Professional Documents

Culture Documents

Good Well Drilling - Safety Manual

Uploaded by

Vandear GoalcantaraOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Good Well Drilling - Safety Manual

Uploaded by

Vandear GoalcantaraCopyright:

Available Formats

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Good Well Drilling

"We're always in the hole for you"

Safety Program Manual

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

1

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Introduction The information contained in this Safety Program Manual is presented to familiarize all workers, including subcontractor employees and owner representatives with Good Well Drillings expectations on all projects. Good Well Drilling (GWD) is responsible at all times for the safety of its employees, its subcontractors employees, visitors, and equipment on all projects. Subcontractors and their employees may not rely on this orientation as representative of all hazards inherent on projects Subcontractors are responsible for the safety of their employees and for public safety. Subcontractors are responsible for conducting their own analysis of project hazards and to develop a site specific safety program addressing those hazards. Owner representatives will conform to GWD Safety Program Manual while on site. Visitors will be escorted at all times by GWD personnel.

ALL Project Safety Rules All employees are required to park in designated parking areas. Only company vehicles shall be allowed on project sites. Workers should immediately report unsafe conditions to their supervisor. No worker will be required, or knowingly permitted, to work in an unsafe area unless the work involved is to correct the hazard, and then only after all safety precautions are implemented. Workers will always report fit for duty. Intoxicating beverages or narcotics are prohibited on the premises. Do not come to work under the influence of alcohol or drugs. Employees shall not ride on any vehicle unless it is provided with approved seating. Fighting, horseplay, practical jokes or unprofessional behaviour will not be tolerated on projects. Will fully damaging or defacing company or project property is prohibited. Threatening or abusive language directed at fellow employees, supervisors or owner representatives is grounds for disciplinary action including termination. Any and all discrimination or harassment will not be tolerated and will be cause for termination. All incidents must be reported immediately to the Business Manager. Theft of any nature or form is cause for immediate dismissal or may result in prosecution. All employees will remain in the work area in which the contract work is being carried out. Personal mobile phones need to be stored in lunch boxes for use at lunch breaks ONLY unless approved by supervision. The use of cigarettes must be reserved for lunch and coffee breaks. Employees are not permitted to bring their pets to projects.

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

2

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

General Safety Rules Fire Protection Fire extinguishers are required for all welding, cutting, flame or spark producing operations Fire extinguishers must be the ABC type and inspected to ensure they are in operable condition prior to commencing work. Fire extinguishers and other fire-fighting equipment shall be distributed throughout the project site as necessary to accommodate the fire load exposure. Remove all combustibles in the area adjacent to the hot work.

Fire Prevention All employees must know what to do and react in sound judgment when dealing with a fire on site. This includes knowing where available fire extinguishers are, as well as any other emergency supply that may be needed during the incident. If you are not familiar with the use of a fire extinguisher, remember the mnemonic PASS. Pull the pin Aim the nozzle at the base of the fire Squeeze the trigger Sweep the nozzle from one side of the fire to the other

Do not place yourself into a position beyond your capabilities. If you cannot safely put out the fire, vacate the area immediately and call for help. Keep areas around the firefighting equipment clear at all times. Do not hang items or store materials near firefighting equipment. Keep your work area clean and tidy. An orderly job site reduces the chance of a fire spreading and reduces accidents in the work place. When you weld or burn near a combustible material, move them, or wet them down. When in doubt consult with your supervisor. Fire extinguishers must be regularly checked by workers and supervisors to ensure they are in service. Report all fires, extinguisher use, or safety issues to your supervisor immediately.

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

3

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Fire Procedures If you discover a fire: 1. Attempt to extinguish with one fire extinguisher or for one minute; if unable to do so, then: 2. Call 911 Hand Tools Hand Tools must be inspected by the employee before each use. Use the proper tool for the job. (A screwdriver is not a chisel; a wrench is not a hammer.) If any tool or piece of equipment is not in good working condition, it is unsafe. Report unsafe tools and equipment to your supervisor. Do not use unsafe tools. Do not bring damaged personal tools on projects. Hazard Communication Material Safety Data Sheets (MSDS) are required and must be readily available for all hazardous materials. Copies of the MSDS documents are available in the drill rig. Housekeeping Each employee must ensure that good housekeeping practices and principles are maintained. All walking, working surfaces and stairwells shall be maintained clear of debris and trash accumulation. Discard all trash and scrap materials in the proper locations. Keep tools, equipment, and materials clear of all walkways and work areas to avoid tripping hazards. Clean up work area and put all tools away at the end of each shift. Storage area containers and trailers are also to be well maintained. Lifting Objects over 23kg (50lbs) may be too heavy to lift alone. Always ask for help or use a trolley. Objects less than 23kg (50lbs) may be too awkward to lift depending upon size and shape; always ask for help or get a trolley. If you are currently under any lifting restrictions, notify your immediate supervisor. Always lift with your legs, keep your back straight and avoid twisting while lifting.

