Professional Documents

Culture Documents

EGR 334 Lecture 16 Control Volume Applications Day1

Uploaded by

Andrea Louisse CorbillonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EGR 334 Lecture 16 Control Volume Applications Day1

Uploaded by

Andrea Louisse CorbillonCopyright:

Available Formats

EGR 334 Thermodynamics

Chapter 4: Section 6-8

Lecture 16:

Control Volume Applications:

Day 1

Quiz Today?

Todays main concepts:

Be able to set up mass and energy balance models for

Turbines

Pumps

Compressors

Boilers

Heat Exchangers

Nozzles

Diffusers

Throttle

Reading Assignment:

Homework Assignment:

Read Chapter 4, Sections 10-12

Problems from Chap 4: 36, 43, 52, 66

3

e

m

CV

dm

dt

i

m

Mass Rate Balance:

Energy Rate Balance:

e e

m e

CV

dE

dt

i i

me

Q

W

Review: For a Control Volume:

2 2

cv

V V

2 2

i e

cv cv i i i e e e

dE

Q W m h gz m h gz

dt

| | | |

= + E + + E + +

| |

\ . \ .

cv

in exit

i i

dm

m m

dt

=

4

e

m

CV

dm

dt

i

m

Mass Rate Balance: 1 path, steady state

Energy Rate Balance: 1 path, steady state

e e

m e

CV

dE

dt

i i

me

Q

W

Modeling applications with Control Volumes:

2 2

1

0 ( ) (V V ) ( )

2

cv cv i e i e i e

Q W m h h g z z

| |

= + + +

|

\ .

0

i e

m m =

Many important applications involve one inlet, one exit control volumes at

steady state. Today a number of these useful models will be developed

using the one inlet, one outlet, steady state forms of the mass balance

and energy balance given below.

i e

m m m = =

Control Volume Applications:

5

Nozzles Diffuser Turbine

Pump Compressor

Boiler

Heat Exchanger

Throttling Valve

6

If:

a) Outer surface of CV is well insulated

Common Modeling assumptions:

0 Q =

Application models generally make use of simplifying assumptions to

reduce the complexity of the Energy Balance. By removing terms that do

not apply to a particular application or whose impact on the application is

generally only minor the models take on simplified, useful, and easy to

use forms.

Assumption:

b) Small change of elevation

0

i e

z z =

c) No mechanical mechanisms present

0

mechanical

W =

d) CV maintains same shape and volume

0

pdV

W =

e) No electrical effects act on CV

0

electric

W =

f) Inlet and Outlet have same physical size

2 2

V V 0

i e

=

g) Outer surface of CV is small

h) Small T between CV and environment

i) flow passes through CV in short time

0 Q =

0 Q =

0 Q =

j) inlet size much larger than outlet size

V >>V V 0

e i i

~

Nozzles and Diffusers

Nozzle: a flow passage of varying cross-

sectional area in which the velocity of a gas

or liquid increases in the direction of flow.

Diffuser: a flow passage of varying cross-

sectional area in which the velocity of a gas

or liquid decreases in the direction of flow.

8 Sec 4.6: Nozzles and Diffusers

Nozzles and Diffusers are used to change the speed of the mass

flow through the control volume.

For continuous flow, changing the size of the cross section alters the

speed of the flow.

if

incompressible

What common assumptions may be used to simplify the energy balance?

i e

m m =

V

i

V

e

V

i

V

e

V V

i i e e

i e

A A

v v

=

V V

i i e e

A A =

if

continuous

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ + + =

e

e

e e i

i

i i CV CV

gz

v

h m gz

v

h m W Q

dt

dE

2 2

2 2

CV

9 Sec 4.6: Nozzles and Diffusers

Typical Energy Balance simplifications,

2 2

CV

V V

2 2

i e

CV CV i i i e e e

dE

Q W m h gz m h gz

dt

| | | |

= + + + + +

| |

\ . \ .

Horizontal Section

(or very short vertical)

No pump/turbines

Even though there is

no insulation, the V

is high so there may

be little heat

transfer.

