Professional Documents

Culture Documents

Etching

Uploaded by

proxyguyscribdOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Etching

Uploaded by

proxyguyscribdCopyright:

Available Formats

http://mordent.

com/etch-howto/

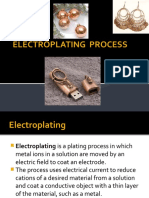

To Electrolytically Etch in Copper, Brass, Steel, Nickel Silver or Silver

Introduction

Electrolytic etching uses electricity, and a solution usually based on the type of metal you want to etch. You attach the positive side of the current to your piece, and the negative side to a piece of the same metal. When the electricity flows, it causes metal from your piece to flow through the solution toward the metal on the negative side. The more metal in the solution, the faster your piece will etch. I originally learned the process of electrolytic etching back in early 2009 in a class taught by David S. Dowling, who does some amazing work. Since then I have etched numerous pieces, including bookmarks, bracelets, rings and other jewelry. Through experience and trial and error, Ive come up with a detailed process that gives me a perfect etch almost every time. Electrolytic etching uses mostly safe chemicals, and electricity. You dont really need respirators or fancy gear to do this process, although it is a good idea to wear rubber gloves, eye protection, and protect your clothing. If you want more info on the chemicals used, you can search the web for the MSDS sheets on the chemicals listed below. I am by no means an expert etcher. I just want to pass on the tips and tricks Ive learned since I started etching, to hopefully make someone elses etching go smoother. Note: You can click almost any picture to see a larger version of it.

Equipment Youll Need

Etching Copper, Brass, or Nickel Silver

Copper Sulfate (or Root Kill, which you can get at a garden or hardware store)

A copper pipe or sheet or any piece of copper that is somewhat large

copper, brass, or nickel silver sheet

Etching Steel

Iron Sulfate. You can sometimes get this from a hardware store on special order (I got mine from Ace Hardware)

A steel bar or other piece of steel steel sheet

Etching Silver

Cupric Nitrate for sterling silver you can get this online from various chemical companies. You can also use silver nitrate for fine and sterling silver but I have never tried it. And, you can also use phosphoric acid for both sterling and fine silver, but unfortunately it leaves behind a pitted surface where it etches, so I wont be talking further about this chemical here. A copper pipe, etc Silver sheet

Items For All Metals

A plastic bucket (not metal!) A car battery charger preferably one that outputs 12 volts at 12 amps; I use the Schumacher SE-1275A that I got from Home Depot for around $70

Heavy gauge (12g) copper wire or some copper sheet bent to form as a holder; you can get the copper wire from the hardware store in the electrical section. An iron

A roller (hard or soft) you can get these at a craft store; you will be pushing on this pretty hard so try to get one that has a metal frame, not a plastic one

An old spoon A computer to create your design

A laser printer to print out your design (Note that Brother brand laser printers use a different kind of toner that does not work for this process) Some black and white line art designs see below Glossy laser or copier paper (the cheap kind). 3M Green Scotch scratchy sponge you need the green kind that will leave scratches on metal (or a satin finish) to really clean the metal

Dish soap I have found that Dawn works best to remove oils from the metal. If you happen to have some Penny bright copper cleaner you can use that too.

A brass brush (you can get it at a hardware store or preferably use a jewelers brass brush). A hard surface to iron on (not an ironing board, but something else, like a piece of wood or wooden desktop surface on which you can press down really hard) Liver of sulfur, selenium toner, or spray paint for metal surfaces you can get liver of sulfur from Rio Grande, and you can usually get selenium toner from a good photography shop (no, not CVS); or you can use any flat spray enamel for metal that you can get from any hardware store (do not use gloss as it is really difficult to remove from the raised areas)

Lacquer spray for metal (if you are doing copper or brass) this is used to protect your work when its done

A couple of bench blocks or other smooth surfaced blocks A dish for soaking (that you will never use to eat off again) 1200 or 2000 grit sandpaper. This will be used to remove patina from raised areas without removing the etched design.

Preparing the solution

For copper, brass, nickel silver and steel, fill the bucket with water leaving plenty of space at the top so it doesnt slosh around and spill when you have to move it later. Add the chemical (copper sulfate or iron sulfate) to the water somewhere around a cup at a time (you can just eyeball it). Stir the solution until the chemical is dissolved. Keep adding the chemical and dissolving it until it will not dissolve any more. This creates a saturated solution. You can keep the solution pretty much forever. As you etch, more copper or iron will end up in the solution, which is great, because that is what causes the copper/iron to move off the metal youre etching across to the pipe or piece of metal on the other side. You may need to filter out the crud at the bottom every once in awhile. Brass and nickel silver are made of mostly copper, thats why copper sulfate works for them. You can reuse the same copper sulfate bucket for all of the copper-based metals (copper, brass, and nickel silver). For silver, pour, very slowly, about a cup of cupric nitrate into a gallon or two of water and stir. Try not to raise any dust from the chemical while you are pouring. Make sure you have sufficient breathing protection for this (dust mask etc) because the dust is dangerous to your health. Please read the MSDS on this chemical for further information. I keep three prepared buckets of chemicals that I reuse over and over again. One with copper sulfate in it, one with iron sulfate, and the last with cupric nitrate (all labeled of course).

The size of the bucket depends on the size/number of the pieces you expect to work on. You dont really need a huge bucket unless you are doing huge pieces. The piece just needs to be totally immersed. You can even use a flat dish instead if you have a long piece. The less space between the piece and the negative side, the faster your etch will be. Unfortunately, you probably cant do this for silver as it etches VERY quickly.

When youre done etching, cover the bucket and put it somewhere it wont get knocked over. For the cupric nitrate, pour the solution slowly into another bucket until all you have left at the bottom is some white goop. Throw that goop out (in the toilet or outside?) and pour the liquid back into your original bucket. When you remove the pipe (or other piece) it will have a bunch of crinkly bits on it. Its ok, its just copper (or whatever metal you etched):

I have also heard that you can use plain salt for your etching solution, but Ive only tried it once, on silver, and it didnt do a deep enough etch and took 3 hours; I may not have done it properly.

The Design

Choose a black and white line art design, either from a clip art book (Dover has some excellent ones), or one that you draw yourself and scan (you must scan it as black and white line art or convert it after scanning). You can use photographs or grayscale art but you will need to convert it to black and white. Converting to black and white is a whole topic on its own that isnt covered here. The great thing about using this etching process is that you can use designs that are either coarse or have very fine detail (youll see examples later). You need to determine what areas of your design you want to be raised and what areas you want to be etched. The etched areas will end up dark (colored by the liver of sulfur or paint) and the raised parts will end up the color of the metal. Here are two examples: As you can see in the below example, the leaves are black (toner) and the background of the leaves is white. When this is etched, the leaves will be the parts that are not etched away, i.e. they will be the color of the metal. The white areas will be etched and end up colored blackish by the liver of sulfur. (In this example, the liver of sulfur was sanded away from most of the background too, leaving just a shadow around the leaves).

As you can see in the below example, the lines of the drawing are white and the background is black. When this is etched, the lines will be etched and will end up blackened by the liver of sulfur, whereas the background will be raised and the color of the metal.

Once you determine which parts you want to etch away and which you want to leave raised, you will need to make sure the parts you want etched away are white and the parts you want to leave raised are black. You may need to invert your image to achieve this. Its sometimes difficult to determine in your head how you want to do this. I have no sort of rules to guide you unfortunately. After choosing your design, get it to the right size. Make sure you save it as 300dpi or higher if it has fine detail. To save on paper costs, you can fit as many designs as youd like to etch now or later on one sheet of paper. I highly recommend that you put at least two copies of each design on the page because if the design doesnt transfer properly you will have to go and print it out again. Believe me, this will happen more than you would like it to!

Prepare the metal

Measure your design to determine the size of the piece of metal sheet youll need to cut out. If your design does not have a good border, I highly recommend cutting the metal bigger than the design as if you dont, the toner may not stick properly (youll see examples of this common problem later in the Troubleshooting section). Once you determine the size, use a square/ruler to measure and cut your sheet metal. I dont recommend that you file or sand your edges yet as the etch may make them rough again; you should do that after the etch. As you can see in this picture, the edges/corners are somewhat rough and thats ok.

