Professional Documents

Culture Documents

Properties of Rock Discontinuities

Uploaded by

vsb5Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Properties of Rock Discontinuities

Uploaded by

vsb5Copyright:

Available Formats

Chapter 5 Properties of Rock Discontinuities

CHAPTER 5 PROPERTIES OF ROCK DISCONTINUITIES

Properties of rock discontinuities govern the overall behaviour of the rock masses. Chapter addresses properties of rock discontinuities. This

Rock discontinuities include joints, fractures, faults and other geological structures. Rock joints are by far the most common discontinuity encountered in rock masses. Rock fractures are random features. Rock faults and folds are major but localised geological structures and therefore are dealt individually.

5.1

Geometrical Characteristics of Rock Joints

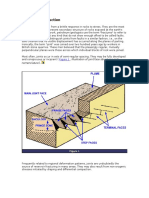

5.1.1 Joint Sets and Length: Joints and Fractures, Set Number, and Persistence As discussed early in the chapter dealing with rock formation, joints are generally in sets, i.e., parallel joints. The number of joint sets can vary from 0 to as many as 5 (Table 5.1.1a). Typically one joint set cuts the rock mass into plates, two perpendicular sets cut rock into column and three into blocks, and more sets cut rocks into mixed shapes of blocks and wedges, as shown in Figure 5.1.1a. The mechanical properties of the rock mass is obviously influenced by the presence of joint sets and the number of joint sets. More joint sets provide more possibilities of potential slide planes for rock wedges or blocks to slide and fall. Rock masses showing one and three joint sets. ISRM suggested description of joint sets Massive, occasional random fractures One joint set One joint set plus random fractures Two joint sets Two joint sets plus random fractures Three joint sets Three joint sets plus random fractures Four or more joint sets Crushed rock, earth-like

Figure 5.1.1a

Table 5.1.1a I II III IV V VI VII VIII IX

Different from joints, rock fractures are considered as a non-systematic discontinuous feature of rock masses. They are not in sets or parallel. They could be large in term of numbers but their distribution is generally random. Rock mass quality is influenced by the number of rock fractures and they are usually considered in the overall degree of fracturing of a rock mass, in term of joint spacing and RQD, discussed in later sections.

Chapter 5 Properties of Rock Discontinuities

Persistence is the areal extent or size of a discontinuity, and can be crudely quantified by observing the trace lengths of discontinuities on exposed surfaces. The persistence of joint sets controls large scale sliding or 'down-stepping' failure of slope, dam foundation and tunnel excavation. Figure 5.1.1b gives diagrams showing persistence of various joint sets, while Table 5.1.1b presents the classification of persistence commonly adopted. Sketches indicating persistence of various joint sets. ISRM classification of discontinuity persistence Surface Trace Length (m) <1 13 3 10 10 20 > 20

Figure 5.1.1b

Table 5.1.1b

Description Very low persistence Low persistence Medium persistence High persistence Very high persistence

5.1.2 Joint Orientation: Joint Plane Orientation and Representation Orientation of a discontinuity is described by its dip and dip direction or its dip and strike. The orientation of major joint set relative to an engineering structure largely controls the possibility of unstable conditions or excessive deformations developing. The mutual orientation of discontinuities will determine the shape of the individual blocks and beds comprising the rock mass. Orientation of a plane is measured by the degree of inclination and the direction of facing of the plane. It does not fix its position. Therefore, two parallel planes have the same orientation. In rock mechanics and engineering geology, the orientation of a plane is generally defined by dip angle (inclination), dip direction (facing) or strike (running), as illustrated in Figure 5.1.2a. Representation of joint plane orientation.

Figure 5.1.2a

Dip or dip angle represents the degree of inclination. It is the acute angle between the plane and the horizontal plane. It is also the acute angle between a line with maximum dip in the inclined plane and its horizontal projection. Dip angle is generally expressed by an acute angle between 0 and 90. Dip direction represents the facing direction. It is the bearing measured clockwise from the north (0) of the line with maximum dip in the inclined plane. Dip direction is generally expressed by a direction angle of 0 to 360.

Chapter 5 Properties of Rock Discontinuities

Strike is the alignment or run. It is the bearing of an imaginary horizontal line in the inclined plane. Strike is generally expressed by a direction angle of 0 to 180. Dip direction and strike direction are always perpendicular. In rock mechanics, dip direction/dip format is generally used, e.g., 210/35, or 030/35, where dip directions always have 3 digitals. Sometime, when strike is used instead of dip direction, the general direction of plane dip must be given, otherwise, it could means two possible planes, e.g., dip/strike 120/35 would be either dip direction/dip 210/35, or 030/35. Therefore correctly it should be presented as strike/dip 120/35SW which is the plane in dip direction/dip 210/35, or 120/35NE which is the plane in dip direction/dip 030/35. Normal to the plane is the imaginary line at right angle to the plane. orientation of the normal is given by, trend of normal = dip direction of the plane 180, plunge of normal = 90 dip. Therefore the

Orientation of a joint plane can be represented graphically using hemispherical projection method. The projection method is to represent a 3D plane by a 2D presentation. The most common projection is the low hemispherical equal angle projection. Use the projection, joint orientation data can be assessed in 2D form. Analysis of joint orientation data using projection method.

Figure 5.1.2b

It is a powerful tool to analyse large number of joint data and examine the rock slope stability, slide of rock block in underground excavation, stability of rock foundation on jointed rock mass. The use of the hemispherical projection method is given in a later section in this chapter.

5.1.3 Joint Spacing: Joint Spacing, Frequency, Block Size, and RQD The degree of fracturing of a rock mass is controlled by the number of joint in a given dimension. A rock mass contains more joints is also considered as more fractured. More joints also mean that average spacing between joints is less. Several parameters can be used to express the fracturing degree of a rock mass. The spacing of adjacent joints largely controls the size of individual blocks of intact rock. It controls the mode of failure. A close spacing gives low mass cohesion and circular or even flow failure. It also influences the mass permeability. Joint spacing for a particular pair of joint is the perpendicular distance between the two joints. For a joint set, is usually expressed as the mean spacing of that joint set. However, when the expose is limited, often the apparent spacing is measured. Figure 5.1.3a shows the relationship between spacing of individual joint set, apparent spacing and average spacing. In the assessment of rock fracturing degree, the overall average

Chapter 5 Properties of Rock Discontinuities

spacing is considered. However, as illustrated in the figure, measurements of the overall average joint spacing are different on different measuring faces. Joint spacing, apparent spacing and true spacing. The

Figure 5.1.3a

ISRM recommends the use of the terms in Table 5.1.3a to describe joint spacing. description ranges from extremely close spacing to extremely wide spacing. Classification of discontinuity spacing Joint Spacing (m) < 0.02 0.02 0.06 0.06 0.2 0.2 0.6 0.6 2 26 >6

Table 5.1.3a

Description Extremely close spacing Very close spacing Close spacing Moderate spacing Wide spacing Very wide spacing Extremely wide spacing

Joint frequency (), is defined as number of joint per metre length. the inverse of joint spacing (sj), i.e., = 1 / sj

It is therefore simply

Another measure of fracturing degree is the Rock Quality Designation (RQD). Is is defined as the percentage of rock cores that have length equal or greater than 100 mm over the total drill length (Figure 5.1.3b). RQD = Length of cores >100 mm 100% Total length of drilling Example of measuring RQD from core logging.

