Professional Documents

Culture Documents

6 X 8.1M Shade

Uploaded by

ehikmatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 X 8.1M Shade

Uploaded by

ehikmatCopyright:

Available Formats

STRUCTURAL DESIGN CALCULATIONS

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR STRUCTURAL DESIGN CALCULATIONS

25-Oct-09

Date

0

Revision Description REVISION HISTORY Calc. by Checkd. By Appd. By

w 21.8 m

0.5H 1H:1

AL JAIDAH AND SONS TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR PROJECT : 6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

Checking of Fabric Sunshade *** COMMERCIAL 95 PRE KNITTED SHADE CLOTH ***

3100

200

0.43

COMMERCIAL 95 PRE KNITTED SHADE CLOTH

Y = C + SAG S2 + C2 = Y2 S2 + C2 = ( C + 0.2 ) 2 S2 + C2 = C2 + 0.4 C + 0.04 S = ( 0.4 C + 0.04 ) X = C ln (( S + Y ) / C ) 1.55 =C ln {( ( 0.4 C + 0.04 )) + ( C + 0.2 )} / C BY TRIAL AND ERROR TRY C = L2 / ( 8 * SAG ) C = 3.1 / ( 8 * 0.2 )

2

6m

1.55 =6 ln {( ( 0.4 * 6 + 0.04 )) + ( 6 + 0.2 )} / 6 1.55 1.54 S = ( 0.4 * 6 + 0.04 ) S = 1.56 Y = = 6 + 0.2 6.2 OK

FABRIC TENSILE FORCE PER LINEAR METER T = = 0.43 * 6.2 2.66 kN/m

TENSILE STRENGTH OF FABRIC ( PRE CONTRAINT 1202S ) 635 daN / 5 cm 6350 N / 50mm 127 kN/m > 2.66 kN/m OK

AL JAIDAH AND SONS TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR PROJECT : 6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

*** 20mm DIA WIRE ROPE ***

8100

500

2.66

Y = C + SAG S2 + C2 = Y2 S2 + C2 = ( C + 0.5 ) 2 S + C = C + 1.0 C + 0.25 S = ( 1.0 C + 0.25 ) X = C ln (( S + Y ) / C ) 4.05 =C ln {( ( 1.0 C + 0.25 )) + ( C + 0.5 )} / C BY TRIAL AND ERROR TRY C = L2 / ( 8 * SAG ) C = 8.1 / ( 8 * 0.5 )

2 2 2 2

16.4 m

4.05 = 16.4 ln {( ( 1.0 *16.4 + 0.25 )) + ( 16.4 + 0.5 )} / 16.4 4.05 4.03 S = ( 1.0 * 20.2 + 0.25 ) S = 4.08 Y = = 16.4 + 0.5 16.9 OK

WIRE ROPE TENSILE FORCE T = = 2.66 * 16.9 44.95 Kn

TENSILE STRENGTH OF 20mm dia WIRE ROPE = 216 kN > 44.95 kN OK

AL JAIDAH AND SONS TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR PROJECT : 6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

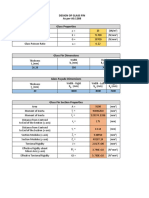

DESIGN REFERENCE BS 5950 part 1: 2000 Structural use of Steel (Code of Practice for Design - Rolled and Welded Section) BS 8110 part 1: 1997 Structural use of Concrete CP3 chapter V : Loading, Part 2 : Wind loads DESIGN CONSIDERATION Compressive Strength, fc Steel Yield Strength, fy Soil Bearing Capacity Unit weight of concrete Grade of Steel as per BS 5950 part 1 : 2000 Grade 8.8 Bolt Loading Consideration

6m 8.1m 8.1m

30 N/mm2 420 N/mm2 100 kPa ( Assumed; subject for soil investigation report ) 24 kN/m3 S275

DEAD LOAD SHADENET + FRAMING WIND LOAD Basic Wind Speed, V Height of Structure Topographical Factor, S1 ( Ground roughness, Bldg size, Height above ground , country with many windbreak, ), S2 Statistical Factor, S3 Design Wind Speed, Vs = = = = 45 m/s 3.2 m 1.0 0.68 = 0.05 kN/m2

( table 3 of CP3 Chap V part 2)

= = = = = =

1.0 VS1S2S3 45 * 1 * 0.68 * 1 30.6 m/s 0.613 * 30.62 * 10-3 0.57 kN/m2

Dynamic Pressure, q

For a duopitch canopy roofs with maximum roof angle of 14.5 Considering overall coefficient = = + 0.4 - 1.2