Once youve cut your metal, you need to make sure its completely flat. If it isnt, you can use two steel blocks and a mallet to flatten it. Place part of the metal in between the steel blocks, hold the upper block in place and hit it with the mallet (watch out for your fingers). Do this all the way down the metal. I find that if you offset the blocks and hit away from the edge where it meets the metal the metal will not get marred by the blocks (unfortunately, my mallet in this picture is a bad example, and should be hitting the block more to the right and not so near the left edge of the block, luckily for me I was just posing the hammer for this picture and not really hitting the block).

Once the metal is flat, you need to clean it. Use some dish detergent and the green scratchy sponge to clean the metal across the width of it, and then along the length of it. Make sure you do not touch the metal with your fingers as they will leave oils on the metal. The reason to clean in two directions is to make sure you remove all the oils and dirt that may be on the metal. Doing it along the length last leaves the scratchy sort of satin finish going along the length of it (youll see details of this in the following picture). This satin finish helps the toner stick better. When I originally learned etching, we used acetone next to further clean any oils off the metal, but Ive found this usually isnt necessary if you clean it well enough with the green sponge and dont touch it again. Thoroughly dry off the metal with a paper towel or old dish towel (again making sure again not to touch it). Cut your design out of the paper, place it toner side down on the metal and tape it in place making sure its flat. If you dont tape it, it will slide. Put your piece on the ironing surface. You can see the vertical scratchy satin finish in the picture on the left here.

Transferring the design onto the metal

Turn on your iron to the highest setting. Lay the iron gently on the piece vertically without pushing on it. If you push down the paper may slide. Leave the iron there for a couple minutes.

Take the iron off the piece. Use the roller, pressing firmly, roll back and forth along the piece. This will start to get the toner sticking to the metal. Next, take an old nail or chopstick or something that wont burn (i.e. not your finger), and hold down the paper and metal with it while you rub the paper really hard with an old spoon, all over the piece. This will force the toner to stick. TBD Put pictures of spoon rubbing here You will need to heat and spoon the piece at least three times (you dont need to use the roller again). If your piece is large, you will need to heat and spoon the different areas separately, at least twice per area. When its done, you should actually see most of the black parts of the design right through the back of the paper.

Note that if your design has large white spots (where there is no toner), those parts of the paper may form a bubble. Thats ok! If a bubble forms on a part of the piece that has toner, thats not ok! This will be discussed more in the Troubleshooting section. By now the toner should hopefully all be transferred to the metal. Turn off the iron. Pick up the piece with tongs or tweezers (dont touch it, it will be hot!) and immediately put it in cold water in a dish to soak for a few minutes. Make sure the entire piece is below the water. The water must be cold in order for the toner to cure onto the metal.

After a couple minutes the paper should be mostly wet. Again, there may be bubbles if your design has large spaces of no toner (and thats ok). Take the piece out of the water and push your thumb in a downward motion away from you to start rolling/peeling the paper away. The paper should peel away pretty easily. You can re-soak the piece as many times as you need, to to get all the paper off. Eventually all that should be left is black toner, and the metal, and maybe some white spots on top of the toner (but there should not be any white spots on the metal).

If you end up removing some of the toner while you are removing the paper, dont worry too much, it may be fixable. You can usually correct that with a paint pen (make sure the painted areas are completely dry before continuing) or masking tape depending on how small the problem is. However, sometimes you just end up taking off some detailed part that you cant easily fix. Dont even try. It takes very little time to redo the toner transfer. Just start over. Youd rather have a good etch than a sloppy one. This will be explained further in the

Troubleshooting section. Ive found that using a Sharpie does not work well at all and comes off in the etch solution.

Etching the piece

Attach the wire to the back of the metal with masking tape. Ive found that less liquid leaks into the tape on the back if you bend the wire upward, so its perpendicular to the metal, ripping the tape at the point where the wire needs to come up, then tape above where the wire originally was, and push it back down and tape again over it (sort of creating a pocket of tape containing the bent part of the wire and where there is only a small hole where the wire is coming out, i.e. you get 2-3 layers of tape around the wire.

Tape the entire back of the piece. This should protect it from being etched. If your piece has a border like this one did and there is some metal showing that was supposed to be covered with toner but got scratched off (see the picture at the end of the last section), you can also tape that off, like below. Depending on the design, you may want to do this anyway to protect the edges.

Make sure the car battery charger is NOT plugged in. Hold the copper pipe (or piece of steel) in the solution on the side of the bucket. Attach the black lead from the car battery charger to the copper pipe and the side of the bucket (if it will fit). This will hold the pipe in place in the bucket, if it doesnt you can use a clamp. Attach the red lead from the car battery charger to the wire coming from the piece. Bend the wire so you can place the piece in the solution and have the wire hang off the side with the red lead. Place the piece in the bucket so that all sides of the piece are the same distance from the pipe, if you can. If its lopsided, the parts farthest away from the pipe will etch less than the parts closest to the pipe and youll have an uneven etch. You can actually etch multiple pieces at once (up to a certain point; i.e. you dont want to etch many huge pieces because there wont be enough juice from the charger, however you can do a bunch of small pieces). Just make sure none of the pieces is in front of the other. They can be on top of each other or side by side. Make sure the entire piece is in the solution and none of it is sticking up out of it.

If you are etching copper, brass, nickel silver, or steel, plug in the charger and go get some tea and relax, or go work on something else, and let the piece etch for about 35-45 minutes (or about 25-30 for nickel silver). Check back every so often to make sure the tape hasnt peeled off and that everything is still connected (sometimes the wire will get eaten away). This will give you a really nice deep etch. If you leave it in less, it may not be deep enough to hold the color you apply later after sanding. You can experiment with the length of time you leave the item in, it all depends on what youre trying to accomplish. You can get a really shallow etch in only minutes and you can get a really deep etch, e.g. halfway through a piece of 20 gauge copper sheet, in about 2 1/2 hours. There will be a lot of examples later on. If youre etching silver, you will need some kind of timer. It usually takes only 4-5 minutes to get a good deep etch in a piece of 20g or thinner silver (the same etch you get for 45 minutes in copper). Ive had a 20g piece eat all the way through in 10 minutes. You have to keep an eye on it because its very very quick. If you are unsure of how deep an etch you want, you can try to check by unplugging the red lead, taking the piece out of the solution, and feeling the etch. However, disturbing the piece can cause the tape to come off (sometimes it does anyway for a long etch even if you dont touch it), and as Ive found with steel and brass, the toner will come off if you touch it at all. I

tend to just leave it alone and take out only at the end. If you have to disturb the piece you will most likely need to completely dry and re-tape the entire piece, including the wire. When the etch is done, remove the piece from the solution. It will have a sort of sludge on it that looks something like this:

Removing the toner

Rinse off the piece and remove the wire and tape. Using a brass brush, remove the toner, brushing very firmly. It will work really quickly and wont take off any of the metal from the design.

Some people say that acetone will get the toner off, however, I have never had any luck with it, I still have to scrub just as hard to remove the toner. Ive also tried using paint remover but thats pretty harsh stuff and I dont recommend it (and its hard to clean it off after; you get a residue left behind that makes it harder to color the piece). Once you get all the toner off, youre ready to clean up (file and sand) and color the piece.

Cleaning up the metal, etc.

Do any cleanup, i.e. filing, sanding, polishing, of the piece that you need to do (leave the etched side alone). Now is also the time to do any further fabrication you need to do, e.g. dome it, solder it to something, etc.