Steady

State

Therefore,

2 2

V V

0

2 2

i e

i i e e

m h m h

| | | |

= + +

| |

\ . \ .

2 2

1

0 ( ) (V V )

2

i e i e

h h = +

10

Example: (4.34) Air with a mass flow rate of 5 lb/s enters a horizontal

nozzle operating at steady state at 800R, 50 psi and a velocity of 10 ft/s.

At the exit, the temperature is 570R and the velocity is 1510 ft/s. Using

the ideal gas model for air determine (a) the area of the inlet, in ft

2

, and

(b) the heat transfer between the nozzle and its surroundings in BTU/lb of

air flowing.

50 psi

800R

10 ft/s

570R

1510 ft/s

A

in

= ?, Q = ?

Sec 4.6: Nozzles and Diffusers

.

m = 5 lb

m

/s

ideal gas

11

Example: (4.34) Using the ideal gas model for air determine (a) the area

of the inlet, in ft

2

, and (b) the heat transfer between the nozzle and its

surroundings in BTU/lb of air flowing.

50 psi

800R

10 ft/s

570R

1510 ft/s

A

in

= ?, Q = ?

Sec 4.6: Nozzles and Diffusers

V

in exit

A

m m m

v

= = =

mass balance

V

V V

i i i

i

i i i

mv m RT A

m A

v p

= = =

2

96 . 2 ft A

i

=

( )

( )

( )

2

2

2

(1545 / ) 800

(5 / )

(10 / ) 28.97 / 144

50 /

f mol

m

i

m mol

f

ft lb lb R R

lb s ft

A

ft s lb lb in

lb in

=

continuity

12

Example: (4.34) Using the ideal gas model for air determine (a) the area

of the inlet, in ft

2

, and (b) the heat transfer between the nozzle and its

surroundings in BTU/lb of air flowing.

50 psi

800R

10ft/s

570R

1510ft/s

Sec 4.6: Nozzles and Diffusers

Energy balance at SS

2 2

0

2 2

i e

CV CV i i i e e e

v v

Q W m h gz m h gz

| | | |

= + + + + +

| |

\ . \ .

2 2

0 0 0 0

2 2

i e

CV i i e e

v v

Q m h m h

| | | |

= + + + + +

| |

\ . \ .

( )

( )

2 2

2

2 2

1510 10

1

1 1

136.26 191.81

2 1 / 32.2 778

f

CV

m f

lb

Q BTU ft slug Btu

m lb s slug ft s lb ft lb

= +

m

CV

lb

BTU

m

Q

01 . 10 =

CV

Q

5 /

m

m lb s =

( )

( )

2 2

2

e i

CV

e i

v v

Q

h h

m

= +

reduced using assumptions:

from Table A-22E

Turbines

Turbine: a device in which power is

developed as a result of a gas or liquid

passing through a set of blades attached to

a shaft free to rotate.

14 Sec 4.7: Turbines

Use Mass and Energy Balances still hold:

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ + + =

e

e

e e i

i

i i CV CV

gz

v

h m gz

v

h m W Q

dt

dE

2 2

2 2

CV

A turbine is a device that develops power from a gas or liquid passing

through a set of blades which are attached to a shaft free to rotate.

in exit

m m m = = 0

in exit

m m =

15

Typical Energy Balance simplifications,

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ + + =

e

e

e e i

i

i i CV CV

gz

v

h m gz

v

h m W Q

dt

dE

2 2

2 2

CV

Horizontal Section

(or very short vertical)

Even though there is

no insulation, the V

is high so there is no

heat transfer.

Steady

State

Therefore,

e e i i CV

h m h m W

+ = 0

Then,

( )

e i CV

h h m W =

AV ~ 0

Sec 4.7: Turbines

W

CV

.

m

in

.

m

exit

16

Example: (4.50) Steam enters the first stage of a turbine at 40 bar and

500 C with a volumetric flow rate of 90 m

3

/min. Steam exits the turbine

at 20 bar and 400C. The steam is then reheated at constant pressure to

500 C before entering the second stage turbine. Steam leaves the second

stage as saturated vapor at 0.6 bar. For operation at steady state, and

ignoring stray heat transfer and KE and PE effects, determine the

40 bar

500C

90 m

3

/min

Sec 4.7: Turbines

(a) Mass flow rate of steam, in kg/hr

(b) Total power produced by both turbines, in kW

(c) The rate of heat transfer to the steam flowing through the reheater, in kW.