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

4

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Equipment All GWD equipment operators must be trained and certified (where appropriate) on the piece of equipment they are operating. No person shall arbitrarily operate a piece of equipment without proper training and/or certification. All workers must follow site safety regulations when dealing with or operating any piece of equipment on site. Never turn your back on a piece of equipment. Keep one ear and one eye trained on the equipment at all times. Never assume the operator can see you just because you can see him. If you need to get past a piece of equipment, make eye contact with the operator and relay your intentions. He will either stop what he is doing, and wave you through or he will tell you to stop and wait until his task is accomplished and then allow you to pass. Always follow an operators instructions. Never approach a piece of equipment from the rear. Do not get on the back side of any load while the equipment is picking or placing the load. You can be crushed by a falling load. Do not have any loose clothing around equipment with rotating cams, shafts and/or gears. These can be dangerous with loose clothing. Portable fire extinguishers can be located on the rig. The daily inspection log book must be completed and signed before each use. Never park a piece of equipment in such a way that it blocks an emergency escape way.

See the BC WCB Regulation, Part 16 Mobile Equipment for more specific information on operation of mobile equipment. Mobile equipment includes but is not limited to: Drill Rigs Portable Welders Hydraulic Power Units Company Site Trucks

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

5

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Operating Equipment and Vehicles All equipment operators shall read the equipment operations manual (where applicable) and demonstrate a level of competency before operating the equipment. Prior to using any equipment daily inspections shall be conducted to ensure equipment meets the manufacturers standards. Seat belts must be in place and used by the equipment operator at all times. Backup alarms must be in working condition and louder than the surrounding environment. If no backup alarm is present then the operator must use the horn repeatedly while backing up. Fire extinguishers must be in place on the equipment, charged and suitable for use. Employees must be qualified and certified (where applicable) before operating equipment. Personal Protective Equipment (PPE) All employees are required to wear Personal Protective Equipment (PPE) as a condition of their employment. Exceptions may be made in designated safe areas. For the remainder of the work site, such as the drill site, the following PPE must be worn at all times. Hard hats are required at all times in the drill site area Steel Toed Work Boots Eye Protection Safety Glasses, Goggles or Welding Lid Reflective Clothing All employees will wear long sleeve shirts and ankle-length trousers. All workers must wear high visibility clothing at all times. Gloves Employees shall use gloves to protect their hands from hazards. Hearing protection

Eye and Face Protection Good Well Drilling mandates that all workers must wear approved eye protection on all sites. When operating grinders workers must wear a full face shield in addition to wearing glasses. Approved tinted goggles or shields must be worn when: o Using welding or metalizing equipment o Doing work which may expose the employee to extremely bright light

If you do not have eye protection for a job please contact your supervisor prior to commencing. Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

6

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Hearing Protection All employees must wear hearing protection when exposed to a steady state of noise. Employees must not be exposed to noise levels greater than 85dBA Lex or 140 dBC peak. GWD provides various hearing protection devices including: Foam ear plugs Ear muffs

If workers are unsure as to the recommended type of hearing devices to use, contact your supervisor. Welding Hood A Welding Hood attached to a hard hat and safety glasses are required for arc welding operations. Welding Lens should be tested periodically for cracks before use. Verify proper welding lens is being used for specific task. Power Tools All electric power tools must be kept in good mechanical condition, including electrical cords. All protective guards must be in place. Double eye protection is required for all grinding operations. Damaged tools must be taken out of service and tagged immediately so co-workers will know a tool is defective. Tools and cords must be used with a Ground Fault Circuit Interrupter (GFCI). Cords must be routed over or around walkways and work areas or be secured to prevent a tripping hazard. Avoid routing cords across sharp edges. Signs and Barricades Each crew is responsible for erecting signs and barricades sufficient to warn others of the hazards associated with the construction work. Yellow Caution tape may be crossed once you check to ensure the area is safe to enter. Red Danger tapes must never be crossed or removed, unless you are part of the work crew in the area. Remove the barricades and tape once the hazard has been removed. Spill Containment/Clean-up 1. 2. 3. 4. Ensure no danger to yourself or others. If necessary, evacuate area around the incident site Contain the hazard or spill if possible. Secure Area

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

7

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

5. 6. 7. 8. 9.