Reduction factor for free standing multibay canopy roofs (on second bay) on Maximum ( + ) = 0.87 On Minimum ( - ) = 0.64 Canopy Wind Pressure, Member Section Rafter Pipe = 4.0 mm x 2.5" dia pipe = = 0.57*0.4*0.87 0.57*1.2*0.64 = = 0.19 kN/m2 0.43 kN/m2

AL JAIDAH AND SONS TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR PROJECT : 6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

DESIGN OF CANOPY ROOF Total surface area = = 6 * 3.1 + (2+8.1)/2 * 3.1*2 49.91 m2

since the wind pressure coefficient on roof varies by zone total wind pressure reduce by 15% consider a 15% reduction of the total pressure on roof Downward force due to wind and weight of canopy roof = 49.91 * 0.19 * 85% + 49.91 * 0.05 = 10.55 kN Upward force due to wind = = = X L tan RAFTER PIPE Section property of 2.5" mm dia pipe 4.0 mm thick Area radius of gyration = = = = 0.785 * ( 63.52 -55.52 ) 747 mm2 ( 63.52 + 55.52 )0.5 / 4 21 mm = = = = = = 49.91 * 0.43 21.46 * 85% -18.24 kN ( 3.052 + 32 )1/2 4.27 m ( 0.782 + 4.272 )1/2 4.34 m 0.78 / 4.27 10.3

0.78m 6m

( case 1 )

8.1m 3.1

( case 2 )

6m

2.0m

3.1

Considering case 1 , force equally resisted by rafter pipe member ( compression ) = = (10.55 / 4) / sin 10.3 14.75 kN

Considering case 2 , force equally resisted by rafter pipe member ( tension ) = = Slenderness ratio From table 24 a, BS 5950 Compressive Strength, rc Compression Resistance Tension Resistance = = = = = = = (18.24 / 4) / sin 10.3 25.5 kN 4340 / 30 206 40 N/mm2 747 * 40 * 10-3 29.88 kN 747 * 275 * 10 205 kN

-3

> 14.75 kN > 25.5 kN

OK OK

AL JAIDAH AND SONS TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR PROJECT : BASE CONNECTION 350 mm x 350 mm x 20 mm thk base plate with 4 nos of M25 Grade 8.8 Anchor Bolt with embedment length of 600 mm Bolts subjected to tension due to Moment 50.89 * 10 T T total Using 25 mm dia Grade 8.8 bolt Capacity Embedment length Plate bending moment Section Modulus Required = = = = = = = = 0.75 * p * 25 /4 * 450 * 10 165.5 kN

2 -3 6

6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

= = = = =

2 * T * 220* 10 115.6 kN 15.37 / 4 3.84 kN 119.4 kN

-3

> 119.4 kN

OK OK

119.4 * 103 / ( p * 25 * 0.5 *30 ) < 600 mm 555 mm 119.4 * 2 * 0.04 9.55 kNm 9.55 * 106 / 275 34734 mm3 34.7 cm3

considering base plate section modulus, Sx = = = 350 * 202 / 6 23333 mm3 23.3 cm3

<

34.73 cm3

not OK

Section property (section A - A) with 12 mm gusset plate N. A. ( x ) Sec. Moment of area, Ix Section Modulus, Sx Welding Capacity of 10mm fillet weld Capacity per 1mm = = 10 * 0.7 * 220 1540 N/mm

350 SECTION A-A

= = = =

126 mm 9606151 mm4 405867mm3 40.5 cm3

150

x

12

>

34.73 cm3

OK

18

40

350 270

40

40

4 nos. 25mm dia grade 8.8 bolt 10mm weld 350 x 350 x 20mm thk STEEL PLATE 6.6" dia x 11mm thk CHS COLUMN 12mm thk STIFFENER PLATE

350

40

270

AL JAIDAH AND SONS TENTS AND UMBRELLA TRADING CO

INDUSTRIAL LINE -18 DOOR -54 QATAR PROJECT : 6.0 x 8.1 CAR PARKING SHADES - PROMER QATAR

Considering 1.6m x 1.6m x 1200mm thick Concrete Footing Weight of Footing

1600

= =

1.6 * 1.6 * 1.2 * 25 56.25 kN

1600

1200

1600

5.27 kN

5.27 kN

* Case 1 Due to Downward Load Moment Soil Bearing Pressure Check Maximum Pressure = = ( 76.8+ 5.27) / (1.6 * 1.6) + 6 * 31.62 / (1.6 * 1.62) 78.38 kN/m2 < 100 = = 5.27 * 6 31.62 kNm