W

CV,1

Reheater

W

CV,2

20 bar

400C

20 bar

500C

Sat. vapor

0.6 bar

Assumptions

AKE= A PE=0

Q

Turbine

= 0

17

Example: (4.50)

40 bar

500C

90 m

3

/min

Sec 4.7: Turbines

(a) Mass flow rate of steam, in kg/hr

(b) Total power produced by both turbines, in kW

(c) The rate of heat transfer to the steam

flowing through the reheater, in kW.

W

CV,1

Reheater

W

CV,2

20 bar

400C

20 bar

500C

Satd vapor

0.6 bar

Assumptions

AKE= A PE=0

Q

Turbine

= 0

2) Find intensive

properties from

Table A-4

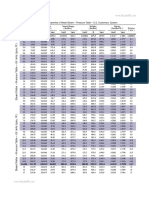

state In T1 Ex T1 Ex RH Ex T2

sat. vapor

P (bar) 40 20 20 0.6

T (C) 500 400 500 36.16

v (m

3

/kg) 0.08643 0.1512 0.1757 23.739

h (kJ/kg) 3445.3 3247.6 3467.6 2567.4

state In T1 Ex T1 Ex RH Ex T2

sat. vapor

P (bar) 40 20 20 0.6

T (C) 500 400 500

v (m

3

/kg)

h (kJ/kg)

state In T1 Ex T1 Ex RH Ex T2

phase

P (bar)

T (C)

v (m

3

/kg)

h (kJ/kg)

1) Identify state

properties given in

problem statement.

18

Example: (4.50)

Sec 4.7: Turbines

(a) Mass flow rate of

steam, in kg/hr

(b) Total power produced

by both turbines, in kW

(c) The rate of heat

transfer to the steam

flowing through the

reheater, in kW.

state In T1 Ex T1 Ex RH Ex T2

Satd vap

P (bar) 40 20 20 0.6

T (C) 500 400 500 36.16

v (m

3

/kg) 0.08643 0.1512 0.1757 23.739

h (kJ/kg) 3445.3 3247.6 3467.6 2567.4

1 1 1

1

1 1

V

inT

A V

m m

v v

= = =

To find mass flow rate from volumetric flow rate:

3

4

3

90 /min 60 min

6.248 10 /

0.08643 / 1

m

kg hr

m kg hr

= =

3

1

90 / min V m =

19

Example: (4.50)

Sec 4.7: Turbines

(a) Mass flow rate of steam,

in kg/hr

(b) Total power produced

by both turbines, in kW

(c) The rate of heat

transfer to the steam

flowing through the

reheater, in kW.

state In T1 Ex T1 Ex RH Ex T2

Satd vap

P (bar) 40 20 20 0.6

T (C) 500 400 500 36.16

v (m

3

/kg) 0.08643 0.1512 0.1757 23.739

h (kJ/kg) 3445.3 3247.6 3467.6 2567.4

( ) ( ) | |

2 2 1 1 eT iT eT inT CV

h h h h m W + =

( ) ( )

4

1

(6.248 10 / ) 3445.3 3247.6 3467.6 2567.4 /

3600

kW hr

kg hr kJ kg

kJ s s

= +

17, 565

CV

W kW =

To find the power produced in both Turbines:

20

Example: (4.50)

Sec 4.7: Turbines

state In T1 Ex T1 Ex RH Ex T2

Satd vap

P (bar) 40 20 20 0.6

T (C) 500 400 500 36.16

v (m

3

/kg) 0.08643 0.1512 0.1757 23.739

h (kJ/kg) 3445.3 3247.6 3467.6 2567.4

2 2

CV

V V

2 2

i e

CV CV i i i e e e

dE

Q W m h gz m h gz

dt

| | | |

= + + + + +

| |

\ . \ .

