Professional Documents

Culture Documents

Fluid Flow Operations - 9201

Uploaded by

Ankit PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluid Flow Operations - 9201

Uploaded by

Ankit PatelCopyright:

Available Formats

Course Name Course Code Semester Subject Title Subject Code

: Chemical Engineering Group : CH : Fourth : Fluid Flow Operations : 9201

Teaching & Examination Scheme: Teaching Scheme TH 03 TU 01 PR 02 PAPER HRS 03 TH 80 Examination Scheme TEST 20 PR 50# OR -TW 25@ TOTAL 175

Rationale: The subject gives the knowledge of measurement of fluid flow and various fluid transportation machinery. The knowledge gained by this subject is directly used in different subjects studied in Chemical Engineering. The knowledge of this subject helps in installation of different fluid flow and fluid transportation machinery. Objectives: After studying the subject student will be able

1. To distinguish between different types of fluids. 2. To understand the concept of viscosity. 3. To Calculate flow rates. 4. To Calculate the power of pump required to do a certain pumping job. 5. To understand the principles behind different flow meters. 6. To be able to install and calculate the flow rate of fluid with different flow meters in closed pipe line. 7. To understand different flow control devices and to gain the knowledge of using different valves for different types of fluids and different flow situations. 8. To understand the principle and working of different fluid flow machinery. 9. To be able to install the fluid flow machinery in closed pipe lines.

Learning Structure:

Applications

Installing and using various fluid flow measurement and moving devices in closed pipe lines for any type of fluid

Principle

Properties of fluids

Equation of continuity

Bernoullis Theorem

Pumping Principles

Concept

Equipments of fluid flow measurement and fluid moving devices

Facts

Principles of fluid flow, Principles of fluid flow measurement and principles of fluid moving machinery used in Chemical Industries

Contents: Theory Chapter Name of the Topic 1.1 Properties of fluids 1.1.1 Density & viscosity (absolute & kinematic) 1.1.2 Vapor pressure & surface tension 1.1.3 Principle of Hydrostatic Equilibrium 1.1.4 Manometers- Types ( U, Inclined, Differential ), 1 Equations, Uses 1.2 Types of fluids 1.2.1 Ideal & Actual fluids, 1.2.2 Compressible & Incompressible Fluids 1.2.3 Newtonian & Non-Newtonian fluids including time dependent & time Independent fluids Flow of Fluids (Incompressible) 2.1 Equation of continuity, Calculation of mass flow rate, volumetric flow rate, average velocity & mass velocity 02 2.2 Bernoullis equation for ideal fluid, actual fluid & with pump work done. Correction in Bernoullis equation 06 2.3 Reynolds experiment & its significance in determining turbulent, laminar & transition regime. 2 straight tubes 2.5 Form friction & skin friction: Relationship between pressure drop, wall shear & shear stress maximum 06 2.6 Laminar flow in circular pipe. Relationship between & average velocity in laminar flow. The HagenPoiseuille equation. 2.7 Friction in pipe, Fannings friction factor, the standard friction factor chart. Friction losses due to sudden 04 expansion/reductio of pipe & in pipefittings. Definition of equivalent length of pipe fittings. 06 03 20 36 2.4 Concept of Boundary layer, Boundary layer formation in 04 08 Hours Marks

2.8 Measurement of fluid flow with the help of flow meters 2.8.1 Venturimeter: Construction, Principle, Working, Coefficient of discharge, Calibration, Derivation for calculating the flow rates. 05 2.8.2 Orifice meter: Construction, Principle, Working, Coefficient of discharge, Calibration, Derivation for calculating the flow rates. Calibration. 04 04 2.8.3 Rotameter: Construction, Principle, Working, 2.8.4 Pitot tube: Construction, Principle, and Working. 2.9 Measurement of flow in open channels with help of notches ( V- notch, square-notch) Pipe, fittings & valves 3.1 MOC 3 3.2 Standard sizes of pipes, wall thickness, Schedule number 04 3.3 Joints & fittings Gate valve, Globe valve, Ball valve, Needle valve, NRV, Butterfly valve, Diaphram Valve Transportation of Fluids 4.1 Pumps 4.1.1Centrifugal Pump: Parts of centrifugal pump, Working of Centrifugal pump, Performance of centrifugal pump (Characteristics of centrifugal pump), Characteristics curves, priming 4.1.2 Developed Head, Cavitations, NPSH Priming. 4 pressure component & based on action of piston/plunger, their construction & working 04 4.1.4 Gear pump, its construction & working 4.2 Fans, blowers & compressors: 4.2.1 Fans & their applications 4.2.2 Blowers & Compressors, Reciprocating & centrifugal compressors Vacuum Pumps, jet ejectors, its working & application 04 Total 48 80 04 04 4.1.5 Diaphragm pump, its utility, construction & working 04 04 20 24 08 04 12 02