Coloring

Clean the metal thoroughly with dish soap and a toothbrush. If you have liver of sulfur, you can use it on copper or silver. Ive found that it doesnt work well on brass or nickel silver. It doesnt work at all on steel. You can also use selenium toner on anything but steel (as far as I know). If you would rather just use paint, I recommend a flat spray enamel. Spray it on

sparingly and let it dry thoroughly before continuing to the color removal section. It may need more than one coat to get all the areas covered; multiple coats are fine as long as you dont spray it on too thick. If you use gloss paint it will be too goopy to remove afterward. There is a ton of info on the web about using liver of sulfur, so it wont be covered here. However, I do have one tip. Liver of sulfur will last FOREVER if you fill the container you mix it in completely with solution and leave no room for air, and then cover it. Ive had a batch of the stuff in a jar for about 6 months now. I dont know too many other web sites that mention selenium toner. Selenium toner usually comes in a liter container with tiny a little opening. I usually pour some into a jar and cover it tightly. It smells really bad, like ammonia, and you should only use it in a well ventilated place and wear protective gloves. To use selenium toner, briefly dip the piece in the toner. It should blacken pretty quickly. Dont let it sit long or it will end up flaking off and you will have no coloring at all. You can also paint the selenium toner onto the metal with a small paint brush. When doing so, use the paint brush to rub it in (or smoosh it in) as you go.

Removing the color from the raised parts

Whatever colorant/patina you used, the next step is to remove it from the raised parts so only the etched parts are dark and the rest is bare metal. I like to use a sanding stick for this. Just take an old paint stick and wrap sandpaper around it. Or you can use a sanding block. The idea is to have a flat surfaced sander so as to not remove the color from the deep, etched spaces. I.e. the flat surface moves over the raised parts of the piece and doesnt touch the etched parts. If you sand it by hand, the unevenness of your skin pressure would allow the sandpaper to get into the etched parts and remove the color there (which is what we dont want). I like to start with 1200 grit sandpaper because it removes less metal. The less metal you remove the better, because when you sand you are removing some of the metal from the raised parts, making those get closer and closer to the level of the etch. 1200 grit will remove pretty much all of the color you need to remove, any higher grit except maybe 2000 doesnt seem to work well, and lesser grits remove too much metal for my liking. Using your 1200 grit sanding stick or block, sand vertically, straight up and down the length of the piece to remove the color from the raised parts. You want to sand in only one direction. There may be some spots that are uneven (it happens all the time). Dont sand too much, just get as much color as you can off. When youve done that, you can use a small piece of the same grit sandpaper with your thumb to get the sections you couldnt reach with the stick. You have to be very careful not to remove the color from any large etched areas when sanding by hand.

Once you get the color removed from the front, you can do the same thing on the back. I like to leave some color on the back:

Heres the final coloring on the front:

From this point, you can either sand with higher grit sanding sticks/blocks or buff it to get a higher shine. You always have to be careful not to remove the color from the etched places (unless you want that kind of look). If you remove too much color you can probably re-color it once, but after that, repeated sanding even with 1200 grit may end up removing too much metal, so be careful (this has happened to me, see the Troubleshooting section). Using a polishing or buffing wheel (either a big one, or even one in a flexshaft) will most likely remove all the color so you may need to find another way to buff/polish the piece afterward.

Protecting the piece

If you want, you can spray lacquer the piece to protect it. I usually do this when the piece is made of copper or brass and is going to be worn, like a bracelet or ring, because copper and brass can discolor the skin (usually turning it green). Also, if you dont lacquer the piece, it can get smudged by peoples fingerprints. I usually spray lacquer the piece once lightly, let it dry for an hour and spray lacquer it a second time. For jewelry, I like to do three coats. Let it dry for at least a day before handling it or you may end up getting fingerprints permanently embedded on the piece. Make sure you lacquer only in a well ventilated area, preferably outside.

Examples

Here are some examples of things you can do with etching. Kitchen fridge magnets Bracelet (brass) Wall plaque (brass) Another bookmark

Earrings

Pendants

Keychain (steel)

Ring (silver)

Another bracelet this is an example of a deep 3 hour etch. The part I etched was the inside channel of the bracelet. Its 20 gauge copper and it etched about halfway through. The moons and suns were punched, not etched.

When I etch a piece of jewelry, I like to also etch my signature mark (or stamp) onto the back of it (I have a whole sheet of these made up just for this purpose):

Ring I made this by etching the runes onto one piece of copper and separating it afterward with shears. At the same time, I etched alchemy symbols onto a piece of brass. At the end I soldered them all together.

Another bracelet this one was made by etching the copper band first for 3 hours to make the channel in the middle that holds the brass part (as I did with the greenish colored piece above). Then I etched the words into the copper and the design into the brass, both together at the same time, for 45 minutes. Once the etch was done I riveted the brass into the channel on the copper band and shaped it.

Another ring this was made in the same manner as the above bracelet except the inner band was soldered instead of riveted.

A pendant and an etched bezel (sterling silver) this pendant has an etched border on the sheet backing around the top quartz stone and an etched bezel (26 gauge) around the piece of amber. Its my favorite bezel! I etched the bezel with cupric nitrate and I think the pendant part with phosphoric acid. You can see how smooth an etch you get with cupric nitrate compared to phosphoric acid.

Another bracelet (nickel silver) this was made with two separate patterns, one for the area surrounding the amethyst and one for the bracelet band.

A bead I etched two circular patterns onto a small sheet of brass and then cut them out and domed them and soldered them together to make this bead.

A book cover I etched two huge sheets of copper for the base plates, and one thin one for the spine base. I then etched three sheets of brass, one containing the 12 square elements of the right side of the piece, another containing all the elements of the left side of the piece, and another containing the recangular inside of the right side and the spine. Because of the size of

the pieces I had to do multiple etches separately, however, I was able to combine a lot of the brass bits together on just a few pieces of sheet metal.

An enameled pin This is an example of a technique of enameling called Champlev. You basically do a very deep etch to make cells that you can then put enamel into. The silver backing was also etched.

Another ring (sterling silver) the band on this ring was etched, and I etched and then domed a circular pattern for the cup part and set a stone in a tube in the middle of the cup.

Another ring (sterling silver) this one was etched using phosphoric acid. You can see the pitted texture I mentioned. This is why I no longer use that chemical and now use cupric nitrate.

As you can see, you can do some pretty complex things with etched metal.

Troubleshooting

This section contains some common problems you may run into and how to deal with them.

Over-sanding when removing the color

If you make a mistake when removing the color and have to re-color and sand more than once, or you use too coarse a grit or sand too heavily, you can remove too much of the raised area, making it blend in with the etched parts. Note the background areas in the picture on the left where the color was sanded away around the head of the monster. This is caused because the raised area is now too close to the level of the etch. You can almost see that the etch is no longer deep enough. In the right picture, you can see that there were etched areas that were just too large and the sanding stick got into those areas anyway, even though I still wanted them colored (note the moon and the wreath in her hand). This can also happen if you arent careful enough when you sand these areas by hand.

Too long of an etch

You can see that clearly in this picture. Note the roughness of the edges. You can see it also in

these pictures along the edge of the inside channel of the left picture (not the jagged bit on the right but on the top and bottom edges of the channel) and on the copper where the brass meets it in the right picture:

Youll also note that the end of the piece in the left picture is totally ragged and eaten away. This is from not protecting it with tape during the 3 hour etch I gave it. Luckily for me, I cut this piece an extra centimeter long on purpose so I could later size it for someone as a ring (I knew I would be cutting the ragged part off anyway so I didnt bother protecting it). Also, note that the middle channel in the left picture is what a 3 hour etch looks like, you probably wont be able to clean this up, so you probably will only ever do that deep an etch if youre covering it up with something, like I did in the right picture (covering it with brass). You can actually etch all the way through a piece. Ive never tried this so I dont know what it looks like.

Dots and nicks

As youll notice in these two pictures, there are black dots and nicks over entire areas of the piece. These are caused by toner not being transferred properly. If you dont heat up portions

of the piece long enough and/or dont give them a good rubbing with the spoon, this can happen. A lot of times you can see where this will happen once youve removed the paper backing. Youll see holes in the black toner. You can usually fix these before you etch by using a paint pen. Make sure the paint dries completely (for at least an hour or quicker if you use a heat lamp) before etching or it will come off in the etch. I have found that Sharpies do not work at all and come off in the etch bath. You can also use tape to mask off larger areas. Some people actually like the dotted look; it gives the piece an aged kind of character. A colleague of mine likes to use a special green plastic toner transfer paper to deal with these holes; the green plastic, when heat transfered to the metal, completely covers the toner areas (including the dots); Ive never tried this and dont know what it would do to highly detailed areas.