Figure 5.1.3b

Although RQD was initially proposed as an attempt to describe rock quality, in reality, it only describes fracturing degree, by in fact considering the spacing of joints. Therefore, statistically, RQD can be correlated to joint spacing or joint frequency the following equation: RQD = 100 e

0.1

(0.1 +1)

For values of in the range 6 to 16/m, the above equation can be approximated by,

Chapter 5 Properties of Rock Discontinuities

RQD = 110.4 3.68 Joint space also defines the size of rock blocks in a rock mass. When a rock mass contains more joints numbers, the joints have lower average spacing and smaller block size. Block size can be classified by the volumetric joint count, Jv, defined as number of joint per m3 volume of rock mass, as presented in Table 5.1.3b. ISRM suggested block size designations Volumetric Joint Count, joints/m3 <1 13 3 10 10 30 > 30 > 60

Table 5.1.3b

Designation Very large blocks Large blocks Medium-sized blocks Small blocks Very small blocks Crushed rock

RQD can be related approximately to Jv by: RQD = 115 3.3 Jv, for Jv between 4.5 and 30.

For Jv < 4.5, RQD is taken as 100%, and for Jv > 30, RQD is 0%.

5.1.4 Joint Surface and Opening: Roughness, Matching, Aperture and Filling A joint is an interface face of two contacting surfaces. The surfaces can be smooth or rough; they can be in good contact and matched, or they can be poorly contacted and mismatched. The condition of contact also governs the aperture of the interface. The interface can also be filled with intrusive or weathered materials. Joint surface roughness is a measure of the inherent surface unevenness and waviness of the discontinuity relative to its mean plane. The roughness is characterised by large scale waviness and small scale unevenness of a discontinuity. It is the principal governing factor the direction of shear displacement and shear strength, and in turn, the stability of potentially sliding blocks. Roughness can be distinguished between small scale surface irregularity or unevenness and large scale undulation or waviness of the discontinuity surface, as illustrated in Figure 5.1.4a. Definition of joint roughness at different scale.

Figure 5.1.4a

Chapter 5 Properties of Rock Discontinuities

A classification of discontinuity roughness has been suggested by ISRM, and is reproduced in Figure 5.1.4b. It describes the roughness first in metre scale (step, undulating, and planar) and then in centimetre scale (rough, smooth, and slickensided). The classification is useful to describe the joint surface but does not give any quantitative measure. Figure 5.1.4b Typical joint surface profile and suggested descriptions and corresponding joint roughness coefficient (JRC) at different scales. Another commonly used roughness classification is proposed by Barton, termed as Joint Roughness Coefficient (JRC). JRC number is 0 for the smooth flat surface and 20 for the very rough surface. The proposed JRC is reproduced in Figure 5.1.4b. Joint roughness is affected by geometrical scale. In the JRC classification, the value of JRC decreases with increasing size. It should be noted that in realty, profiles of joint surfaces are 3D features (Figure 5.1.4c). The above descriptions are 2D based. It is therefore suggested to take several linear profiles of a surface for the description and JRC indexing. 3D presentation of joint surface.

Figure 5.1.4c

Joint surface is a rough profile that can be described by statistic method and fractal. (A section on fractal describing surface profile.) Fractal method is applicable not only in 2D (linear profile), but also in 3D (surface plane profile), as shown in Figure 5.1.4d. It is a very powerful tool to quantify the surface profile. (More) 3D joint surface profiles and fractal numbers.

Figure 5.1.4d

However, a joint is an interface of two surfaces. The properties of a joint are therefore controlled by the relative positioning of the two surfaces, in addition to the profiles of both surfaces. For example, joints in fully contacted and interlocked positions has little possibility of movement and is also difficult to shear, as compared to the same rough joints in point contact where movement can easily occur. Often, joints are differentiated as matched and mismatched (Figure 5.1.4e). A Joint Matching Coefficient (JMC) has been suggested by considering the contact percentage of two surfaces, as shown in Figure 5.1.4f. JMC various from 0, representing completely mismatched with a few contact points only in the joint interface, to 1, representing completely matched with fully in contact of the joint.

Chapter 5 Properties of Rock Discontinuities

Figure 5.1.4e

Matched and mismatched joint surface. Scheme of Joint Matching Coefficient (JMC) for rock joints.

Figure 5.1.4f

In a natural joint, it is very seldom that the two surfaces are in complete contact. There usually exists a gap or an opening between the two surfaces. The perpendicular distance separating the adjacent rock walls is termed as aperture. Descriptions of aperture are suggested in Table 5.1.4a. Joint opening is either filled with air and water (open joint) or with infill materials (filled joint), as illustrated in Figure 5.1.4g. Open or filled joints with large apertures have low shear strength. Open aperture also associates with high permeability and storage capacity. Joint aperture and joint with filling. Classification of discontinuity aperture Description Very tight Tight Partly open Open Widely open Very widely open Extremely widely open Cavernous

Figure 5.1.4g

Table 5.1.4a Aperture < 0.1 mm 0.1 ~ 0.25 mm 0.25 ~ 0.5 mm 0.5 ~ 2.5 mm 2.5 ~ 10 mm 1 ~ 10 cm 10 ~ 100 cm >1m

"Closed feature" "Gapped feature" "Open feature"

Aperture can be separated by mechanical aperture or real aperture and equivalent hydraulic aperture or conducting aperture. The later is particularly important when permeability is concerned. Filling is material in the rock discontinuities. The material separating the adjacent rock walls of discontinuities. The wide range of physical behaviour depends on the properties of the filling material. In general, filling affects the shear strength, deformability and permeability of the discontinuities. 5.1.5 Correlation between Various Geometrical Properties Figure 5.1.5a is an illustration of all the important geometrical properties of rock joints and fractures. As all the features in a rock mass have undergone the same geological processes, some of the geometrical features has certain degree of correlation.

Chapter 5 Properties of Rock Discontinuities

Figure 5.1.5a fractures.

Illustration of various geometrical characteristics of rock joints and

(Discussions on correlations between: joint set number and joint spacing/RQD, JRC and aperture, etc)

5.2

Mechanical and Hydraulic Properties of Rock Joints and Fractures

5.2.1 Normal Stiffness and Displacement Normal deformation characteristics and normal stiffness of rock joints are important parameters for analysis and design. As discussed in an earlier chapter, a joint represents a discontinuity of stress and displacement. A natural joint always has opening aperture of less than 1 mm to a few mm. With increasing normal stresses, the opening closes, and contact areas of the joint surfaces increase. Therefore as shown in Figure 5.2.1a, the normal stress normal displacement curve can be highly non-linear. The normal stiffness, slope of the curve, is therefore not a constant. Normal stress - normal displacement relation of joints in a granite

Figure 5.2.1a

There are several mathematical models describing the normal stress displacement relationship. In developing a joint element finite element model, Goodman (1976) used a hyperbolic relation between normal stress, n, and normal displacement, dn,

t dn n ni =A( ) dmax dn ni

where dmax is the maximum possible closure, ni = a seating pressure defining the initial normal stress conditions for measuring normal displacement, and A and t are experimentally determined constants. Based on a great number of laboratory experiments on matched rock fractures in dolorite, limestone, siltstone and sandstone, Bandis et al. (1983) proposed a hyperbolic function to express the normal effective stress-closure relation of a matched fracture. Assuming positive signs for compression and fracture closure and negative signs for tension and fracture opening, the normal effective stress-closure relation is, n = kni dn 1 (dn/dmax)