( )

0

CV i i e

Q m h h = +

| |

4

1

(6.248 10 / ) 3467.6 3247.6 / 3, 819

3600

CV

kW hr

Q kg hr kJ kg kW

kJ s s

= =

Heat transferred in the reheaterstarting with energy balance

( )

CV i e i

Q m h h =

Simplified with assumptions:

(a) Mass flow rate of

steam, in kg/hr

(b) Total power produced

by both turbines, in kW

(c) The rate of heat

transfer to the steam

flowing through the

reheater, in kW.

Compressors and Pumps

Compressors and Pumps:

devices in which work is done

on the substance flowing

through them to change the

state of the substance,

typically to increase the

pressure and/or elevation.

Compressor : substance is gas

Pump: substance is liquid

22 Sec 4.8: Compressors and Pumps

Compressors and Pumps:

Device where work is used to increase pressure and/or elevation of the flow substance.

Pump Model:

used for liquids

Compressor Model:

used for gases

W

CV

m

in

.

m

exit

.

. W

CV

m

in

m

exit

.

.

.

23

Typical Energy Balance simplifications,

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ + + =

e

e

e e i

i

i i CV CV

gz

v

h m gz

v

h m W Q

dt

dE

2 2

2 2

CV

Horizontal Section

(or very short vertical)

Even though there is

no insulation, the V

is high so there is no

heat transfer.

Steady

State

Therefore,

e e i i CV

h m h m W

+ = 0

Then,

( )

e i CV

h h m W =

Av~0

Sec 4.8: Compressors and Pumps

W

CV

m

in

m

exit

.

.

.

24

Example: (4.60) Air is compressed at steady state from 1 bar, 300 K, to 6

bar with a mass flow rate of 4 kg/s. Each unit of mass passing from the

inlet to the exit undergoes a process described by pV

1.27

= constant. Heat

transfer occurs at a rate of 46.95 kJ/kg of air flowing to the cooling water

circulating in a water jacket enclosing the compressor. If KE and PE of

the air are negligible, calculate the compressor power in kW.

1 bar

300 K

4 kg/s

6 bar

Q

CV

/m= 46.95 kJ/kg

Assumptions

Steady State

AKE= APE=0

pV

1.27

= constant

Ideal gas

state In Ex

P (bar) 1 6

T (K) 300

h (kJ/kg) 300.19

Sec 4.8: Compressors and Pumps

Table A-22 (Ideal Gas Properties of Air)

h is independent of p

W

CV

.

state In Ex

P (bar) 1 6

T (K) 300

h (kJ/kg)

state In Ex

P (bar)

T (K)

h (kJ/kg)

25

Example: (4.60)

1 bar

300 K

4 kg/s

6 bar

Q

CV

= -46.95 kJ/kg

state In Ex

P (bar) 1 6

T (K) 300

h (kJ/kg) 300.19

Sec 4.8: Compressors and Pumps

From ideal gas equation and polytropic eq.

W

CV

.

pV mRT =

1 1 2 2

1 2

pV p V

T T

=

onstant

n

pV c =

1 1 2 2

n n

pV p V =

Rearranging:

2 1 2

1 2 1

V p T

V p T

=

1/

2 1

1/

1 2

n

n

V p

V p

=

Combining

1/

1 2 1

1/

2 1 2

n

n

p T p

p T p

=

1

1/ 1 (1/ )

2 2 2 2 2

1/ 1 (1/ )

1 1 1 1 1

n

n n n

n n

T p p p p

T p p p p

| |

= = =

|

\ .

state In Ex

P (bar) 1 6

T (K) 300 439.1

h (kJ/kg) 300.19 440.7

26

Example: (4.60) 1 bar

300 K

4 kg/s

6 bar

Q

CV

= -46.95 kJ/kg

state In Ex

P (bar) 1 6

T (K) 300

h (kJ/kg) 300.19

Sec 4.8: Compressors and Pumps

( )

0

CV CV i i e

Q W m h h = +

1

2

2 1

1

n

n

P

T T

P

| |

=

|

\ .

( ) ( )

4 / 46.95 / 300.19 440.7 / 750

CV

kW

W kg s kJ kg kJ kg kW

kJ s

= + =

Therefore the exit temperature is

W

CV

.

