagesSteel Bridges Types History ConstructionyhproNo ratings yet

- RebarDocument32 pagesRebarMustafa UzyardoğanNo ratings yet

- Piles Foundations PDFDocument48 pagesPiles Foundations PDFyhproNo ratings yet

- Foundation Engineering ch2 PDFDocument38 pagesFoundation Engineering ch2 PDFyhproNo ratings yet

- Shallow Foundations PDFDocument55 pagesShallow Foundations PDFyhpro100% (7)

- Civil Engineering - Bridge Design ManualDocument937 pagesCivil Engineering - Bridge Design ManualDeepali ChausalkarNo ratings yet

- SOIL Charts and Tables PDFDocument31 pagesSOIL Charts and Tables PDFyhproNo ratings yet

- Steel Beam Design As Per AISC ASDDocument2 pagesSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- Crack Width CalculationDocument3 pagesCrack Width CalculationgvgbabuNo ratings yet

- S. SLabDocument4 pagesS. SLabyhproNo ratings yet

- Steel Beam Design As Per AISC ASDDocument2 pagesSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- Allowable Stress Design: BD A E E NDocument14 pagesAllowable Stress Design: BD A E E NyhproNo ratings yet

- Crack Width CalculationDocument3 pagesCrack Width CalculationgvgbabuNo ratings yet

- Steel Beam Design As Per AISC ASDDocument2 pagesSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- Welding Handbook2009 PDFDocument202 pagesWelding Handbook2009 PDFyhproNo ratings yet

- BRIDGES Sanaa UN PDFDocument78 pagesBRIDGES Sanaa UN PDFyhproNo ratings yet

- Reels: CatalogueDocument24 pagesReels: CatalogueMatteo BaldassariNo ratings yet

- Mastic Asphalt Mix DesignDocument3 pagesMastic Asphalt Mix DesignRaghav100% (4)

- Corrosion-Guide 1 Stainless Steel CategoriesDocument8 pagesCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéNo ratings yet

- IATG 02.20 symbolsDocument3 pagesIATG 02.20 symbolsturamyuwiteka samuelNo ratings yet

- History of PiezopolymersDocument14 pagesHistory of PiezopolymersrachmajuwitaNo ratings yet

- Introduction To Properties of Materials: Badi 1 John Errington MSCDocument42 pagesIntroduction To Properties of Materials: Badi 1 John Errington MSCgereNo ratings yet

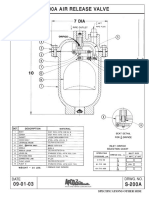

- APCO. S-200a Air Release ValveDocument2 pagesAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Aditi VosDocument1 pageAditi VosXELIXCELINNo ratings yet

- ChemFlo AsDocument2 pagesChemFlo Assmart construction solution solutionNo ratings yet

- Surface Vehicle Recommended Practice: Issued OCT1999Document19 pagesSurface Vehicle Recommended Practice: Issued OCT1999Paco LMNo ratings yet

- Dokumen - Tips - Pompe de Caldura BuclaDocument96 pagesDokumen - Tips - Pompe de Caldura BuclaAnonymous oKTCFZNTmNo ratings yet

- Ce 6 Sem Structural Analysis 2 Non Cbs Summer 2016Document4 pagesCe 6 Sem Structural Analysis 2 Non Cbs Summer 2016Pranay ManwarNo ratings yet

- 1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00Document107 pages1033 H000 A11000 019 XXXX XXXX (Construction Manual For Final) Rev 00vhpatel67No ratings yet

- TDS - Bronco Pre HDPE Membrane (S)Document3 pagesTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniNo ratings yet

- Computational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaDocument7 pagesComputational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaAravind KumarNo ratings yet

- Vahterus Plate and Ring Prhe-EnDocument4 pagesVahterus Plate and Ring Prhe-EnMartin CorkeryNo ratings yet

- Arl On ProductsDocument0 pagesArl On Productscasda73No ratings yet

- Energies 14 02463Document17 pagesEnergies 14 02463RoberticoZeaNo ratings yet

- Schletter Product Component ListDocument39 pagesSchletter Product Component ListKirsten HernandezNo ratings yet

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Document7 pagesSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- Fuse in XpandercrossDocument16 pagesFuse in XpandercrossMUHAMMAD IKHWANUDINNo ratings yet

- 250-122 (F) Equipment-Grounding Conductors For Parallel RunsDocument3 pages250-122 (F) Equipment-Grounding Conductors For Parallel RunsJOSE LUIS FALCON CHAVEZNo ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- Numerical Study of Stretch-Blow Molding of PET Bottles: January 2010Document7 pagesNumerical Study of Stretch-Blow Molding of PET Bottles: January 2010Anas AlbasarhNo ratings yet

- SFD N004 2013 PDFDocument21 pagesSFD N004 2013 PDFMohamed Abo-ZaidNo ratings yet

- Causeway BOQDocument7 pagesCauseway BOQSujan GhimireNo ratings yet

- Barrier Performance of Common Plastic FilmDocument1 pageBarrier Performance of Common Plastic FilmAriane Victoria DantesNo ratings yet