Chapter 5 Properties of Rock Discontinuities

or dn = n kni + (n/dmax)

where n is the normal effective stress, dn is the fracture closure, dmax is the maximum allowable closure, kni is the normal stiffness of the fracture at initial stress. When normal stress becomes infinite, fracture closure approaches the maximum allowable fracture closure, and simultaneously, normal fracture specific stiffness becomes infinite. The fracture becomes a welded interface. On the other hand, when normal stress is zero, fracture closure becomes zero, and the corresponding normal fracture specific stiffness is named as initial normal fracture specific stiffness. The initial normal stiffness (kni) and maximum allowable closure (dmax) can be determined from regular static fracture deformation tests or fracture properties, i.e., fracture wall compressive strength (JCS), fracture roughness coefficient (JRC) and average aperture thickness (ai) at initial seating normal stress, as described by Barton et al. (1985). The model is commonly known as the BB (Barton-Bandis) model. The above hyperbolic BB model of the fracture normal behaviour is commonly used in rock mechanics and engineering. Under cyclic loading/unloading condition, the BB model describes that the initial load and unload cycles may cause a hysteresis between them. Successive load/unload cycles can continue to stiffen the fractures, and the BB model eventually tends to a hyperbolic elastic model without the hysteresis between the load and unload cycles. On the other hand, in the laboratory experiments on mismatched rock fractures, Bandis et al. (1983) also found that the mismatched rock fractures exhibit much reduced normal stiffness, compared to the matched fractures. A semi-log function was used to fit the normal stress-closure curves, as expressed in the following: log n = p + q dn where n is normal effective stress, dn is the fracture closure, p and q are material constants. Logarithmic functions have also been used by others to describe the normal behaviour of rock fractures. For example, Zhao and Brown (1992) found that the normal stress normal displacement could be fitted by a function below, dmax dn = 1 A ln(n/ni) dmax dni where dni = displacement at a reference normal stress ni, usually equal to the seating pressure, and A is constant varies from 0.16 to 0.21.

Chapter 5 Properties of Rock Discontinuities

10

The curve shown in Figure 5.2.1a indicates that at high normal stress, when the joint is highly closed, the normal stiffness approaches that corresponding to the elastic modulus of the rock material. When the joint is completely closed, there is no further closure of the joint, the displacement is therefore only by the elastic deformation of the rock material.

5.2.2 Shear Strength of Rock Joints and Fractures Shear behaviour of rock joints is perhaps one of most important feature in civil engineering rock mechanics. Conditions for sliding of rock blocks along existing joints and faults at slope or excavation opening are governed by the shear strengths developed on the sliding rock discontinuities. As seen in Figure 5.2.2a, in slope, shear is subjected to a constant normal load generated by the weight of the blocks; while in tunnel, shear is subjected to constant stiffness due to the constraints of lateral displacement. Figure 5.2.2a Controlled normal load (a, c) and controlled normal displacement (b, d) shearing modes and tests. The shear properties are usually determined by direct shear test shown in Figure 5.2.2a. Detailed description of test preparation and methodology is given in a later section. As shown early in chapter on mechanics, sliding between two smooth horizontal contact surfaces gives the relationship between the friction angle , the normal force (N) and shear force (Fs), as Fs = N tan. It is therefore not surprised that shear tests carried out on smooth, clean fracture surfaces at controlled normal load condition generally give shear strength (s) - effective normal stress (n) curve (Figure 5.2.2b) and it follows the simple Coulomb law: = n tan where is the effective angle of friction of the fracture surfaces. Figure 5.2.2b, = 35, a typical value for quartz-rich rocks. For the case shown in

Figure 5.2.2b

Shearing of smooth quartzite surfaces under various conditions.

Naturally occurring discontinuity surfaces are far from being smooth. Figure 5.2.2c is typical of the results obtained for clean, rough fractures. As observed in the tests, shear stress quickly mobilised and reaches a peak. When shearing is progressed, the shear strength stablised to a residual level. The peak is usually term as the peak shear strength and the residual is the residual shear strength. For rough joints, peak shears strength is significantly higher than the residual strength.

Chapter 5 Properties of Rock Discontinuities

11

Figure 5.2.2c

Results of a direct shear test on a clean rough rock joint.

Observations of shear test results show that residual strength follows the linear friction law, i.e., r = n tan r On the other hand, peak shear strength does not follow the linear fiction law. The peak strength for rough joints does not linearly proportional to normal stress. The gradient of the peak shear strength normal stress decreases with increasing normal stress. As shown early in Chapter 3, for idealized rough fracture models by Patton (1966) shown in Figure 5.2.2d, it is similar as sliding between two contact surface at an inclination. Therefore, at low normal stress and at relatively short shear distance, shear strength is also influenced by the inclination angle, = n tan(+i) It was found that when the normal stress is increased above a critical value, shear stress can eventually be developed so high that it causes shear failure through the asperities. When such shearing through asperity occurs, the shear strength is somehow related to the shear strength of the materials of the asperities. Comparing to rock joint, rock materials have higher cohesion and internal friction angle of generally around 30. Figure 5.2.2d Idealized surface roughness models and bilinear peak strength envelope.

Therefore, shear strength for a rough fracture could exhibit two features, a lower portion representing shearing by climbing the asperity angle, and an upper portion representing shearing off the asperities. This leads to a bilinear shear strength model shown in Figure 5.2.2d, and is expressed by the equations below. In the equation, n is the critical normal stress when shearing of asperity is assumed to start.

n tan (+i) c + n tan

for n n for n n

However, in reality, there is not clear boundary between shearing by climbing the asperity angle and shearing off the asperities. With increasing normal stress, asperity shearing off increases progressively. Therefore, the actual shear stress normal stress relation is represented by a curve, as shown in Figure 5.2.2c.

Chapter 5 Properties of Rock Discontinuities

12

Based on extensive test results and noticing the progressive damage of asperities, Barton (1973) proposed that the peak shear strengths of joints could be represented by the empirical relation below, = n tan [JRC log10 JCS ) + r] ( n where n = effective normal stress, JRC = joint roughness coefficient on a scale of 1 for the smoothest to 20 for the roughest surfaces, JCS = joint wall compressive strength, and r = drained residual friction angle. (Discussion on dilation and dilation angle.)

5.2.3 Other Factors Affecting Joint Shear Behaviour Roughness effect can cause shear strength to be a directional property. Figure 5.2.3a illustrates a case in which rough discontinuity surfaces were prepared in slate specimens. Directional effects are not just in foliated rocks, but rather universal. As discussed in the geometrical properties, surface profile is a 3D feature while shearing is a directional activity. Surface profile along a particular direction would be different along another direction and hence gives different shear strength. Effect of shearing direction on the shear strength of a joint in a slate.

Figure 5.2.3a

The natural discontinuities normally suffered weathering and alteration, which in term, also change the degree of matching of the discontinuity surfaces. It was found that the mismatched discontinuities generally have much lower shear strength than matched (interlocked) ones (Figure 5.2.3b). Shear strength of matched and mismatched fractures in a granite.

Figure 5.2.3b

When a joint is wet, it has generally a lower friction angle than a dry joint. The shear strength of a wet joint is calculated use the wet friction angle. If the joint is subjected to groundwater pressure, the normal stress in the shear strength equation is the effective normal stress, i.e., total stress water pressure. The JRC-JCS shear strength equation shows that the shear strength of a rough joint is both scale dependent and stress dependent. As n increases, the term log10(JCS/n) decreases, and so the net apparent friction angle decreases. As the scale increases, the steeper asperities shear off and the inclination of the controlling roughness decreases. Similarly, the asperity failure component of roughness decreases with increasing scale

Chapter 5 Properties of Rock Discontinuities

13

because the material compressive strength, JCS, decreases with increasing size, as illustrated in Figure 5.2.3c. Influence of scale on the three components of discontinuity shear

Figure 5.2.3c strength.