Refer to MSDS before commencing clean-up. Ensure you have proper PPE for clean-up procedures Inform Supervisor of incident Complete investigation report. Notify Authorities where required.

Welding/Cutting/Burning A fire extinguisher is required for all hot operations. Fire extinguishers shall be appropriate to the hazards and be located within 8m (25 ft) of hot work. Welding at eye level shall be shielded to protect employees from welding arcs. Propane or gasoline-powered welding equipment must have a fire extinguisher within 8m (25ft). All acetylene and oxygen cylinders must have an approved flash arrester. Good Well Drilling Substance Abuse Prevention Policy Intoxicating beverages, narcotics, designer drugs and other drugs or drug paraphernalia are prohibited on all projects. Any employee, subcontractor employee, subcontractors, contractors or other invitees to the project site, who use, posses, conceal, transport, promote, or sell the above mentioned drugs shall be denied access to the project site. GWD is committed to a 100% drug and alcohol free workplace. In accordance with that commitment each contractor is expected to provide a drug free workforce to staff projects. If you have an illness that may cause you to be weakened, dizzy, drowsy, or might otherwise limit your sensory abilities, report it to your supervisor. Your safety and the safety of others on projects is our primary concern. Alcohol consumption during the course of your scheduled workday is prohibited. Safety Meetings Daily Safety Meetings Daily toolbox meetings will be held; all employees are required to attend. Joint Health and Safety Committee (JHSC) Joint Health and Safety Committee meetings will be held twice a year. The Joint Health and Safety Committee is made up of employee and employer representatives consulting in a cooperative atmosphere to identify and resolve health and safety problems in support of a planned occupational health and safety program. The following structure will exist for the committee: Make recommendations for the establishment and enforcement of safety and health policies and practices

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

8

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Participate in the identifications of dangers to safety and health in places of employment and recommend means of controlling hazards Obtain information from the employer and from such other sources as necessary regarding the identification of existing or potential dangers to safety and health Advise on and promote safety and health programs for the education and information of the employer and workers; Receive, consider where necessary, investigate complaints respecting safety and health of workers at the workplace and, where necessary to make recommendations to the employer Maintain records regarding complaints received and the resolution of those complaints; Where applicable, review the information resulting from monitoring and measuring procedures and, where necessary, make recommendations to the employer; Participate in inspections of the workplace; and Assist in investigations of accidents and incidents. Minutes will be recorded and available for those interested.

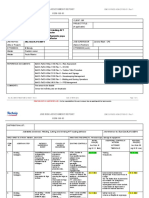

WAIR Forms WAIR Forms Safety Awareness Check Shall be filled out prior to start of work and any deficiencies found must be corrected before work continues. *NOTE-Each WAIR card must be legibly signed and dated by employee and supervisor. Health and Safety Reporting Requirements The following must be reported to your supervisor or safety personnel: Accidents Incidents Near Misses Unsafe working conditions

All workplace and incidents will be investigated for the following purposes: Determine the cause(s) Identify any failure in the system; Identify inadequate job procedures that contributed to the result; and Develop and implement corrective action to prevent recurrence.

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

9

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Surface Fire Extinguish the fire if possible and safe. If you cannot put out the fire, alert the crew by sounding the alarm with the Air Horn located in the drill rig. AIR HORN: sound for 10 seconds followed by a series of 3 short blasts-pause-3 short blasts.., repeated WORKERS MUST IMMEDIATELY STOP WORK AND SHUT DOWN EQUIPMENT WHEN AN EMERGENCY ALERT HAS BEEN CALLED. STANDBY AND AWAIT FURTHER INSTRUCTIONS FROM YOUR SUPERVISOR.

First Aid Alert your supervisor. If necessary sound AIR HORN for 10 seconds. Air Horn is located in drill rig. WORKERS MUST IMMEDIATELY STOP WORK AND SHUT DOWN EQUIPMENT WHEN AN EMERGENCY ALERT HAS BEEN CALLED. STANDBY AND AWAIT FURTHER INSTRUCTIONS FROM YOUR SUPERVISOR. The responding first aid attendant is in control of the entire incident scene and patient care until the patient is handed off to higher medical aid. WORK CANNOT RECOMMENCE UNTIL THE ALL CLEAR HAS BEEN GIVEN BY THE SUPERVISOR. If there has been a serious incident on the worksite, the scene must be roped off and left as is for an incident investigation to be conducted.