6m

OK

* Case 2 Due to Upward Load Stability Check of Footing Overturning Moment Resisting Moment due to passive pressure F.S. Overturning

= = = = = = = =

9.12 * 6 54.72 kNm ( 76.8 - 9.12 )* 0.8 54.15 kNm 3*18*0.9*1.6*.9/2*.9/3 10.49 kNm (54.14+10.49) / 54.17 1.18

9.12 kN

9.12 kN

6m

>

OK

Reinforcement for 1200mm thk base for cracking Minimum each face, As Provided

= 0.13 * 250 = 325 mm2 T12 @ 150 ( 757 mm2 )

You might also like

- Design Calculation-Parapet Steel StructureDocument5 pagesDesign Calculation-Parapet Steel Structuremsiddiq1No ratings yet

- Steel Staircase DesignDocument4 pagesSteel Staircase DesignSenthooran MahendranNo ratings yet

- MONOSLOPE Roof Open Building TERRACE Wind LoadsDocument2 pagesMONOSLOPE Roof Open Building TERRACE Wind LoadsAnkita Pal100% (1)

- Design of Grating For PlatformDocument5 pagesDesign of Grating For Platformvj8584100% (2)

- Example of Structural CalculationDocument18 pagesExample of Structural Calculationdeua2004No ratings yet

- Insert Plate DesignDocument8 pagesInsert Plate Designvrajan1988No ratings yet

- Design Basis Report For Car Parking Shed r1Document37 pagesDesign Basis Report For Car Parking Shed r1MdShahbazAhmed60% (10)

- Design of Glass Fin for Glass FaçadeDocument4 pagesDesign of Glass Fin for Glass FaçadeZaido Al HalabiNo ratings yet

- Design of Sleeper Pedestal Reinforcement in CulvertDocument2 pagesDesign of Sleeper Pedestal Reinforcement in Culvertmunishant10% (1)

- Design Calculations For Steel ShedDocument7 pagesDesign Calculations For Steel Shedmsiddiq1100% (3)

- Insert Plate Design LugsDocument8 pagesInsert Plate Design Lugsvrajan1988No ratings yet

- 5.5m Span X 6m Bay Pyramidal Car Shade LoadsDocument1 page5.5m Span X 6m Bay Pyramidal Car Shade LoadsShaikh Muhammad Ateeq50% (2)

- Skylight Structure Design CalculationsDocument5 pagesSkylight Structure Design Calculationsmsiddiq150% (4)

- Design Calculations For Umbrella Carparksheds-PVCDocument4 pagesDesign Calculations For Umbrella Carparksheds-PVCmsiddiq167% (9)

- Struct ReportDocument40 pagesStruct Reportsam_antony2005No ratings yet

- Design of Acp SheetDocument4 pagesDesign of Acp SheetRAVI PRAKASH SAINI100% (1)

- Car Park Shade StructureDocument14 pagesCar Park Shade Structuremsiddiq1100% (2)

- 6.0 X 8.1 Car Parking Shades - Promer Qatar Structural Design CalculationsDocument11 pages6.0 X 8.1 Car Parking Shades - Promer Qatar Structural Design Calculationssehikmat67% (3)

- Loading On CanopyDocument9 pagesLoading On CanopyanbuaedNo ratings yet

- Sample and Reference Calculations for Guardrail DesignDocument24 pagesSample and Reference Calculations for Guardrail DesignRommel Angelo KirongNo ratings yet

- Union Contracting - Car Parking Rev02Document47 pagesUnion Contracting - Car Parking Rev02krvprasadNo ratings yet

- Stainless Steel Handrail Structural CalculationDocument31 pagesStainless Steel Handrail Structural CalculationZaido Al Halabi100% (4)

- Design of Base Plate For BS5950Document2 pagesDesign of Base Plate For BS5950dantevarias89% (19)

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- Isolated & Combined Footing Design Bs8110.1985Document6 pagesIsolated & Combined Footing Design Bs8110.1985EdwinNo ratings yet

- Car Parking Shade Design ReportDocument28 pagesCar Parking Shade Design Reportsiso hegoNo ratings yet

- Roof Canopy DesignDocument146 pagesRoof Canopy Designmreh12No ratings yet

- DESIGN CALCULATION Report PDFDocument61 pagesDESIGN CALCULATION Report PDFShaikh Muhammad Ateeq100% (1)

