Professional Documents

Culture Documents

En Ecoplus

Uploaded by

vijendramlOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En Ecoplus

Uploaded by

vijendramlCopyright:

Available Formats

Water Cooled Screw Products

McQuay Single Screw

ECOPLUS

ECOPLUS - Water Cooled Screw Product

SIZE

050.1 SE or XE 060.1 SE or XE 073.1 SE or XE 100.2 SE or XE 110.2 SE or XE

Cooling Cap. kW

161 or 181 195 or 217 245 or 265 324 or 356 361 or 396 16 sizes in 400 kW of cooling capacity range :

120.2 SE or XE

133.2 SE or XE

391 or 431

435 or 482

Big Flexibility

146.2 SE or XE

479 or 525

ECOPLUS - Water Cooled Screw Product

Unit Efficiency

5

4,5

COP

SE (Standard Efficiency) XE (High Efficiency)

3,5 100 200 300

kW

400

500

600

Two efficiency versions to match exactly the customer needs

ECOPLUS - Water Cooled Screw Product

McQuay Single Screw compressor with integrated oil separator. Very compact design. Full flanged for an easy maintenance activity Check valve and STOP valve on the discharge line to keep the refrigerant in the condenser during maintenance activities EEXV: Electronic EXpansion Valve as standard

Dry-Expansion evaporator with ONE pass on refrigerant side Microtech II C Plus No Clorine No ODP Best Efficiency Low pressure No glide

D.O.L. 33% Y-D

Wye-Delta Starter as standard feature to reduce the inrush current

ECOPLUS - Water Cooled Screw Product

McQuay Single Screw compressor with integrated oil separator. Very compact design. Full flanged for an easy maintenance activity less space required on the unit simplified oil circulation oil reservoir into the bell sight-glasses to easely check the oil level

balanced radial loads balanced axial loads no vibrations less noise no critical bearings

Y - D Starter as standard Soft Starter as option suction gas cooled electric motor

ECOPLUS - Water Cooled Screw Product

McQuay Single Screw compressor with integrated oil separator. Very compact design. Full flanged for an easy maintenance activity

STEPLESS cooling capacity modulation

down to 25% for each compressor

(12,5% of the total unit cooling power)

always a perfect chilled water temperature

control ( 0.5C ) without fluctuations

spring return to minimum load to guarantee a

very fast compressor start, with minimum inrush currents and stress

good part load performances to save money

in unit management cost

ECOPLUS - Water Cooled Screw Product

McQuay Single Screw compressor with integrated oil separator. Very compact design. Full flanged for an easy maintenance activity

Flanges for an easy access to every compressor component to perform ordinary maintenance and keep very long the compressors life

way to gate rotors bearings

way to oil separator

way to internal oil filter

electrical box

way to gate-rotor way to electric motor

ECOPLUS - Water Cooled Screw Product

Check valve and STOP valve on the discharge line to keep the refrigerant in the condenser during maintenance activities

Compressor discharge check and discharge STOP valve as standard

An important standard feature to make easy maintenance activities on the chiller: keep all the refrigerant charge into the condenser and open the refrigerant circuit without problem

ECOPLUS - Water Cooled Screw Product

Electronic Expansion Device means:

EEXV: Electronic EXpansion Valve as standard

a better refrigerant flow control at each chillers load; a perfect chilled water temperature control; a wider chiller operating range; a faster chillers working load change to promptly

satisfy the changed plants request;

a faster unit start-up;

no need solenoid valve on the expansion pipeline;

opportunity for a big MONEY SAVING in unit electrical

consuption thanks to lower condensing pressure during colder year months (Its no possible with TEXV);

8 7

EER

6 5 4

Evaporator conditions: IN 12C OUT 7C

3 25 30 35 40 45 50 Condensation Temperature [C]

COP increases with condensating temperature reduction!

ECOPLUS - Water Cooled Screw Product

ODP

Ozone Depletion Potential

=0

GWP

Global Warming Potential

= 1330

*

the lowest value *

Greenhouse effect

between 134a 407C 410A

Good thermodinamic efficiency, so good COP to have low TEWI value

ECOPLUS - Water Cooled Screw Product

Refrigerants conditions at point 2

lower work pressure lower work temperature

good working conditions for the compressor

values for water cooled application

lower DP between suction and discharge line

DP = 10 bar

1

DP = 16 bar

lower tip clearence refrigerant leakage

10

bar

15

20

25

values for air cooled application *

ECOPLUS - Water Cooled Screw Product

D.O.L. 33% Y-D

Compressor unloading Spring return to minimum load

Spring return system, at the component stop, ensure a next restart at

minimum load (25%) for the compressor

Wye-Delta starter system as standard feature ensure a 33% of the

RotorLockedAmp during inrush

Compressor start sequence with minimum inrush current for a good electric motor and electric components reliability

ECOPLUS - Water Cooled Screw Product

ECOPLUS

Best choice for old chiller repleacement

very slim, light and compact unit to help installation through most standard industrial doorways without modification.