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

10

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

Emergency Response Contact Numbers Emergency 911 911 911 911 Non-Emergency 250-562-7241 250-561-7664 250-561-3300 250-565-2000 1-800-474-6886

Ambulance Fire Police Hospital Call Before You Dig

Good Well Drilling Personnel Denis Caron Danny Caron Danelle Sloboda Senior Driller/Supervisor Driller/Safety Supervisor Business Manager 250-613-3535 (cell) 250-963-9281 (home) 250-640-9994 (cell) 250-964-7024 (office & home) 250-964-7024 (office & home)

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

11

Good Well Drilling

Safety Program Manual Date: July 2010 Version: 01

ORIENTATION REVIEW

I _______________________________________ have received my safety program manual and am aware of the Project Rules and Regulations. I have read them, fully understand them and also intend to follow them. Date Employee Signature SIN Birthdate

Employee Address:

Employee Phone #:

#1 Emergency Contact Name: Phone Number: #2 Emergency Contact Name: Phone Number:

Date

Company Representative

Good Well Drilling 3245 Monahan Crescent Prince George, BC V2N 4E4 Tel 1: 250.964.7024 Tel 2: 250.963.9281 Cell1: 250.613.3535 Cell2: 250.640.9994 Email: info@goodwelldrilling.com

12

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Casing Design Manual - BG (2001)Document51 pagesCasing Design Manual - BG (2001)PetroleumEngineering100% (21)

- Wk9 Sample ScriptDocument4 pagesWk9 Sample ScriptVandear GoalcantaraNo ratings yet

- Communication TheoryDocument127 pagesCommunication TheoryJennifer BarreraNo ratings yet

- Action 4Document10 pagesAction 4Vandear GoalcantaraNo ratings yet

- Action Assembly TheoryDocument12 pagesAction Assembly TheoryRatri Kartika WidyaNo ratings yet

- ReservoirFluidClassification GuidelinesDocument4 pagesReservoirFluidClassification GuidelinesVandear GoalcantaraNo ratings yet

- Casing Design User ManualDocument29 pagesCasing Design User Manualmadonnite3781No ratings yet

- PETE 625 Well Control: Lesson 1Document37 pagesPETE 625 Well Control: Lesson 1Vandear GoalcantaraNo ratings yet

- Spe 21157Document8 pagesSpe 21157Vandear GoalcantaraNo ratings yet

- Drilling Formulas Calculation Sheet Verson 1.3Document186 pagesDrilling Formulas Calculation Sheet Verson 1.3Sarhad Ahmed100% (1)

- Reservoir Seals - How They Work and How To Chose A Good OneDocument23 pagesReservoir Seals - How They Work and How To Chose A Good OneVandear GoalcantaraNo ratings yet

- Fluid Saturation and Capillary Pressure MSc NotesDocument23 pagesFluid Saturation and Capillary Pressure MSc NotesVandear GoalcantaraNo ratings yet

- QUIZ 1: PETROLEUM DEFINITION, RESERVOIR TYPES, FLUID SYSTEMS & PHASE BEHAVIORDocument1 pageQUIZ 1: PETROLEUM DEFINITION, RESERVOIR TYPES, FLUID SYSTEMS & PHASE BEHAVIORVandear GoalcantaraNo ratings yet

- Petroleum Presentation PDFDocument19 pagesPetroleum Presentation PDFtokkxylahNo ratings yet

- Magnets Design Guide: Table 2.1 Magnet Material ComparisonsDocument44 pagesMagnets Design Guide: Table 2.1 Magnet Material ComparisonsVandear GoalcantaraNo ratings yet

- GEOL 463 Oilfield Water NotesDocument2 pagesGEOL 463 Oilfield Water NotesVandear GoalcantaraNo ratings yet

- Optimize for 11-7/8Document1 pageOptimize for 11-7/8Vandear GoalcantaraNo ratings yet

- Protocol ON Mining: S A D CDocument11 pagesProtocol ON Mining: S A D CVandear GoalcantaraNo ratings yet

- Drilling and Well ConstructionDocument36 pagesDrilling and Well ConstructionMarcio Nascimento BezerraNo ratings yet

- Gas in A WellDocument53 pagesGas in A WellGoldschmidt ArnonNo ratings yet

- Kicks and Gas MigrationDocument42 pagesKicks and Gas MigrationVandear GoalcantaraNo ratings yet

- Gas Solubility in Drilling MudsDocument59 pagesGas Solubility in Drilling MudsDavid ReyesNo ratings yet

- Application of Minimum Curvature Method To Wellpath CalculationsDocument8 pagesApplication of Minimum Curvature Method To Wellpath CalculationsVandear GoalcantaraNo ratings yet

- Algebra Success in 20 Minutes A DayDocument224 pagesAlgebra Success in 20 Minutes A Daygingerbd69100% (1)