The energy balance can then find the pump work

(Since T

2

and p

2

are now

known, h

2

may be found

on table A22)

1.27 1

1.27

2

6

300 439.1

1

T K K

| |

= =

|

\ .

( )

CV

CV i i e

i

Q

W m h h

m

= +

27

end of Lecture 16 Slides

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Ac Voltage Compressors 07-2019 Desk490a802 PDFDocument212 pagesAc Voltage Compressors 07-2019 Desk490a802 PDFsaid3232No ratings yet

- Pipe Flow-Friction Factor Calculations With Excel CourseDocument30 pagesPipe Flow-Friction Factor Calculations With Excel CourseMohamed ZahranNo ratings yet

- Formation Multi-Tester (FMT) Principles, Theory, and InterpretationDocument61 pagesFormation Multi-Tester (FMT) Principles, Theory, and InterpretationMannbeard0% (1)

- Gas Turbine Air Filter System OptimizationDocument10 pagesGas Turbine Air Filter System Optimizationsevero97No ratings yet

- Reminders For The Thesis DefenseDocument2 pagesReminders For The Thesis DefenseAndrea Louisse CorbillonNo ratings yet

- Instructions On The Preparation and Submission of The Iee ChecklistDocument18 pagesInstructions On The Preparation and Submission of The Iee ChecklistAndrea Louisse CorbillonNo ratings yet

- Major Fuel Sources for PCDD/PCDF Releases in ESEA RegionDocument8 pagesMajor Fuel Sources for PCDD/PCDF Releases in ESEA RegionJen ChavezNo ratings yet

- Process Dynamics and Control - LEC 1Document15 pagesProcess Dynamics and Control - LEC 1Andrea Louisse Corbillon100% (1)

- Schematic Diagram of Dengue PathogenesisDocument4 pagesSchematic Diagram of Dengue PathogenesisGuia Rose Sibayan0% (1)

- 2nd Semester AY 2014 - Time Monday Tuesday Wednesday ThursdayDocument4 pages2nd Semester AY 2014 - Time Monday Tuesday Wednesday ThursdayAndrea Louisse CorbillonNo ratings yet

- Steam TablesDocument11 pagesSteam TablesAntony AbirawaNo ratings yet

- JsiakdDocument12 pagesJsiakdAndrea Louisse CorbillonNo ratings yet

- Partial Fraction DecompositionsDocument4 pagesPartial Fraction DecompositionsAndrea Louisse CorbillonNo ratings yet

- Tutorial Menggunakan MathcadDocument15 pagesTutorial Menggunakan MathcadKOMPATRIOTNo ratings yet

- Unit 3 Exam-1GHDocument8 pagesUnit 3 Exam-1GHAndrea Louisse CorbillonNo ratings yet

- Mass Transfer Lectures on Drying ProcessesDocument10 pagesMass Transfer Lectures on Drying ProcessesAndrea Louisse CorbillonNo ratings yet

- Proposal Template 2013 For Natural Sciences ResearchDocument15 pagesProposal Template 2013 For Natural Sciences ResearchAndrea Louisse CorbillonNo ratings yet

- Unit 3 Exam-1GHDocument8 pagesUnit 3 Exam-1GHAndrea Louisse CorbillonNo ratings yet

- Hydraulic Conductivity: K, Permeability, Flow NetsDocument22 pagesHydraulic Conductivity: K, Permeability, Flow NetsYashika Bhathiya JayasingheNo ratings yet

- PermeabilityDocument7 pagesPermeabilityRaven1013No ratings yet

- C3 FluidizationDocument10 pagesC3 FluidizationAndrea Louisse CorbillonNo ratings yet

- Darcy's Data For Two Different Sands: Figure From Hornberger Et Al. (1998)Document20 pagesDarcy's Data For Two Different Sands: Figure From Hornberger Et Al. (1998)Andrea Louisse CorbillonNo ratings yet

- BDocument2 pagesBAndrea Louisse CorbillonNo ratings yet

- Assignment in BiologyDocument1 pageAssignment in BiologyAndrea Louisse CorbillonNo ratings yet