5.2.4 Flow and Permeability of Rock Joints From the early chapter on mechanics, it showed that flow in parallel plates is governed by the cubic flow law. The parallel plates theory is applicable to flow in rock joints. Therefore, flow and permeability of a rock joint are given as, Q= w i g de 12 g de 12

2 3

(5.2.4a)

k=

(5.2.4b)

where g = acceleration due to gravity, = kinematic viscosity of the fluid, w = width of the joint, and d = aperture of smooth plates or equivalent hydraulic aperture of the rough joint. The parallel plates theory is assumed for smooth plates and laminar flow. When it is applied to actual rock joints with rough surfaces, which are far from smooth, the equation does not truly represent the real case. The original equation therefore, does not account for the deviations from the ideal conditions due to the joint surface geometry and other effects. Somehow, modification has to be introduced to reflect the effects of joint roughness and flow path. Therefore, in the above equation, instead of the aperture of smooth plates, in natural rock joints, equivalent hydraulic aperture is used. The equivalent hydraulic aperture of a rock joint (de)is estimated from, de = f d (5.2.4b)

where d is the actual aperture of the rock joint, and f is a factor that accounts for deviations from the ideal conditions that are assumed in the parallel smooth plate theory, and f 1. It is found that for a given joint, f is a constant at different apertures, without change of joint surface profile (Witherspoon et al 1980). It is also noted that f value is generally lower when the joint surfaces are rougher. This means that rougher joints deviate more from smooth parallel plates and hence require higher corrections.

5.3

Correlations between Geometrical, Mechanical and Hydraulic Properties

Chapter 5 Properties of Rock Discontinuities

14

5.3.1 Joint Surface Profile and Normal Stiffness It was observed that closure under load was more complete in smooth joints than in rough joints. Conversely, rough joints in strong rocks close least under normal stress. The initial normal stiffness and maximum closure were dependent on roughness (JRC) and wall strength (JCS). The effect of joint surface mismatch was noticed. Earlier experiments performed by Bandis (1980) suggested that when mismatch occurs the number of contact points may reduce, although the individual areas of contacting asperities may become larger.

5.3.2 Joint Surface Profile and Shear Strength The JRC-JCS joint shear strength criterion has already highlighted the relationship between joint roughness and strength. It is evident that rougher joint surface leads to higher shear strength. (Discussion on correlation between fractal and shear strength.)

5.3.3 Joint Surface Profile and Permeability Many studies have been conducted on strength, deformation and conductivity coupling of rock joints in an attempt to relate these to the joint surface roughness. A relationship between equivalent hydraulic aperture and real joint aperture based on the Joint Roughness Coefficient (JRC) was proposed by Barton and Choubey [1977]: de = JRC 2 (d/de)

2.5

(5.2.5b)

where de is the equivalent hydraulic aperture and d is the real aperture of a joint.

5.3.4 Joint Closure and Permeability The permeability and hydraulic aperture of rock joints changes with effective normal stress. As shown in Figure 5.3.4a, joint permeability reduces asymptotically and approaches to zero with increasing effective normal stress. Changes of permeability with effective normal stress of rock joints in a

Figure 5.3.4a granite.

Chapter 5 Properties of Rock Discontinuities

15

A hydraulic model describing the hydraulic behaviour of discontinuities was proposed by Walsh (1981) and modified by Zhao and Brown (1992). The model suggested a logarithmic relation between the joint permeability, kj and the effective normal stress, (n), kj 2 = [1 B Ln ( n ) ] kr r (5.3.4a)

where kr = the rock joint permeability at a reference effective normal stress r, and B is a parameter dependent on surface properties of the joint.

5.3.5 Joint Shear, Aperture and Permeability For an originally matched and closed joint, shear will start to general separation of the joint surface and creating larger aperture and high permeability, as illustrated in Figure 5.3.5a. As seen from the figure, when shear occurs, dilation occurs due the climbing effects. The climbing effects may be less obvious if the joint is under high normal stress. In this case, the asperities would be crashed and crashed particles may be filled in the joint. This may still result in increasing of permeability but not as significant as in the previous case. Change of aperture with shear displacement of a matched joint.

Figure 5.3.5a

For a non-matched joint, the situation may be quite different. Depending on the original situation, the aperture could be reduced if shearing of the joint causes close up of the joint, or vice versa.

5.4

Behaviour of Joints under Cyclic and Dynamic Loading

5.4.1 Joint Surface Damage under Cyclic Loading

5.4.2 Joint Behaviour under Dynamic Loads

5.4.3 Factors affect Rate Dependent Characteristics of Joints

5.5

Effects of Joints on Transient Stress Wave Propagation

5.5.1 General Concept of Dynamic Stress and Transient Waves

Chapter 5 Properties of Rock Discontinuities

16

5.5.2 Effects of Single Joint on Wave Transmission

5.5.3 Effects of Joint Set on Wave Transmission

5.6

Characteristics of Rock Faults and Folds

5.6.1 Single Fault Single fault should be characterised similarly as joint, including orientation, persistence, surface roughness, aperture and filling. Persistence or length of the fault is particularly important in order to appreciate the impact and influence of the fault. Another aspect of importance is groundwater flow in the fault. Faults are usually of great length; they generally are better connected than most of the joints, and hence create a water flow channel.

5.6.2 Fault Zone of Extended Thickness In addition to the characteristics of planer fault, thickness of a fault zone has important influence on the overall properties. Together with the thickness, the materials within the fault zone should be properly described and understood. The materials can vary from crushed to completely decomposed rocks. The properties of those materials need to be tested and determined in order to estimate the strength and deformation characteristics. Similarly to single fault, fault zones also often become major groundwater flow channel. Major faults sometimes are associated with and connected to surface geographic depression and water body.

5.6.3 Bedding Planes and Rock Formation Interfaces Bedding planes of sedimentary rocks without being folded are planner. Important characteristics need to be described are the orientation and interface types. In most cases, conformable or unconformable bedding planes are cemented and do not represent a separation with an opening. Unconformable bedding planes may be represented by a mixed interface in which materials of both rocks of each side are mixed and hence dose not show a clear line separating the two rocks. Non-conformable interfaces are the interfaces between sedimentary rocks with nonsedimentary (igneous and metamorphic) rocks. They may not be planner, and may be

Chapter 5 Properties of Rock Discontinuities

17

represented by mixed interfaces containing fragments of rocks on both sides, or may be represented by localised contact metamorphism caused by intrusion. Dykes and sills are localised intrusions of igneous materials into existing rocks. The interfaces between dykes/sills with the existing rocks are represented by contact metamorphism. Interfaces between two non-sedimentary rocks are usually well welded, by intrusion or by metamorphism. The interfaces therefore only represent a discontinuity of materials but not necessarily a weak zone or failure plane. The condition of rocks, particularly carbonate sedimentary rocks (limestone and dolomite) close to the interface needs to be carefully examines. For example, at an interface between porous sandstone and limestone with active groundwater flow, limestone may be weathered and showing well developed cavities.

5.6.4 Intensively Folded Thin Layers Sedimentary layers of relative thin thickness and intensively folded often represent a zone of fractured and weak rock. Description of discontinuities is not easy. However, general descriptions should include the layer thickness, materials in the layers, degree and type of folding, and groundwater condition. In the Chapter dealing with rock mass, such zones will be discussed in term of rock mass classification.