Masking gone wrong

If you dont mask off your piece properly with tape, or there are openings in the tape, you will get jagged areas in your piece like the ones shown in the pictures above. This is due to the area at the edges of the tape being etched away. This tends to happen a lot on the backs of pieces where the wire touches. The etch solution tends to get inside the tape and causes parts of the area to get eaten away. Sometimes no matter how well you mask it it will still leak in. You just have to try to be as careful as you can when attaching the wire to not leave any holes. Luckily this seems to only happen on the backs of pieces. You can sand it away if you want. Another common problem is if you disturb the piece while it is etching, the tape can come loose and the solution will leak inside and cause this same problem. If you have to disturb the piece you will need to dry and re-tape the entire piece, including the wire. Ive heard that at least one way around this problem is to solder the wire to your piece and then use some kind of spray on rubber like coating on the back of the piece. Ive never tried the rubber like spray method so I cant tell you much about it. However, you cant solder a wire on after you transfer the image because it will melt off the toner. And doing it before you transfer your image makes it hard to keep it flat to iron/smoosh with the spoon. If you know anything about that please let me know!

The toner came off!

Sometimes, no matter how careful you are, the toner can come off. If its in an area like the very upper left corner (the border) of the left picture, you can either mask it with tape or use a paint pen. Unfortunately though, as you can see in the inner part of the left picture and most of the right picture, the toner came off in a very bad place. There really is no fix for this. You really dont want to try to use a paint pen to re-draw these areas by hand. Its not worth it. This is why I recommended that you always print at least two copies of your design. When this happens, its time to get out the brass brush, brush off all the toner, clean off the metal, and iron the design on again (i.e. repeat the process). At least you can still use the same metal. The number one reason for this problem happening is not heating up the metal long enough with the iron and/or not using the spoon enough to make sure the entire piece gets covered. In these two cases, I was in a hurry and didnt heat up the metal enough. I went ahead with the left etch anyway and here is the result:

See that big black splotch there? Its pretty ugly. The 2nd biggest reason this happens is from pushing too hard with your finger on the metal when removing the paper backing. You really have to try to push only very lightly to get the paper backing off the metal. Another reason this can happen is bumps in your metal (your metal isnt flat). If youve tried ironing your design on more than once and this keeps happening, thats usually the cause. You can either try to reflatten the metal again, or get a new piece of metal. Ive had this happen numerous times.

Ugly gashes, uneven edges, etc

You can see in the first two pictures that the edges are all jagged, and in all four pictures there are gashes and nicks all over. This was caused by disturbing the piece while it was etching and from using a Sharpie (before I discovered the paint pen) to fix areas that werent completely covered with toner. When I went to check on the piece in the middle of the etch, some of the toner and all of the Sharpie ink came off and I didnt know. So when the etch continued, it etched parts that were supposed to be covered with toner but no longer were! Ive found that brass and steel are notorious for this problem.

Not enough of a border, the toner doesnt stick

If your design does not have enough of a border, the toner will not stick. You can see in the left picture how the entire bottom of the words on the bottom of the piece are missing, and how parts of the runes on the bottom right of the right picture are missing. This happened because the design was small and didnt have a good border, i.e. it was all letters with very little black space around them (maybe 2 pixels at most), not only that but the metal was the same size as the design. If your design has a border without enough black space in it you need to cut your metal larger than the design and trim that off after you etch. In these two cases, the toner didnt have enough room to stick to something and came off when I was scrubbing the white off. I made a second set of these pieces later on, and even though my design still only had about a 2 pixel black border, I cut the metal about 1/16 to 1/8 larger than the design. That time, the toner stayed on and I got a perfect etch as you can somewhat see here in the unfinished/colored pieces:

I probably should have also added some more border around the design (you can see it is somewhat too short in the rightmost picture).

An alternative quick light etch

For copper, brass, nickel silver, and steel, if you dont need a deep etch and dont really expect to color your piece, i.e. you just want to mark it in some way, you can get a very light etch by the following procedure: Take a cloth and soak it in the etching solution. Wring it out but leave it somewhat dripping. Put your piece with the toner on it in a dish and attach the positive (red) lead to it. Put the drenched cloth on top. Turn on your charger and push the negative lead into the cloth. In about a minute you will have a light etch that you can actually feel.

Copper Plating A nice extra

You can copper plate a piece of steel very simply by taking a brush or cloth, dipping it into the copper sulfate solution and brushing it onto your steel piece. This works because there is a small charge between the steel and the solution and that small charge electroplates the steel with the copper from the solution. Its basically the reverse of electrolytic etching. Instead of copper getting eaten away, its getting deposited.

References

David S. Dowling teaches electrolytic etching in Boston through the School of the MFA, the Stonybrook Fine Arts School, and possibly other art schools. Thanks to John Flynn for his article on etching silver with phosphoric acid.

If you have any questions, please feel free to contact me and Ill do what I can to help you. You can reach me via e-mail at etch10@mordent.com.

http://jewelrymakingjournal.com/acid-etching-metal-jewelry-part-1/

Acid Etching Metal Jewelry, Part 1

by Virginia Vivier. (Esprit Mystique Jewelry)

Etched brass design by Virginia Vivier

Acid Etching Brass, Copper and Silver Jewelry

Part 1: Design Transfer What is your favorite design? Wish you could transform it into a series of etched pendants? If drawing multiple designs by hand would take hours, here is speedy way to transfer complex designs to metal for acid etching. First, scale the design to the exact size you need. You can do this on your computer, or you can go to any photocopy store to reduce (or increase) the image size. Make sure you have a flat design with strong black and white contrast areas. (Shaded, or gray areas, wont work.) The design must be black and white:

Above is an example of a design that can be used as a positive or negative image. (You could reverse the design via the invert setting on your computer in Paint.net or PhotoShop graphic application.) While you are in the Copy Store, make a few copies of your designs on a copy machine that uses dry toner. Make each copy as dark (bold) as you can. The layer of dry toner that is transferred from the paper copy to the metal acts as a resist to the acid. Below is an example of brass that was etched using ferric chloride:

In acid etching, the black design areas act as a resist to the acid, the white design areas will be etched deeper than the black design areas. Generally, the etched (white) part of the design can be thought of as the background. If your design has any letters or numbers, make sure you make a Mirror image so the words will read right when you transfer them to the metal. Here is an example of a name plate for a key ring. In the design below,Nikki is a mirror image:

that will read correctly after it is transferred to metal:

If you have a copy machine at home that has a dry toner cartridge, it should work fine. But do NOT use an ink jet printer. Ink jet copies WONT transfer. I have an old Canon K140 copy machine that uses dry toner. You should test other dry toner copiers before you buy one to make sure the toner transfers well. The best transfer paper is free. Save your old magazines and use them as transfer paper:

(You can also use Sunday newspaper magazine section, but if the sheets are too thin they may get stuck in the copier.) The heavy paper from a fancy magazine works best. Regular copy paper does NOT work. You can gang your designs on one sheet of paper to transfer multiple images on a single sheet of metal:

I know this sounds strange, but trust me, only the dry toner from your paper copy will transfer to the metal. The print on the magazine page wont transfer. Think of the magazine paper as a carrier for the dry toner. And, isnt it great that we can recycle the magazine paper while we are creating something new and beautiful? Set your designs aside and prepare the metal (bronze, brass, copper, or silver) for transfer. The metal needs to be spotlessly clean. Bar Keepers Friend is a powdered cleanser (with oxalic acid) that works well to clean off any oil from fingerprints and tarnish on the metal. It also roughens the surface enough to help grab the dry toner. The most important step is to make sure your metal is meticulously clean and the water sheets off evenly, without any spots. If your metal has even the tiniest bit of dirt or oil, the toner wont adhere to the metal. Next, find a flat work area near an electric outlet where you can plug in an iron and press the dry toner paper onto the metal. Use your regular iron in dry setting (not steam), and turn it up as high as it will go (usually the Cotton setting).