- Darcy's Data For Two Different Sands: Figure From Hornberger Et Al. (1998)Document20 pagesDarcy's Data For Two Different Sands: Figure From Hornberger Et Al. (1998)Andrea Louisse CorbillonNo ratings yet

- Globalization and Society PDFDocument9 pagesGlobalization and Society PDFAndrea Louisse CorbillonNo ratings yet

- Mandalina Ghosh (Greenhouse Effect)Document13 pagesMandalina Ghosh (Greenhouse Effect)amrittapadarNo ratings yet

- Electrolux Compressor DataDocument3 pagesElectrolux Compressor DataSyed Noman Ahmed0% (1)

- SC F1 C7 Air NotesDocument36 pagesSC F1 C7 Air Notesjasonyeoh333No ratings yet

- User Guide For Com Prop 2Document43 pagesUser Guide For Com Prop 2Dipranjan GuptaNo ratings yet

- 6 Multiple Evaporator and Compressor Systems SheetDocument1 page6 Multiple Evaporator and Compressor Systems SheethanyassawyNo ratings yet

- Sublimation of CaffeineDocument3 pagesSublimation of CaffeineNabil ShaikhNo ratings yet

- Leybold FundamentalsDocument199 pagesLeybold FundamentalsvelmuruganNo ratings yet

- Fluid Mechanics & HydraulicsDocument4 pagesFluid Mechanics & HydraulicsFreezeNo ratings yet

- Modelling of Natural Gas Sweetening and Dehydration Prior To LiquefactionDocument10 pagesModelling of Natural Gas Sweetening and Dehydration Prior To LiquefactionAhmed ShaepNo ratings yet

- Simple DistillationDocument5 pagesSimple DistillationJheian Christian TubleNo ratings yet

- Expanded Air Valve Program 1Document8 pagesExpanded Air Valve Program 1Capital Diesel SASNo ratings yet

- Dwg-001 - D Almacenamiento Arcilla CalcinadaDocument1 pageDwg-001 - D Almacenamiento Arcilla CalcinadaCarlos Andrade GómezNo ratings yet

- Hydraulic Principles Unit2l1Document26 pagesHydraulic Principles Unit2l1KJDNKJZEFNo ratings yet

- Pro2 Check Elite User ManualDocument10 pagesPro2 Check Elite User ManuallakshmivillegasNo ratings yet

- RefDocument5 pagesRefSana AkhtarNo ratings yet

- Compressed Substances ProcedureDocument8 pagesCompressed Substances ProcedureAditya Raj MishraNo ratings yet

- A Review of Tesla ValveDocument33 pagesA Review of Tesla ValveMogambo Khushua100% (1)

- 123Document13 pages123Cheska FernandezNo ratings yet

- Water-Steam Saturation Properties (By Pressure in US Units)Document5 pagesWater-Steam Saturation Properties (By Pressure in US Units)Juan Carlos Ramirez DariasNo ratings yet

- Booster PumpDocument1 pageBooster PumpDani HambalinaNo ratings yet

- Intake and ExhaustDocument10 pagesIntake and ExhaustpintuNo ratings yet

- Review Module 15 Hydraulics 1 May 2021 Part 1Document1 pageReview Module 15 Hydraulics 1 May 2021 Part 1RamonNo ratings yet

- Bernoulli Lab Report-CorrectDocument20 pagesBernoulli Lab Report-CorrectJerle ParondoNo ratings yet

- Sieve Tray Rating Data Registered To: PAVAN, ZEPPELIN KG-TOWER® Version 5.0Document1 pageSieve Tray Rating Data Registered To: PAVAN, ZEPPELIN KG-TOWER® Version 5.0Pavan KumarNo ratings yet

- 6.hydraulic Machinery TurbinesDocument17 pages6.hydraulic Machinery TurbinesHitesh GahlawatNo ratings yet

- Fluid Mechanics Lab AssignmnentDocument8 pagesFluid Mechanics Lab AssignmnentMuhammad AbdullahNo ratings yet

- PR-3Document1 pagePR-3Fernanda QuelNo ratings yet