5.7

Field and Laboratory Characterisation of Rock Joints

5.7.1 Overview on Field and Laboratory Methods Characterisation of rock discontinuities are done by three means, most convenient and best mean is by mapping at outcrops. Therefore outcrop mapping should always be the first choice of exposure of rock face is available. Rock cores from boreholes provides many useful information on rock discontinuities, and core logging remains an important exercise of rock discontinuity characterisation. In addition to core logging, further information can often be supplemented by log the borehole. Geophysical borehole logging becomes increasingly useful in rock discontinuity and rock mass characterisation. Table 5.7.1a provides an overview on the applicability of various methods to measure rock discontinuities from outcrop mapping and core logging. Table 5.7.1a Feature Measurement of discontinuity geometrical features Measurement Method Outcrop Mapping Core Borehole Logging Logging

Chapter 5 Properties of Rock Discontinuities

18

Discontinuities type Orientation Spacing Persistence Roughness Wall strength Aperture Filling Seepage Number of joint sets Block size

Visual Compass-clinometer Measuring tape Measuring tape Profile gauge Schmidt hammer Scale or feeler gauge Visual Timed observation Hemispherical projection 3-D fracture frequency

good good good good good good good good good good good

good medium good poor medium medium poor poor poor medium poor

medium good medium poor poor poor poor poor good poor poor

5.7.2 Identification of Joint Sets Measurements on joint set number are usually done by observation and orientation measurements at outcrops. Descriptions of joint sets are suggested by ISRM, as reproduced in Table 5.7.2a. Table 5.7.2a I II III IV V VI VII VIII IX ISRM suggested description of joint sets Massive, occasional random fractures One joint set One joint set plus random fractures Two joint sets Two joint sets plus random fractures Three joint sets Three joint sets plus random fractures Four or more joint sets Crushed rock, earth-like

It is not easy to measure joint set number by logging the rock cores. Often dominating joint sets or joint sets most perpendicular to drilling can be identified. Joints parallel and sub-parallel to drilling are not well represented in core and hence not easily notified.

5.7.3 Measurement of Joint Orientation (a) By Outcrop Mapping The most convenient way to measure joint orientation is from accessible outcrops or exposed faces of slope cuts or underground excavation. The measurements can be made by a geological compass, which gives readings of dip direction (bearing) and dip angle (inclination), as shown in Figure 5.7.3a.

Chapter 5 Properties of Rock Discontinuities

19

Orientation of a joint plane daylighted on exposed surfaces may be obtained by surveying methods from an inaccessible outcrop. The measurement may give orientations of the daylighted lines. Orientation of the joint plane can be calculated from the orientations of the daylighted traces of the same joint plane, as shown in Figure 5.7.3b. Assume the orientations of the two trace lines are 1, 1, and 2, 2 (plunge and trend), from 3D geometry, the orientation of the joint plane (dip angle , dip direction ) is given by the equation below, tan 1 = cos (| 1|) tan and tan 2 = cos (| 2|) tan By combining the above two equations, we have, cos (| 1|) tan 1 = tan 2 cos (| 2|) With given 1, 1, and 2, 2, dip direction of the plane can be calculated by the above equation. Dip angle can be calculated by substitute to one of the earlier equations. The determination of plane orientation from the two daylighted lines can also be done by projection method, which will be presented in a later section in this Chapter. The dip angle shown by the trace of the daylighted joint plane is called apparent dip. Apparent dip is always smaller then the true dip, as the true dip is defined as the maximum dip angle of the plane. (b) By Core and Borehole Logging Joint are intersected by borehole drilling and hence can be seen from the cores obtained from coring. Boreholes mostly are drilled vertically. Therefore, dip angle of joints and fractured can be easily estimated, as the angle between the joint plane (when core is placed vertically) and the horizontal. However, drilling is by rotational coring and usually the bearing of cores is not fixed. Therefore, the dip direction cannot be determined, in normal drilling. Dip direction determination is possible if core orientation is known. Core orientation is possible in reasonably good quality rock, where joints are reasonable close and matched. mark, indicating, say, north, is printed on the core before drilling and when the cores are taken out and reconnected, the whole core samples can be reoriented and dip directions of all the joints and fractures can be determined, as illustrated in Figure 5.7.3c.

Chapter 5 Properties of Rock Discontinuities

20

In inclined and horizontal drilling, core orientation can be done within a drilling system. The core barrel can have a steel ball which sit at the lowest position, i.e., lower side of the core. The steel ball is locked in the core barrel and kept therefore the in the same orientation as the cores. When the cores are taken out from the borehole, cores can be reoriented with the aid of the steel ball, as shown in Figure 5.7.3d. Orientation can also be determined by log the borehole, for example, by impression packer or acoustic imaging. Those methods are aimed at obtaining the images of the borehole walls. The images can be reconstructed to produce the joint plane cutting through the borehole. With know orientation of the image, the orientation of the joint can be easily determined, as shown in Figure 5.7.3e.

5.7.4 Measurement of Joint Spacing and RQD (a) By Outcrop Mapping At an outcrop where rock is exposed, a scanline, say, horizonally along a straight outcrop surface is planed. Along the scanline, using a measuring tape, spacing of joint daylighted on the outcrop can be measured. Measurements can be done in three ways: (a) measuring the total amount of joint numbers with the scanline length, to calculate the joint frequency; (b) measuring all the individual spacing between all the joints, to calculate average spacing of all the joints: (c) measuring spacing of joints of individual joint sets, to calculate joing spacing for different joint sets; and (d) measuring all the spacing longer than 10 cm, to calculate RQD. Various measurements are illustrated in Figure 5.7.4a. It should be noted that the measurements on the outcrop surface give the apparent spacing of joints. The measurements are also directional, i.e., if the scanline is in different direction, say vertical, the measurements will be different. (b) By Core and Borehole Logging Measuring RQD is almost a standard practice during core logging. It is usually measured for each core run (generally 1 3 m), or for the length of cores in a core box (generally 1 1.5 m). By placing a measuring tape along one side of the core length, rock cores have a length longer than 10 cm are noted and summed, dividing to the drilling length, giving the RQD. Alternatively, the total number of fractures can be counted to calculate the joint frequency. The measurements are illustrated in Figure 5.7.4b. In core logging for RQD or frequency, the length to be divided is the total drilling length, not the core length. In competent rock and with good drilling practice, the core length can be the same as drilling length. Sometimes, rock cores are not fully recovered from drilling, and then the core length is shorter than the drilling length. The ratio of recovered core length to the drilling length is termed as core recovery. When coring

Chapter 5 Properties of Rock Discontinuities

21

through a highly fractured rock mass or a faulted zone, core recovery could be low due to loss of loss materials in the fractured and faulted zones.

5.7.5 Joint Surface Profile Measurements (a) Measurement of Large Scale Waviness at Site Large scale waviness of a joint at site can be obtained by placing a long ruler over the joint surface and then to measurement at a fixed interval the gap between the ruler and the profile surface, as indicated by illustration in Figure 5.7.5a. (b) Measurement of Roughness at Small Scale Roughness measurements are usually done by a profile gauge shown in Figure 5.7.5b. More precise measurement can be obtained by using a laser device, as shown in Figure 5.7.5c. A simple profile gauge provides a profile along a scanline and each profile is then compared with a typical profile to give the roughness description or the roughness number. Alternatively, fractal number can be computed. With a laser profile capable to move along x and y directions, a series linear profiles can be scanned to provide a 3D profile plane. With the 2D profile or 3D profile, toughness can be described, or fractal numbers be calculated.