Press down on the iron to make sure the paper design makes good contact with the metal. (If you wish, you can place a piece of paper towel between the iron and the paper design to keep the bottom of your iron clean, but if you do it right, your iron wont pick up any of the dry toner.) Let the iron set on top of the paper design for at least 2 minutes. Dont rush it and dont move the iron, or it may smear the dry toner before it is set. (Leaving it for 5 minutes will work as well, if not better.) Next, carefully lift the iron up and turn it off. Let the metal and paper transfer cool on its own. When the metal is cool enough to touch, put it in a bowl of water to soak off the magazine paper. Dont rush it. Let the paper get thoroughly saturated. After the paper is softened, you can rub it off with your thumb and the toner will remain intact. Dont worry if some of the paper is attached to the toner. It will dissolve in the acid etch bath.

Alternate Method: If you dont want to use your iron, you can use an old electric skillet. In the center of the electric skillet, layer the design paper (right side up), then metal, and on top of the metal, place a brick to press the metal onto the paper design. Heat your electric skillet to 350 degrees for 2-3 minutes. Turn it off and let everything cool gradually before you remove the metal. In some cases you can touch up any missing spots with a special type of felt pen, but the entire design etches best if the resist is uniform. In case you find that part of your design didnt transfer properly, (maybe there was a bit of oil on the metal?) you can remove the dry toner with acetone and start over. If your design didnt transfer fully, you may want to increase the length of time under the iron or skillet. 5 minutes may work better as some iron temperatures may not be as hot as others.

Now, you are ready for the etch bath. Well cover that in detail, in future articles.

Acid Etching Metal Jewelry, Part 2

by Virginia Vivier. (Esprit Mystique Jewelry)

Acid Etching Brass and Copper Jewelry

Part 2: Hand-Drawing Designs on Brass and Copper for Acid Etching (My unscientific, but personally tested results.) In the first article of this series, Part 1: Design Transfer, we discussed how to transfer photocopied graphic designs to flat pieces of brass and copper for etching multiple designs. Here in Part 2, well cover another way of preparing brass or copper for etching by drawing directly on the metal using a special ink as a resist. You need a special kind of ink that will resist the acid without deteriorating during the etching process. If you Google acid etching on metal, you will find a wide variety of articles, many very helpful. Thats how I got started. I experimented with many methods before I found one that worked consistently for me. Some methods require expensive materials, like PNP (Press N Peel) transfer paper, which I found to be hit or miss compared to the heat transfer method (as explained in Part 1 of this article series.) Other methods recommended special pens for drawing designs on copper circuit boards.

Still others recommended very expensive printing press engraver inks that dry up too quickly and are messy to use. In my research, the pen that works best consistently (for me) is made in Germany. I have tried many other brands, but the ink breaks down during the etching process and ruins the final design. I can CONFIDENTLY recommend felt tip pens Staedtler Lumocolor CD-R Pen They come in a package of 4 colors, Red, Black, Blue and Green. You can buy a 4-pack on Amazon for $6.99. The red pen works best as a strong resist to Ferric Chloride and Ferric Nitrate. But in a pinch, the black pen works for short etching sessions of 1 hour or less. However, if you want a very deep etch, and need to leave it in the etching bath for more than 1 hour, I would not use any color other than red. The other colors may break down in Ferric Chloride and Ferric Nitrate after 1 hour or so. Upon examining one of these pens carefully, I noticed that it says, refillable, which I find very interesting. I couldnt find a way to open it for refilling. But if anyone knows how to refill one, please share your knowledge! Note for Acid Etching Using the Transfer Method in Part 1: You can use a red Staedtler pen to touch up any missed spots for heat transferred designs that youve made using photocopies with dry toner. If there is a bubble or small spot missing that didnt transfer to the metal, simply use a red Staedtler pen to fill it in. A limitation of Staedtler CD-R Lumocolor pens is that they are only available in medium point. I would LOVE a fine point for delicate designs! I have tried at least 20 different brands of CD, waterproof, permanent felt tip pens, in a fine point, but none held up in the etching process. I even tried tapering the end of the red Staedtler medium tip pen with an Xactoknife and a pair of sharp scissors, but the tip fibers frayed unsatisfactorily. Again, if you have had good luck with a specific brand of fine point felt pen that has a stable ink resist for Ferric Chloride etchant, please share the good news with all of us! One nice thing about drawing your design by hand is that you can etch round objects, like bracelets.

I etch designs on recycled, pure brass bullet shells and have found it very relaxing to draw designs on 100 shells or so, while watching TV at night. This photo shows a 7mm Magnum, pure brass, recycled bullet shell with black ink resist, ready for etching:

(I used black ink so it will show up in the photo.) Black ink will hold up for a fairly shallow etch, but I normally suggest red Staedtler pen. (Red Staedtler ink is somewhat transparent and doesnt provide enough contrast to show up well in a photo.) Here is an example of a pure brass, bangle bracelet that was etched on both the inside and the outside, at the same time:

Metalliferous carries an interesting variety of pure brass bracelets that etch nicely. Pure copper, or pure brass, will etch equally well in Ferric Chloride. Do NOT use plated metals. Before you start drawing, make sure the brass or copper is roughened up slightly with #0000 steel wool, or scrubbed with powdered cleanser like Bar Keepers Friend. That helps the ink adhere to the metal. But to be truthful, I have been lazy, and used a red Staedtler pen on tarnished brass and it worked just fine.

After the ink has dried, test your ink resist to see if it smears or flakes off. Gently rub it with your fingers. If the design stays put, it will hold up well in the acid bath. Alternate Method: A faster method of cleaning older scrap (or dirty brass and copper) is to dip it in a pickle bath solution of PH Down (Sodium Bisulfate). You can buy PH Down at any pool supply or hardware store. Use 1 cup of PH Down crystals to 1 pint of tap water. (Water warmed up in the microwave works even better.) This pickle bath will clean up the metal nicely. Then, rinse copper or brass in water and dry thoroughly before drawing your design on the metal. Once you have drawn your design on the metal using a red Staedtler pen, you can store it for months without etching it. Keep it clean, in a bag or box, and the ink will hold up well until you are ready to etch it. NOTE: If you make a mistake and need to start over with your hand-drawn design using red Staedtler pen, you can quickly remove the ink with acetone or 70% isopropyl alcohol.

Acid Etching Metal Jewelry, Part 3a

by Virginia Vivier. (Esprit Mystique Jewelry)

Etched brass design by Virginia Vivier

Acid Etching Brass and Copper Jewelry

Part 3a: Ferric Chloride Acid Bath So far in this 4-part series of articles, weve covered two different ways of preparing your brass or copper piece for etching in the acid bath: Part 1: Design Transfer onto Metal Part 2: Drawing Your Design onto Metal . Here in Part 3 well cover how to etch your prepared piece of brass or copper in the Ferric Chloride acid bath. Ferric Chloride is not a dangerous acid, like Nitric acid or Hydrochloric acid. All it does is make metal rust. You can safely neutralize it with baking soda and pour it down the drain, or in the ground.