4.1.3 Positive displacement reciprocating pumps based on

Practical: Intellectual Skills 1. Observations and interpretation of data. 2. Calculations. 3. Analysis. Motor Skills 1. Equipment handling 2. Performing LISTS OF Practical: 1. Determination of coefficient of discharge of venturi meter & plot a calibration curve 2. Determination of coefficient of discharge of orifice meter & plot a calibration curve 3. To calibrate a rotameter for different liquids & plot the calibration curve. 4. To perform experiment on Bernoullis Theorem and prove that the summation of pressure head, kinetic head and potential head is constant. 5. To perform Reynolds Experiment and determine the Reynolds number at the end of laminar region and beginning of turbulent region. 6. To determination of equivalent length of pipe fittings 7. To plot the characteristics curves of centrifugal pump 8. To determine the relationship between Fannings friction factor & Reynolds Number 9. To measure the viscosity of different liquids (Ostwalds Viscometer or Redwood Viscometer) 10. To measure the flow rate of gases using flow meter. Learning Resources: Books: Sr. No 1. 2. 3. Author McCabe, Smith Badger & Banchero Richardson & Coulson Title Unit Operations of Chemical Engineering Introduction to Chemical Engineering Chemical Engineering Volume-I Publisher McGraw Hill McGraw Hill Pergamon Press

You might also like

- Fundamentals of Gas Lift Engineering: Well Design and TroubleshootingFrom EverandFundamentals of Gas Lift Engineering: Well Design and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- BH023332 HNCD L45 in Engineering Units 070610Document4 pagesBH023332 HNCD L45 in Engineering Units 070610Eng Islam Kamal ElDinNo ratings yet

- FM SYLLABUS PolyDocument7 pagesFM SYLLABUS PolyprasobhaNo ratings yet

- Gujarat Technological University: Fluid Flow Operation B.E. Semester: IIIDocument3 pagesGujarat Technological University: Fluid Flow Operation B.E. Semester: IIIMohammad ImranNo ratings yet

- Aysu Zamanova Lab1Document38 pagesAysu Zamanova Lab1leman quliyevaNo ratings yet

- Flow Measuring Techniques for Steady and Pulsating Compressible FlowsDocument99 pagesFlow Measuring Techniques for Steady and Pulsating Compressible FlowsKhaled RemchiNo ratings yet

- Experiment No. 1Document6 pagesExperiment No. 1mian0306hateemNo ratings yet

- Fluid and Particle Mechanics Lab ExperimentsDocument4 pagesFluid and Particle Mechanics Lab ExperimentsSaiVenkatNo ratings yet

- Fluid Mechanics Lab-I (Report)Document18 pagesFluid Mechanics Lab-I (Report)Mohammad Usman HabibNo ratings yet

- USMNADocument12 pagesUSMNAHanan AliNo ratings yet

- Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 AcpDocument2 pagesChe1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acpblub blueNo ratings yet

- 5th Sem 7 Mechanical EngineeringDocument44 pages5th Sem 7 Mechanical EngineeringEmperorNo ratings yet

- Topics NO No of Hours Marks Weightage in ExamDocument8 pagesTopics NO No of Hours Marks Weightage in ExamSaeed cecos1913No ratings yet

- FM230-Hydraulics Lab 2 2010 Small Rig ADLDocument12 pagesFM230-Hydraulics Lab 2 2010 Small Rig ADLAlex RepseviciusNo ratings yet

- 2.fluid Mechanics and MachinesDocument9 pages2.fluid Mechanics and MachinesVikram RaoNo ratings yet

- Construction of VenturimeterDocument36 pagesConstruction of Venturimeterjamessabraham2No ratings yet

- Design and Development of Liquid Flow Test BedDocument19 pagesDesign and Development of Liquid Flow Test BedFrankie NovelaNo ratings yet

- Design and Development of Liquid Flow Test BedDocument19 pagesDesign and Development of Liquid Flow Test BedFrankie NovelaNo ratings yet

- University of Soran Faculty of Engineering Chemical Department SIMDocument5 pagesUniversity of Soran Faculty of Engineering Chemical Department SIMZhiar KoyeNo ratings yet

- Fluid Flow and Fluid DynamicsDocument58 pagesFluid Flow and Fluid DynamicsJeff Poi100% (4)

- Flow MeasurementDocument10 pagesFlow Measurementiroshauk67% (3)

- L3 FMHM LabDocument1 pageL3 FMHM LabASIST MechNo ratings yet

- sem-3Document29 pagessem-3rajindermechNo ratings yet

- 2160503Document3 pages2160503Yash MadlaniNo ratings yet

- LHN Meter Proving 25231-01Document12 pagesLHN Meter Proving 25231-01Afam-Anadu UcheNo ratings yet