- Basics of Seismic Reservoir CharacterizationDocument30 pagesBasics of Seismic Reservoir Characterizationgodfrey edezuNo ratings yet

- Purlin DesignDocument34 pagesPurlin Designhemantkle2uNo ratings yet

- Load Analysis as per IS 875 (Part-3Document15 pagesLoad Analysis as per IS 875 (Part-3Anonymous lEmizZaJ100% (1)

- Design of Grade SlabDocument7 pagesDesign of Grade SlabMUTHUKKUMARAM100% (1)

- 1.0 Design Calculation For Louver 1Document6 pages1.0 Design Calculation For Louver 1msiddiq1No ratings yet

- Car Shade (Double Span) LoadsDocument1 pageCar Shade (Double Span) LoadsShaikh Muhammad Ateeq100% (1)

- Eave Valley Gutter Design Sheet For KspanDocument1 pageEave Valley Gutter Design Sheet For KspanBipin AgarwalNo ratings yet

- Load Calculation HDPE Fabric Car Parking ShadesDocument1 pageLoad Calculation HDPE Fabric Car Parking ShadesSiddiqui Rana100% (1)

- Ware House Purlin DesignDocument4 pagesWare House Purlin DesignSuhail Ahamed100% (1)

- 6 X 8 1M ShadeDocument11 pages6 X 8 1M ShadeamachmouchiNo ratings yet

- MAT421Document5 pagesMAT421Amirul IqbaNo ratings yet

- Design of Chequered Plates BS QCS PDFDocument1 pageDesign of Chequered Plates BS QCS PDFEddySyahputraBenSyahrenNo ratings yet

- Design Project1Document19 pagesDesign Project1Syed Munawar Ali100% (1)

- Louver Report Rev02Document12 pagesLouver Report Rev02MuraleedharanNo ratings yet

- General MT Procedure - Rekind OffshoreDocument5 pagesGeneral MT Procedure - Rekind OffshoreNicko Arya Dharma100% (1)

- 4 - 002 Qafco Urea3 Plant High PressureDocument13 pages4 - 002 Qafco Urea3 Plant High PressureJUNAID RAFEYNo ratings yet

- Why Phase Information Is Important For Diagnosing Machinery ProblemsDocument3 pagesWhy Phase Information Is Important For Diagnosing Machinery ProblemsdinhdtNo ratings yet

- Basement Wall CalculationDocument3 pagesBasement Wall CalculationSaurav Silwal100% (1)

- Military RadarDocument20 pagesMilitary Radarrakesh100% (2)

- MBMA-96load Combinations PDFDocument2 pagesMBMA-96load Combinations PDFsonofalexander100% (1)

- Z-Purlin Technical Data SheetDocument22 pagesZ-Purlin Technical Data SheetSBNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument18 pagesStructural Steel Design Project: Calculation Sheetrameshbabu_1979No ratings yet

- Design Calculations For StructureDocument3 pagesDesign Calculations For Structuremsiddiq1100% (3)

- Peb Shed StaadDocument22 pagesPeb Shed StaadShashank PatoleNo ratings yet

- 2nd Mid Assingnment QuestionsDocument3 pages2nd Mid Assingnment QuestionsSatya TejaNo ratings yet

- Prefab Canopies Technical SpecificationDocument10 pagesPrefab Canopies Technical SpecificationTabish IzharNo ratings yet

- Wind Load As Per ASCE-7-10Document17 pagesWind Load As Per ASCE-7-10Tri huỳnhNo ratings yet

- Steel Formwork Design for Pile CapDocument10 pagesSteel Formwork Design for Pile CapAbdelrahman ElkhollyNo ratings yet

- BS 6399-2 Wind Load Calculation for Proposed TowerDocument3 pagesBS 6399-2 Wind Load Calculation for Proposed Towerjeddij100% (1)

- SKYLIGHT REPORT - Rev 01Document16 pagesSKYLIGHT REPORT - Rev 01Muraleedharan100% (1)

- How Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?Document6 pagesHow Do We Classify An Antipumping Relay?: What Will Happen If Antipumping Relay Circuit Is Not Present?joseNo ratings yet

- Mullion AnalysisDocument4 pagesMullion AnalysisganeshNo ratings yet

- ComFlor 46/1.2/S280 design calculationsDocument6 pagesComFlor 46/1.2/S280 design calculationsKawser HossainNo ratings yet

- Design With Steel Hollow SectionsDocument55 pagesDesign With Steel Hollow Sectionsvutsuak100% (1)