But it does leave dark stains on your hands if you touch it, so use rubber gloves when working with it. And of course, keep children and pets out of the area at all times. Another caution: I forgot to cover a small container of Ferric Chloride that I re-use for etching in my workshop. I found that (over time) a pegboard stocked full of tools, screw drivers, wire cutters, scissors, and other metals containing iron, mysteriously rusted much faster than normal. (I live in Tucson, AZ where we have a very dry climate and rust is rarely a problem.) So, keep the container of Ferric Chloride covered, or store it away from tools. If left uncovered for more than an hour or two, it may evaporate into the air and attack tools containing iron left in the same room. This is my very own personal unscientific theory. So take this advice FWIW. Where to buy Ferric Chloride: Ferric Chloride is used by copper circuit board designers. Radio Shack used to carry Ferric Chloride in pints. But they no longer carry it in Tucson, AZ. I buy it, by the gallon, from a chemical supplier here in Tucson. Note: If you order it from an out-of-state supplier, they will add substantial HAZMAT shipping charges, so it is best to find a local chemical supplier. Many electronic specialty stores carry Ferric Chloride. I have purchased it in crystal form, which works fine too, but I cant remember the ratio of crystals to water. So if you buy it in crystal form, ask your supplier what quantity to mix with water to make a solution that will etch brass or copper quickly. This bottle of liquid Ferric Chloride (below) is what I am using now. It works great, full strength, straight out of the bottle:

I store the brown glass gallon bottle in a cool, dark place, as sunlight will weaken it. You can cover it with a black plastic garbage bag, but make sure you mark it so no one bumps into it accidentally. I have had this bottle for over a year and it hasnt lost any strength. Make sure your Ferric Chloride bottle has a plastic cap. Never use metal caps on Ferric Chloride containers. I only use about 3 cups at a time, and keep reusing it until it takes longer and longer to achieve the same etch results. Then I throw it out, and start over with a fresh batch. When I use a fresh batch, it will deep etch my copper and brass quickly, in about 30 minutes, so it is good to set a timer and check the etching progress often. After you have used the same batch about 10 times, it will take about 30 minutes longer to achieve the same depth of etch, depending on how many pieces of metal are in the acid bath. I read an article about adding a teaspoon of powdered Ester C to 3 cups of Ferric Chloride to maintain its strength, and it seems to be working. You can buy powdered Ester C at any drug store:

ester c for ferric chloride used in etching metal jewelry

Acid Etching Metal Jewelry, Part 3b

by Virginia Vivier. (Esprit Mystique Jewelry)

Etched brass bracelet by Virginia Vivier

Acid Etching Brass and Copper Jewelry

Part 3b: Ferric Chloride Acid Bath . . . Continued from Part 3a This messy looking picture is my acid bath with 7 different pieces of brass, in different thicknesses, submerged for etching at the same time:

Always use a plastic (or glass) container for your Ferric Chloride acid bath. The container size depends on the size and shapes of metal you are etching. I have a red metal rolling cart that I bought at Harbor Freight to hold all my etching supplies. The 11 x 9 black plastic tray (a recycled frozen lasagna dish) underneath the etch bath container, protects the red metal rolling cart from any acid drips or spills. The clear plastic container holding the Ferric Chloride acid bath is 6 square by 3 high. You can buy them at any grocery store. They come with covers that fit tightly. Note: Never use a metal container for your acid bath. Ferric Chloride will attack it and quickly corrode it into pieces. Aquarium Air Pump to Vibrate the Acid and Keep the Design Clean When the Ferric Chloride etches brass or copper, tiny loose particles of the etched metal accumulate and clog up the design. In order to get a clean etch, the liquid bath must be kept moving to bump the loose particles to the bottom of the container. Best Methods for a Clean Etch: a.) Tape your flat metal design to a 1 thick (or more) piece of Styrofoam using double-sided carpet tape. Your metal/Styrofoam sandwich acts like a boat and floats upside-down on the surface of the Ferric Chloride. Loose particles will fall off the metal design to the bottom of the bath. (See Styrofoam boat design below):

b.) Buy a small 3 aquarium air pump ($5 at WalMart) and tape it to the outside of the acid container so it vibrates and keeps the liquid moving. (Note small gray aquarium pump next to acid container, in the lower right corner of this photo):

Alternative Vibration Method: Use Your Clothes Dryer Alternatively, you can place the Ferric Chloride container on top of your dryer and run the empty dryer on air dry while the etching is taking place. The vibration of the running dryer will keep the loose particles from accumulating on the submerged metal. But make sure you use a protective plastic covering to keep any drips of Ferric Chloride off the top of your dryer! Ferric Chloride drips on your dryer will quickly corrode the finish. If you are etching round objects, like bullet shell casings, you can plug the open end of the bullet shell with 4 inch length of thin wooden doweling:

This accomplishes 2 things: 1. It keeps any Ferric Chloride from etching the inside of the bullet shell casing. 2. It keeps the bullet shell submerged, but still floating above the bottom of the container, so the etched particles fall off easily. If you dont want to take the time to make a Styrofoam boat for flat pieces of metal, you can punch a small hole in the upper corner of the metal:

. . . and tie a piece of fishing line to make a loop.

Hang these loops over a wooden stick across the top of the Ferric Chloride bath container. The pieces of metal will hang vertically, so the loose particles of etched metal will fall to the bottom of the etching bath. The only problem is that you can sometimes see the deep etched lines that are made by the loose particles falling in a vertical direction as on this round disk with MOM design drawn with black Staedtler pen:

The disk was hung vertically and you can see the vertical lines etched in the finished pendant. If you use a Styrofoam boat for flat pieces, the metal will etch evenly (horizontally) without leaving any vertical lines. Below are photos of hand-drawn etch resist on flat metal which was etched horizontally on a Styrofoam boat. Make sure you cover any large areas of metal that you DONT want to etch (like the back) with clear plastic packing tape. Ferric Chloride will not etch through clear sticky tape if it covers the back of the metal without any bubbles or loose edges. It is a good idea to cut your metal larger than the finished design so you can overlap the tape around the edges of the design (see photo below). You can also use strips of tape or fingernail polish as a resist.

Simple geometric designs using tape or organic designs using floor polish or nail polish can be interesting. This hand-drawn design was etched on a floating Styrofoam boat. The back of the metal was taped to prevent any etching on the back:

Finished design:

However, you CAN make a 2-sided design by etching the front and back, at the same time. Use a thick piece of brass (or copper) so you can get a deep etch on both sides. A thinner piece of metal may etch holes all the way through the metal, if you etch both sides at the same time.

Acid Etching Metal Jewelry, Part 3c

by Virginia Vivier. (Esprit Mystique Jewelry)

Etched brass amulet by Virginia Vivier

Acid Etching Brass and Copper Jewelry

Part 3c: Ferric Chloride Acid Bath . . . Continued from Part 3b How Do You Know When the Etching Process is Done? While etching, check on your metal designs in the etch bath about every 30 minutes. I use a bamboo shish-ka-bob skewer to gently touch the edges of the design. If the point of the skewer catches on the edges of the lines, you can feel how deep the etch is, without removing the brass or copper piece from the etch bath. If the skewer slides across the design, then it hasnt etched deep enough and needs to stay in the bath longer.

This is also a good time to check if any parts of the design are breaking down and need to be touched up. (I have never had to do this, but it can be done.) To touch up a design, rinse the Ferric Chloride off the metal using a separate container with baking soda and water to stop the etching process. Then rinse in plain water and dry so any areas can be touched up with a red Staedtler pen. Then return the touched up design to the etch bath and proceed as before. Neutralize the Acid to Finish the Process When you are satisfied with the depth of the etch, submerge the metal in a separate plastic container (clean yogurt tub, cottage cheese container or other plastic or glass works fine), with solution of water and 3 or 4 tablespoons of baking soda. This solution neutralizes the Ferric Chloride that is still on the metal. You can see the baking soda solution fizzing as it neutralizes the acid. If you dont neutralize the Ferric Chloride that is left on the metal with baking soda, it will continue to etch in microscopic crevices of your design and ruin it later. Next, rinse your metal designs in water and dry them. Tightly cover your Ferric Chloride bath so you can use it later. (Option: Sprinkle a teaspoon of powdered Ester C in the acid bath so it will keep its strength.) If you want to dispose of an exhausted Ferric Chloride bath, make sure you add enough baking soda to neutralize it. You can tell it is neutralized when it stops fizzing. Then you can safely dispose of the neutralized acid, down the drain, or in the ground. Note: Waste Not Want Not

If you wind up with a finished etched design that is missing details and you feel it is ruined, fear not! You can use the GOOD PARTS of the etched metal for smaller patterned designs. Below are interesting pendants made from scrap pieces of etched metal:

This is the third in a series of 4 parts about acid etched designs on brass, copper and silver.