5.7.6 Description of Joint Surface and Filling (a) Weathering and Alteration Weathering and alternation is usually visible at outcrops or from the cores. When the joint surface is weathered, it often shows the change of colour and appearance. Often, weathered products, such as grain particles may also remain inside the joint. Detailed description is necessary. Table 5.7.6a gives the suggested description by ISRM. Table 5.7.6a Term Fresh Discoloured ISRM suggested descriptive terms for joint surface alteration Description No visible sign of weathering of rock material at joint wall. Colour of the original fresh rock material is changed. The degree of change from the original colour should be indicated. If the colour change is confined to particular minerals this should be mentioned. Rock is weathered to the condition of a soil in which the original materials fabric is still intact, but some or all of the mineral grains are decomposed.

Decomposed

Chapter 5 Properties of Rock Discontinuities

22

Disintegrated

Rock is weathered to the condition of a soil in which the original materials fabric is still intact. The rock is friable, but the mineral grains are not decomposed.

(b) Filling in Joint Joint can be clean or filled with weathered products and deposits, ranging from sandy particles to swelling clays. Descriptions of filling materials need be given in details, in term types of the materials, thickness, and particle sizes. If swelling clays are found, swelling characteristics should be described. (c) Estimating Joint Wall Strength Joint wall strength is also an indicating of weathering and alteration of joint wall. When the joint is weathered, the strength of the rock at joint wall reduces significantly. As we discussed earlier, this affects greatly the shear strength of the joint. Joint wall strength can be estimated by a Schmidt hammer. number, uniaxial compressive strength can be estimated. With the Schmidt hammer

5.7.7 Estimation of Joint Aperture and Contact Areas (a) By Outcrop Mapping and Core Logging At outcrop mapping, joint aperture can only be roughly estimated, through direct observation of joint exposed at outcrop, according to the ISRM suggested description represented in Table 5.1.4a. The actual measurement is rather difficult, if not impossible. (b) By Laboratory Measurements Specific methods have been developed in the laboratory to measure the aperture and contact area of rock joints. The most common method is by impress trace. Materials are injected into the joint and are allowed to set. When the joint is opened, the hardened injected material gives the impression of the joint, including gaps and contacts. Contact points and areas as well as aperture can then be estimated.

5.7.8 Permeability Measurements of Rock Joints (a) In Situ Tests

Chapter 5 Properties of Rock Discontinuities

23

In situ permeability tests usually are done in boreholes for a section of rock mass, and they will be described in details in the next Chapter. For measuring permeability of individual joint, tests can be done in a borehole with packers. From core or borehole logging, the joint to be tested should be selected. The joint should be able to be isolated by a pair and packer and between the packers, there should be only that joint within the tested section. A pair of packers are lowered down into the borehole to the positions, to include the joint between the packers. The packers are inflated to seal the section. Permeability tests are conducted by injecting high pressure water within the section sealed by the packers. The test is often referred as borehole packer test, and is illustrated in Figure5.7.8a. Permeability (often expressed as transmissivity) can be calculated from flow characteristics, flow transmitting rate and flow pressure. (b) Laboratory Tests Permeability tests on joint in laboratory can be set up using a system similar to Darcys experiment. In addition, normal stress may be applied to the joint to determine the flow rate and permeability at various stress conditions. A typical set-up using a triaxial cell is shown in Figure 5.7.8b. Permeability can be calculated from the flow rate measurements, hydraulic gradient and specimen geometry, when the water flow is steady state laminar flow in the joint. Using the parallel plates theory, equivalent hydraulic aperture can be estimated. Change of pressure in the cell causes change of normal stress acting on the joint, and leads to change of joint aperture. Such change will also be reflected in the change of permeability.

5.7.9 Normal Compression and Stiffness Measurement of Joints Rock sample containing a joint is prepared. Ideally, the joint should be placed horizontally, parallel to the loading plane. The specimen can be cut into circular cylinder or rectangular block and cross section area is measured. The joint surface is carefully protected from mechanical damage during cutting and preparation. The profiles of joint surfaces are recorded using a profiling gauge. The specimen is loaded under a standard compression machine with load measurement. LVDTs or dial gauges are placed near and across the joint to measure the normal displacement of the section containing the joints, as shown in Figure 5.7.9a. Load and displacement measurement should be taken regularly. If the displacement are measured a relative large section of the rock, the displacement of the rock material should be subtracted from the total displacement to give the net displacement of the joint.

Chapter 5 Properties of Rock Discontinuities

24

Stress (load/cross-section area) and joint normal displacement are plotted to give the stress-normal displacement behaviour of the joint. Normal stiffness at a specific stress level is the gradient of the tangent to the stress-normal displacement curve at that stress, as illustrated in Figure 5.7.9b. It should be noted that the stress-normal displacement behaviour of a rough joint is a curve.

5.7.10 Direct Shear Strength Test of Joints Rock sample containing discontinuity is prepared and encapsulated in laboratory shear box, with the discontinuity laid horizontally. The discontinuity is carefully protected from mechanical damage during cutting and preparation. The sample is then mounted in shear box using plaster, as shown in Figure 5.7.10a. The profile of discontinuity surface are recorded using a profiling gauge. Area of the discontinuity is also measured. The discontinuity is loaded under a constant normal load, and shear force is applied using a mechanical gear-drive system (Figure 5.7.10b). Shear displacement, shear force and normal displacement are recorded at a constant shear displacement interval (0.2-0.25 mm). The tests are continued until residual shear strength is obtained or about 10% of the specimen length (Figure 5.7.10c). Normal stress (n), peak shear strength (p) and residual shear strength (r) are calculated as normal load, peak shear force and residual shear force divided by the shear area. Peak shear strength, normal stress and angle of friction () can be adjusted to account for dilation. The angle of dilation (i) is estimated from normal displacement (n) - shear displacement curve (h) as i = n / h Adjusted basic angle of friction () = ( i ). Adjusted normal stress (n) = ( n cos i + p sin i ) cos i Adjusted peak shear strength (p) = ( p cos i n sin i ) cos i Reporting of results includes description of rock specimen and discontinuity, surface roughness profile, shear stress - shear displacement and normal displacement - shear displacement curves, peak shear strength, residual shear strength at each normal stress, plots of peak shear strength and residual shear strength against normal stress .

5.8

Hemispherical Projection Method

5.8.1 Principle of Projection

5.8.2 Projection of Planes and Lines

5.8.3 Use of Projection for Geometrical Analysis

Chapter 5 Properties of Rock Discontinuities

25

5.8.4 Applications of Projection Methods

Chapter 5 Properties of Rock Discontinuities

26

5.7.8 Permeability Measurements of Rock Joints (a) In Situ Tests In situ permeability tests usually are done in boreholes for a section of rock mass, and they will be described in details in the next Chapter. For measuring permeability of individual joint, tests can be done in a borehole with packers. From core or borehole logging, the joint to be tested should be selected. The joint should be able to be isolated by a pair and packer and between the packers, there should be only that joint within the tested section. A pair of packers are lowered down into the borehole to the positions, to include the joint between the packers. The packers are inflated to seal the section. Permeability tests are conducted by injecting high pressure water within the section sealed by the packers. The test is often referred as borehole packer test, and is illustrated in Figure5.7.8a. Permeability (often expressed as transmissivity) can be calculated from flow characteristics, flow transmitting rate and flow pressure. The basic injection flow test procedures are outlined below: (a) Open water feeding system valve and maintain constant pressure (PA), record the elapsed time and total volume of consumed water every 0.5 minute, for the first 3 minute, then every minute, for about 10-15 minutes, until the pressure appears to have stabilised. (b) After pressure PA has stabilised for approximately 3 minutes, increase the water pressure to pressure PB. Record the time and flow the same way as for PA, for about 10-15 minutes, until the pressure appears to have stabilised. (c) After pressure PB has stabilised for approximately 3 minutes, increase the water pressure to pressure PC. Repeating the same procedure by recording the time and flow until pressure stabilised. (d) Continue the tests for pressures PD and PE, following the same procedure.