ECOPLUS - Water Cooled Screw Product

Balanced axial loads

Balanced radial loads

Balanced radial and axial loads

on screw

McQuay Single Screw

compression techology

McQuay Single Screw

A sinergy to have minimum structural vibrations

NO NEED FOR ANTIVIBRATION MOUNTED PADS

ECOPLUS - Water Cooled Screw Product

The lowest sound pressure levels on the water cooled chillers market

Less than 70 dB(A)

72 70 68 66 64 62 60 1 160 2 190 3 250 4 320 5 360 6 390 7

Cooling Capacity

Std Low Noise

8480

ISO 3744

Declaration according

Less than 65 dB(A)

Less than 67 dB(A)

Unit can satisfy the most critical customers acoustical needs

ECOPLUS - Water Cooled Screw Product

ECOPLUS

the best compromise for a chiller:

efficient

reliable

silent

ecological

You might also like

- Water ChillerDocument32 pagesWater ChillerPaing Phyo Ko78% (9)

- Green Box PDFDocument20 pagesGreen Box PDFRolando El BlancoNo ratings yet

- PFSB Mcquay Manual R 134a 01 PDFDocument24 pagesPFSB Mcquay Manual R 134a 01 PDFevrimk100% (1)

- Ewyq FDocument54 pagesEwyq FRicardo Molina SánchezNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- dwhufrrohgvfuhzfkloohuv: Product ManualDocument24 pagesdwhufrrohgvfuhzfkloohuv: Product Manualer_sanjaypatel100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Process Description &: Control PhilosophyDocument12 pagesProcess Description &: Control PhilosophyHendiko PanggabeanNo ratings yet

- Model YK-EP Efficiency Plus Centrifugal Liquid Chiller Style BDocument104 pagesModel YK-EP Efficiency Plus Centrifugal Liquid Chiller Style BThe Ka1serNo ratings yet

- Ledeen Actuator General Catalogue - Entire LineDocument24 pagesLedeen Actuator General Catalogue - Entire LineJair LamasNo ratings yet

- Applied Systems Catalogue ECPEN12-401 Tcm135-251492Document66 pagesApplied Systems Catalogue ECPEN12-401 Tcm135-251492António NunesNo ratings yet

- Sop Grease Trap PDFDocument2 pagesSop Grease Trap PDFAdilen DelNo ratings yet

- CompressorDocument6 pagesCompressorproxywarNo ratings yet

- PCU0610A - Chiller (Small)Document16 pagesPCU0610A - Chiller (Small)jeromeduytscheNo ratings yet

- Energy Efficient BuildingDocument11 pagesEnergy Efficient BuildingSantosh Basnet100% (2)

- McQuay WHS E XE Technical Manual EngDocument24 pagesMcQuay WHS E XE Technical Manual EngAnbarasan NagarajanNo ratings yet

- PCXZAM15 Air-Cooled Scroll Modular ChillerDocument12 pagesPCXZAM15 Air-Cooled Scroll Modular ChillerAsyraf ZaidiNo ratings yet

- Dr. Fixit Polyplus CP Admix - Submittal & Test Certifictes PDFDocument100 pagesDr. Fixit Polyplus CP Admix - Submittal & Test Certifictes PDFVimal Gopalakrishnan100% (1)

- Technical Specification For Proposed Two-Storey House: House Construction Tips and GuidelinesDocument9 pagesTechnical Specification For Proposed Two-Storey House: House Construction Tips and GuidelinesNovel LopezNo ratings yet

- SUStoM GuidelineDocument45 pagesSUStoM GuidelineNur Hazirah SadonNo ratings yet

- Kaeser CompressorsDocument4 pagesKaeser Compressorsozy05100% (1)

- Clean Kitchen Premises and Equipment SITHKOP001 - PowerpointDocument57 pagesClean Kitchen Premises and Equipment SITHKOP001 - PowerpointJuan Diego Pulgarín Henao0% (2)

- Yca PDFDocument44 pagesYca PDFsugirin100% (2)