- CAR PARK SHADE STRUCTURE QUOTATIONDocument2 pagesCAR PARK SHADE STRUCTURE QUOTATIONAnonymous 94TBTBRksNo ratings yet

- Chequered Plate PlatformDocument3 pagesChequered Plate PlatformFilip RisteskiNo ratings yet

- Tapered I-Section Design in StaadproDocument1 pageTapered I-Section Design in StaadproMichael DixonNo ratings yet

- M.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.CDocument3 pagesM.K.Trading & M.K.Trading & M.K.Trading & M.K.Trading & Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.C Cont. Co.L.L.Ccheligp1981No ratings yet

- Fuel Tank Pad DesignDocument32 pagesFuel Tank Pad DesigndjgiumixNo ratings yet

- Design and Analysis of Single Plate Friction ClutchDocument29 pagesDesign and Analysis of Single Plate Friction ClutchSagar BhoiteNo ratings yet

- The Circle and Its Parts: NameDocument4 pagesThe Circle and Its Parts: NameDaniel DubeNo ratings yet

- 0053 Dynamics of Commodity Forward CurvesDocument25 pages0053 Dynamics of Commodity Forward Curvesamitnp7373No ratings yet

- BMP Assignment IIDocument3 pagesBMP Assignment IIShahminan ShahNo ratings yet

- Current Mode Pi ControllerDocument19 pagesCurrent Mode Pi ControllersunitaNo ratings yet

- Structural Analysis & Design QuizDocument5 pagesStructural Analysis & Design QuizBongA.SalinasNo ratings yet

- C 0024 - TLZ THLZ - 04 08Document46 pagesC 0024 - TLZ THLZ - 04 08Oscar Alvitez DominguezNo ratings yet

- Micro Diaphragm Gas Sampling Pumps: Operating and Installation InstructionsDocument12 pagesMicro Diaphragm Gas Sampling Pumps: Operating and Installation Instructionssunilsheelavant100% (1)

- Matrices and Linear Systems: Matrix AlgebraDocument11 pagesMatrices and Linear Systems: Matrix AlgebraPavirlene Escaño NorteNo ratings yet

- The Thermal Expansion of The Fireclay BricksDocument38 pagesThe Thermal Expansion of The Fireclay BricksanuarsgNo ratings yet

- BSC Physics Iind SemDocument4 pagesBSC Physics Iind SemDavid JonesNo ratings yet

- Monninghoff 546 - DatasheetDocument11 pagesMonninghoff 546 - DatasheetirfannadineNo ratings yet

- Determine COP of a Heat Pump/Refrigeration MachineDocument2 pagesDetermine COP of a Heat Pump/Refrigeration MachineJeremy Tay0% (2)

- Neuber Plasticity Correction R&O Material CurveUR2202Document1 pageNeuber Plasticity Correction R&O Material CurveUR2202Eduardo Javier Granados SanchezNo ratings yet

- Magma (Computer Algebra System) - Wikipedia, The Free EncyclopediaDocument3 pagesMagma (Computer Algebra System) - Wikipedia, The Free Encyclopediabeta2009No ratings yet

- Statistical and Thermal Physics Fundamentals and ApplicationsDocument13 pagesStatistical and Thermal Physics Fundamentals and Applicationsgul jahanNo ratings yet

- Solar ThermalDocument31 pagesSolar ThermalatulsemiloNo ratings yet

- Committed To Quality Assurance And Certified In Accordance With DIN EN ISO 9001 08.94Document8 pagesCommitted To Quality Assurance And Certified In Accordance With DIN EN ISO 9001 08.94อุดมเดช ปานเงินNo ratings yet

- Lightning Protection System Analysis of High Voltage 70 KV Transmission Line in Area With High Lightning Density, Study Case Sutt 70 KV MalangDocument8 pagesLightning Protection System Analysis of High Voltage 70 KV Transmission Line in Area With High Lightning Density, Study Case Sutt 70 KV MalangGdeKomangFmoNo ratings yet

- FIN330 Analysis 3Document5 pagesFIN330 Analysis 3Jylle AmigoNo ratings yet

- Alat Ukur Ketebalan Besi - Jual Ultrasonick Thickness Gauge Mitech MT 180 0812 9595 8196Document2 pagesAlat Ukur Ketebalan Besi - Jual Ultrasonick Thickness Gauge Mitech MT 180 0812 9595 8196Regi EgiNo ratings yet

- Vulkollan: The Ultimate ElastomerDocument24 pagesVulkollan: The Ultimate ElastomerMS Mechanic HSM 2No ratings yet