5.1.1a

5.1.1a

Strike

Dip direction

Vertical plane Dip angle

N Measured on vertical plane: 55

Line of maximum dip Horizontal plane

Orientation: Dip direction / Dip 220/55

Measured clockwise on horizontal plane: 220

5.1.2a

5.1.2b

Apparent spacing On the plane

Apparent spacing in x direction

Apparent spacing in y direction

True spacing

5.1.3a

5.1.3b

5.1.4a

5.1.4b

5.1.4c

5.1.4d

5.1.4e

5.1.4f

5.1.4g

5.1.5a

5.2.1a

(a)

(b)

(c) (d)

5.2.2a

5.2.2b

Shear Force

(a)

Shear Displacement

Shear Strength

(b)

Peak

Residual

Normal Stress

5.2.2c

N S S

N S

i

N S

i

+i

+i

5.2.2d

5.2.3a

10

5.2.3b

5.2.3c

11

5.3.4a

5.3.5a

12

5.7.3a

Orientation of the joint daylighted

Apparent spacing on the measuring surface

Apparent spacing in 3 directions

5.7.3b

13

RQD = (L1 + L2 + + Ln) / L x 100% = number of joints / length = n / L

Outcrop Face

1 2

Tape

L1

L2

L3

X <10 cm

L4

L5

Li

X X

Ln

L

<10 cm <10 cm fault

5.7.4a

<10 cm L1 L2 L3 L4

<10 cm

<10 cm core loss L5 Li Ln

X X

RQD = (L1 + L2 + + Ln) / L x 100%

5.7.4b

14

Load measured by load cell

Displacements measured by LVDTs

5.7.9a

15

You might also like

- Joints & FracturesDocument14 pagesJoints & Fracturesfiqia nchaNo ratings yet

- Block Size MeasurementsDocument12 pagesBlock Size MeasurementsAndres Puerta MejíaNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument31 pagesWWW - MINEPORTAL.in: Online Test Series ForSheshu BabuNo ratings yet

- WWW - MINEPORTAL.in: Online Test Series ForDocument31 pagesWWW - MINEPORTAL.in: Online Test Series ForSusil SenapatiNo ratings yet

- 2cracteristic of DiscontinuDocument5 pages2cracteristic of DiscontinuAms JumrotinNo ratings yet

- Kuliah 7. DiscontinuitiesDocument55 pagesKuliah 7. DiscontinuitiestrumanNo ratings yet

- Strain EllipsoidDocument7 pagesStrain EllipsoidArkaprabha Sarkar100% (1)

- Q-System Guide for Evaluating Rock Mass StabilityDocument17 pagesQ-System Guide for Evaluating Rock Mass StabilityariffakhrNo ratings yet

- Correlation Between Block Size & RQDDocument23 pagesCorrelation Between Block Size & RQDJohNnyDjaKunNo ratings yet

- US Army DeformationandSettlement Ch-5Document7 pagesUS Army DeformationandSettlement Ch-5Ludy RamírezNo ratings yet

- Chapter 5 Discontinuities Terminology and DescriptionsDocument37 pagesChapter 5 Discontinuities Terminology and DescriptionspleyvazeNo ratings yet

- 240-Chapter5 Rock Engineering PDFDocument9 pages240-Chapter5 Rock Engineering PDFBrayan ItoNo ratings yet

- C7 Engineering Materials Metals: Prof. Dr. Rer. Nat. S. SchmauderDocument72 pagesC7 Engineering Materials Metals: Prof. Dr. Rer. Nat. S. SchmauderPratik D UpadhyayNo ratings yet

- JPB - 2016 PDFDocument22 pagesJPB - 2016 PDFOlfer EduardoNo ratings yet

- Structural Geology: Joint PatternsDocument4 pagesStructural Geology: Joint PatternsbuhlejoyNo ratings yet

- SPE-166505 Defining Three Regions of Hydraulic Fracture Connectivity in Unconventional ReservoirsDocument14 pagesSPE-166505 Defining Three Regions of Hydraulic Fracture Connectivity in Unconventional ReservoirsFabricetoussaintNo ratings yet

- Perpendicular To The Line Direction.: Figure 1: Schematic Diagram Showing An Edge DislocationDocument5 pagesPerpendicular To The Line Direction.: Figure 1: Schematic Diagram Showing An Edge DislocationYashveer02No ratings yet

- Index Properties of Intact RockDocument12 pagesIndex Properties of Intact RockChidi HenryNo ratings yet

- CHAPTER 10: Folds, Faults and Rock DeformationDocument5 pagesCHAPTER 10: Folds, Faults and Rock DeformationAshley ThereseNo ratings yet

- Joints: Joint Sets and SystemsDocument22 pagesJoints: Joint Sets and Systemspallavi tripathyNo ratings yet

- Discontinuity Spacings in RockDocument14 pagesDiscontinuity Spacings in RockGisber Mamani ColcaNo ratings yet

- A New Approach For Persistence in Probabilistic Rock Slope Stability AnalysisDocument7 pagesA New Approach For Persistence in Probabilistic Rock Slope Stability AnalysisCostas SachpazisNo ratings yet

- 1982 Palmstrom - On - Vol - Joint - Count - IAEGDocument9 pages1982 Palmstrom - On - Vol - Joint - Count - IAEGNicolas Pino TorresNo ratings yet

- Joints: Joint Sets and SystemsDocument22 pagesJoints: Joint Sets and SystemsFaizal AkbarNo ratings yet

- 03 Types of Slope Failure PDFDocument14 pages03 Types of Slope Failure PDFEd HPNo ratings yet

- 03 Types of Slope Failure PDFDocument14 pages03 Types of Slope Failure PDFRobby GinanjarNo ratings yet

- Joints: Joint Sets and SystemsDocument22 pagesJoints: Joint Sets and Systemsمحمد باسم محمد حسين ANo ratings yet

- Joints: Joint Sets and SystemsDocument26 pagesJoints: Joint Sets and Systemskurddoski28No ratings yet

- Power-Law Distributions of Natural Rock Fracture AperturesDocument12 pagesPower-Law Distributions of Natural Rock Fracture AperturesISRAel JuniorNo ratings yet

- CourseICCE1992 BurcharthADocument35 pagesCourseICCE1992 BurcharthAAlexandru PavelNo ratings yet

- Balancing IN MAPPINGDocument34 pagesBalancing IN MAPPINGGEOLOGIST_MTA100% (1)

- CHAPTER THREE Fractures - JointDocument27 pagesCHAPTER THREE Fractures - Jointأمجد هاتف منفي جفالNo ratings yet

- Einstein, H.H., Veneziano, D., Baecher, G.B. and Oreilly, K.J., 1983, The Effect of Discontinuity Persistence On Rock Slope StabilityDocument10 pagesEinstein, H.H., Veneziano, D., Baecher, G.B. and Oreilly, K.J., 1983, The Effect of Discontinuity Persistence On Rock Slope StabilityAzeNo ratings yet