Acid Etching Metal Jewelry, Part 4a

by Virginia Vivier. (Esprit Mystique Jewelry)

Acid Etching Metal Jewelry

Part 4a: Etching on Silver Using Ferric Nitrate Part 1 of this Acid Etching Metal Jewelry series covered how to transfer designs on metal. Part 2 and Part 3 covered how to prepare an acid etch bath for copper and brass. Here in Part 4, the same techniques apply for etching on silver, except the acid is different. Please review Parts 1 3 to help understand the basic etching process. Heres my unscientific method for etching on silver, plus how you can avoid making the same mistakes I did. Ferric nitrate provides a clean etch on sterling silver and fine silver. You can buy ferric nitrate crystals at most chemical supply stores. I buy from Adchemco Scientific in Tucson, Arizona. If you order ferric nitrate from an out-of-state supplier, the cost will include shipping and HAZMAT packing costs, so try to find a local supplier to save $$$. (When I was an ASU student I bought it through my local University Chemistry Store, but 9-11 may have changed that.)

Ferric nitrate crystals look like lumps of sugar with a light hues of purple. Ferric nitrate crystals should be combined with distilled water, but I confess, I use tap water and have not had any problems. You may have more minerals in your water supply that could make a difference, but I apologize in that I havent researched those variables. So, to be safe, jot down distilled water on your grocery list and have it handy. When it comes to a recipe for mixing a ferric nitrate solution, I have done a bit of research and experimenting. I found that a 50/50 mix works well. So, you dont need to buy a gram scale if you dont have one.

By now, you may be thinking, She probably adds a pinch of this and a dollop of that when she cooks, rather than following a strict recipe. Very true! Im attempting to show where you can cut corners and where you must be careful.

Note: Please do not confuse ferric nitrate with ferric chloride. Ferric chloride works well on copper and brass, but does NOT work on silver. Ferric chloride and ferric nitrate are corrosive iron salts. Although they are potentially harmful chemicals, they are much safer to use than acid. They do not have noxious fumes and are not absorbed through the skin. They will stain skin, counter tops, and clothes, so wear gloves, protect your working surfaces, and wear old clothes when etching. To be safe, please read the precautions listed in the Goss Studios article on etching, sent courtesy of Art Chemicals.com. I have never experienced fumes or flammability, as mentioned in the article and am not cavalier about handling chemicals, but feel that some precautions are overkill. I smile when I see a warning on a paper coffee cup: Caution, hot liquid may cause severe burns. (OK, I can see the steam I get it. : )

Goss Design Studios Ferric Nitrate Etching Recipe: 400 ml of distilled water 300 grams of Ferric Nitrate Always add crystals to water! NEVER water to crystals. My Unscientific Etching Process:

Fill a quart size (glass or plastic) measuring pitcher with 2 cups of tap water.

Slowly add enough ferric nitrate crystals (about 2 cups) to make a total solution of 1 quart. Mix carefully with a wooden or plastic spoon (DO NOT not use anything metal) until the crystals are dissolved. The solution will turn a dark greenish color that is fairly clear compared to the thick, opaque, greenish ferric chloride, which is used straight out of the bottle. (I feel like I should be chanting a Spell while stirring, as it reminds me of a Witchs brew. : ) The instruction from Goss Studios says to kick start the solution with a teaspoon of old, 5:1 diluted, nitric acid solution. I skipped that. I have worked with nitric acid and it is very dangerous stuff. I avoid it whenever possible. If you are more daring than I, please try the Goss recipe. It may increase the strength of your ferric nitrate solution. Id love to learn about your results. Note on Nitric Acid Etching: An accepted way of etching silver is to use nitric acid. I tried etching silver, using 3:1 nitric acid solution, and was very disappointed in the results. The acid quickly corroded the dry toner design and red Staedtler pen resist. The edges of the design came out fuzzy. The fumes were so bad that I decided it was not something I wanted in my studio. However, many professional jewelers swear by it as a clean etch method. They use a stronger resist, like asphaultum, which I find messy and hard to work with. I calculated that it costs less to use nitric acid than ferric nitrate, as it lasts longer and a smaller amount is required per etch. Nitric acid concentration gets stronger as the water evaporates, unlike ferric nitrate, which is weakened by moisture. It is necessary to follow safe OSHA disposal requirements. You can get more info on nitric acid etching on the internet.

You can etch about 20 pendant-sized pieces of silver in a quart solution of ferric nitrate before it starts to slow down and finally exhaust. I calculated that (in a perfect world) 5 pounds of

ferric nitrate, at $60, should produce approximately 100 etched pendants at a cost of 60 cents per piece, just to etch. This technique is better for creating your own special unique, one-of-a-kind designs. This may not be an economical way to create a wholesale line of jewelry. There are more economical ways of producing a jewelry design that appears to be etched, such as having a wax model cast by professionals. This photo shows the original 4 inch x 2 inch, 16 gauge, piece of sterling silver intended to be a bracelet:

The design has been ironed on and the edges filled in with red Staedtler pen resist. The back of the silver is covered with clear plastic packing tape as a resist to the ferric nitrate. The transfer design was made with of a sheet of IBM transparency acetate copied on my dry toner copy machine. The copy machine transferred a thick layer of dry toner (dark black lines) on to the acetate.

The acetate was then placed (toner side down) on the squeaky clean piece of sterling silver. I put a piece of paper towel on top of the acetate. I placed a hot iron on top of the paper towel (for about 3 minutes) this heated the acetate and melted the dry toner on to the silver. When the hot metal cooled enough to touch, it was placed in a glass jar of water. The acetate popped off easily, leaving the dry toner design on the silver. I used a red Steadtler pen to touch up a couple of places that didnt transfer fully to the silver.

The outside borders of the design were filled in with red Staedtler pen as a resist to the acid.

Acid Etching Metal Jewelry, Part 4b

by Virginia Vivier. (Esprit Mystique Jewelry)

Acid etched silver pendant with brass background, by Virginia Vivier

Acid Etching Metal Jewelry

Part 4b: Etching on Silver Using Ferric Nitrate . . . Continued from Part 4a HERE IS WHERE I BLEW IT! A 50/50 solution of ferric nitrate takes twice as long to etch silver as ferric chloride does to etch copper and brass. CAUTION: Dont be blas about it. I learned the hard way. Below is a photo of a nice, thick piece of silver I was etching for a bracelet. I got involved in another project and lost track of time. It was in the etch bath for 6 hours and the ferric nitrate etched holes all the way through the silver in some spots:

I was miffed at my neglect (and material loss), but it was a valuable lesson. I was pleased to see that the dry toner resist held up very well the whole time. The red Staedler border ink mask did break down somewhat. I should have taped it, but I didnt think it would be etching for 6 hours! Since then, I always carry a loud alarm timer set for 30 minutes as a reminder to check on the etch bath. (Fortunately, I was able use the middle section of the design, so it wasnt a complete loss. And, you can always send silver (mistake) scraps to a refiner in exchange for a $$ check.) The back of the silver sheet was covered with clear packing tape to protect it from etching. So the etching came from the front side of the piece. The clear acetate shows how well the dry toner melted onto the metal. Only a few spots of the black dry toner are left on the clear acetate. Most of the dry toner melted on to the silver nicely. In case you place the iron on the design too long, delicate lines may run together. So it might take a bit of experimenting to see how long it takes to melt the toner and still retain crisp design elements. You can always start over if the toner smears or doesnt transfer completely. Just clean off the metal with acetone (or alcohol) and begin again. No loss. Youll get the hang of it after a few tries. Summary of Etching on Silver: THE DESIGN