- Rotameter ExperimentDocument5 pagesRotameter ExperimentMeet Mac PatelNo ratings yet

- Experiment 3Document3 pagesExperiment 3MaisarahNo ratings yet

- GTU Fluid Flow Operations Core CourseDocument3 pagesGTU Fluid Flow Operations Core Coursesuraj nakumNo ratings yet

- S. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentDocument5 pagesS. Y. B. Tech. (Civil Engineering) - I, Semester-III: Course ContentashoknrNo ratings yet

- Lab 4 (Thermofluids Lab)Document32 pagesLab 4 (Thermofluids Lab)Adnan Nanda0% (1)

- Fluid Mechanics Course Code, Name, CreditsDocument3 pagesFluid Mechanics Course Code, Name, CreditsParmeshwarPaulNo ratings yet

- Dinamica de Fluido Sucker Rod PumpDocument26 pagesDinamica de Fluido Sucker Rod PumpyeralhNo ratings yet

- To Understand Concepts Fluid Machinery and Mechanics by PracticeDocument1 pageTo Understand Concepts Fluid Machinery and Mechanics by PracticesumikannuNo ratings yet

- Reviol 2018Document36 pagesReviol 2018mouad jaidaneNo ratings yet

- Fluid Mechanics & Machinery LabDocument3 pagesFluid Mechanics & Machinery Labraghav dhamaniNo ratings yet

- SONA COLLEGE LAB MANUAL FOR HYDRAULIC AND PNEUMATIC SYSTEMSDocument41 pagesSONA COLLEGE LAB MANUAL FOR HYDRAULIC AND PNEUMATIC SYSTEMSKanishk KannaNo ratings yet

- Fluid Mechanics Lab Experiments UET LahoreDocument13 pagesFluid Mechanics Lab Experiments UET LahoreLim Andrew0% (1)

- ContentsDocument2 pagesContents8055713345No ratings yet

- WeirDocument94 pagesWeirGurung Gurung0% (1)

- Lecture 0 Intro GuidanceDocument18 pagesLecture 0 Intro GuidanceNawaz441No ratings yet

- Flow Analysis of Butterfly Valve Using CFDDocument7 pagesFlow Analysis of Butterfly Valve Using CFDIJMERNo ratings yet

- Mech. Engg. DepartmentDocument37 pagesMech. Engg. DepartmentHamza AhmadNo ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Mechanical Engineering JUL. 2008Document52 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Mechanical Engineering JUL. 2008ephremNo ratings yet

- FLUID MECH LAB EQUIPMENTDocument12 pagesFLUID MECH LAB EQUIPMENTAhmad HusnainNo ratings yet

- Lesson PlanDocument8 pagesLesson PlanAbdur RashidNo ratings yet

- Lecture 0 Intro+GuidanceDocument18 pagesLecture 0 Intro+GuidanceHistoric MemeNo ratings yet

- Laboratory Manual: II Year B. Tech I-Semester Mechanical EngineeringDocument45 pagesLaboratory Manual: II Year B. Tech I-Semester Mechanical Engineeringmuhammad ahsanNo ratings yet

- Updated Notes On FlowmeasurementDocument30 pagesUpdated Notes On FlowmeasurementbetruckoumaNo ratings yet

- Experimental Study of Performance Characteristics of Turbine Meter in Oil Medium, by Onwunyili Christian ChimeDocument73 pagesExperimental Study of Performance Characteristics of Turbine Meter in Oil Medium, by Onwunyili Christian Chimecoskwejie100% (1)

- Lab Session 03 UptadeDocument7 pagesLab Session 03 UptadeAbdullah SahirNo ratings yet

- Selecting the Best Flow Meter for LPG PipelinesDocument29 pagesSelecting the Best Flow Meter for LPG Pipelinesابوالحروف العربي ابوالحروفNo ratings yet

- Lab 5Document23 pagesLab 5mmmd.krmv.00No ratings yet

- Mechanical (Automobile) EngineeringDocument96 pagesMechanical (Automobile) Engineeringshiyas sNo ratings yet

- Flow Analysis of Butterfly Valve Using CFD: JournalDocument7 pagesFlow Analysis of Butterfly Valve Using CFD: JournalMary Grace VelitarioNo ratings yet

- Mechanical Engineering / Mechanical Engineering (RAC)Document17 pagesMechanical Engineering / Mechanical Engineering (RAC)satwant singhNo ratings yet

- Fluid Mechanics and Hydraulic MachineryDocument45 pagesFluid Mechanics and Hydraulic MachineryRajeevNo ratings yet