- Vaccum DehydratorDocument4 pagesVaccum DehydratorSimbu ArasanNo ratings yet

- McI Ecoplus TMDocument32 pagesMcI Ecoplus TMJunaid YNo ratings yet

- HVAC en CatalogueDocument64 pagesHVAC en CataloguesafinditNo ratings yet

- 4052 - Mcquay MNG 115.2 PDFDocument88 pages4052 - Mcquay MNG 115.2 PDFFarrukhAhmedKhanNo ratings yet

- Technical YKDocument16 pagesTechnical YKnairam2003No ratings yet

- McQuay WHS ChillerDocument28 pagesMcQuay WHS ChillerYorkist100% (1)

- Mcsmart Eng PMDocument28 pagesMcsmart Eng PMELDUVINA RIBASNo ratings yet

- Aquasnap: Air Conditioning Made SimpleDocument6 pagesAquasnap: Air Conditioning Made SimpleMiguel Rojo GomezNo ratings yet

- Clivet Toplotne PumpeDocument15 pagesClivet Toplotne PumpeSean ThomasNo ratings yet

- Ewaq Ewyq DaynDocument96 pagesEwaq Ewyq DaynValentin MalihinNo ratings yet

- Databook Ewwd-Vz A - Eeden16 (En)Document31 pagesDatabook Ewwd-Vz A - Eeden16 (En)Abian100% (1)

- Ecoplus 806B-04-07C Eng PM PDFDocument32 pagesEcoplus 806B-04-07C Eng PM PDFIvanNo ratings yet

- York Cat LC 2012 enDocument148 pagesYork Cat LC 2012 enMary Andrews100% (1)

- Technical Ycre YcseDocument18 pagesTechnical Ycre Ycsenairam2003No ratings yet

- Aquaflair: Technical Cooling ChillersDocument27 pagesAquaflair: Technical Cooling ChillersmanuelNo ratings yet

- Weco en - 03-08Document6 pagesWeco en - 03-08Mohd NaserNo ratings yet

- Proximus 807B-04-07C Eng PM PDFDocument32 pagesProximus 807B-04-07C Eng PM PDFIvanNo ratings yet

- Instalatii de ClimatizareDocument19 pagesInstalatii de ClimatizareAdi MusatNo ratings yet

- McQuay McEnergy HPI Technical Manual EngDocument48 pagesMcQuay McEnergy HPI Technical Manual EngZhenqian HNo ratings yet

- Chillers & Fan Coil Units: Catalogue 2012Document20 pagesChillers & Fan Coil Units: Catalogue 2012birlograresNo ratings yet

- Technical YLAEDocument16 pagesTechnical YLAEnairam2003No ratings yet

- Chiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingDocument7 pagesChiller Daikin Ewadc12cfxs - 1118 Kw-Free CoolingBogdan-iulian BalintNo ratings yet

- RecoveryDocument14 pagesRecoveryDavid DavisNo ratings yet

- TECS Water Cooled ChillerDocument8 pagesTECS Water Cooled Chillerntt_121987No ratings yet

- Model CYK Compound Centrifugal Liquid Chillers Design Level GDocument38 pagesModel CYK Compound Centrifugal Liquid Chillers Design Level GSharon Lambert100% (1)

- CXB 036Document11 pagesCXB 036Zvonimir PerasovićNo ratings yet

- Inverter Air Cooled Screw Chillers: Product ManualDocument52 pagesInverter Air Cooled Screw Chillers: Product ManualKyaw San OoNo ratings yet

- Introducing AquafanDocument24 pagesIntroducing AquafanWatco GroupNo ratings yet

- Guide SpecsDocument38 pagesGuide Specsenigmazee100% (1)

- Skymark VAC - 8-25T Engineering GuideDocument16 pagesSkymark VAC - 8-25T Engineering Guideastrowiz88No ratings yet

- Air Blue UFC ChillerDocument130 pagesAir Blue UFC ChillerAashanram SayeeramNo ratings yet

- 30RW/30RWA: Water-Cooled/Condenserless Liquid Chillers With Integrated Hydronic ModuleDocument20 pages30RW/30RWA: Water-Cooled/Condenserless Liquid Chillers With Integrated Hydronic ModuleKossu69No ratings yet

- Chillere Daikin MariDocument12 pagesChillere Daikin MariProiectare InstalatiiNo ratings yet