Branch Bracelet, sterling silver, by Sandra Noble Goss. a.) Draw your design directly on silver using a red Staedtler pen. b.) Or, use Future clear floor wax (or fingernail polish) as a resist. Scratch out a design through the resist. You can also use tape as a resist to block off areas. c.) Or, draw a design on paper, then scan it, resize it, and save it on Photoshop using the darkest black / white contrast available. Print out the design in highest resolution possible. d.) Make sure any lettering or numbers in your design are mirror image, so they read right when transferred to the silver:

e.) Copy the design at a photocopy store (or use your own copier) on a machine that uses dry toner. Set the copy as dark as possible to achieve a thick layer of dry toner on a sheet of heavy magazine paper or acetate transparency. f.) Cut out the dry toner design copy leaving a inch margin around the perimeter. DESIGN TRANSFER TO SILVER a.) To recap Layer design, silver and paper towels, per diagram as shown:

(Make sure your flat workspace is not harmed by the heat of the iron. I have scorch marks on my dining room table! An old desk or wood table works well. Must be completely FLAT. An ironing board does not work.) b.) Heat an old iron to hottest setting. (Note: A newer, expensive iron that has an automatic shut off wont work.) c.) You can use an old electric skillet, set at 350 degrees, just reverse the order of the diagram above so the silver design is facing up. Use something very flat and very heavy (an iron?) to lay on top of the design. Dont wiggle it when you remove it or it may smear the melted toner. It helps if the weight has a handle so it can be lifted straight up easily. d.) The iron (or skillet) remains in contact with the silver until the dry toner melts on the metal. Note: The time may vary depending on the thickness of the silver, depth of toner and heat of the iron (or skillet). You can hear the iron and the skillet thermostats clicking on and off to maintain the temperature. e.) When you lift the iron off the metal, dont remove the paper (or transparency acetate) from the silver. Let it cool down slowly. When it is cool enough to touch, carefully pick it up by the edges and drop it into a glass jar of water. When it is cool, you can pop off the transparency acetate or soak off the magazine paper, leaving the dry toner layer that has melted onto the silver.

f.) Tape off areas of your design (such as the back) that you do not want to etch. g.) Attach silver (dry toner side down) to a piece of Styrofoam, or a piece of plastic bubble envelope, so it will float (like a flat bottomed boat) on top of the ferric chloride etch bath. THE FERRIC NITRATE ETCH BATH a.) Using a plastic or glass container, wide enough to accommodate your silver boats, mix 50:50 solution of ferric nitrate. Container can be shallow in depth since the silver will be floating on top of the ferric nitrate solution. Make sure your ferric nitrate container is sitting on top of, or beside something that vibrates, (Part 3 refers to dryer or aquarium air pump) to help move the etched particles off the metal. b.) Set timer for 30 minutes and lay the silver boats on top of the ferric nitrate solution. c.) Check every 30 minutes for level of etch you wish to achieve for your design. (I admit that sometimes I quickly stick my fingers into the ferric nitrate to pluck out a floating boat, and all it does is stain my fingers a bit. If washed off quickly, no stain on skin, but sometimes need to soak fingernails in weak bleach solution to remove the stains later that night.)

Note: I found it necessary to rinse off gunk that accumulated on the design side of the silver boats every 30 minutes or so. This was not necessary for etches on brass and copper using ferric chloride. Also check for any missing areas in your design that may have deteriorated. You can rinse off the ferric nitrate and repair missing areas with red Staedtler pen if needed. Then return to acid bath.

d.) When design is etched to your satisfaction, remove from ferric nitrate and place in separate solution of 3 TBL baking soda and 1 cup water. When the solution stops fizzing, remove the silver and rinse thoroughly in water. Remove all tape and rinse again. e.) Make sure you put a secure (plastic) lid on the ferric nitrate solution. Admire your etched design

This is the last in a series of 4 parts about acid etched designs on brass, copper and silver.

http://www.wikihow.com/Acid-Etch-Steel

How to Acid Etch Steel

Because copper and zinc have gone up in price, many artisans who etch designs in metals have turned to etching steel. Although not as fine a metal as copper, steel is finer than zinc, and it is also more durable--particularly when used as a printing plate. Several kinds of steel can be etched with acid, including both mild steel and stainless steel. Following are instructions on how to acid-etch steel.

Preparing the Steel for Etching

1. 1 Choose the type of steel you want to etch. You can etch stainless steel, mild steel, or high-carbon steel. Which type of steel you etch will determine the best acid or chemical to use to etch it with.

Ads by Google

Micro Nano Manfacturing

New journal on micro & nano- manufacturing. Accepting papers now www.asmedl.org/nano_micro_mfg 2. 2 Remove any burrs on the edges of the steel. File away any burrs on the side of the steel you plan to etch with acid. You can leave the burrs on the other side if you're etching a steel plate.

3. 3 Scrub the steel. Use a chlorine cleanser on an abrasive sponge, a wire brush, fine steel wool, wet number 600 emery paper, or corundum paper, scrubbing in a circular motion. You want to leave the surface just gritty enough to grip the resist material, but not so scratched that you end up etching extra lines that aren't part of your design.

4. 4 Rinse the steel with water. The water should sheet off the steel surface.

5. 5 Clean the steel a second time with isopropyl alcohol.

Etching the Steel

1. 1 Choose the image you want to etch into the steel. You can either draw a freehand image or replicate an existing image onto the steel surface. Depending on which transfer method you use, you can have a fairly simple design or a complex one.

o o

If you plan to replicate an existing design, choose something in high-contrast black and white. If you plan to make and sell prints of your etching, choose an image in the public domain or get the permission of the copyright holder, if there is one.

2. 2 Transfer your design onto the steel surface. You can transfer the design in 1 of several ways, as described below. Be aware that however you transfer your design, it will print the reverse of the way you etch it into the steel. If you plan to use the etched steel plate solely as a decoration, not to print with, this won't matter to you.

The oldest method for transferring designs is to coat the steel surface with a liquid varnish or wax-like substance (like beeswax), or even enamel paint or nail polish. This coating is called a ground. You then scratch your design into the ground using needles or wider-bladed cutting tools. (This is similar to woodcutting.) The ground will serve as a resist to keep the etching acid off the steel it covers. Another method is to cover the steel surface with permanent markers in those places where you want the acid not to etch the steel and leave the surface exposed where you want to etch the steel. You may need to experiment with several brands and colors of permanent marker to determine which make the best resists. A third method is to create an iron-on stencil by either photocopying an image onto transfer paper or printing it onto glossy photo paper with an inkjet printer. Place the paper onto the steel surface, image-side down, and using a clothes iron set to "high," iron with smooth, circular strokes for 2 to 5 minutes. (Press gently if using transfer paper; press hard if using photo paper.) You can then remove the paper. (Transfer paper will peel away on its own, but photo paper requires soaking in a tray of hot water to soften it for removal.) The transferred ink becomes the resist for the etching acid.

3. 3 Cover the steel's edges. You can tape over the edges or paint them. Either method keeps the acid from etching the edges.

4. 4 Choose the acid you want to etch the steel with. Possible acids include muriatic (hydrochloric) acid (HCl), nitric acid (HNO3), or sulfuric acid (H2SO4). Certain nonacids that form acid in water, such as ferric chloride (FeCl3) or copper sulfate (CuSO4), can also be used as etching chemicals. How strong the acid is generally determines how fast the steel will be etched, or "bitten." You can obtain etching acids and chemicals through chemical supply stores or electronics supply shops.

Ferric chloride is normally mixed with water in equal parts to form hydrochloric acid in solution. It's more commonly used to etch copper, but it also works well to etch stainless steel. It also works with a wider range of resist materials than pure acids do; however, it can pit the surface if not attended to properly. Copper sulfate is better suited to etching mild steels than stainless steel. It is best mixed in a 1 to 1 ratio with sodium chloride (NaCl - common table salt) to keep the copper sulfate from coating the steel with a deposit of copper that will stop the etching process. The blue solution gradually fades as the etching progresses and turns colorless when it's finished. Nitric acid is commonly mixed in a ratio of 1 part nitric acid to 3 parts water. It can also be mixed with acetic acid (vinegar), in a 1 to 1 ratio, or with hydrochloric acid. Sulfuric acid should be used only in concentrations from 10 to 25 percent. Generally, dilute solutions are more effective than concentrated ones. Acids generally take longer to etch steel than do chemicals that form acids in water, however.