- Maintenance Manual FOR Turbine Flow Meter: Shanghai Cowell Machinery Co., LTDDocument29 pagesMaintenance Manual FOR Turbine Flow Meter: Shanghai Cowell Machinery Co., LTDasmoosa_scribdNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Plumbing Notes: Legend:: 1.50 0.70 Mts 0.70 MtsDocument1 pagePlumbing Notes: Legend:: 1.50 0.70 Mts 0.70 MtsGhian Carlo Garcia CalibuyotNo ratings yet

- Sample of Form MDRDocument11 pagesSample of Form MDRYuwantoniAlNo ratings yet

- RHH and LTSH links overviewDocument4 pagesRHH and LTSH links overviewrpshvjuNo ratings yet

- Construction QuotationDocument5 pagesConstruction QuotationYou & Me100% (1)

- DK ValvetecDocument30 pagesDK ValvetecSandi AslanNo ratings yet

- BOQ Pharma UtilitiesDocument109 pagesBOQ Pharma UtilitiesSajeshKumarNo ratings yet

- Hydraulic Diagram, With Option Components: Service InformationDocument4 pagesHydraulic Diagram, With Option Components: Service InformationPetrus Kanisius WiratnoNo ratings yet

- Plumbing Terms 4 Questionswith AnswersDocument6 pagesPlumbing Terms 4 Questionswith AnswersJoshua Padlan EchavarriaNo ratings yet

- VERNACULAR TERMS FOR PHILIPPINE CONSTRUCTIONDocument4 pagesVERNACULAR TERMS FOR PHILIPPINE CONSTRUCTIONLyka Mendoza MojaresNo ratings yet

- Quotation Gas Js 2023Document188 pagesQuotation Gas Js 2023logisticsNo ratings yet

- Certificate of Compliance: Gasketed Pipe Fittings For Use With Aboveground Sprinkler SystemsDocument3 pagesCertificate of Compliance: Gasketed Pipe Fittings For Use With Aboveground Sprinkler SystemsJosé Luis ValderramaNo ratings yet

- DixonDocument515 pagesDixonCentral HydraulicsNo ratings yet

- Hydraulic Access FittingsDocument2 pagesHydraulic Access FittingsMido MahmoudNo ratings yet

- 8-EN 5850-B - Stack Valves CETOP 07Document7 pages8-EN 5850-B - Stack Valves CETOP 07Tamer Elsebaei EbarhimNo ratings yet

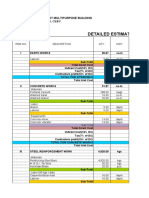

- Detailed Estimates: Construction of 1-Unit Multipurpose Building Brgy. San Jose, Borbon, CebuDocument12 pagesDetailed Estimates: Construction of 1-Unit Multipurpose Building Brgy. San Jose, Borbon, CebuAnna Rose PueblaNo ratings yet

- Un NecessaryDocument86 pagesUn NecessaryAbdul AhadNo ratings yet

- Fully Developed Turbulent Flow in PipeDocument29 pagesFully Developed Turbulent Flow in PipeRamadhanu SuwondoNo ratings yet

- 09 Waste Water Hydraulics Planning, Dimensioning and DesignDocument36 pages09 Waste Water Hydraulics Planning, Dimensioning and DesignkymeNo ratings yet

- AGA3Document1 pageAGA3Alan BkNo ratings yet

- Plumbing System: Prepared By: Group 7Document56 pagesPlumbing System: Prepared By: Group 7Glenn Midel Delos SantosNo ratings yet

- CPP Pipeline Proposed Pwps List For Mol Project: 36' Pipe To Anchor Flange Repair WeldingDocument2 pagesCPP Pipeline Proposed Pwps List For Mol Project: 36' Pipe To Anchor Flange Repair WeldingYasar ArshadNo ratings yet

- Method of Statement PlumbingDocument13 pagesMethod of Statement PlumbingJesin Abdul Jaleel A100% (1)

- Fitting CatalogDocument28 pagesFitting CatalognotreadyNo ratings yet

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocument16 pagesDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNo ratings yet

- Install, Operate & Maintain Ejector AssemblyDocument4 pagesInstall, Operate & Maintain Ejector AssemblyFernando PuentesNo ratings yet

- Hose & FittingDocument124 pagesHose & FittingYoga Sugi100% (1)

- Exhibit D Construction Budget TemplateDocument10 pagesExhibit D Construction Budget Templateivona009100% (1)

- RKG-RMG - Type 370 Datasheet ENDocument8 pagesRKG-RMG - Type 370 Datasheet ENWill Baca BadajosNo ratings yet

- Q H Ha HB: Bukaan Valve 25%Document10 pagesQ H Ha HB: Bukaan Valve 25%Sigit WardanaNo ratings yet