- Alzb 304B 04 07F Eng PM PDFDocument20 pagesAlzb 304B 04 07F Eng PM PDFΓεώργιος ΠαπαδόπουλοςNo ratings yet

- FOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01Document15 pagesFOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01ntt_121987No ratings yet

- ChillersDocument88 pagesChillers9810482818No ratings yet

- 1 MideaDocument22 pages1 MideaManuel GutierrezNo ratings yet

- 2.5 GSHP CiatesaDocument20 pages2.5 GSHP CiatesaFPrueba1No ratings yet

- KR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TRDocument58 pagesKR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TR1969MAZHARNo ratings yet

- Air Cooled Chillers1Document6 pagesAir Cooled Chillers1jonathandacumosNo ratings yet

- Chiller Data SheetDocument7 pagesChiller Data SheetMohammed AzharNo ratings yet

- Midea Window and Portable Brochure A4 - 4PP - FADocument4 pagesMidea Window and Portable Brochure A4 - 4PP - FAMohazil Ajil MohamedNo ratings yet

- Gifts of NatureDocument2 pagesGifts of NatureŚáńtőśh MőkáśhíNo ratings yet

- WASH MIS - Final ReportDocument123 pagesWASH MIS - Final ReportDebergeNo ratings yet

- Scan-Water and LMS ManufactureDocument19 pagesScan-Water and LMS Manufactureshivani guptaNo ratings yet

- 3-Site Analysis - Natural Factors Part 2Document25 pages3-Site Analysis - Natural Factors Part 2Catherine Joy TagsipNo ratings yet

- Basic Terms: Sustainable Agriculture AND Farming System Farming System Ss Rana SrscientistDocument40 pagesBasic Terms: Sustainable Agriculture AND Farming System Farming System Ss Rana SrscientistSofi MehrajNo ratings yet

- Sample - MapDocument3 pagesSample - MapAnh ThảoNo ratings yet

- Hi-Temp 1027 PDFDocument4 pagesHi-Temp 1027 PDFquiron2014No ratings yet

- MP 221 Tanael PLUMBING CODE CleanoutsDocument3 pagesMP 221 Tanael PLUMBING CODE CleanoutsLouie BarredoNo ratings yet

- Water Supply: Water Surplus and Water Deficit and ReasonsDocument11 pagesWater Supply: Water Surplus and Water Deficit and ReasonsAdolf MwesigeNo ratings yet

- Shiraj Baral - Cleanup of River Thames...Document2 pagesShiraj Baral - Cleanup of River Thames...Samita sharmaNo ratings yet

- JettyDocument7 pagesJettyCesillia MardillaNo ratings yet

- Mining and Its Impacts On Environment With Special Reference To IndiaDocument7 pagesMining and Its Impacts On Environment With Special Reference To Indiaana maria borda contrerasNo ratings yet

- Status Codes: Well Status Codes Wellbore Status Codes Formation Completion Status CodesDocument1 pageStatus Codes: Well Status Codes Wellbore Status Codes Formation Completion Status Codesalexander_salas_5No ratings yet

- Plumbing in ArchitectureDocument8 pagesPlumbing in ArchitectureNethajiNo ratings yet

- Lilly Maritime Pvt. LTD.: Company ProfileDocument17 pagesLilly Maritime Pvt. LTD.: Company Profilebalaji2kNo ratings yet

- Survey of ProkaryotesDocument25 pagesSurvey of ProkaryotesBryan JanierNo ratings yet

- Lake Washington RecoveryDocument1 pageLake Washington RecoveryJoyce PalmosNo ratings yet

- Environmental Laws in IndiaDocument16 pagesEnvironmental Laws in IndiaRaGa JoThi100% (1)

- 4-PSCRB Actions To Take Aboard A CraftDocument45 pages4-PSCRB Actions To Take Aboard A CraftRishintiran GovindarajanNo ratings yet

- Speaking: TechnicallyDocument5 pagesSpeaking: TechnicallyDeepak KumarNo ratings yet

- Wre Micro ProjectDocument16 pagesWre Micro ProjectTejas DeoreNo ratings yet

- Sea Otter: Sea Otters Navigation Search Marine Otter Sea Otter (Disambiguation)Document41 pagesSea Otter: Sea Otters Navigation Search Marine Otter Sea Otter (Disambiguation)Laila UbandoNo ratings yet

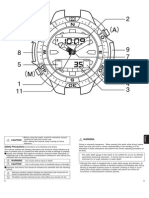

- Citizen Instruction Manual C900Document47 pagesCitizen Instruction Manual C900magyar300% (1)