- IJHIT-Vol.1-No.1 - An Improved PSO-Based of Harmony Search For Complicated Optimization ProblemsDocument8 pagesIJHIT-Vol.1-No.1 - An Improved PSO-Based of Harmony Search For Complicated Optimization ProblemsVandear GoalcantaraNo ratings yet

- BT2 LapDocument8 pagesBT2 LapAulia UllahNo ratings yet

- Laplace For EngineersDocument37 pagesLaplace For EngineersKaran_Chadha_8531No ratings yet

- ADocument15 pagesAVandear GoalcantaraNo ratings yet

- Tabular Integration by Parts - David HorowitzDocument6 pagesTabular Integration by Parts - David HorowitzAbhinav100% (4)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Welding Washers For Steel DeckDocument2 pagesWelding Washers For Steel DecktylerlhsmithNo ratings yet

- 02.CARBO - RC 3 Blau eDocument1 page02.CARBO - RC 3 Blau eMario CastilloNo ratings yet

- Aircraft Construction and Repair Chap.2Document8 pagesAircraft Construction and Repair Chap.2Yenoh SisoNo ratings yet

- Updated Resume 2016Document4 pagesUpdated Resume 2016Ralph ManuelNo ratings yet

- Asme B31.3-2016 CC 181Document3 pagesAsme B31.3-2016 CC 181MubeenNo ratings yet

- 2 Terms and Definitions SectionDocument12 pages2 Terms and Definitions SectionJawed AkhterNo ratings yet

- Knowledge in Autocad Plant3DDocument5 pagesKnowledge in Autocad Plant3DrajNo ratings yet

- Storage Tank Erection Procedure PDFDocument6 pagesStorage Tank Erection Procedure PDFEko Kurniawan89% (19)

- Welding Part 2Document38 pagesWelding Part 2Balqees Al RiyamiNo ratings yet

- AK Hot Rolled Steel 062212 HSLA 60Document6 pagesAK Hot Rolled Steel 062212 HSLA 60Alexandre Lima LopesNo ratings yet

- ULTERSONIC CLEANING MACHINE MANUFACTURERS-Microsupersonic Ultrasonic Cleaning MachineDocument23 pagesULTERSONIC CLEANING MACHINE MANUFACTURERS-Microsupersonic Ultrasonic Cleaning MachineChetan GoudaNo ratings yet

- Replacing Materials in Aging Aircraft to Improve Corrosion Resistance and Fatigue PerformanceDocument22 pagesReplacing Materials in Aging Aircraft to Improve Corrosion Resistance and Fatigue Performancemarin.petre2815100% (1)

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- Thungsten ClassificationDocument3 pagesThungsten ClassificationBoyan RadomirovNo ratings yet

- Using Welding Inspection ToolsDocument9 pagesUsing Welding Inspection ToolsVinoth RajendraNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Fabrication Quality Dossier IndexDocument22 pagesFabrication Quality Dossier IndexAli KayaNo ratings yet

- Invertec v350 ProDocument167 pagesInvertec v350 ProferdialvascribdNo ratings yet

- Method Statement & Risk Assessment For Hot Works WeldingDocument4 pagesMethod Statement & Risk Assessment For Hot Works Weldingchandanprakash30100% (1)

- Pressure Gauges GBDocument56 pagesPressure Gauges GBMRRogueNo ratings yet

- List of Steel Conference ExhibitorsDocument18 pagesList of Steel Conference ExhibitorsJitendra100% (1)

- App 037Document19 pagesApp 037Hung Nguyen VanNo ratings yet

- JRA-CDA-PL-071-REV-0 - Welding, Cutting and Grinding AFT Loading DeflectorDocument4 pagesJRA-CDA-PL-071-REV-0 - Welding, Cutting and Grinding AFT Loading DeflectorMiller DutraNo ratings yet

- OA Cutting and WeldingDocument24 pagesOA Cutting and WeldingJames Hale0% (1)

- MIGDocument7 pagesMIGMuhammad RedzuanNo ratings yet

- (1mj16me027) InternshipDocument26 pages(1mj16me027) InternshipHarsh GamingNo ratings yet

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- Welding Safety QuizDocument3 pagesWelding Safety Quizapi-525855204100% (1)

- High-Strength Low-Alloy Structural Steel: Standard Specification ForDocument3 pagesHigh-Strength Low-Alloy Structural Steel: Standard Specification ForJaleel ClaasenNo ratings yet

- Pipe Ready Engine Drives: Cross Country 300 SAE - 300 MP Classic 300 MPDocument1 pagePipe Ready Engine Drives: Cross Country 300 SAE - 300 MP Classic 300 MPJorge CarrascoNo ratings yet