- Rock Mass ClassificationDocument59 pagesRock Mass ClassificationUsmanAshrafNo ratings yet

- Fault and FoldDocument42 pagesFault and FoldUtkarsh Sharma100% (1)

- Types of Slope FailureDocument14 pagesTypes of Slope FailureJpver1000No ratings yet

- Ductile deformation finite strain analysisDocument27 pagesDuctile deformation finite strain analysisJorgeBarriosMurielNo ratings yet

- Rock Slope Stability Analysis 3Document13 pagesRock Slope Stability Analysis 3Zafira EdinaNo ratings yet

- Tunnels - 2015-04-10 - Toth - 2-Temporary Support Design Based On RMR and Q PDFDocument128 pagesTunnels - 2015-04-10 - Toth - 2-Temporary Support Design Based On RMR and Q PDFZhi ChinNo ratings yet

- Ranalli 1974Document8 pagesRanalli 1974Som DevNo ratings yet

- 1.1-Review of A New Shear Strength Criterion For Rock Joints PDFDocument46 pages1.1-Review of A New Shear Strength Criterion For Rock Joints PDFSANTIAGO NAVIA VÁSQUEZNo ratings yet

- Capitol7 Stike Slip FaultsDocument15 pagesCapitol7 Stike Slip FaultsgabrielamariNo ratings yet

- JointsDocument9 pagesJointsUtkarsh SharmaNo ratings yet

- Mass Angle of Repose of Open-Graded Rock Riprap: Technical NoteDocument8 pagesMass Angle of Repose of Open-Graded Rock Riprap: Technical NoteCarlos Ediver Arias RestrepoNo ratings yet

- Strike: The Direction (Compass Bearing) of A Line Formed by The Intersection of A RockDocument16 pagesStrike: The Direction (Compass Bearing) of A Line Formed by The Intersection of A RockGanguli Tutor RajNo ratings yet

- Seg-2005-0364 PDFDocument5 pagesSeg-2005-0364 PDFleonelz6aNo ratings yet

- Angulo de Dilatancia de RocasDocument4 pagesAngulo de Dilatancia de RocasVerónica Longo FazaNo ratings yet

- Particle AnalysisDocument93 pagesParticle AnalysisBatepola BacNo ratings yet

- Rock mass classification systemDocument5 pagesRock mass classification systemAkash BhartiNo ratings yet

- Knowledge of In-situ Stress for Drilling Horizontal WellsDocument5 pagesKnowledge of In-situ Stress for Drilling Horizontal WellsianherzogNo ratings yet

- Planes of Weakness in Rocks, Rock Frctures and Fractured RockDocument10 pagesPlanes of Weakness in Rocks, Rock Frctures and Fractured Rockفردوس سليمانNo ratings yet

- Is 13365 Part4 DraftDocument15 pagesIs 13365 Part4 DraftPalak Shivhare0% (1)

- Dislocations and Strengthening Mechanisms: 7 - 1 I N T R o D U C T I o NDocument16 pagesDislocations and Strengthening Mechanisms: 7 - 1 I N T R o D U C T I o NstevangracianoNo ratings yet

- Characterizing Rock Joint Geometry with Joint System ModelsDocument31 pagesCharacterizing Rock Joint Geometry with Joint System ModelsrNo ratings yet

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Fault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionFrom EverandFault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionNo ratings yet

- Fault and Joint Development: In Brittle and Semi-Brittle RockFrom EverandFault and Joint Development: In Brittle and Semi-Brittle RockNo ratings yet

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- Páginas Extraídas Sin TítuloDocument1 pagePáginas Extraídas Sin TítuloJordi EscorciaNo ratings yet

- IRA Handbook Guerilla WarfareDocument33 pagesIRA Handbook Guerilla WarfareCommissar Coprobo0% (1)

- Páginas Extraídas Sin TítuloDocument1 pagePáginas Extraídas Sin TítuloJordi EscorciaNo ratings yet

- Páginas Extraídas Sin TítuloDocument1 pagePáginas Extraídas Sin TítuloJordi EscorciaNo ratings yet

- French Infantry of the War of the Spanish SuccessionDocument16 pagesFrench Infantry of the War of the Spanish Successionjunkyardbcn100% (1)

- Applied HydrogeologyDocument370 pagesApplied HydrogeologyJordi Escorcia50% (6)

- Logo Kinross AntiqueDocument1 pageLogo Kinross AntiqueJordi EscorciaNo ratings yet

- Páginas Extraídas Sin TítuloDocument1 pagePáginas Extraídas Sin TítuloJordi EscorciaNo ratings yet

- Advanced PhotogeologyDocument133 pagesAdvanced PhotogeologyJordi EscorciaNo ratings yet

- Committee On USGS Water Resources Research, Water Science and Technology Board, National Research Co Investigating Groundwater Systems On Regional and National Scales 2000Document158 pagesCommittee On USGS Water Resources Research, Water Science and Technology Board, National Research Co Investigating Groundwater Systems On Regional and National Scales 2000Jordi EscorciaNo ratings yet

- Weight Training For The Martial Artist Geoff ThompsonDocument96 pagesWeight Training For The Martial Artist Geoff Thompsonkmivanov100% (1)

- NGWA 2004mcellhiney PDFDocument44 pagesNGWA 2004mcellhiney PDFJordi EscorciaNo ratings yet

- Hydrological Processes Volume 13 Issue 3 1999 (Doi 10.1002/ (Sici) 1099-1085 (19990228) 13:3-255::aid-Hyp737-3.0.Co 2-Y) D. A. Sear P. D. Armitage F. H. Dawson - Groundwater Dominated RiversDocument22 pagesHydrological Processes Volume 13 Issue 3 1999 (Doi 10.1002/ (Sici) 1099-1085 (19990228) 13:3-255::aid-Hyp737-3.0.Co 2-Y) D. A. Sear P. D. Armitage F. H. Dawson - Groundwater Dominated RiversJordi EscorciaNo ratings yet

- The Wreck of CataloniaDocument297 pagesThe Wreck of CataloniaJordi EscorciaNo ratings yet

- Osprey Publishing Series Warrior 115Document2 pagesOsprey Publishing Series Warrior 115Jordi EscorciaNo ratings yet

- Iswscoop 18 PDFDocument68 pagesIswscoop 18 PDFJordi EscorciaNo ratings yet

- Renard Philippe - Understanding Diagnostic Plots For Well-Test 20090909Document12 pagesRenard Philippe - Understanding Diagnostic Plots For Well-Test 20090909Suseendaran BabuNo ratings yet

- Geophysical Methods Guide to Groundwater ExplorationDocument8 pagesGeophysical Methods Guide to Groundwater ExplorationGhassen LaouiniNo ratings yet

- WWM CONSTRUCTION REPORTDocument3 pagesWWM CONSTRUCTION REPORTJordi EscorciaNo ratings yet

- Airlift Testing in Exploration Coreholes RLH Final PDFDocument6 pagesAirlift Testing in Exploration Coreholes RLH Final PDFJordi EscorciaNo ratings yet

- Fractured Rock Aquifers in Broken Hill RegionDocument9 pagesFractured Rock Aquifers in Broken Hill RegionJordi EscorciaNo ratings yet

- Tracing Groundwater Evvolution Sr-Geology 1994Document4 pagesTracing Groundwater Evvolution Sr-Geology 1994Jordi EscorciaNo ratings yet

- BioFiltro Cleantech OpenDocument2 pagesBioFiltro Cleantech OpenJordi EscorciaNo ratings yet